Compare over 20 aluminum alloys to find the right material for you—all with material certificates for traceability.

Textured Corrosion-Resistant 3003 Aluminum Sheets

- Yield Strength: 17,000 psi

- Hardness: Brinell 40 (Soft)

- Temper: H14 (1/2 Hard)

- Fabrication: Cold Rolled

- Specifications Met: ASTM B209

The textured surface on these sheets increases rigidity and hides fingerprints and dents. They are intended for use in decorative applications, such as partitions and surface protectors, and should not be confused with traction floor plates. 3003 aluminum stands up to outdoor use, as well as exposure to chemicals. It offers a good combination of strength, formability, and weldability.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

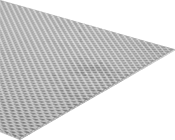

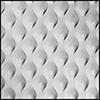

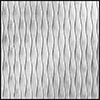

Diamond | Tread | Weave | |||||

|---|---|---|---|---|---|---|---|

| Thick. | Thick. Tolerance | Each | Each | Each | |||

12" × 12" | |||||||

| 0.032" | -0.004" to 0.004" | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 000000 |

| 0.063" | -0.004" to 0.004" | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 |

| 0.080" | -0.004" to 0.004" | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 |

12" × 24" | |||||||

| 0.032" | -0.004" to 0.004" | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 |

| 0.063" | -0.004" to 0.004" | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 |

| 0.080" | -0.004" to 0.004" | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 |

24" × 24" | |||||||

| 0.032" | -0.004" to 0.004" | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 |

| 0.063" | -0.004" to 0.004" | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 |

| 0.080" | -0.004" to 0.004" | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 |

24" × 36" | |||||||

| 0.032" | -0.004" to 0.004" | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 |

| 0.063" | -0.004" to 0.004" | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 |

| 0.080" | -0.004" to 0.004" | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 000000 |

24" × 48" | |||||||

| 0.032" | -0.004" to 0.004" | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 |

| 0.063" | -0.004" to 0.004" | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 000000 |

| 0.080" | -0.004" to 0.004" | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 000000 |

48" × 48" | |||||||

| 0.032" | -0.004" to 0.004" | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 |

| 0.063" | -0.004" to 0.004" | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 000000 |

| 0.080" | -0.004" to 0.004" | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 000000 |

Corrosion-Resistant 3003 Aluminum Texture Selector Packs

Includes one 11/2"×3"×0.032" thick piece of each texture: weave, diamond, and tread. 3003 aluminum stands up to outdoor use, as well as exposure to chemicals. It offers a good combination of strength, formability, and weldability.

For technical drawings and 3-D models, click on a part number.

| Thick. | Wd. | Lg. | Texture | Pkg. Qty. | Pkg. | |

| 0.032" | 1 1/2" | 3" | Diamond, Tread, Weave | 3 | 000000 | 00000 |

Metal Panels

Close off openings in structures while allowing air to pass through.

For technical drawings and 3-D models, click on a part number.

Expanded panels are more rigid than perforated panels and are for use when structural stability is important. They can be formed and welded; however, they are more difficult to cut than perforated panels. Raised panels have strands that overlap to provide a skid-resistant surface. Use them to create safety guards for equipment and machinery.

3003 aluminum is easier to form than 1100 aluminum. It's about half the weight of steel and resists corrosion in wet environments.

Opening | Strand | |||||

|---|---|---|---|---|---|---|

| Overall Thick. | Wd. | Lg. | Wd. | Thick. | Each | |

12" × 12" | ||||||

3003 Aluminum | ||||||

| 0.19" | 0.94" | 0.38" | 0.093" | 0.05" | 00000000 | 000000 |

| 0.208" | 0.94" | 0.35" | 0.096" | 0.08" | 00000000 | 00000 |

| 0.219" | 1.75" | 0.79" | 0.109" | 0.05" | 00000000 | 00000 |

| 0.369" | 1.68" | 0.67" | 0.169" | 0.125" | 00000000 | 00000 |

24" × 24" | ||||||

3003 Aluminum | ||||||

| 0.19" | 0.94" | 0.38" | 0.093" | 0.05" | 0000000 | 00000 |

| 0.208" | 0.94" | 0.35" | 0.096" | 0.08" | 0000000 | 00000 |

| 0.219" | 1.75" | 0.79" | 0.109" | 0.05" | 0000000 | 00000 |

| 0.369" | 1.68" | 0.67" | 0.169" | 0.125" | 0000000 | 00000 |

48" × 48" | ||||||

3003 Aluminum | ||||||

| 0.19" | 0.94" | 0.38" | 0.093" | 0.05" | 0000000 | 00000 |

| 0.208" | 0.94" | 0.35" | 0.096" | 0.08" | 0000000 | 000000 |

| 0.219" | 1.75" | 0.79" | 0.109" | 0.05" | 0000000 | 00000 |

| 0.369" | 1.68" | 0.67" | 0.169" | 0.125" | 0000000 | 000000 |

48" × 96" | ||||||

3003 Aluminum | ||||||

| 0.19" | 0.94" | 0.38" | 0.093" | 0.05" | 0000000 | 000000 |

| 0.208" | 0.94" | 0.35" | 0.096" | 0.08" | 0000000 | 000000 |

| 0.219" | 1.75" | 0.79" | 0.109" | 0.05" | 0000000 | 000000 |

| 0.369" | 1.68" | 0.67" | 0.169" | 0.125" | 0000000 | 000000 |

Expanded panels are more rigid than perforated panels and are for use when structural stability is important. They can be formed and welded; however, they are more difficult to cut than perforated panels. Flattened panels begin as raised panels, then they're rolled to a smooth and flat finish. Use them to create protective enclosures, shelving, grilles, and baskets.

1100 aluminum is about half the weight of steel and resists corrosion in wet environments.

3003 aluminum is easier to form than 1100 aluminum. It's about half the weight of steel and resists corrosion in wet environments.

Opening | Strand | |||||

|---|---|---|---|---|---|---|

| Overall Thick. | Wd. | Lg. | Wd. | Thick. | Each | |

12" × 12" | ||||||

1100 Aluminum | ||||||

| 0.029" | 0.76" | 0.19" | 0.078" | 0.029" | 00000000 | 000000 |

3003 Aluminum | ||||||

| 0.029" | 0.31" | 0.09" | 0.06" | 0.029" | 00000000 | 00000 |

| 0.038" | 1" | 0.29" | 0.104" | 0.038" | 00000000 | 00000 |

| 0.038" | 1.81" | 0.68" | 0.122" | 0.038" | 00000000 | 00000 |

| 0.06" | 1" | 0.29" | 0.105" | 0.06" | 00000000 | 00000 |

| 0.06" | 1.75" | 0.64" | 0.143" | 0.06" | 00000000 | 00000 |

| 0.094" | 1.75" | 0.55" | 0.187" | 0.094" | 00000000 | 00000 |

| 0.094" | 2.75" | 0.97" | 0.181" | 0.094" | 00000000 | 00000 |

24" × 24" | ||||||

1100 Aluminum | ||||||

| 0.029" | 0.76" | 0.19" | 0.078" | 0.029" | 0000000 | 00000 |

3003 Aluminum | ||||||

| 0.029" | 0.31" | 0.09" | 0.06" | 0.029" | 0000000 | 00000 |

| 0.038" | 1" | 0.29" | 0.104" | 0.038" | 0000000 | 00000 |

| 0.038" | 1.81" | 0.68" | 0.122" | 0.038" | 0000000 | 00000 |

| 0.06" | 1" | 0.29" | 0.105" | 0.06" | 0000000 | 00000 |

| 0.06" | 1.75" | 0.64" | 0.143" | 0.06" | 0000000 | 00000 |

| 0.094" | 1.75" | 0.55" | 0.187" | 0.094" | 0000000 | 00000 |

| 0.094" | 2.75" | 0.97" | 0.181" | 0.094" | 0000000 | 00000 |

48" × 48" | ||||||

1100 Aluminum | ||||||

| 0.029" | 0.76" | 0.19" | 0.078" | 0.029" | 0000000 | 000000 |

3003 Aluminum | ||||||

| 0.029" | 0.31" | 0.09" | 0.06" | 0.029" | 0000000 | 000000 |

| 0.038" | 1" | 0.29" | 0.104" | 0.038" | 0000000 | 000000 |

| 0.038" | 1.81" | 0.68" | 0.122" | 0.038" | 0000000 | 00000 |

| 0.06" | 1" | 0.29" | 0.105" | 0.06" | 0000000 | 000000 |

| 0.06" | 1.75" | 0.64" | 0.143" | 0.06" | 0000000 | 000000 |

| 0.094" | 1.75" | 0.55" | 0.187" | 0.094" | 0000000 | 000000 |

| 0.094" | 2.75" | 0.97" | 0.181" | 0.094" | 0000000 | 000000 |

48" × 96" | ||||||

1100 Aluminum | ||||||

| 0.029" | 0.76" | 0.19" | 0.078" | 0.029" | 0000000 | 000000 |

3003 Aluminum | ||||||

| 0.029" | 0.31" | 0.09" | 0.06" | 0.029" | 0000000 | 000000 |

| 0.038" | 1" | 0.29" | 0.104" | 0.038" | 0000000 | 000000 |

| 0.038" | 1.81" | 0.68" | 0.122" | 0.038" | 0000000 | 000000 |

| 0.06" | 1" | 0.29" | 0.105" | 0.06" | 0000000 | 000000 |

| 0.06" | 1.75" | 0.64" | 0.143" | 0.06" | 0000000 | 000000 |

| 0.094" | 1.75" | 0.55" | 0.187" | 0.094" | 0000000 | 000000 |

| 0.094" | 2.75" | 0.97" | 0.181" | 0.094" | 0000000 | 000000 |

Perforated panels are for use in decorative applications. They can be cut, formed, and welded.

3003 aluminum is easier to form than 1100 aluminum. It's about half the weight of steel and resists corrosion in wet environments.

Overall | Opening | |||||||

|---|---|---|---|---|---|---|---|---|

| Opening Pattern | Thick. | Wd. Tolerance | Lg. Tolerance | Wd. | Lg. | Open Area | Each | |

36" × 40" | ||||||||

3003 Aluminum | ||||||||

| Circle | 0.032" | -1/8" to +1/8" | -1/8" to +1/8" | __ | __ | 44% | 0000000 | 0000000 |

| Diamond | 0.032" | -1/8" to +1/8" | -1/8" to +1/8" | 0.25" | 0.5" | 64% | 0000000 | 000000 |

| Oval | 0.032" | -1/8" to +1/8" | -1/8" to +1/8" | 0.25" | 0.75" | 66% | 0000000 | 00000 |

| Weave | 0.032" | -1/8" to +1/8" | -1/8" to +1/8" | __ | __ | 53% | 0000000 | 00000 |

36" × 60" | ||||||||

3003 Aluminum | ||||||||

| Circle | 0.032" | -1/8" to +1/8" | -1/8" to +1/8" | __ | __ | 44% | 0000000 | 000000 |

| Diamond | 0.032" | -1/8" to +1/8" | -1/8" to +1/8" | 0.25" | 0.5" | 64% | 0000000 | 000000 |

| Oval | 0.032" | -1/8" to +1/8" | -1/8" to +1/8" | 0.25" | 0.75" | 66% | 0000000 | 000000 |

| Weave | 0.032" | -1/8" to +1/8" | -1/8" to +1/8" | __ | __ | 53% | 0000000 | 000000 |