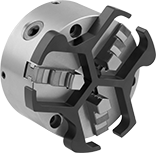

Three-Jaw Lathe Chucks

Mount to a lathe's spindle to hold round workpieces. Also known as scroll chucks, these are self centering—all three jaws move in unison, centering the workpiece as they close. Use the included lathe chuck wrench to open and close the jaws.

Chuck with solid jaws comes with one set of outside jaws and one set of inside jaws.

Chucks with reversible jaws come with one set of jaws that can be installed for either an inside or outside grip.

A mounting plate (sold separately) is required to mount the chuck to a lathe. Select a mounting plate that matches the diameter of the lathe chuck and your lathe’s spindle type and spindle OD.

For technical drawings and 3-D models, click on a part number.

Lathe Chucks | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Workpiece | Replacement Reversible Jaw Set | |||||||||||

| Dia. | OD | ID | Center Through-Hole Dia. | TIR (Total Indicated Runout) Accuracy | Overall Lg. | Max. Speed, rpm | Material | Weight, lbs. | Each | Each | ||

| 6" | 0.31"-5.51" | 2.17"-5.91" | 1.78" | 0.0005" | 2.76" | 4,600 | Steel | 23 | 0000000 | 000000000 | 0000000 | 0000000 |

| 8" | 0.39"-7.87" | 2.17"-7.09" | 2.37" | 0.0005" | 3.15" | 4,000 | Steel | 37 | 0000000 | 00000000 | 0000000 | 000000 |

For Spindle | For Spindle Nose | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Type | OD | Size | Thread Size | Type | Dia. | Lg. | Center Through-Hole Dia. | Material | Each | |

For 5" Lathe Chuck Dia. | ||||||||||

| A1, A2 | 2 1/8" | 3 | __ | A-3 | 3.725" | 0.765" | 1.28" | Steel | 0000000 | 0000000 |

| A1, A2 | 4 1/4" | 4 | __ | A-4 | 2 1/2" | 0.437" | 1.28" | Steel | 0000000 | 000000 |

| D1 Camlock | 3 5/8" | 3 | __ | D1-3 | 2 1/8" | 0.437" | 1.28" | Steel | 0000000 | 000000 |

| D1 Camlock | 4 1/4" | 4 | __ | D1-4 | 2 1/2" | 0.437" | 1.28" | Steel | 0000000 | 000000 |

| Hardinge | 3.126" | __ | __ | 4-Degree | 2.316" | 1.472" | 1.32" | Steel | 0000000 | 000000 |

| Threaded | 5.11" | __ | 2 3/16"-10 | __ | 2 3/16" | 1.38" | 2.19" | Steel | 0000000 | 000000 |

For 6" Lathe Chuck Dia. | ||||||||||

| A1, A2 | 5 1/4" | 5 | __ | A-5 | 3.251" | 0.563" | 1.8" | Steel | 0000000 | 000000 |

| A1, A2 | 6 1/2" | 6 | __ | A-6 | 4.188" | 5/8" | 1.8" | Steel | 0000000 | 000000 |

| A1, A2 | 8 1/4" | 8 | __ | A-8 | 5.501" | 0.688" | 1.8" | Steel | 0000000 | 00000000 |

| D1 Camlock | 4 1/4" | 4 | __ | D1-4 | 2 1/2" | 0.437" | 1.8" | Steel | 0000000 | 000000 |

| D1 Camlock | 7 1/8" | 6 | __ | D1-6 | 4.188" | 5/8" | 1.8" | Steel | 0000000 | 000000 |

| Hardinge | 3.126" | __ | __ | 4-Degree | 2.316" | 1.472" | 1.32" | Steel | 0000000 | 000000 |

| Threaded | 6 1/2" | __ | 2 3/16"-10 | __ | 2 3/16" | 1.63" | 2.19" | Steel | 0000000 | 000000 |

For 8" Lathe Chuck Dia. | ||||||||||

| A1, A2 | 5 1/4" | 5 | __ | A-5 | 3.251" | 0.563" | 2.39" | Steel | 0000000 | 000000 |

| A1, A2 | 6 1/2" | 6 | __ | A-6 | 4.188" | 5/8" | 2.39" | Steel | 0000000 | 000000 |

| A1, A2 | 8 1/4" | 8 | __ | A-8 | 5.501" | 0.688" | 2.39" | Steel | 0000000 | 000000 |

| D1 Camlock | 4 1/4" | 4 | __ | D1-4 | 2 1/2" | 0.437" | 2.4" | Steel | 0000000 | 000000 |

| D1 Camlock | 7 1/8" | 6 | __ | D1-6 | 4.188" | 5/8" | 2.39" | Steel | 0000000 | 000000 |

5C Collet to Lathe Chuck Adapters

No need to break down a collet set up when a workpiece doesn't fit a 5C collet. Install one of these lathe chuck adapters in your 5C collet chuck or holder and its three jaws will securely grasp the workpiece. These chuck adapters are self centering—all three jaws move in unison, centering the workpiece as they close. Use the included lathe chuck wrench to open and close the jaws.

For Workpiece | Lg. | Thread Size | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | OD | ID | Head | Shaft | O'all | Center Through-Hole Dia. | Internal | External | Material | Includes | Each | |

| 3" | 5/64"-2 15/32" | 63/64"-2 3/4" | 2 41/64" | 3 13/32" | 6 3/64" | 5/8" | 7/8"-20 | 1.238"-20 | Hardened Steel | One Set of Solid Outside-Grip Jaws, One Set of Solid Inside-Grip Jaws, Lathe Chuck Wrench | 00000000 | 0000000 |

| 4" | 5/64"-3 5/32" | 1 3/16"-3 35/64" | 2 27/32" | 3 13/32" | 6 1/4" | 7/8" | 7/8"-20 | 1.238"-20 | Hardened Steel | One Set of Solid Outside-Grip Jaws, One Set of Solid Inside-Grip Jaws, Lathe Chuck Wrench | 00000000 | 000000 |

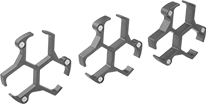

Boring Rings for Machinable Lathe Chuck Jaws

Hold machinable lathe chuck jaws in place during machining to make accurate cuts, ensuring the jaws will securely grip your workpiece. These boring rings pin the jaws down, creating the same clamping pressure you’ll use on your workpiece, which keeps the jaws from warping or deforming while they hold your workpiece.

Designed with an open center, these rings leave room for you to machine the center of your jaws. Fit the pins on the rings to the screw holes on your jaws, then clamp the jaws down to hold the ring in place. Once the ring is attached, rotate it to adjust the jaws to the center of their stroke before machining.

Match standard rings to your lathe chuck’s diameter for machining the center of your jaws. Line them up with your jaws by sliding the pins along their curved tracks.

Adjustable rings fit a range of lathe chuck diameters. The pins are mounted to straight tracks—slide them in and out of the ring to adjust the diameter. They are also reversible, which allows you to machine both the inside and outside of your jaws. When the pin screws are outside the ring, you can machine the center of your jaws. Flip them around to the center of the ring to machine the outside of your jaws.

Pin | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Lathe Chuck Dia. | For Jaw Grip Style | OD | ID | Ht. | Dia. | Ht. | Max. Speed, rpm | Material | Each | |

Standard | ||||||||||

| 6" | Outside | 6.6" | 3.2" | 0.47" | 0.65" | 0.354" | 900 | Alloy Steel | 00000000 | 0000000 |

| 8" | Outside | 8.6" | 4 1/2" | 0.47" | 0.728" | 0.354" | 900 | Alloy Steel | 00000000 | 000000 |

| 10" | Outside | 10.2" | 5.9" | 0.47" | 0.728" | 0.354" | 900 | Alloy Steel | 00000000 | 000000 |

| 12" | Outside | 12.4" | 7.4" | 0.59" | 0.886" | 0.354" | 900 | Alloy Steel | 00000000 | 000000 |

| 15" | Outside | 15" | 9.1" | 0.79" | 1.22" | 0.63" | 900 | Alloy Steel | 00000000 | 000000 |

Adjustable | ||||||||||

| 5"-8" | Inside, Outside | 6.7" | 3.9" | 1.02" | 0.512" | 0.276" | 800 | Alloy Steel | 00000000 | 000000 |

| 6"-10" | Inside, Outside | 7.9" | 4.9" | 1.02" | 0.642" | 0.315" | 700 | Alloy Steel | 00000000 | 000000 |

| 8"-12" | Inside, Outside | 9.8" | 6.3" | 1.22" | 0.72" | 0.315" | 600 | Alloy Steel | 00000000 | 000000 |

Chuck Stops

Consistently position workpieces in a three-jaw lathe chuck by installing a chuck stop. These stops enable short workpieces to extend beyond the chuck's jaws, providing additional clearance.

| For Max. Chuck Jaw Thick. | Parallel Tolerance | Mount Type | Number of Mounting Magnets | Includes | Material | Each | |

| 2 1/8" | -0.0004" to 0.0004" | Magnetic Back | 3 | One 15 mm thick stop, One 20 mm thick stop, One 25 mm thick stop | Aluminum | 0000000 | 0000000 |

Lathe Chuck Jaw Nuts

Secure jaws to a CNC lathe chuck with industry standard 1.5 mm × 60° serrations or wider 3 mm × 60° serrations.

Jaw nuts with M6, M8, M10, M12, M16, and M20 threads fit most chucks made by Kitagawa, LMC, Samchully, Seoam, Auto Strong, and other brands.

Jaw nuts with inch and M14 threads fit most chucks made by Matsumoto.

For technical drawings and 3-D models, click on a part number.

Thread | Base | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Lathe Chuck Dia. | For Slot Wd. | Size | Pitch, mm | Ht. | Lg. | Wd. | Overall Ht. | For Serration Size | Mounting Hole Ctr.-to-Ctr. | Material | Each | |

| 4" | 0.315" | M6 | 1 | 11/64" | 61/64" | 29/64" | 17/32" | 1.5 mm × 60° | 0.591" | Steel | 0000000 | 000000 |

| 5" | 0.392" | M8 | 1.25 | 7/32" | 1 11/64" | 35/64" | 39/64" | 1.5 mm × 60° | 0.713" | Steel | 0000000 | 00000 |

| 6" | 0.472" | M10 | 1.5 | 19/64" | 1 13/32" | 11/16" | 23/32" | 1.5 mm × 60° | 0.787" | Steel | 0000000 | 00000 |

| 8" | 0.551" | M12 | 1.75 | 11/32" | 1 27/32" | 13/16" | 13/16" | 1.5 mm × 60° | 0.984" | Steel | 0000000 | 00000 |

| 10" | 0.63" | M12 | 1.75 | 11/32" | 1 63/64" | 7/8" | 27/32" | 1.5 mm × 60° | 1.181" | Steel | 0000000 | 00000 |

| 12" | 0.705" | M14 | 2 | 17/32" | 2 3/16" | 1 1/8" | 1 11/64" | 1.5 mm × 60° | 1.26" | Steel | 0000000 | 00000 |

| 12" | 0.827" | M16 | 2 | 29/64" | 2 9/16" | 1 5/32" | 1 3/32" | 1.5 mm × 60° | 1.181" | Steel | 0000000 | 00000 |

| 15" | 0.866" | M20 | 2.5 | 21/32" | 3 5/32" | 1 5/16" | 1 51/64" | 1.5 mm × 60° | 1.693" | Steel | 0000000 | 00000 |

| 21", 24" | 0.982" | M20 | 2.5 | 11/16" | 3 59/64" | 1 7/16" | 2 1/16" | 3 mm × 60° | 2.36" | Steel | 0000000 | 00000 |

Base | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Lathe Chuck Dia. | For Slot Wd. | Thread Size | Ht. | Lg. | Wd. | Overall Ht. | For Serration Size | Mounting Hole Ctr.-to-Ctr. | Material | Each | |

| 6" | 0.432" | 5/16"-18 | 9/32" | 1 9/16" | 11/16" | 25/32" | 1.5 mm × 60° | 0.984" | Steel | 0000000 | 000000 |

| 8" | 0.551" | 7/16"-14 | 21/64" | 1 3/4" | 51/64" | 7/8" | 1.5 mm × 60° | 0.984" | Steel | 0000000 | 00000 |

| 10" | 0.629" | 1/2"-13 | 5/16" | 2 3/64" | 57/64" | 57/64" | 1.5 mm × 60° | 1.26" | Steel | 0000000 | 00000 |

| 15" | 0.865" | 3/4"-10 | 49/64" | 3 9/64" | 1 21/64" | 1 35/64" | 3 mm × 60° | 1.96" | Steel | 0000000 | 00000 |

Machinable Lathe Chuck Jaws

Machine these jaws to fit the curves and edges of your unique workpiece for a tighter hold and more stability than standard hardened jaws. They have industry standard 1.5 mm x 60° serrations, which mount to most CNC lathe chucks from Kitagawa, LMC, Samchully, Seoam, and Auto Strong. Attach to your chuck with jaw nuts (not included). For the tightest fit to your workpiece, use boring rings to hold your jaws in place while machining.

Pointed jaws provide three points of contact on the workpiece. They are the best choice for most custom workholding.

Full-grip jaws surround the workpiece for maximum grip from every angle, ensuring an exact fit on thin or intricate parts.

Aluminum jaws are lighter in weight than steel and can be turned at higher speeds with less wear on your machine.

Steel jaws are more durable than aluminum. For repeated use, harden them after machining.

For technical drawings and 3-D models, click on a part number.

| For Lathe Chuck Dia. | Ht. | Lg. | Wd. | Slot Wd. | No. of Pieces | Serration Size | For Screw Size | Mounting Hole Ctr.-to-Ctr. | Weight, lbs. | Each | |

6061 Aluminum | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 6" | 1 1/2" | 3" | 1 1/4" | 0.472" | 3 | 1.5 mm × 60° | M10 | 0.787" | 1.2 | 0000000 | 000000 |

| 6" | 2" | 3" | 1 1/4" | 0.472" | 3 | 1.5 mm × 60° | M10 | 0.787" | 1.8 | 00000000 | 00000 |

| 6" | 3" | 3" | 1 1/4" | 0.472" | 3 | 1.5 mm × 60° | M10 | 0.787" | 2.4 | 00000000 | 00000 |

| 8" | 2" | 4" | 1 1/2" | 0.551" | 3 | 1.5 mm × 60° | M12 | 0.984" | 3 | 00000000 | 00000 |

| 8" | 3" | 4" | 1 1/2" | 0.551" | 3 | 1.5 mm × 60° | M12 | 0.984" | 4.2 | 00000000 | 00000 |

| 8" | 4" | 4" | 1 1/2" | 0.551" | 3 | 1.5 mm × 60° | M12 | 0.984" | 5.7 | 00000000 | 00000 |

| 10" | 2" | 4 1/2" | 1 1/2" | 0.63" | 3 | 1.5 mm × 60° | M12 | 1.181" | 3.3 | 00000000 | 00000 |

| 10" | 3" | 4 1/2" | 1 1/2" | 0.63" | 3 | 1.5 mm × 60° | M12 | 1.181" | 4.8 | 00000000 | 00000 |

| 10" | 4" | 4 1/2" | 1 1/2" | 0.63" | 3 | 1.5 mm × 60° | M12 | 1.181" | 6.6 | 00000000 | 000000 |

| 12" | 2" | 5 1/2" | 2" | 0.827" | 3 | 1.5 mm × 60° | M16 | 1.181" | 5.4 | 00000000 | 00000 |

| 12" | 3" | 5 1/2" | 2" | 0.827" | 3 | 1.5 mm × 60° | M16 | 1.181" | 7.8 | 0000000 | 000000 |

| 12" | 4" | 5 1/2" | 2" | 0.827" | 3 | 1.5 mm × 60° | M16 | 1.181" | 10.5 | 00000000 | 000000 |

| 15" | 3" | 6 1/2" | 2 1/2" | 0.866" | 3 | 1.5 mm × 60° | M20 | 1.693" | 11.4 | 00000000 | 000000 |

| 15" | 4" | 6 1/2" | 2 1/2" | 0.866" | 3 | 1.5 mm × 60° | M20 | 1.693" | 15.3 | 00000000 | 000000 |

1018 Carbon Steel | |||||||||||

| 6" | 1 1/2" | 3" | 1 1/4" | 0.472" | 3 | 1.5 mm × 60° | M10 | 0.787" | 3.5 | 00000000 | 00000 |

| 6" | 2" | 3" | 1 1/4" | 0.472" | 3 | 1.5 mm × 60° | M10 | 0.787" | 4.7 | 00000000 | 00000 |

| 6" | 3" | 3" | 1 1/4" | 0.472" | 3 | 1.5 mm × 60° | M10 | 0.787" | 7.1 | 00000000 | 00000 |

| 8" | 2" | 4" | 1 1/2" | 0.551" | 3 | 1.5 mm × 60° | M12 | 0.984" | 8.1 | 00000000 | 00000 |

| 8" | 3" | 4" | 1 1/2" | 0.551" | 3 | 1.5 mm × 60° | M12 | 0.984" | 12.3 | 00000000 | 00000 |

| 8" | 4" | 4" | 1 1/2" | 0.551" | 3 | 1.5 mm × 60° | M12 | 0.984" | 16.2 | 00000000 | 000000 |

| 10" | 2" | 4 1/2" | 1 1/2" | 0.63" | 3 | 1.5 mm × 60° | M12 | 1.181" | 9.1 | 0000000 | 00000 |

| 10" | 3" | 4 1/2" | 1 1/2" | 0.63" | 3 | 1.5 mm × 60° | M12 | 1.181" | 13.8 | 00000000 | 000000 |

| 10" | 4" | 4 1/2" | 1 1/2" | 0.63" | 3 | 1.5 mm × 60° | M12 | 1.181" | 18.5 | 00000000 | 000000 |

| 12" | 2" | 5 1/2" | 2" | 0.827" | 3 | 1.5 mm × 60° | M16 | 1.181" | 15 | 00000000 | 000000 |

| 12" | 3" | 5 1/2" | 2" | 0.827" | 3 | 1.5 mm × 60° | M16 | 1.181" | 22.5 | 00000000 | 000000 |

| 12" | 4" | 5 1/2" | 2" | 0.827" | 3 | 1.5 mm × 60° | M16 | 1.181" | 30.3 | 00000000 | 000000 |

| 15" | 3" | 6 1/2" | 2 1/2" | 0.866" | 3 | 1.5 mm × 60° | M20 | 1.693" | 33.1 | 00000000 | 000000 |

| 15" | 4" | 6 1/2" | 2 1/2" | 0.866" | 3 | 1.5 mm × 60° | M20 | 1.693" | 45 | 00000000 | 000000 |

6061 Aluminum | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Lathe Chuck Dia. | Ht. | Dia. | Slot Wd. | No. of Pieces | Serration Size | For Screw Size | Mounting Hole Ctr.-to-Ctr. | Weight, lbs. | Each | |

| 6" | 2" | 6" | 0.472" | 3 | 1.5 mm × 60° | M10 | 0.787" | 5.7 | 00000000 | 000000 |

| 6" | 3" | 6" | 0.472" | 3 | 1.5 mm × 60° | M10 | 0.787" | 8.1 | 00000000 | 000000 |

| 6" | 4" | 6" | 0.472" | 3 | 1.5 mm × 60° | M10 | 0.787" | 10.8 | 0000000 | 000000 |

| 8" | 2" | 8" | 0.551" | 3 | 1.5 mm × 60° | M12 | 0.984" | 10.2 | 00000000 | 000000 |

| 8" | 3" | 8" | 0.551" | 3 | 1.5 mm × 60° | M12 | 0.984" | 14.7 | 00000000 | 000000 |

| 8" | 4" | 8" | 0.551" | 3 | 1.5 mm × 60° | M12 | 0.984" | 19.8 | 00000000 | 000000 |

| 10" | 2" | 10" | 0.63" | 3 | 1.5 mm × 60° | M12 | 1.181" | 16.2 | 00000000 | 000000 |

| 10" | 3" | 10" | 0.63" | 3 | 1.5 mm × 60° | M12 | 1.181" | 24 | 00000000 | 000000 |

| 10" | 4" | 10" | 0.63" | 3 | 1.5 mm × 60° | M12 | 1.181" | 31.5 | 00000000 | 000000 |

| 12" | 2" | 12" | 0.827" | 3 | 1.5 mm × 60° | M16 | 1.181" | 23.4 | 00000000 | 000000 |

| 12" | 3" | 12" | 0.827" | 3 | 1.5 mm × 60° | M16 | 1.181" | 34.2 | 00000000 | 000000 |

| 12" | 4" | 12" | 0.827" | 3 | 1.5 mm × 60° | M16 | 1.181" | 45.3 | 00000000 | 000000 |

| 15" | 3" | 15" | 0.866" | 3 | 1.5 mm × 60° | M20 | 1.693" | 53.7 | 0000000 | 000000 |

| 15" | 4" | 15" | 0.866" | 3 | 1.5 mm × 60° | M20 | 1.693" | 70.8 | 00000000 | 000000 |

Hardened Lathe Chuck Jaws

Made from hardened steel, these jaws have a long service life even when performing heavy machining such as roughing cuts. Jaws are reversible and have teeth to grip a workpiece from its outside or inside. Fits most CNC lathe chucks made by Kitagawa, LMC, Samchully, Seoam, and Auto Strong. To ensure compatibility, match your chuck's diameter, slot width, serration type, and mounting-hole center-to-center distance. Attach to your chuck with jaw nuts (not included). Each set includes three jaws.

For technical drawings and 3-D models, click on a part number.

Step Ht. | Steel | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Lathe Chuck Dia. | Ht. | Lg. | Wd. | Slot Wd. | (A) | (B) | No. of Pieces | Serration Size | For Screw Size | Mounting Hole Ctr.-to-Ctr. | Weight, lbs. | Each | |

Reversible Jaws | |||||||||||||

| 6" | 2" | 2.846" | 1 1/4" | 0.472" | 1" | 1 1/2" | 3 | 1.5 mm × 60° | M10 | 0.787" | 4.5 | 0000000 | 0000000 |

| 8" | 2 1/2" | 3.802" | 1 1/2" | 0.551" | 1 1/4" | 1 7/8" | 3 | 1.5 mm × 60° | M12 | 1" | 6.1 | 0000000 | 000000 |

| 10" | 2 1/2" | 4.352" | 1 3/4" | 0.63" | 1 1/4" | 1.937" | 3 | 1.5 mm × 60° | M12 | 1.187" | 9.1 | 0000000 | 000000 |

| 12" | 2 3/4" | 4.003" | 2" | 0.827" | 1 1/4" | 2" | 3 | 1.5 mm × 60° | M16 | 1.181" | 8.3 | 0000000 | 00000000 |

| 15" | 2.94" | 5.712" | 2 1/2" | 0.866" | 1 5/8" | 2.312" | 3 | 1.5 mm × 60° | M20 | 1.693" | 18.8 | 0000000 | 00000000 |