About Actuated On/Off Valves

More

About On/Off Valves

More

On/Off Valves with Sanitary Quick-Clamp Fittings for Food and Beverage

- For Use With: Food, Beverage

- Valve Type: Ball

- Specifications Met: FDA Compliant 21 CFR 177.1550

To maintain sanitary standards in food, beverage, and dairy systems that require frequent cleaning, these valves are made of FDA compliant materials. Polished to a 32 Ra finish, they have smooth internal surfaces that prevent product buildup and inhibit bacteria growth. All have sanitary quick-clamp fittings for easy disassembly. They also have a three-piece bolted body that comes apart for cleaning and inline access to internal components. Body is 316 stainless steel for excellent corrosion resistance. Valves have a lockable lever that can be fixed in place using a padlock (not included). They are full port, so they do not restrict flow.

Choose the seal material that suits your application. PTFE resists a broad range of food-processing chemicals, organic food acids, and fats and oils. Glass-filled PTFE won’t expand when exposed to water and heat, thanks to its glass reinforcement. More durable than unfilled PTFE, it’s good for high-stress applications. Polyethylene has a low-friction surface that prevents sticking and binding. This wear-resistant plastic handles scuffs and scrapes, and it won't degrade from food irradiation. It's often used in place of PTFE for applications where fluorocarbons can't be used.

For technical drawings and 3-D models, click on a part number.

Valves | Replacement Handles | Repair Kits | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | Max. Pressure | Temperature Range, °F | End-to-End Lg. | For Max. Shackle Dia. | Interior Smoothness, Ra | Each | Each | Each | ||||

316 Stainless Steel Body—PTFE Plastic Seal | |||||||||||||

Quick Clamp × Quick Clamp | |||||||||||||

| 1/2" | 0.984" | 1000 psi @ 150° F | 0° | 300° | 4 5/16" | 1/4" | 32 | 000000000 | 0000000 | 000000000 | 000000 | 00000000 | 000000 |

| 3/4" | 0.984" | 1000 psi @ 150° F | 0° | 300° | 4 11/16" | 1/4" | 32 | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 1" | 1.984" | 1000 psi @ 150° F | 0° | 300° | 5" | 1/4" | 32 | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 1 1/2" | 1.984" | 1000 psi @ 150° F | 0° | 300° | 5 5/8" | 9/32" | 32 | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 000000 |

| 2" | 2.516" | 1000 psi @ 150° F | 0° | 300° | 6 7/16" | 9/32" | 32 | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 000000 |

| 2 1/2" | 3.047" | 800 psi @ 150° F | 0° | 300° | 7 13/16" | 3/8" | 32 | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 000000 |

| 3" | 3.579" | 800 psi @ 150° F | 0° | 300° | 9" | 3/8" | 32 | 000000000 | 00000000 | 000000000 | 00000 | 00000000 | 000000 |

| 4" | 4.682" | 800 psi @ 150° F | 0° | 300° | 9 5/8" | 3/8" | 32 | 000000000 | 00000000 | 000000000 | 000000 | 000000000 | 000000 |

316 Stainless Steel Body—Glass-Filled PTFE Plastic Seal | |||||||||||||

Quick Clamp × Quick Clamp | |||||||||||||

| 1/2" | 0.984" | 1000 psi @ 150° F | 0° | 300° | 4 5/16" | 1/4" | 32 | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 00000 |

| 3/4" | 0.984" | 1000 psi @ 150° F | 0° | 300° | 4 11/16" | 1/4" | 32 | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 00000 |

| 1" | 1.984" | 1000 psi @ 150° F | 0° | 300° | 5" | 1/4" | 32 | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 00000 |

| 1 1/2" | 1.984" | 1000 psi @ 150° F | 0° | 300° | 5 5/8" | 9/32" | 32 | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 000000 |

| 2" | 2.516" | 1000 psi @ 150° F | 0° | 300° | 6 7/16" | 9/32" | 32 | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 000000 |

316 Stainless Steel Body—Polyethylene Plastic Seal | |||||||||||||

Quick Clamp × Quick Clamp | |||||||||||||

| 1/2" | 0.984" | 700 psi @ 150° F | 0° | 150° | 4 5/16" | 1/4" | 32 | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 00000 |

| 3/4" | 0.984" | 700 psi @ 150° F | 0° | 150° | 4 11/16" | 1/4" | 32 | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 00000 |

| 1" | 1.984" | 700 psi @ 150° F | 0° | 150° | 5" | 1/4" | 32 | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 000000 |

| 1 1/2" | 1.984" | 700 psi @ 150° F | 0° | 150° | 5 5/8" | 9/32" | 32 | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 000000 |

On/Off Valves with Butt-Weld Fittings for Food and Beverage

- Valve Type: Ball

- For Use With: Food, Beverage

- Seal Material: PTFE Plastic

Weld these valves to unthreaded metal pipe for a permanent, flush connection that permits smooth flow through a line. For easy cleaning in food and beverage systems, they have polished internal surfaces and a three-piece bolted body that disassembles inline for access to internal components without cutting welded connections. All valves have a lockable lever handle that can be fixed in place using a padlock (not included). They are full port, so they do not restrict flow.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | Max. Pressure | Temperature Range, °F | End-to-End Lg. | For Max. Shackle Dia. | Each | |

316 Stainless Steel Body | ||||||

|---|---|---|---|---|---|---|

Butt Weld × Butt Weld | ||||||

| 1/2" | 1000 psi @ 150° F | 0° to 300° | 4 5/16" | 1/4" | 000000000 | 0000000 |

| 3/4" | 1000 psi @ 150° F | 0° to 300° | 4 11/16" | 1/4" | 000000000 | 000000 |

| 1" | 1000 psi @ 150° F | 0° to 300° | 5" | 1/4" | 000000000 | 000000 |

| 1 1/2" | 1000 psi @ 150° F | 0° to 300° | 5 5/8" | 9/32" | 000000000 | 000000 |

| 2" | 1000 psi @ 150° F | 0° to 300° | 6 7/16" | 9/32" | 000000000 | 000000 |

| 3" | 800 psi @ 150° F | 0° to 300° | 9" | 3/8" | 000000000 | 00000000 |

Sanitary On/Off Valves for Food and Beverage

- For Use With: Food, Beverage

- Valve Type: Ball

- Seal Material: Mica-Filled PTFE Plastic

- Specifications Met: 3-A Certified 68-00

3-A certified as meeting sanitary design standards, these valves control the flow of liquids in food, dairy, pharmaceutical, and cosmetic plants. Made of stainless steel, they won’t corrode from frequent washdowns with harsh cleaners. They have a highly polished surface, leaving no crevices for bacteria to grow. These valves connect to quick-clamp fittings—also known as tri-clamp fittings—so they’re easily taken apart for frequent sanitizing.

Valves open to the full port size, so they won’t restrict flow. They can be disassembled by hand since their two-piece body is held together by bolts and wing nuts, making them easier to take apart for cleaning than traditional three-piece ball valves. The mica-filled PTFE seal resists food-processing chemicals, organic food acids, and fat and oil. It resists high heat and pressure better than standard PTFE seals.

For technical drawings and 3-D models, click on a part number.

Valves | Repair Kits | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | Maximum Pressure | Temperature Range, °F | End-to-End Length | Interior Smoothness, Ra | Each | Each | ||

316 Stainless Steel Body | |||||||||

Quick Clamp × Quick Clamp | |||||||||

| 1/2" | 0.984" | 300 psi @ 150° F | 32° to 450° | 5 1/16" | 32 | 0000000 | 000000000 | 0000000 | 0000000 |

| 1 1/2" | 1.984" | 300 psi @ 150° F | 32° to 450° | 5 13/16" | 32 | 0000000 | 00000000 | 0000000 | 000000 |

| 2" | 2.516" | 300 psi @ 150° F | 32° to 450° | 6 13/16" | 32 | 0000000 | 00000000 | 0000000 | 000000 |

| 3" | 3.579" | 300 psi @ 150° F | 32° to 450° | 9 7/16" | 32 | 0000000 | 00000000 | 0000000 | 00000000 |

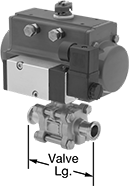

Air-Driven On/Off Valves for Food and Beverage

- Valve Type: Ball

- For Use With: Beverage, Food

- Seal Material : PTFE Plastic

To maintain sanitary standards in food and beverage applications, these valves have sanitary quick-clamp connections and polished internal surfaces for easy cleaning. The three-piece bolted body comes apart for access to internal components without unthreading pipe connections and removing the valve from your line. They have a ball-valve design that provides higher flow rates than other air-driven valves. All operate on compressed air to automatically start and stop flow faster than motor-driven valves. You must control the air to the actuator using either an electric pilot valve or a manual on/off valve (not included). These valves do not require a minimum pressure drop between the inlet and the outlet for operation. All are full port, so they do not restrict flow.

Body is 316 stainless steel for excellent corrosion resistance. The actuator is directly mounted to the valve body to minimize movement and reduce wear. A visual flow indicator on the top of the actuator shows whether the valve is open or closed. The manual override allows you to operate the valve during power outages.

Single-acting actuators only require air pressure to open the valve; they automatically spring closed when the air turns off. These valves are normally closed unless actuated. Double-acting actuators require air pressure to open and close the valve. Once actuated, these valves remain actuated until air pressure is applied, so they do not have a valve starting position.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

Overall | Air | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Gender | Connection Style | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Temp. Range, °F | Valve Lg. | Lg. | Ht. | Connection | Pressure Range, psi | Each | |

316 Stainless Steel Body with Screw Terminals | |||||||||||||

Single Acting: Air-to-Open, Spring Return (Normally Closed)—120V AC | |||||||||||||

| 1/2" | Female | Quick Clamp | 15 | 1000 psi @ 100° F | Zero Pressure Drop | -20° to 365° | 3 1/2" | 6 3/8" | 5 13/16" | 1/4 NPT Female | 40 to 115 | 0000000 | 0000000 |

| 3/4" | Female | Quick Clamp | 34 | 1000 psi @ 100° F | Zero Pressure Drop | -20° to 365° | 4" | 6 3/8" | 5 13/16" | 1/4 NPT Female | 40 to 115 | 0000000 | 000000 |

| 1" | Female | Quick Clamp | 56 | 1000 psi @ 100° F | Zero Pressure Drop | -20° to 365° | 4 1/2" | 8 1/8" | 7 1/4" | 1/4 NPT Female | 40 to 115 | 0000000 | 000000 |

| 1 1/2" | Female | Quick Clamp | 125 | 1000 psi @ 100° F | Zero Pressure Drop | -20° to 365° | 5 1/2" | 9 3/8" | 8 13/16" | 1/4 NPT Female | 40 to 115 | 0000000 | 000000 |

| 2" | Female | Quick Clamp | 250 | 1000 psi @ 100° F | Zero Pressure Drop | -20° to 365° | 6 1/4" | 10 11/16" | 9 7/8" | 1/4 NPT Female | 40 to 115 | 0000000 | 00000000 |

Double Acting: Air-to-Open, Air-to-Close—120V AC | |||||||||||||

| 1/2" | Female | Quick Clamp | 15 | 1000 psi @ 100° F | Zero Pressure Drop | -20° to 365° | 3 1/2" | 5 1/2" | 5 3/8" | 1/4 NPT Female | 40 to 115 | 0000000 | 000000 |

| 3/4" | Female | Quick Clamp | 34 | 1000 psi @ 100° F | Zero Pressure Drop | -20° to 365° | 4" | 5 1/2" | 5 11/16" | 1/4 NPT Female | 40 to 115 | 0000000 | 000000 |

| 1" | Female | Quick Clamp | 56 | 1000 psi @ 100° F | Zero Pressure Drop | -20° to 365° | 4 1/2" | 5 1/2" | 6 3/16" | 1/4 NPT Female | 40 to 115 | 0000000 | 000000 |

| 1 1/2" | Female | Quick Clamp | 125 | 1000 psi @ 100° F | Zero Pressure Drop | -20° to 365° | 5 1/2" | 6 3/8" | 7 11/16" | 1/4 NPT Female | 40 to 115 | 0000000 | 000000 |

| 2" | Female | Quick Clamp | 250 | 1000 psi @ 100° F | Zero Pressure Drop | -20° to 365° | 6 1/4" | 8 1/8" | 8 5/8" | 1/4 NPT Female | 40 to 115 | 0000000 | 000000 |

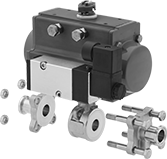

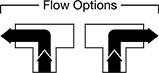

Air-Driven Diverting Valves for Food and Beverage

- Valve Type: Ball

- For Use With: Beverage, Food

- Seal Material: PTFE Plastic

For food and beverage systems that require frequent cleaning, these valves have sanitary quick-clamp connections for easy disassembly. They operate on compressed air to divert flow between ports between ports more quickly than motor-driven valves. You must control the air supply to the actuator using either an electric pilot valve (not included) or a manual on/off valve (not included). These valves don’t require a minimum pressure drop between the inlet and outlet for operation. All are full port, so they do not restrict flow.

Body is 316 stainless steel for excellent corrosion resistance. The actuator is directly mounted to the valve body to minimize movement and wear. A visual flow indicator on the top of the actuator shows which direction flow is being diverted.

Air-to-divert/air-to-return valves require air pressure to divert flow to the right-port outlet and air pressure to return flow to the left-port outlet.

Air-to-divert/spring-return valves require air pressure to divert flow to the right-port outlet. They automatically return flow to the left-port outlet when the air turns off to ensure the valve only diverts flow to the right port when air is on.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

For Tube | Air | Mounting Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Flow Pattern | Flow Coefficient (Cv) | Max. Pressure | Pressure Range, psi | Connection Pipe Size | Connection Gender | Pressure Drop | Temp. Range, °F | Actuation Time | Valve Lg. | Mounting Fasteners Included | No. of | Dia. | Each | |

316 Stainless Steel Body—Quick Clamp × Quick Clamp × Quick Clamp | ||||||||||||||||

Single Acting: Air-to-Divert / Spring Return | ||||||||||||||||

| 3/8" | 1/2" | L-Pattern | 6 | 115 psi @ 120° F | 80 to 150 | 1/8 | Female | Zero Pressure Drop | -30° to 500° | 1 sec. | 4 21/64" | No | 4 | 3/8" | 0000000 | 000000000 |

| 5/8" | 3/4" | L-Pattern | 16 | 115 psi @ 120° F | 80 to 150 | 1/4 | Female | Zero Pressure Drop | -30° to 500° | 1 sec. | 5 33/64" | No | 5 | 7/16" | 0000000 | 00000000 |

| 7/8" | 1" | L-Pattern | 31 | 115 psi @ 120° F | 80 to 150 | 1/4 | Female | Zero Pressure Drop | -30° to 500° | 1 sec. | 6 19/64" | No | 6 | 7/16" | 0000000 | 00000000 |

| 1 3/8" | 1 1/2" | L-Pattern | 75 | 115 psi @ 120° F | 80 to 150 | 1/4 | Female | Zero Pressure Drop | -30° to 500° | 2 sec. | 7 7/8" | No | 7 | 3/4" | 0000000 | 00000000 |

| 1 7/8" | 2" | L-Pattern | 140 | 115 psi @ 120° F | 80 to 150 | 1/4 | Female | Zero Pressure Drop | -30° to 500° | 2 sec. | 8 21/32" | No | 8 | 3/4" | 0000000 | 00000000 |

Double Acting: Air-to-Divert / Air-to-Return | ||||||||||||||||

| 3/8" | 1/2" | L-Pattern | 6 | 115 psi @ 120° F | 80 to 150 | 1/8 | Female | Zero Pressure Drop | -30° to 500° | 1 sec. | 4 21/64" | No | 9 | 3/8" | 0000000 | 000000 |

| 5/8" | 3/4" | L-Pattern | 16 | 115 psi @ 120° F | 80 to 150 | 1/8 | Female | Zero Pressure Drop | -30° to 500° | 1 sec. | 5 33/64" | No | 10 | 7/16" | 0000000 | 00000000 |

| 7/8" | 1" | L-Pattern | 31 | 115 psi @ 120° F | 80 to 150 | 1/4 | Female | Zero Pressure Drop | -30° to 500° | 1 sec. | 6 19/64" | No | 11 | 7/16" | 0000000 | 00000000 |

| 1 3/8" | 1 1/2" | L-Pattern | 75 | 115 psi @ 120° F | 80 to 150 | 1/4 | Female | Zero Pressure Drop | -30° to 500° | 1 sec. | 7 7/8" | No | 12 | 3/4" | 0000000 | 00000000 |

| 1 7/8" | 2" | L-Pattern | 140 | 115 psi @ 120° F | 80 to 150 | 1/4 | Female | Zero Pressure Drop | -30° to 500° | 1 sec. | 8 21/32" | No | 13 | 3/4" | 0000000 | 00000000 |

- Valve Type: Solenoid

- For Use With: Beverage, Food

- Seal Material: Buna-N Rubber

| Flow Pattern | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Min. Pressure Drop Required | Temp. Range, °F | Actuation Time | Valve Lg. | Each | |

120V AC | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Aluminum Body with DIN Connection | |||||||||

| L-Pattern | 1.4 | 150 psi @ 120° F | Pressure Drop Assisted | 5 psi | 35° to 120° | 1 sec. | 5 13/16" | 0000000 | 0000000 |

24V DC | |||||||||

Aluminum Body with DIN Connection | |||||||||

| L-Pattern | 1.4 | 150 psi @ 120° F | Pressure Drop Assisted | 5 psi | 35° to 120° | 1 sec. | 5 13/16" | 0000000 | 000000 |