How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Backflow-Prevention Valves

More

About Actuated On/Off Valves

More

About On/Off Valves

More

About Fire-Fighting Hose Threads

More

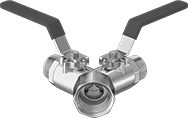

Dual Shut-Off Threaded Diverting Valves

Female x Male x Male |  Female x Female x Female |

|

- Valve Type: Ball

- For Use With:

NPT Female × NPT Female × NPT Female: Air, Water

NPT Female × NPT Male × NPT Male: Air, Argon, Helium, Krypton, Neon, Oil, Water, Xenon - Seal Material: PTFE Plastic

Control flow in two directions from a single source—these valves have two handles for independent operation of each outlet. They can direct flow from the center-port inlet to one side-port outlet at full capacity, direct flow to both side-port outlets simultaneously at reduced capacity, or shut off flow to both outlet ports completely. Valves are standard port, so they slightly restrict flow.

For technical drawings and 3-D models, click on a part number.

| Inlet Pipe Size | Outlet Pipe Sizes | Flow Pattern | Max. Pressure | Temp. Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | Each | |

Brass Body | ||||||||

|---|---|---|---|---|---|---|---|---|

NPT Female × NPT Male × NPT Male | ||||||||

| 1 | 3/4 × 3/4 | Y-Pattern | 600 psi @ 200° F | -40° to 365° | 29 | 3 1/4" | 0000000 | 000000 |

Bronze Body | ||||||||

NPT Female × NPT Female × NPT Female | ||||||||

| 1 | 3/4 × 3/4 | Y-Pattern | 550 psi @ 150° F | Not Rated | 29 | 3 7/16" | 0000000 | 000000 |

| 1 1/4 | 3/4 × 3/4 | Y-Pattern | 550 psi @ 150° F | Not Rated | 29 | 3 7/16" | 0000000 | 000000 |

Threaded Solenoid Diverting Valves

- For Use With: Air, Argon, Helium, Krypton, Neon, Oil, Water, Xenon

- Seal Material: Buna-N Rubber

These valves operate on electricity to automatically divert flow between ports. All can direct flow from the center-port inlet to either side-port outlet. Valves cannot shut off flow. They require a minimum pressure drop between the inlet and outlet for operation; the upstream pressure must be 10 psi greater than the downstream pressure. The actuator is directly mounted to the valve body to minimize movement and reduce wear.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Flow Pattern | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Min. Pressure Drop Required | Temp. Range, °F | Actuation Time | Valve Lg. | O'all Ht. | Each | |

Brass Body with Wire Leads—120V AC | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

NPT Female × NPT Female × NPT Female | |||||||||||

| 3/8 | L-Pattern | 2.1 | 180 psi @ 165° F | Pressure Drop Assisted | 10 psi | 35° to 165° | 0 sec. | 3" | 4 7/8" | 0000000 | 0000000 |

Clear-View Socket-Connect Check Valves

- For Use With: Air, Water

- Piston Material: PVC Plastic

- Seal Material: EPDM Rubber

Visually inspect flow and debris accumulation through the transparent valve body. Insert unthreaded pipe into the socket ends and bond with primer and cement to create a permanent, leak-tight connection. These valves open to allow flow in one direction and close when flow stops or reverses. They have a removable cap that provides easy access to internal components for maintenance.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | For Pipe Schedule | Flow Coefficient (Cv) | Max. Pressure | Min. Opening Pressure, psi | Temperature Range, °F | Color | End-to-End Lg. | Features | Each | |

PVC Plastic Body | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Socket Connect × Socket Connect | ||||||||||

| 1/2 | 40, 80 | 6.7 | 150 psi @ 70° F | 0.29 | 35° to 140° | Clear | 5 5/8" | Removable Cap | 0000000 | 000000 |

| 3/4 | 40, 80 | 11.9 | 150 psi @ 70° F | 0.29 | 35° to 140° | Clear | 6 5/16" | Removable Cap | 0000000 | 00000 |

| 1 | 40, 80 | 21 | 150 psi @ 70° F | 0.29 | 35° to 140° | Clear | 6 7/8" | Removable Cap | 0000000 | 00000 |

| 1 1/2 | 40, 80 | 49 | 150 psi @ 70° F | 0.29 | 35° to 140° | Clear | 8 1/8" | Removable Cap | 0000000 | 000000 |

| 2 | 40, 80 | 77 | 150 psi @ 70° F | 0.29 | 35° to 140° | Clear | 8 7/8" | Removable Cap | 0000000 | 000000 |

| 3 | 40, 80 | 168 | 150 psi @ 70° F | 0.29 | 35° to 140° | Clear | 12 1/4" | Removable Cap | 0000000 | 000000 |

Check Valves with Solder-Connect Fittings

- For Use With: Steam, Water

- Disc Material: Bronze

- Seal Material: Bronze

Solder these valves to copper tubing for a permanent, leak-tight connection. They open to allow flow in one direction and close when flow stops or reverses. All have a removable cap that provides easy access to internal components for maintenance.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| For Copper Tube Size | For Tube OD | Flow Coefficient (Cv) | Pressure Class | Max. Pressure | Max. Steam Pressure | Min. Opening Pressure, psi | Temperature Range, °F | End-to-End Lg. | Features | Each | |

Bronze Body | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Solder Connect × Solder Connect | |||||||||||

| 1/4 | 3/8" | 1.3 | 125 | 200 psi @ 70° F | 125 psi @ 350° F | 0.5 | -20° to 405° | 2 1/16" | Removable Cap | 0000000 | 000000 |

| 3/8 | 1/2" | 2.5 | 125 | 200 psi @ 70° F | 125 psi @ 350° F | 0.5 | -20° to 405° | 2 1/16" | Removable Cap | 0000000 | 00000 |

| 1/2 | 5/8" | 4.8 | 125 | 200 psi @ 70° F | 125 psi @ 350° F | 0.5 | -20° to 405° | 2 9/16" | Removable Cap | 0000000 | 00000 |

| 3/4 | 7/8" | 14.3 | 125 | 200 psi @ 70° F | 125 psi @ 350° F | 0.5 | -20° to 405° | 3 3/8" | Removable Cap | 0000000 | 000000 |

| 1 | 1 1/8" | 24 | 125 | 200 psi @ 70° F | 125 psi @ 350° F | 0.5 | -20° to 405° | 4 1/16" | Removable Cap | 0000000 | 000000 |

| 1 1/2 | 1 5/8" | 60 | 125 | 200 psi @ 70° F | 125 psi @ 350° F | 0.5 | -20° to 405° | 5 1/4" | Removable Cap | 0000000 | 000000 |

| 2 | 2 1/8" | 102 | 125 | 200 psi @ 70° F | 125 psi @ 350° F | 0.5 | -20° to 405° | 6 3/8" | Removable Cap | 0000000 | 000000 |

Socket-Connect Check Valves for Harsh Chemicals

Insert unthreaded pipe into the socket ends and bond with primer and cement to create a permanent, leak-tight connection. These valves have a plastic body and a fluoroelastomer seal for excellent chemical resistance. They open to allow flow in one direction and close when flow stops or reverses.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- For Use With: Citric Acid, Deionized Water, Diesel Fuel, Ethylene Glycol, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Mineral Spirits, Nitric Acid, Oil, Phosphoric Acid, Salt Water, Sodium Hypochlorite, Water

- Piston Material: PVC Plastic

- Spring Material: PVC Plastic

- Seal Material: Fluoroelastomer Rubber

| Pipe Size | For Pipe Schedule | Flow Coefficient (Cv) | Max. Pressure | Min. Opening Pressure, psi | Temperature Range, °F | Color | End-to-End Lg. | Each | |

Socket Connect × Socket Connect | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 3/4 | 40, 80 | 3 | 150 psi @ 70° F | 2 | 40° to 140° | Dark Gray | 4 3/16" | 000000 | 0000000 |

| 1 | 40, 80 | 9 | 150 psi @ 70° F | 2 | 40° to 140° | Dark Gray | 5 3/16" | 000000 | 000000 |

| 1 1/4 | 40, 80 | 26 | 150 psi @ 70° F | 2 | 40° to 140° | Dark Gray | 6 5/8" | 000000 | 000000 |

| 1 1/2 | 40, 80 | 45 | 150 psi @ 70° F | 2 | 40° to 140° | Dark Gray | 6 5/8" | 000000 | 000000 |

| 2 | 40, 80 | 65 | 150 psi @ 70° F | 2 | 40° to 140° | Dark Gray | 7 5/8" | 000000 | 000000 |

- For Use With: Citric Acid, Deionized Water, Diesel Fuel, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Mineral Spirits, Nitric Acid, Oil, Phosphoric Acid, Salt Water, Sodium Hypochlorite, Water

- Piston Material: CPVC Plastic

- Spring Material: CPVC Plastic

- Seal Material: Fluoroelastomer Rubber

| Pipe Size | For Pipe Schedule | Flow Coefficient (Cv) | Max. Pressure | Min. Opening Pressure, psi | Temperature Range, °F | Color | End-to-End Lg. | Each | |

Socket Connect × Socket Connect | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 40, 80 | 0.8 | 150 psi @ 70° F | 2 | 40° to 190° | Light Gray | 3 3/8" | 0000000 | 0000000 |

| 3/4 | 40, 80 | 3 | 150 psi @ 70° F | 2 | 40° to 190° | Light Gray | 4 3/16" | 0000000 | 000000 |

| 1 | 40, 80 | 9 | 150 psi @ 70° F | 2 | 40° to 190° | Light Gray | 5 3/16" | 0000000 | 000000 |

| 1 1/2 | 40, 80 | 45 | 150 psi @ 70° F | 2 | 40° to 190° | Light Gray | 6 5/8" | 0000000 | 000000 |

| 2 | 40, 80 | 65 | 150 psi @ 70° F | 2 | 40° to 190° | Light Gray | 7 5/8" | 0000000 | 000000 |

Clear-View Socket-Connect Check Valves for Harsh Chemicals

- For Use With: Carbon Dioxide, Citric Acid, Deionized Water, Diesel Fuel, Hydrochloric Acid, Methanol, Nitric Acid, Phosphoric Acid, Salt Water, Sulfuric Acid, Water

- Piston Material: PVC Plastic

- Seal Material: Fluoroelastomer Rubber

Visually inspect flow and debris accumulation through the transparent valve body. Insert unthreaded pipe into the socket ends and bond with primer and cement to create a permanent, leak-tight connection. Valves have a PVC body and a fluoroelastomer seal for excellent chemical resistance. They open to allow flow in one direction and close when flow stops or reverses. All have a removable cap that provides easy access to internal components for maintenance.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | For Pipe Schedule | Flow Coefficient (Cv) | Max. Pressure | Min. Opening Pressure, psi | Temperature Range, °F | Color | End-to-End Lg. | Features | Each | |

PVC Plastic Body | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Socket Connect × Socket Connect | ||||||||||

| 1/2 | 40, 80 | 6.7 | 150 psi @ 70° F | 0.29 | 35° to 140° | Clear | 5 5/8" | Removable Cap | 0000000 | 000000 |

| 3/4 | 40, 80 | 11.9 | 150 psi @ 70° F | 0.29 | 35° to 140° | Clear | 6 5/16" | Removable Cap | 0000000 | 00000 |

| 1 | 40, 80 | 21 | 150 psi @ 70° F | 0.29 | 35° to 140° | Clear | 6 7/8" | Removable Cap | 0000000 | 000000 |

Wye-Shaped On/Off Valves with Garden Hose Threads

Convert one faucet into two, four, or five outlets.

All valves have shut-off outlets, so you can start and stop the flow to outlets individually. You can also use the shut-off to release pressure or drain residual water after disconnecting hose. Some valves also have open-flow outlets in addition to shut-off outlets. Open-flow outlets don't give you any flow control—they work like standard outlets.

Plastic valves are lighter in weight than metal valves, but they’re not as durable. Zinc valves are stronger and more resistant to wear and tear than plastic valves. Brass valves are stronger than plastic, zinc, and aluminum valves. Aluminum valves resist the highest pressures.

Contoured lever handles give you a better grip—choose them if you’ll be wearing gloves often or if they’re in an area where they’ll get wet and slippery. Toggle-switch handles easily flick on and off like a light switch.

Valves with TPR coating protect your hands by keeping the valve’s surface from getting too hot or cold.

Valves with a support brace can be secured against a wall for extra stability.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Ball

- For Use With: Water

- Temperature Range: 35° to 100° F

Valves with a flexible kink absorber protect your hose from sharp bends at the outlet that reduce flow and damage the hose.

| Handle Style | No. of Shut-Off Outlets | No. of Open-Flow Outlets | Flow Coefficient (Cv) | Max. Pressure | End-to-End Lg. | Body Finish | Includes | Each | |

Plastic Body | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Lever Handle | 2 | 0 | 27 | 60 psi @ 72° F | 3 3/8" | __ | Washers, Flexible Kink Absorbers | 0000000 | 00000 |

| Contoured Lever Handle | 2 | 0 | 14.1 | 60 psi @ 72° F | 3 7/8" | TPR Coated | Washers | 0000000 | 00000 |

| Contoured Lever Handle | 2 | 0 | 15.8 | 60 psi @ 72° F | 6" | TPR Coated | Washers, Flexible Kink Absorbers | 0000000 | 00000 |

| T-Handle | 2 | 0 | Not Rated | Not Rated | 4 3/4" | __ | Washers | 0000000 | 0000 |

| Toggle Switch | 2 | 0 | 1.3 | 60 psi @ 72° F | 4 1/8" | TPR Coated | Washers | 0000000 | 00000 |

Zinc Body | |||||||||

| Lever Handle | 2 | 0 | Not Rated | 120 psi @ 72° F | 3 3/4" | TPR Coated | Washers | 0000000 | 00000 |

| Lever Handle | 2 | 0 | Not Rated | 120 psi @ 72° F | 6 11/16" | TPR Coated | Washers, Flexible Kink Absorbers | 0000000 | 00000 |

| Lever Handle | 2 | 0 | 29.2 | 60 psi @ 72° F | 3 3/8" | __ | Washers | 0000000 | 0000 |

| T-Handle | 2 | 0 | 6.5 | 60 psi @ 72° F | 4 3/4" | __ | Washers | 0000000 | 00000 |

Brass Body | |||||||||

| Lever Handle | 2 | 0 | 31.3 | 60 psi @ 72° F | 2 5/8" | __ | Washers | 0000000 | 00000 |

| Lever Handle | 2 | 0 | 44.7 | 60 psi @ 72° F | 3 5/16" | __ | Washers | 0000000 | 00000 |

Aluminum Body | |||||||||

| Lever Handle | 2 | 0 | 4.5 | 445 psi @ 72° F | 2 5/8" | __ | Washers | 0000000 | 00000 |

- Valve Type: Ball

- For Use With: Water

- Temperature Range: 35° to 100° F

| Handle Style | No. of Shut-Off Outlets | No. of Open-Flow Outlets | Flow Coefficient (Cv) | Max. Pressure | End-to-End Lg. | Body Finish | Includes | Each | |

Plastic Body | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Toggle Switch | 4 | 0 | 1.3 | 60 psi @ 72° F | 5 5/16" | TPR Coated | Washers | 0000000 | 000000 |

Zinc Body | |||||||||

| Lever Handle | 4 | 0 | Not Rated | 120 psi @ 72° F | 4 1/2" | TPR Coated | Washers, Support Brace | 0000000 | 00000 |

Brass Body | |||||||||

| Lever Handle | 4 | 0 | 41.6 | 60 psi @ 72° F | 3 5/16" | __ | Washers | 0000000 | 00000 |

| Lever Handle | 4 | 0 | 46.8 | 60 psi @ 72° F | 4 11/16" | __ | Washers | 0000000 | 00000 |

Aluminum Body | |||||||||

| Lever Handle | 4 | 0 | 4.6 | 415 psi @ 72° F | 3 1/8" | __ | Washers | 0000000 | 00000 |

- Valve Type: Ball

- For Use With: Water

- Temperature Range: 35° to 100° F

| Handle Style | No. of Shut-Off Outlets | No. of Open-Flow Outlets | Flow Coefficient (Cv) | Max. Pressure | End-to-End Lg. | Body Finish | Includes | Each | |

Plastic Body | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Lever Handle | 3 | 2 | Not Rated | 120 psi @ 72° F | 3 5/16" | __ | Washers, Support Brace, Mounting Hardware | 0000000 | 00000 |

| T-Handle | 4 | 1 | 6.6 | 60 psi @ 72° F | 5" | __ | Washers | 0000000 | 00000 |

Zinc Body | |||||||||

| Lever Handle | 5 | 0 | Not Rated | 120 psi @ 72° F | 3 5/16" | TPR Coated | Washers, Support Brace, Mounting Hardware | 0000000 | 00000 |

| T-Handle | 4 | 1 | 6.6 | 60 psi @ 72° F | 5" | __ | Washers | 0000000 | 00000 |

Flexible kink absorbers protect your hose from sharp bends at the outlet that reduce flow and damage the hose.

Hose | ||||||||

|---|---|---|---|---|---|---|---|---|

| Max. Pressure | Lg. | Fitting Material | Material | Color | Outer Coil Material | Washer Material | Each | |

| 120 psi @ 72° F | 5 49/64" | Zinc | PVC Plastic | Green | Steel | TPR Rubber | 0000000 | 00000 |

Diverting Valves with Fire-Fighting Hose Fittings

- Valve Type: Ball

- For Use With: Water

- Seal Material: Buna-N Rubber

Control the flow of water in two directions from a single source—these diverting valves have two balls and handles for independent operation of each outlet. They can direct flow to one side outlet at full capacity while shutting off flow to the second side outlet, direct flow to both side outlets at reduced capacity, or shut off flow to both side outlets. Valves have a brass body for good corrosion resistance. They are for use with fire-fighting hose.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

NH/NST (National Hose/National Standard) threads are only compatible with other NH/NST threads. Male NPSH (National Pipe Straight Hose) threads are compatible with female NPSH threads. Female NPSH threads are compatible with male NPSH, NPT, NPTF, and NPSM threads.

For technical drawings and 3-D models, click on a part number.

| Inlet Fire Hose Trade Size | Outlet Fire Hose Trade Sizes | Flow Pattern | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

Brass Body | ||||||||

|---|---|---|---|---|---|---|---|---|

| 2 1/2 | 1 1/2 × 1 1/2 | Y-Pattern | Not Rated | 300 psi @ 150° F | -20° to 150° | 5 5/8" | 000000 | 0000000 |

| Inlet Pipe Size | Outlet Pipe Sizes | Flow Pattern | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

Brass Body | ||||||||

|---|---|---|---|---|---|---|---|---|

| 2 1/2 | 1 1/2 × 1 1/2 | Y-Pattern | Not Rated | 300 psi @ 150° F | -20° to 150° | 5 5/8" | 000000 | 0000000 |

Air On/Off Valves

Turn airflow on and off with these valves. They have two balls to independently shut off airflow to one of two outlets from a single source. When closed, they vent air pressure to the atmosphere so you can disconnect air tools safely.

Flow coefficient (Cv) is a measurement that indicates how much airflow can pass through a valve.

For technical drawings and 3-D models, click on a part number.

Number of Ports | Overall | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Inlet | Outlet | Inlet Pipe Size | Outlet Pipe Size | Flow Coefficient (Cv) | Temp. Range, °F | Lg. | Wd. | Ht. | Ball Material | Each | |

NPT Female Inlet × NPT Female Outlet | |||||||||||

Bronze Body | |||||||||||

| 1 | 2 | 1 | 3/4 | 43 | -20° to 400° | 3 1/2" | 10" | 2 9/16" | Bronze | 0000000 | 0000000 |

| 1 | 2 | 1 1/4 | 3/4 | 43 | -20° to 400° | 3 1/2" | 10" | 2 9/16" | Bronze | 0000000 | 000000 |

NPT Female Inlet × NPT Male Outlet | |||||||||||

Brass Body | |||||||||||

| 1 | 2 | 1 | 3/4 | 30 | -40° to 365° | 5 5/8" | 8 1/8" | 2 13/16" | Chrome-Plated Brass | 0000000 | 00000 |