About Carbon Steel, Alloy Steel, Spring Steel, and Cast Iron

More

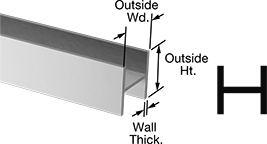

A992 Alloy Steel H-Bars

- Yield Strength: 50,000 psi

- Hardness: Not Rated

- Heat Treatable: Yes

- Maximum Hardness After Heat Treatment: Not Rated

- Fabrication: Hot Rolled

- Specifications Met: ASTM A992

Also known as W- and WF-beams, H-bars have wide flanges for strength. Made of alloy steel, they're often used in machine bases, platforms, and frames. Alloy steel contains silicon and vanadium to boost strength and hardness, so it bends less under load than carbon steel. Surface harden it for added wear resistance.

H-bars have wider flanges than I-beams, making them stronger but also heavier. They’re easier to weld as their straight flanges offer more surface area than I-beams’ tapered flanges. These H-bars are manufactured to meet ASTM A992 standards for quality and performance.

The beam trade number indicates the channel’s outside width and weight in lbs./ft. This gives you an easy reference for selecting the right size and strength for your needs.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Outside | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Ht. | Wd. | Beam Trade Number | Wall Thick. | Inside Wd. | Min. Temperature, °F | Straightness Tolerance | 3 ft. Lg. | 6 ft. Lg. | |

| 3.94" | 5.9" | W6×9 | 0.215" | 5.47" | Not Rated | 0.025" per ft. | 0000000 | ||

| 4" | 6.03" | W6×12 | 0.28" | 5.47" | Not Rated | 0.025" per ft. | 0000000 | ||

| 4" | 7.99" | W8×13 | 0.255" | 7.48" | Not Rated | 0.025" per ft. | 00000000 | ||

| 4.06" | 4.16" | W4×13 | 0.345" | 3.47" | Not Rated | 0.025" per ft. | 0000000 | ||

| 5" | 5.01" | W5×16 | 0.36" | 4.28" | Not Rated | 0.025" per ft. | 00000000 | ||

| 5.25" | 8.14" | W8×18 | 0.33" | 7.48" | Not Rated | 0.025" per ft. | 00000000 | ||

| 5.27" | 8.28" | W8×21 | 0.4" | 7.48" | Not Rated | 0.025" per ft. | 00000000 | ||

| 5.81" | 10.47" | W10×30 | 0.51" | 9.45" | Not Rated | 0.025" per ft. | 00000000 | ||

| 5.99" | 5.99" | W6×15 | 0.26" | 5.47" | Not Rated | 0.025" per ft. | 0000000 | ||

| 6.02" | 6.2" | W6×20 | 0.365" | 5.47" | Not Rated | 0.025" per ft. | 0000000 | ||

| 6.08" | 6.38" | W6×25 | 0.455" | 5.47" | Not Rated | 0.025" per ft. | 0000000 | ||

| 6.495" | 7.93" | W8×24 | 0.4" | 7.13" | Not Rated | 0.025" per ft. | 00000000 | ||

| 7.995" | 8" | W8×13 | 0.435" | 7.13" | Not Rated | 0.025" per ft. | 0000000 | ||

| 8.02" | 10.1" | W10×45 | 0.62" | 8.86" | Not Rated | 0.025" per ft. | 00000000 | ||

| 8.07" | 8.25" | W8×40 | 0.56" | 7.13" | Not Rated | 0.025" per ft. | 0000000 | ||

| 8.08" | 12.19" | W12×50 | 0.64" | 10.91" | Not Rated | 0.025" per ft. | 00000000 | ||

Multipurpose 304 Stainless Steel

From cookware to chemical-processing equipment, 304 stainless steel is a good all-around choice for a wide range of applications. It maintains its corrosion resistance in temperatures up to 1500° F.

Bars with sheared edges are also known as Gauer bar and are sheared from plate.

H-bars have larger flange widths and thicknesses than I-beams, so they’re stronger and carry heavier loads, yet also weigh more.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

- Yield Strength: 35,000 psi

- Hardness: Rockwell B80 (Medium)

- Heat Treatment: Annealed (Softened)

- Heat Treatable: No

- Specifications Met: ASTM A240

Outside | Corner Shape | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Ht. Tolerance | Wd. | Wd. Tolerance | Inside Wd. | Fabrication | Edge Fabrication | Outside | Inside | Straightness Tolerance | 3 ft. Lg. | 6 ft. Lg. | |

0.26" Wall Thick. | ||||||||||||

| 5.99" | -1/8" to 1/8" | 5.99" | -0.188" to 1/4" | 5.47" | Welded | Sheared | Square | Square | 0.0625" per 6 ft. | 0000000 | ||

0.33" Wall Thick. | ||||||||||||

| 5 1/4" | -1/8" to 1/8" | 8.14" | -0.188" to 1/4" | 7.48" | Welded | Sheared | Square | Square | 0.0625" per 6 ft. | 0000000 | ||

0.345" Wall Thick. | ||||||||||||

| 4.06" | -1/8" to 1/8" | 4.16" | -0.188" to 1/4" | 3.47" | Welded | Sheared | Square | Square | 0.0625" per 6 ft. | 0000000 | ||

0.365" Wall Thick. | ||||||||||||

| 6.02" | -1/8" to 1/8" | 6.2" | -0.188" to 1/4" | 5.47" | Welded | Sheared | Square | Square | 0.0625" per 6 ft. | 0000000 | ||

0.4" Wall Thick. | ||||||||||||

| 6.495" | -1/8" to 1/8" | 7.93" | -0.188" to 1/4" | 7.13" | Welded | Sheared | Square | Square | 0.0625" per 6 ft. | 0000000 | ||

0.435" Wall Thick. | ||||||||||||

| 7.995" | -1/8" to 1/8" | 8" | -0.188" to 1/4" | 7.13" | Welded | Sheared | Square | Square | 0.0625" per 6 ft. | 0000000 | ||

Architectural 6063 Aluminum H-Bars

- Yield Strength: 16,000 psi

- Hardness: Brinell 60 (Soft)

- Temper: T5

- Fabrication: Extruded

- Specifications Met: ASTM B221

More corrosion resistant and easier to form than multipurpose 6061 aluminum, 6063 is primarily used for exterior railings, decorative trim, and door frames.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Outside | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Ht. Tolerance | Wd. | Inside Wd. | Heat Treatment | Temperature Range, °F | Straightness Tolerance | 1 ft. Lg. | 3 ft. Lg. | 6 ft. Lg. | |

0.05" Wall Thick. (-0.008" to 0.008" Tolerance) | ||||||||||

| 1.000" | -0.024" to 0.024" | 1.950" | 1.85" | Hardened | -320° to 212° | 0.050" per ft. | 0000000 | |||

| 1.060" | -0.024" to 0.024" | 0.700" | 0.60" | Hardened | -320° to 212° | 0.050" per ft. | 0000000 | |||

| 1.074" | -0.024" to 0.024" | 1.040" | 0.94" | Hardened | -320° to 212° | 0.050" per ft. | 0000000 | |||

| 1.724" | -0.024" to 0.024" | 1.120" | 1.02" | Hardened | -320° to 212° | 0.050" per ft. | 0000000 | |||

0.055" Wall Thick. (-0.008" to 0.008" Tolerance) | ||||||||||

| 1.500" | -0.024" to 0.024" | 2.110" | 2.00" | Hardened | -320° to 212° | 0.050" per ft. | 0000000 | |||

0.062" Wall Thick. (-0.008" to 0.008" Tolerance) | ||||||||||

| 1.500" | -0.024" to 0.024" | 1.034" | 0.91" | Hardened | -320° to 212° | 0.050" per ft. | 0000000 | |||

0.094" Wall Thick. (-0.008" to 0.008" Tolerance) | ||||||||||

| 1.500" | -0.024" to 0.024" | 0.688" | 0.50" | Hardened | -320° to 212° | 0.050" per ft. | 0000000 | |||

1/8" Wall Thick. (-0.008" to 0.008" Tolerance) | ||||||||||

| 2.000" | -0.024" to 0.024" | 2.000" | 1.75" | Hardened | -320° to 212° | 0.050" per ft. | 0000000 | |||

0.188" Wall Thick. (-0.008" to 0.008" Tolerance) | ||||||||||

| 1.500" | -0.024" to 0.024" | 0.876" | 0.50" | Hardened | -320° to 212° | 0.050" per ft. | 0000000 | |||

0.2" Wall Thick. (-0.008" to 0.008" Tolerance) | ||||||||||

| 2.400" | -0.024" to 0.024" | 1.750" | 1.35" | Hardened | -320° to 212° | 0.050" per ft. | 0000000 | |||

1/4" Wall Thick. (-0.008" to 0.008" Tolerance) | ||||||||||

| 2.375" | -0.024" to 0.024" | 1.000" | 0.50" | Hardened | -320° to 212° | 0.050" per ft. | 0000000 | |||