Wheel Chocks

Keep wheels stationary while loading, unloading, and servicing vehicles. Chocks for wheel diameters 30" and larger are typically used for commercial vehicles, including semi-trucks and tractors. Chocks for wheel diameters under 30" are for use on small cars, trucks, and vans.

Reversible chocks can be used on both sides for twice the service life.

Steel chocks are wear resistant for a long service life. Chocks with a rope, carrying handle, or U-bolt handle give you a gripping point for easy carrying.

Chocks with a hole, an anchor plate with hole, an eyebolt, or a chain let you connect two chocks or can be secured to prevent theft.

Chocks with an antislip or serrated surface improve traction between wheels and the chock.

Chocks with a hollow middle are lighter in weight than solid chocks.

| Style | For Max. Wheel Dia. | Lg. | Wd. | Ht. | Color | For Max. Vehicle Wt., lbs. | Features | Each | |

Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 9 | 32" | 10 3/4" | 8" | 9" | Yellow | Not Rated | 1/2" Dia. Hole | 000000 | 000000 |

| 10 | 16" | 8 1/4" | 8 1/2" | 7 1/8" | __ | 20,000 | Hollow Middle | 000000000 | 00000 |

| 11 | 28" | 15 1/4" | 8 1/2" | 8 1/2" | __ | 20,000 | Hollow Middle | 000000000 | 000000 |

| 12 | 30" | 9 1/2" | 7 1/2" | 8 5/8" | Yellow | Not Rated | Carrying Handle | 0000000 | 00000 |

| 13 | 30" | 9 15/16" | 9 13/16" | 8 1/4" | Yellow | Not Rated | 10-ft. Long Chain | 0000000 | 00000 |

| Style | For Max. Wheel Dia. | Lg. | Wd. | Ht. | Base Texture | Surface Texture | Construction | For Max. Vehicle Wt., lbs. | Features | Each | |

Steel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 30 | 20" | 10 7/8" | 9" | 5 1/8" | Gripping Teeth | Serrated | Closed Base | 20,000 | Carrying Handle | 000000000 | 000000 |

Wheel Chocks with Extended-Length Handle

Quickly and safely secure a vehicle’s wheels without bending down. The handle makes these wheel chocks ergonomic and reduces the risk of injury if your vehicle moves during installation. Use them during loading, unloading, and servicing vehicles.

Steel chocks are wear resistant for a long service life.

Chocks with a flag increase visibility for safety. Chocks with a chain can be easily secured when not in use. Chocks with a hollow middle are lighter and easier to transport than solid chocks.

| For Max. Wheel Dia. | Flag Color | Handle Ht. | Lg. | Wd. | Ht. | Handle Color | Color | For Max. Vehicle Wt., lbs. | Features | Specifications Met | Each | |

Powder-Coated Steel | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 32" | __ | 37 7/8" | 9 1/2" | 9 13/16" | 8 1/4" | Safety Yellow | Safety Yellow | 30,000 | 10-ft. Long Chain, Hollow Middle | OSHA Compliant 29 CFR 1910.178 | 0000000 | 000000 |

| 32" | Orange | 37 7/8" | 10" | 9 13/16" | 8 1/4" | Safety Yellow | Safety Yellow | 30,000 | 10-ft. Long Chain, Hollow Middle | OSHA Compliant 29 CFR 1910.178 | 0000000 | 00000 |

Wheel Chock Holders

Store wheel chocks near docks and loading zones so they’re on hand when vehicles arrive.

Style A and B holders have a wide top opening so you can easily pull out your wheel chock. They also have openings on each side to accommodate chocks that have eye bolts or chains on the ends. Style B holders have a sign reminding drivers to chock their wheels.

Style C holders have a narrow top opening for a tight fit and a support bar on the bottom to keep wheel chocks from falling through. They’re often mounted to vehicles because they’ll keep chocks from jostling and falling out during movement.

Railcar Wheel Chocks

Chock the wheels on stationary railcars to keep them from moving during loading, unloading, and servicing. They’re for chocking railcars on a flat track, so they’re not recommended for use on tracks at an incline or decline. Chocks install quickly, without tools.

A flag indicates that chocks are in use.

Single chocks prevent forward motion.

Double chocks prevent forward and backward motion. Painted steel chocks are connected by a chain; a rubber strap attaches to the chain and draws the chocks together.

For Rail | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Style | Size, lbs. per 3 ft. | For Wheel Dia. | Lg. | Ht. | Material | Color | Specifications Met | Features | Each | |

Single Chock | ||||||||||

| Exposed | 75-141 | 28"-44" | 7 1/2" | 2 3/4" | Painted Steel | Safety Yellow | OSHA Compliant 29 CFR 1910.110, OSHA Compliant 29 CFR 1910.111, OSHA Compliant 29 CFR 1910.30 | Angled Handle | 0000000 | 0000000 |

| Paved | 75-141 | 28"-44" | 7 1/2" | 2 3/4" | Painted Steel | Safety Yellow | OSHA Compliant 29 CFR 1910.110, OSHA Compliant 29 CFR 1910.111, OSHA Compliant 29 CFR 1910.30 | Angled Handle | 0000000 | 000000 |

Double Chock | ||||||||||

| Exposed | 75-141 | 28"-44" | 5" | 2" | Painted Steel | Safety Yellow | OSHA Compliant 29 CFR 1910.110, OSHA Compliant 29 CFR 1910.111, OSHA Compliant 29 CFR 1910.30 | Angled Handle | 0000000 | 000000 |

| Paved | 75-141 | 28"-44" | 5" | 2" | Painted Steel | Safety Yellow | OSHA Compliant 29 CFR 1910.110, OSHA Compliant 29 CFR 1910.111, OSHA Compliant 29 CFR 1910.30 | Angled Handle | 0000000 | 000000 |

For Rail | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Style | Size, lbs. per 3 ft. | For Wheel Dia. | Lg. | Ht. | Material | Color | Specifications Met | Distance Between Chock and Flag | Each | |

Single Chock | ||||||||||

| Exposed | 75-141 | 28"-44" | 7 1/2" | 2 3/4" | Painted Steel | Safety Yellow | OSHA Compliant 29 CFR 1910.110, OSHA Compliant 29 CFR 1910.111, OSHA Compliant 29 CFR 1910.30 | 17" | 000000 | 0000000 |

| Paved | 75-141 | 28"-44" | 7 1/2" | 2 3/4" | Painted Steel | Safety Yellow | OSHA Compliant 29 CFR 1910.110, OSHA Compliant 29 CFR 1910.111, OSHA Compliant 29 CFR 1910.30 | 17" | 000000 | 000000 |

Double Chock | ||||||||||

| Exposed | 75-141 | 28"-44" | 5" | 2" | Painted Steel | Safety Yellow | OSHA Compliant 29 CFR 1910.110, OSHA Compliant 29 CFR 1910.111, OSHA Compliant 29 CFR 1910.30 | 17" | 000000 | 000000 |

| Paved | 75-141 | 28"-44" | 5" | 2" | Painted Steel | Safety Yellow | OSHA Compliant 29 CFR 1910.110, OSHA Compliant 29 CFR 1910.111, OSHA Compliant 29 CFR 1910.30 | 17" | 000000 | 000000 |

Railcar Wheel Stops

Stop moving railcars at track ends and as they approach buildings and doors.

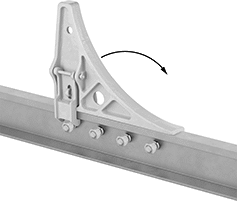

Foldable wheel stops swing down to the outside of the rail when not in use. You’ll need a left and right stop for a complete pair. They come with a padlock to keep them in the upright or lowered position, preventing unauthorized use. Bolt these stops onto your rail after drilling four 1 1/16″ holes into the rail web.

For technical drawings and 3-D models, click on a part number.