Auto-Darkening Welding Helmets

Protect your eyes the moment you start welding—four sensors detect the light and automatically darken the lens. Unlike traditional green welding lenses, these helmets use a true color lens to enhance clarity and color accuracy. They allow for a better look at your weld pool to increase weld quality and reduce eye strain. To customize the helmet’s fit so you can focus on welding, these helmets have a ratchet adjustment with an easy-turn knob. Solar cells recharge the helmet’s battery while you work.

Nylon plastic helmets offer a wider range of shade numbers and better optical clarity than polycarbonate helmets. They use digital controls to adjust settings such as shade number, light sensitivity, and mode selection.

Optical clarity measures how clearly a welder can see through the lens based on four categories: visual accuracy, light diffusion, consistency, and distortion. Each category is given a rating on a scale of 1 to 3. The lower the number, the better the clarity. Better optical clarity allows for precise welds, reduces eye strain, and improves focus.

Welding Lens | Lens | Helmet | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Shade No. | Optical Clarity | Technology | Color | Material | Ht. | Wd. | Color | Wd. | Hat Size | Wt., lbs. | Batteries Included | Switching Time, ms | Features | Each | |

Nylon Plastic Helmet | |||||||||||||||

| 4, 5, 6, 7, 8, 9, 10, 11, 12, 13 | 1/1/1/1 | True Color View | Blue | Polycarbonate Plastic | 5 1/4" | 4 1/2" | Red/White/Blue | 8 1/2" | 6 1/2-8 | 1.25 | Yes | 0.04 | Digital Controls | 00000000 | 0000000 |

Auto-Darkening Welding Helmets with Bluetooth

Protect your eyes the moment you start welding with a helmet that senses light and automatically darkens. You can change the shade of the lens without removing these helmets by using a Bluetooth-connected app. The app also monitors battery life and tracks the time spent cutting. Save up to 10 setting combinations to switch tasks quickly. Along with the app, these helmets use a tap function to switch between welding and grinding modes. To change modes, tap the side of the helmet twice.

To improve your weld quality and decrease eye strain, you can switch between cool, neutral, and warm tones. The true color lens enhances clarity and color accuracy to reduce the color distortion of your view.

Every inch of these helmets is designed to improve your welding experience. A rounded, slim design helps you fit in tight spaces. Levers adjust the helmet’s tilt and position on your head. The head suspension sits comfortably on the back of the head and balances the helmet’s weight for a barely-there feel. Side windows increase peripheral vision for high-quality welds.

Use side window covers when you need to block peripheral light.

Lens | Helmet | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Shade No. | Welding Lens Technology | Color | Material | Ht. | Wd. | Color | Wd. | Hat Size | Wt., lbs. | Batteries Included | Switching Time, ms | No. of Arc Sensors | Features | Specifications Met | Each | |

Nylon Plastic Helmet | ||||||||||||||||

| 3, 5, 8, 9, 10, 11, 12, 13, 14 | True Color View | Purple | Polycarbonate Plastic | 2 3/4" | 4 1/4" | Black | 8" | 6 3/8-8 | 1.5 | Yes | 0.1 | 4 | Adjustable Color Tones, Side Windows, Tap Function, Setting Memory | ANSI/ISEA Z87.1 | 0000000 | 0000000 |

For Lens | ||||

|---|---|---|---|---|

| Ht. | Wd. | Pkg. Qty. | Pkg. | |

| 2 3/4" | 4 1/4" | 5 | 0000000 | 000000 |

For Lens | ||||

|---|---|---|---|---|

| Ht. | Wd. | Pkg. Qty. | Pkg. | |

| 2 3/4" | 4 1/4" | 2 | 0000000 | 000000 |

Helmet | |||

|---|---|---|---|

| Color | Material | Each | |

| Black | Nylon Plastic | 0000000 | 000000 |

Auto-Darkening Welding Helmets with Integrated Light

Weld with the same quality as you would in bright conditions. These helmets have a built-in LED light that brightens your workspace, so you can see your weld and maintain precision even in dark areas. Turn the LED light on with the press of a button, and when it detects an arc or intense light, the light automatically turns off.

As you begin to weld, four arc sensors detect the light and automatically darken the lens. Unlike traditional green welding lenses, these helmets use a true color lens to enhance clarity and color accuracy. They have digital controls behind the lens where you can set the shade number, delay time, and sensitivity. To switch to grind mode without removing your helmet, use the button above the lens.

Mount these helmets to a hard-hat adapter when working in areas that require extra head protection. Attach magnifying lenses to see details better.

Optical clarity measures how clearly a welder can see through the lens based on four categories: visual accuracy, light diffusion, consistency, and distortion. Each category is given a rating on a scale of 1 to 3. The lower the number, the better the clarity. Better optical clarity allows for precise welds, reduces eye strain, and improves focus.

Welding Lens | Lens | Helmet | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Shade No. | Optical Clarity | Technology | Color | Material | Ht. | Wd. | Color | Wd. | Hat Size | Wt., lbs. | No. of Lights | Brightness, lumens | Batteries Included | Features | Includes | Each | |

Nylon Plastic Helmet | |||||||||||||||||

LED | |||||||||||||||||

| 3, 5, 6, 7, 8, 9, 10, 11, 12, 13 | 1/1/1/1 | True Color View | Clear | Glass | 2 1/4" | 4" | Black | 10 1/2" | 6 1/2-7 1/2 | 3.2 | 2 | 50 | Yes | Digital Controls, External Controls | One Helmet, Two Replacement Inner Lenses, Four Replacement Outer Lenses, Carrying Bag | 0000000 | 0000000 |

| Adjustment Style | Each | |

| Ratchet | 0000000 | 000000 |

| Material | Each | |

| Nylon | 0000000 | 000000 |

| Material | Pkg. Qty. | Pkg. | |

| Polyester Fabric | 5 | 0000000 | 000000 |

Precise-Shade Auto-Darkening Welding Helmets

Take full control of your shade level with these helmets—you can set the lens to adjust in half-shade increments. They have digital controls behind the lens where you can set the shade number, delay time, and sensitivity. Save up to nine settings to quickly switch between tasks. To switch to grind mode without removing your helmet, press the button above the lens.

As you weld, four sensors detect the light and automatically darken the lens. To improve weld quality and reduce eye strain, these helmets have a wide panoramic view and a true color lens. The lens enhances clarity and color accuracy to reduce the color distortion of your view.

Solar cells recharge the helmet’s battery while you work.

Mount these helmets to a hard-hat adapter when working in areas that require extra head protection. Attach a magnifying lens to enhance details.

Optical clarity measures how clearly a welder can see through the lens based on four categories: visual accuracy, light diffusion, consistency, and distortion. Each category is given a rating on a scale of 1 to 3. The lower the number, the better the clarity. Better optical clarity allows for precise welds, reduces eye strain, and improves focus.

Welding Lens | Lens | Helmet | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Shade No. | Optical Clarity | Technology | Color | Material | Ht. | Wd. | Color | Wd. | Hat Size | Wt., oz. | Batteries Included | Features | Includes | Each | |

Nylon Plastic Helmet | |||||||||||||||

| 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13 | 1/1/1/1 | True Color View | Yellow | Glass | 2 3/4" | 4 1/2" | Black | 10 1/4" | 6 1/2-7 1/2 | 60.3 | Yes | Setting Memory, Digital Controls, External Controls, Precision Adjustment, Panoramic View | One Helmet, Two Replacement Inner Lenses, Four Replacement Outer Lenses, Carrying Bag | 0000000 | 0000000 |

| Adjustment Style | Each | |

| Ratchet | 0000000 | 000000 |

| Material | Each | |

| Nylon | 0000000 | 000000 |

| Material | Pkg. Qty. | Pkg. | |

| Polyester Fabric | 5 | 0000000 | 000000 |

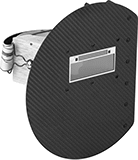

Low-Profile Auto-Darkening Welding Helmets

Also known as pancake welding helmets, these helmets have a flat face so you can get close to your welds. They’re often used when welding pipes, but are also useful where a standard welding helmet would be too bulky. These helmets extend further on one side than a standard welding helmet does for increased face protection from UV light, sparks, and spatter. A balsa wood box mounted inside the helmet fits around your face and eyes to block all light, even when working outdoors. Sand the box for a customizable fit. Designed for all-day comfort, they’re made of lightweight carbon fiber and have an open back for plenty of airflow.

These helmets have a large viewing area for a clear view of your workspace. The instant you start to weld, the lens darkens. Solar cells recharge the helmet’s battery while you work.

Choose a helmet based on which hand you use to hold your torch—they’re designed to protect the side opposite your welding hand, where sparks are most likely to fly. This means that left-hand helmets extend further on the right while right-hand helmets extend further on the left.

Optical clarity measures how clearly a welder can see through the lens based on four categories: visual accuracy, light diffusion, consistency, and distortion. Each category is given a rating on a scale of 1 to 3. The lower the number, the better the clarity. Better optical clarity allows for precise welds, reduces eye strain, and improves focus.

Warning: These helmets are made of carbon fiber, a conductive material. Never let them touch the welding rod holder and the material your ground cable is on at the same time. This could result in electrical shocks, burns, or eye injuries.

| Color | Each | |

| Blue | 00000000 | 000000 |

Filter Lenses for Welding Helmets and Goggles

Replace the filter lens on your welding helmet or goggles. These lenses reduce glare and filter out harmful infrared radiation. They are available in shade numbers 4 through 14.

Use green lenses for welding applications. They increase visual contrast so you can see the weld pool without making the environment too dark.

For technical drawings and 3-D models, click on a part number.

Welding Face Shields

For full-face protection while welding, select one of these shields. They meet ANSI/ISEA Z87.1+ high-impact standards when worn with safety glasses or goggles. All have a ratchet adjustment with an easy-turn knob.

Flip-up lenses have a welding shade that raises to expose a viewing lens. These shields are good for cutting and brazing jobs.

Face shields with chin guard provide added protection.

Face Shields | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lens | Replacement Lenses | |||||||||||

| Shade No. | Color | Material | Ht. | Wd. | Thick. | Hat Size | Features | Specifications Met | Each | Each | ||

Standard Lens | ||||||||||||

| 5 | Green | Polycarbonate Plastic | 9" | 12" | 0.06" | 6 1/2-8 | __ | ANSI/ISEA Z87.1+ | 000000000 | 000000 | 000000000 | 000000 |

| 5 | Green | Acetate Plastic | 6 1/2" | 19 1/2" | 0.06" | 6 1/2-8 | Chin Guard | ANSI/ISEA Z87.1+ | 00000000 | 00000 | 00000000 | 00000 |

Flip-Up Lens | ||||||||||||

| 5 | Green | Polycarbonate Plastic | 4 1/2" | 9" | 0.07" | 6 1/2-8 | Concealed Viewing Lens | ANSI/ISEA Z87.1+ | 0000000 | 00000 | 0000000 | 00000 |

Laser Welding Face Shields

The lens on these shields filters out harmful light to protect your eyes during traditional and laser welding. They meet ANSI Z136.1 specifications for laser safety. The curved design offers better peripheral vision than laser welding goggles and additional face protection from impact, sparks, and radiation. To meet ANSI Z87.1 standards for eye protection, wear these shields with compliant safety glasses. Customize the shield’s fit by twisting the easy-turn knob on the ratchet adjustment.

Visible light is the percentage of visible light that passes through the lens. The lower the percentage, the more light is blocked. Make sure enough light passes through to see your welding work clearly but not so much that it becomes dangerous.

Optical density indicates how much light a lens absorbs at a specific wavelength. The higher the density, the more UV, infrared, and visible light is blocked. Powerful lasers often require an optical density of 5 or higher.

Shade number indicates how much light is filtered by lenses. The higher the shade number, the darker and more protective the lens.

Lens | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Visible Light | Optical Density | Shade No. | Color | Material | Ht. | Wd. | Thick. | Hat Size | Specifications Met | Each | |

Flip-Up Lens | |||||||||||

| 2% | 5 @ 850-2,700 nm 6 @ 190-400 nm 6 @ 9,000-11,000 nm 7 @ 1,000-2,500 nm 8 @ 1,200-2,450 nm | 5 | Green | Acrylic Plastic | 5 1/2" | 16 1/2" | 0.1" | 7-8 | ANSI Z136.1 | 00000000 | 0000000 |

Filter Lenses for Laser Welding Helmets and Goggles

Replace scratched lenses in your laser welding helmet or goggles. These lenses keep harmful UV and infrared light from damaging your eyes. Do not use with regular welding helmets or goggles.

Optical density indicates how much light a lens absorbs at a specific wavelength. The higher the density, the more UV, infrared, and visible light is blocked. To meet ANSI Z136.1 standards for protection from lasers, factor the strength of your laser. Powerful, Class 4 lasers require an optical density of 5 or higher.

Visible light is the percentage of visible light that passes through the lens. The lower the percentage, the more light is blocked.

For technical drawings and 3-D models, click on a part number.

Lens | |||||||

|---|---|---|---|---|---|---|---|

| Shade No. | Optical Density | Visible Light | Color | Material | Specifications Met | Each | |

2" Ht. × 4 1/4" Wd. | |||||||

| 5 | 5 @ 850-2,700 nm 6 @ 190-400 nm 6 @ 9,000-11,000 nm 7 @ 1,000-2,500 nm 8 @ 1,200-2,450 nm | 2% | Green | Acrylic Plastic | ANSI Z136.1 | 0000000 | 0000000 |

4 1/2" Ht. × 5 1/4" Wd. | |||||||

| 5 | 5 @ 850-2,700 nm 6 @ 190-400 nm 6 @ 9,000-11,000 nm 7 @ 1,000-2,500 nm 8 @ 1,200-2,450 nm | 2% | Green | Acrylic Plastic | ANSI Z136.1 | 0000000 | 000000 |

Lens | 2" Dia. | |||||||

|---|---|---|---|---|---|---|---|---|

| Shade No. | Optical Density | Visible Light | Color | Material | Specifications Met | Pkg. Qty. | Pkg. | |

| 5 | 5 @ 850-2,700 nm 6 @ 190-400 nm 6 @ 9,000-11,000 nm 7 @ 1,000-2,500 nm 8 @ 1,200-2,450 nm | 2% | Green | Acrylic Plastic | ANSI Z136.1 | 2 | 0000000 | 0000000 |