How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Low-Pressure Iron and Steel Threaded Pipe Fittings

Use these fittings for low-pressure applications in noncorrosive environments.

Adapters for tanks create an inlet or outlet connection on the surface of any tank, pressure vessel, or drum. Adapters with weld end allow for a permanent connection. Adapters with extension fit tightly into the hole, which keeps the fitting steady during welding.

NPTF (Dryseal) threads, NPSC (National Pipe Straight Coupling) threads, and NPSL (National Pipe Straight Locknut) threads are compatible with NPT threads.

For technical drawings and 3-D models, click on a part number.

- For Use With: Diesel Fuel, Gasoline, Oil, Water

- Specifications Met: ASTM A181, ASME B1.20.1

| Pipe Size | For Hole Dia. | OD | Lg. | Material | Each | |

NPT Female × Weld | ||||||

|---|---|---|---|---|---|---|

| 1/8 | 15/16" | 1 5/16" | 3/8" | Carbon Steel | 00000000 | 00000 |

| 1/8 | 15/16" | 1 1/2" | 9/16" | Carbon Steel | 00000000 | 0000 |

| 1/4 | 15/16" | 1 5/16" | 3/8" | Carbon Steel | 00000000 | 0000 |

| 1/4 | 15/16" | 1 1/2" | 9/16" | Carbon Steel | 00000000 | 0000 |

| 3/8 | 15/16" | 1 5/16" | 3/8" | Carbon Steel | 00000000 | 0000 |

| 3/8 | 15/16" | 1 1/2" | 9/16" | Carbon Steel | 00000000 | 0000 |

| 1/2 | 1 1/8" | 1 5/8" | 7/16" | Carbon Steel | 00000000 | 0000 |

| 1/2 | 1 1/8" | 1 3/4" | 5/8" | Carbon Steel | 00000000 | 0000 |

| 3/4 | 1 5/16" | 1 15/16" | 1/2" | Carbon Steel | 00000000 | 0000 |

| 3/4 | 1 3/8" | 2 1/8" | 11/16" | Carbon Steel | 00000000 | 0000 |

| 1 | 1 5/8" | 2 3/8" | 3/4" | Carbon Steel | 00000000 | 0000 |

| 1 | 1 11/16" | 2 1/4" | 9/16" | Carbon Steel | 00000000 | 0000 |

| 1 1/4 | 2" | 2 9/16" | 9/16" | Carbon Steel | 00000000 | 00000 |

| 1 1/4 | 2" | 2 11/16" | 3/4" | Carbon Steel | 00000000 | 0000 |

| 1 1/2 | 2 1/4" | 2 13/16" | 9/16" | Carbon Steel | 00000000 | 0000 |

| 1 1/2 | 2 1/4" | 3" | 3/4" | Carbon Steel | 00000000 | 0000 |

| 2 | 2 5/8" | 3 3/8" | 5/8" | Carbon Steel | 00000000 | 0000 |

| 2 | 2 5/8" | 3 1/2" | 27/32" | Carbon Steel | 00000000 | 00000 |

| 2 1/2 | 3 1/8" | 4 1/16" | 1" | Carbon Steel | 00000000 | 00000 |

| 3 | 3 5/8" | 4 5/8" | 1" | Carbon Steel | 00000000 | 00000 |

| 4 | 4 11/16" | 5 13/16" | 1 7/32" | Carbon Steel | 00000000 | 00000 |

- For Use With: Diesel Fuel, Gasoline, Oil, Water

- Specifications Met: ASTM A105, ASTM A181

| Pipe Size | For Hole Dia. | OD | Lg. | Material | Each | |

NPT Female × Weld | ||||||

|---|---|---|---|---|---|---|

| 1/4 | 3/4" | 1 1/4" | 5/16" | Carbon Steel | 00000000 | 00000 |

| 3/8 | 15/16" | 1 1/4" | 3/8" | Carbon Steel | 00000000 | 00000 |

| 1/2 | 1 1/8" | 1 1/2" | 1/2" | Carbon Steel | 00000000 | 0000 |

| 3/4 | 1 3/8" | 1 3/4" | 5/8" | Carbon Steel | 00000000 | 0000 |

| 1 | 1 11/16" | 2 1/8" | 5/8" | Carbon Steel | 00000000 | 0000 |

| 1 1/4 | 2" | 2 1/2" | 3/4" | Carbon Steel | 00000000 | 0000 |

| 1 1/2 | 2 3/8" | 3" | 3/4" | Carbon Steel | 00000000 | 00000 |

| 2 | 2 7/8" | 3 1/2" | 13/16" | Carbon Steel | 00000000 | 00000 |

| 2 1/2 | 3 1/2" | 4 1/4" | 1" | Carbon Steel | 00000000 | 00000 |

| 3 | 4 1/8" | 4 3/4" | 1" | Carbon Steel | 00000000 | 00000 |

| 4 | 5 1/8" | 5 3/4" | 1 3/16" | Carbon Steel | 00000000 | 00000 |

- For Use With: Diesel Fuel, Gasoline, Oil, Water

- Pipe Nipples and Pipe: Use Schedule 40 steel

Low-Pressure Stainless Steel Threaded Pipe Fittings

Use these fittings in a low-pressure pipe line. 316 stainless steel fittings have excellent corrosion resistance. Adapters with weld end allow for a permanent connection.

Adapters for tanks create an inlet or outlet connection on the surface of any tank, pressure vessel, or drum. Adapters with extension fit tightly into the hole, which keeps the fitting steady during welding.

NPTF (Dryseal) threads and NPSL (National Pipe Straight Locknut) threads are compatible with NPT threads.

For technical drawings and 3-D models, click on a part number.

- For Use With: Water, Oil, Gasoline, Diesel Fuel

- Specifications Met: ASTM A182, ASME B1.20.1

316 Stainless Steel | |||||

|---|---|---|---|---|---|

| Pipe Size | For Hole Dia. | OD | Lg. | Each | |

NPT Female × Weld | |||||

| 1/4 | 15/16" | 1 1/2" | 5/16" | 0000000 | 000000 |

| 3/8 | 15/16" | 1 1/2" | 5/16" | 0000000 | 00000 |

| 1/2 | 1 1/8" | 1 3/4" | 3/8" | 0000000 | 00000 |

| 3/4 | 1 3/8" | 2 1/8" | 7/16" | 0000000 | 00000 |

| 1 | 1 5/8" | 2 3/8" | 1/2" | 0000000 | 00000 |

| 1 1/4 | 2" | 2 11/16" | 1/2" | 0000000 | 00000 |

| 1 1/2 | 2 1/4" | 3" | 1/2" | 0000000 | 00000 |

| 2 | 2 5/8" | 3 1/2" | 9/16" | 0000000 | 00000 |

| 2 1/2 | 3 1/8" | 4 1/16" | 13/16" | 0000000 | 000000 |

| 3 | 3 5/8" | 4 5/8" | 13/16" | 0000000 | 000000 |

| 4 | 4 7/8" | 5 3/4" | 1 3/16" | 0000000 | 000000 |

Low-Pressure Aluminum Threaded Pipe Fittings

In addition to being lightweight, these aluminum fittings offer good corrosion resistance. Use them in low-pressure flow applications. To prevent cracking, do not tighten more than a 1/4-turn past hand tight.

Adapters for tanks weld onto the surface of any tank, pressure vessel, or drum to create a permanent inlet or outlet connection. Adapters with extended lip fit tightly into the hole, which keeps the fitting steady during welding.

NPTF (Dryseal) threads and NPSL (National Pipe Straight Locknut) threads are compatible with NPT threads.

For technical drawings and 3-D models, click on a part number.

- For Use With: Water, Oil, Gasoline, Diesel Fuel

- Specifications Met: ASTM B221

- Pipe Nipples and Pipe: Use Schedule 40 aluminum

| Pipe Size | For Hole Dia. | OD | Lg. | Each | |

NPT Female × Weld | |||||

|---|---|---|---|---|---|

| 1/8 | 7/8" | 1 5/16" | 1/4" | 0000000 | 00000 |

| 1/4 | 7/8" | 1 5/16" | 1/4" | 0000000 | 00000 |

| 3/8 | 1 3/16" | 1 7/16" | 1/4" | 0000000 | 00000 |

| 1/2 | 1 1/8" | 1 5/8" | 1/4" | 0000000 | 00000 |

| 3/4 | 1 5/16" | 2" | 1/4" | 0000000 | 00000 |

| 1 | 1 11/16" | 2 1/4" | 1/4" | 0000000 | 00000 |

| 1 1/4 | 1 15/16" | 2 9/16" | 5/16" | 0000000 | 00000 |

| 1 1/2 | 2 1/4" | 2 15/16" | 5/16" | 0000000 | 00000 |

| 2 | 2 5/8" | 3 3/8" | 5/16" | 0000000 | 00000 |

| 3 | 3 11/16" | 4 5/8" | 3/4" | 0000000 | 000000 |

| 4 | 4 3/4" | 5 13/16" | 7/8" | 0000000 | 000000 |

High-Purity Polypropylene Pipe Fittings for Corrosive Chemicals

The inside of these fittings won’t leach contaminants into your line or accumulate particles—they’re polished to an ultra-smooth 12 Ra finish, which also makes them easy to clean. Made of polypropylene, they resist organic solvents, acids, and alkalis better than CPVC fittings. These fittings meet NSF/ANSI 61 for use with drinking water, and they’re FDA compliant for direct contact with food. They also meet ASTM requirements for material and performance, and ISO requirements for dimensions.

Connect them to pipe with socket fusion welding for a strong, permanent bond. Use a socket fusion tool with a heater bushing (sold separately) that matches your pipe size.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Deionized Water, Drinking Water, Hydrochloric Acid, Phosphoric Acid, Salt Water, Solvents

- Temperature Range: 32° to 200° F

- Specifications Met: ASTM D2837, ASTM D4101, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.3297, ISO 7279, NSF/ANSI 61

- Pipe Nipples and Pipe: Use SDR 11 Polypropylene Plastic

- Flanges: Use Polypropylene Plastic

Union connectors separate into three pieces, so you can access your line without unthreading pipe connections.

| Pipe Size | Socket Dp. | Material | Color | Max. Pressure | Each | |

EPDM Rubber O-Ring | ||||||

|---|---|---|---|---|---|---|

| 1/2 | 19/32" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 0000000 |

| 3/4 | 5/8" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

| 1 | 45/64" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

| 1 1/2 | 15/16" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

| 2 | 1 1/16" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

Viton® Fluoroelastomer Rubber O-Ring | ||||||

| 1/2 | 19/32" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

| 3/4 | 5/8" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

| 1 | 45/64" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

| 1 1/2 | 15/16" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

| 2 | 1 1/16" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

- For Use With: Deionized Water, Drinking Water, Hydrochloric Acid, Phosphoric Acid, Salt Water, Solvents

- Temperature Range: 32° to 200° F

- Specifications Met: ASTM D2837, ASTM D4101, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.3297, ISO 7279, NSF/ANSI 61

- Seal Material: See table

- Seat Material: PTFE Plastic

Add a ball valve to control the flow in your line.

| Pipe Size | Flow Coefficient (Cv) | Vacuum Rating, in. of Hg | Port Type | End-to-End Lg. | Color | Max. Pressure | Each | |

EPDM Rubber Seal | ||||||||

|---|---|---|---|---|---|---|---|---|

Polypropylene Plastic | ||||||||

| 1/2 | 12.5 | 29.92 | Full | 3 13/16" | Light Gray | 150 psi @ 0° F | 00000000 | 0000000 |

| 3/4 | 28 | 29.92 | Full | 4 9/32" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 1 | 50.9 | 29.92 | Full | 4 23/32" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 1 1/2 | 150 | 29.92 | Full | 6 1/16" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 2 | 230 | 29.92 | Full | 6 13/16" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

Viton® Fluoroelastomer Rubber Seal | ||||||||

Polypropylene Plastic | ||||||||

| 1/2 | 12.5 | 29.92 | Full | 3 13/16" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 3/4 | 28 | 29.92 | Full | 4 9/32" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 1 | 50.9 | 29.92 | Full | 4 23/32" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 1 1/2 | 150 | 29.92 | Full | 6 1/16" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 2 | 230 | 29.92 | Full | 6 13/16" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| Includes | Each | |

| 5 Bushing Sets (1 each in 1/2, 3/4, 1, 1 1/2, and 2 Pipe Sizes) | 00000000 | 0000000 |

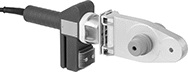

Spin-Weld Through-Wall Plastic Tank Fittings

Create a leak-free, durable connection in plastic tanks, walls, or panels without gaskets or sealants. As you spin these fittings with a handheld electric router, they melt into the surface of your tank for a seal without any joints. To hold these fittings in your router, you’ll need the installation tool (sold separately).

For proper installation, you’ll want to use a hole saw to drill a hole that matches the For Hole Diameter listed and check that your router meets the speed and power requirements shown in the table.

For technical drawings and 3-D models, click on a part number.

- For Use With: Oil, Water

- Temperature Range: 40° to 140° F

For Tank | For Router | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Hose Size | For Hole Dia. | For Min. Wall Thick. | Lg. | Material | Material | Surface | Color | Power | Speed, rpm | Each | |

NPT Female Threaded Pipe × Weld | ||||||||||||

| 1/4 | __ | 0.88" | 3/16" | 15/16" | LDPE Plastic | LDPE Plastic | Flat | White | 1 1/2 | 18,000-25,000 | 0000000 | 00000 |

| 1/2 | __ | 0.88" | 3/16" | 7/8" | LDPE Plastic | LDPE Plastic | Flat | White | 1 1/2 | 18,000-25,000 | 0000000 | 0000 |

| 3/4 | __ | 1.31" | 3/16" | 13/16" | LDPE Plastic | LDPE Plastic | Flat | White | 1 1/2 | 18,000-25,000 | 0000000 | 0000 |

| 1 | __ | 1.5" | 3/16" | 1" | LDPE Plastic | LDPE Plastic | Flat | White | 1 1/2 | 18,000-25,000 | 0000000 | 0000 |

| 1 1/2 | __ | 2" | 3/16" | 1 3/16" | LDPE Plastic | LDPE Plastic | Flat | White | 1 1/2 | 18,000-25,000 | 0000000 | 0000 |

| 2 | __ | 2.5" | 3/16" | 1 3/16" | LDPE Plastic | LDPE Plastic | Flat | White | 1 1/2 | 18,000-25,000 | 0000000 | 0000 |

GHT Male Threaded Hose × Weld | ||||||||||||

| __ | 3/4 | 1" | 3/16" | 7/8" | LDPE Plastic | LDPE Plastic | Flat | White | 1 1/2 | 18,000-25,000 | 0000000 | 0000 |

| For Pipe Size | For Hose Size | Shank Dia. | Overall Lg. | Material | Shank Type | For Tool Type | Each | |

For Pipe Connection | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/4 | __ | 1/4" | 1 5/8" | Aluminum | Straight | Hand Router | 000000 | 0000000 |

| 1/2 | __ | 1/4" | 1 5/8" | Aluminum | Straight | Hand Router | 000000 | 000000 |

| 3/4 | __ | 1/2" | 2" | Aluminum | Straight | Hand Router | 000000 | 000000 |

| 1 | __ | 1/2" | 2 1/4" | Aluminum | Straight | Hand Router | 000000 | 000000 |

| 1 1/2 | __ | 1/2" | 2 1/4" | Aluminum | Straight | Hand Router | 000000 | 000000 |

| 2 | __ | 1/2" | 2 1/4" | Aluminum | Straight | Hand Router | 000000 | 000000 |

For Hose Connection | ||||||||

| __ | 3/4 | 1/4" | 1 3/4" | Aluminum | Straight | Hand Router | 000000 | 000000 |