Filter by

Mount Type

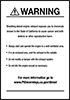

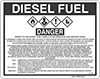

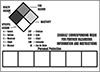

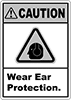

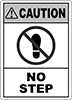

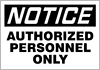

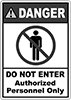

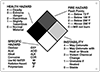

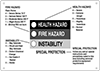

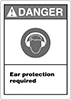

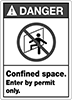

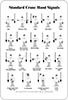

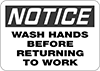

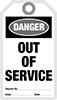

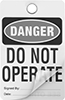

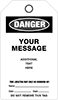

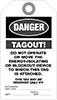

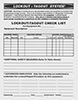

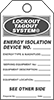

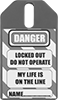

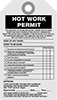

Message Type

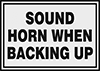

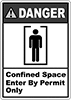

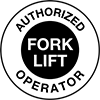

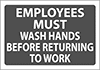

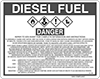

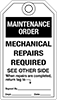

Message

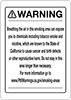

Accident Prevention Message Type

Color

Message Contains

Message Color

Header Color

Specifications Met

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Thickness

About Accident Prevention Signs

More