About Backflow-Prevention Valves

More

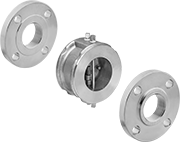

Flange-Mount Check Valves

- For Use With: Air, Argon, Helium, Krypton, Neon, Water, Xenon

- Disc Material: Bronze

- Seal Material: Buna-N Rubber

Sandwich these valves between two ANSI flanges for backflow prevention at a fraction of the weight of flanged check valves and a reduced pipeline footprint. ANSI flanges are sold separately. All valves open to allow flow in one direction and close when flow stops or reverses.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Min. Opening Pressure, psi | Temperature Range, °F | End-to-End Lg. | For Flange Class | Each | |

Cast Iron Body | ||||||||

|---|---|---|---|---|---|---|---|---|

Flanged × Flanged | ||||||||

| 2 | 60 | 200 psi @ 70° F | 1.25 | -20° to 250° | 2 1/8" | 125 | 0000000 | 000000 |

| 2 1/2 | 100 | 200 psi @ 70° F | 1.25 | -20° to 250° | 2 1/8" | 125 | 0000000 | 00000 |

| 3 | 170 | 200 psi @ 70° F | 1.25 | -20° to 250° | 2 1/4" | 125 | 0000000 | 000000 |

| 4 | 340 | 200 psi @ 70° F | 1.25 | -20° to 250° | 2 1/2" | 125 | 0000000 | 000000 |

| 5 | 520 | 200 psi @ 70° F | 1.25 | -20° to 250° | 2 3/4" | 125 | 0000000 | 000000 |

| 6 | 850 | 200 psi @ 70° F | 1.25 | -20° to 250° | 3" | 125 | 0000000 | 000000 |

| 8 | 1,600 | 200 psi @ 70° F | 1.25 | -20° to 250° | 3 3/4" | 125 | 0000000 | 000000 |

| 10 | 2,400 | 200 psi @ 70° F | 1.25 | -20° to 250° | 4 1/4" | 125 | 0000000 | 000000 |

Compact Flange-Mount Check Valves

- For Use With: Air, Argon, Helium, Krypton, Neon, Water, Xenon

- Piston Material: 316 Stainless Steel

- Spring Material: 316 Stainless Steel

- Seal Material: Viton® Fluoroelastomer

Less than half the end-to-end length of standard flange-mount check valves, these can be installed between ANSI flanges in pipelines with limited clearance. ANSI flanges are sold separately. Valves open to allow flow in one direction and close when flow stops or reverses. All have a 316 stainless steel body for excellent corrosion resistance.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Min. Opening Pressure, psi | Temperature Range, °F | End-to-End Lg. | For Flange Class | Each | |

316 Stainless Steel Body | ||||||||

|---|---|---|---|---|---|---|---|---|

Flanged × Flanged | ||||||||

| 1/2 | 2.4 | 720 psi @ 100° F | 0.5 | -10° to 400° | 1/4" | 150, 300 | 0000000 | 0000000 |

| 3/4 | 4.4 | 720 psi @ 100° F | 0.5 | -10° to 400° | 1/4" | 150, 300 | 0000000 | 000000 |

| 1 | 6.1 | 720 psi @ 100° F | 0.5 | -10° to 400° | 1/4" | 150, 300 | 0000000 | 000000 |

| 1 1/4 | 12.7 | 720 psi @ 100° F | 0.5 | -10° to 400° | 1/4" | 150, 300 | 0000000 | 000000 |

| 1 1/2 | 18.8 | 720 psi @ 100° F | 0.5 | -10° to 400° | 1/4" | 150, 300 | 0000000 | 000000 |

| 2 | 32 | 720 psi @ 100° F | 0.5 | -10° to 400° | 1/4" | 150, 300 | 0000000 | 000000 |

| 3 | 89 | 720 psi @ 100° F | 0.5 | -10° to 400° | 5/16" | 150, 300 | 0000000 | 000000 |

| 4 | 144 | 720 psi @ 100° F | 0.5 | -10° to 400° | 3/8" | 150, 300 | 0000000 | 000000 |

Flange-Mount Check Valves for Oil and Fuel

- For Use With: Butane, Diesel Fuel, Fuel Oil, Gasoline, Kerosene, Natural Gas, Oil, Propane

- Disc Material: 316 Stainless Steel

- Seal Material: 316 Stainless Steel

Install these valves between ANSI flanges. ANSI flanges are sold separately. All valves open to allow flow in one direction and close when flow stops or reverses. Body is 316 stainless steel for excellent corrosion resistance.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Min. Opening Pressure, psi | Temperature Range, °F | End-to-End Lg. | For Flange Class | Each | |

316 Stainless Steel Body | ||||||||

|---|---|---|---|---|---|---|---|---|

Flanged × Flanged | ||||||||

| 2 | 48 | 275 psi @ 70° F | 1.25 | -20° to 1000° | 2 3/8" | 150, 300, 600 | 0000000 | 0000000 |

| 2 1/2 | 90 | 275 psi @ 70° F | 1.25 | -20° to 1000° | 2 5/8" | 150, 300, 600 | 0000000 | 000000 |

| 3 | 171 | 275 psi @ 70° F | 1.25 | -20° to 1000° | 2 7/8" | 150, 300, 600 | 0000000 | 000000 |

| 4 | 291 | 275 psi @ 70° F | 1.25 | -20° to 1000° | 2 7/8" | 150, 300 | 0000000 | 000000 |

| 6 | 705 | 275 psi @ 70° F | 1.25 | -20° to 1000° | 3 7/8" | 150, 300 | 0000000 | 00000000 |

| 8 | 1,795 | 275 psi @ 70° F | 1.25 | -20° to 1000° | 5" | 150, 300 | 0000000 | 00000000 |

Flange-Mount Check Valves for Drinking Water

- For Use With: Drinking Water

- Disc Material: 316 Stainless Steel

- Spring Material: 302 Stainless Steel

- Seal Material: EPDM Rubber

Sandwich these valves between ANSI flanges in drinking water pipelines. ANSI flanges are sold separately. Valves meet NSF/ANSI Standard 61, which designates them as safe to use with drinking water. All open to allow flow in one direction and close when flow stops or reverses.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Min. Opening Pressure, psi | Temperature Range, °F | End-to-End Lg. | For Flange Class | Each | |

Iron Body | ||||||||

|---|---|---|---|---|---|---|---|---|

Flanged × Flanged | ||||||||

| 2 | 70 | 200 psi @ 300° F | 2 | 0° to 200° | 1 11/16" | 125, 150 | 000000 | 000000 |

| 2 1/2 | 120 | 200 psi @ 300° F | 2 | 0° to 200° | 1 13/16" | 125, 150 | 000000 | 00000 |

| 3 | 190 | 200 psi @ 300° F | 2 | 0° to 200° | 2 1/2" | 125, 150 | 000000 | 000000 |

| 4 | 340 | 200 psi @ 300° F | 2 | 0° to 200° | 2 1/2" | 125, 150 | 000000 | 000000 |

| 5 | 590 | 200 psi @ 300° F | 2 | 0° to 200° | 2 3/4" | 125, 150 | 000000 | 000000 |

| 6 | 870 | 200 psi @ 300° F | 2 | 0° to 200° | 3" | 125, 150 | 000000 | 000000 |