Vertical Band Saws

Make precise cuts in a variety of materials by pushing your workpiece through the vertical blade. Unlike horizontal band saws, these saws can make curved and intricate cuts. They can also make straight cuts when you use a fence to guide your material.

Style A saws are a good choice if you’re only cutting wood, plastic, and soft metals. They have a chip collection port that connects to your dust collector.

Style B saws are more versatile than Style A saws because they cut through hard metals, such as steel, in addition to wood, plastic, and soft metals. They have a chip collection system that blows debris away from your cut line and into a chip chute. Hook up your dust collector to the chip collection port to suck away the debris.

Style C saws can cut through the thickest and hardest material without stalling because they produce the most torque compared to these other styles. Designed to run at lower speeds, they can cut through plastics and metals, including steel and other hard metals. To help you see your cut line, they have a chip blower that keeps debris out of the way and a light for illuminating your work. These saws come with a blade maintenance station, so you can create band saw blades from coil stock, repair broken blades, and sharpen your blades.

Max. Cutting | Blade | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Current | Power, hp | Dia. | Dp. | Ht. | No-Load Speed, sfpm | Lg. | Wd. | Thick. | Features | Includes | Each | |

| A | 14 A @ 120 V AC 7 A @ 240 V AC | 1 3/4 | 13" | 14" | 13" | 1,445; 2,950 | 111" | 5/8" | 0.035" | Chip Collection Port Tool-Free Blade Guide Adjustment Quick-Adjust Material Guide Fence | One 111" Lg. × 5/8" Wd. Spring Steel Blade with High-Speed Steel Teeth for Metal, Plastic, and Wood (4 Teeth per Inch) | 00000000 | 000000000 |

| B | 14 A @ 120 V AC 7 A @ 240 V AC | 1 | 10" | 15" | 10" | 45; 65; 90; 110; 155; 215; 3,000 | 114" | 1/2" | 0.035" | Material Guide Fence Chip Blower Chip Chute Chip Collection Port Miter Gauge | One 114" Lg. × 1/2" Wd. Carbon Steel Blade for Wood (6 Teeth per Inch), One 114" Lg. × 1/2" Wd. Carbon Steel Blade with High-Speed Steel Teeth for Metal (14 Teeth per Inch) | 0000000 | 00000000 |

| B | 20 A @ 120 V AC 10 A @ 240 V AC | 1 1/2 | 12" | 18" | 12" | 45; 65; 90; 110; 155; 215; 3,000 | 136" | 3/4" | 0.035" | Material Guide Fence Chip Blower Chip Chute Chip Collection Port Miter Gauge | One 136" Lg. × 3/4" Wd. Carbon Steel Blade for Wood (8 Teeth per Inch), One 136" Lg. × 3/4" Wd. Carbon Steel Blade with High-Speed Steel Teeth for Metal (14 Teeth per Inch) | 00000000 | 00000000 |

| C | 18 A @ 120 V AC 9 A @ 240 V AC | 1 1/2 | 11" | 18" | 11" | 82-385 | 140" | 1/2" | 0.025" | Chip Blower Blade Maintenance Station Work Light Carbide Blade Guides | One 140" Lg. × 1/2" Wd. Carbon Steel Blade with High-Speed Steel Teeth for Metal (14 Teeth per Inch) | 00000000 | 00000000 |

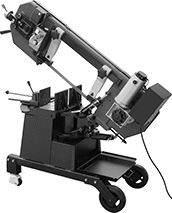

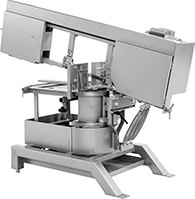

Adjustable Band Saws for Metal

Highly versatile, these saws make precise horizontal and vertical cuts from a single saw. They work well whether you’re simply cutting metal into smaller pieces or creating complex shapes. When the blade is horizontal, these saws cut from above, making square or angled cuts. For straight or intricate curved cuts, position the blade vertically and feed your workpiece through. They’re powerful enough to cut through aluminum, steel, and stainless steel. However, they should only be used for dry cutting.

The higher the horsepower, the smoother the cut, even in thick and hard metals.

Direct-drive saws send power straight to the blade instead of a belt, which keeps power and speed steady when cutting thick, hard metals. They also have fewer parts, which means they need less maintenance.

Saws with an automatic feed push material into the blade at a steady pace, so they’re more accurate than those you feed manually. Once the blade reaches your material, the weight of the saw head completes the cut for you.

Max. Cutting | Blade | Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Current | Power, hp | Drive Type | Dia. | Dp. | Ht. | Max. Miter Cut Angle (Swivel Direction) | No-Load Speed, sfpm | Lg. | Wd. | Thick. | Lg. | Wd. | Ht. | Wt., lbs. | No. of Wheels | Each | |

Manual Feed System | |||||||||||||||||

| 5 A @ 120 V AC | 1 1/4 | Direct | 10" | 8" | 10" | 45° (Left/Right) | 65-250 | 118" | 1" | 0.035" | 60" | 24" | 50" | 560 | 4 | 00000000 | 000000000 |

| 8 A @ 120 V AC 4 A @ 240 V AC | 1/2 | Belt | 5" | 5" | 5 3/4" | 45° (Left) | 80, 120, 200 | 64 1/2" | 1/2" | 0.025" | 36" | 20" | 39 1/2" | 115 | 2 | 0000000 | 000000 |

Automatic Feed System | |||||||||||||||||

| 20 A @ 120 V AC | 1 1/2 | Belt | 11" | 13" | 11" | 60° (Left/Right) | 60, 115, 230 | 144" | 1" | 0.037" | 72" | 38 1/4" | 47" | 680 | 0 | 00000000 | 00000000 |

| 20 A @ 120 V AC 20 A @ 240 V AC | 1 | Belt | 10" | 7" | 9" | 45° (Left/Right) | 70, 135, 250 | 120" | 1" | 0.037" | 59 1/4" | 24 3/4" | 47" | 475 | 2 | 0000000 | 00000000 |

| 20 A @ 120 V AC 20 A @ 240 V AC | 1 | Belt | 11" | 11" | 10" | 45° (Left/Right) | 70, 135, 250 | 132" | 1" | 0.037" | 66" | 29" | 47" | 650 | 0 | 0000000 | 00000000 |

| 20 A @ 240 V AC | 1 1/2 | Belt | 11" | 13" | 11" | 60° (Left/Right) | 60, 115, 230 | 144" | 1" | 0.037" | 72" | 38 1/4" | 47" | 680 | 0 | 00000000 | 00000000 |

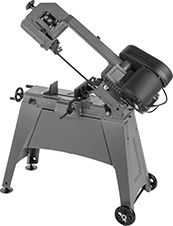

Bench-Top Band Saws for Metal

Save space with these saws when you only need to make cuts in small pieces of metal. For smoother cuts in thick and hard metals, choose a saw with higher horsepower (hp). Saws with higher horsepower also handle continuous use better. These band saws are only for dry cutting.

Vertical-blade saws—roughly the size of a mini-fridge—are for curved, detailed, and intricate cuts. If you use a fence as a guide, these saws can also make straight cuts in long pieces of material. Connect the chip collection port to a dust collector to keep your work area clean. These saws are compatible with replacement blades between 67”-68” long.

Max. Cutting | Blade | Overall | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Current | Dia. | Dp. | Ht. | Work Table Tilt Angle (Tilt Direction) | No-Load Speed, sfpm | Lg. | Wd. | Thick. | Lg. | Wd. | Ht. | Features | Each | |

Manual Feed System | |||||||||||||||

| 1/3 | 3.5 A @ 120 V AC | 4" | 9 1/2" | 4" | 45° (Right) | 250, 350, 450 | 67 3/8" | 1/2" | 0.025" | 21" | 16 1/2" | 34" | Chip Collection Port | 00000000 | 0000000 |

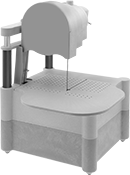

Bench-Top Band Saws for Ceramics and Masonry

The grinding action of the diamond-grit blade creates a smooth finish on hard materials such as glass, stone, tile, brick, and fiberglass. This saw is not for cutting metal. It makes straight and curved cuts. A recirculating tap water coolant system extends blade life.

Max. Cutting | For Blade | Overall | Table | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Current | Dia. | Dp. | Ht. | No-Load Speed, sfpm | Lg. | Wd. | Thick. | Lg. | Wd. | Ht. | Wt., lbs. | Dp. | Wd. | Includes | Each | |

| 1 A @ 120 V AC | 3 3/4" | 5 1/2" | 3 1/2" | 3,520 | 37" | 9/64" | 0.02" | 13" | 14" | 17" | 18 | 12" | 12" | One 37" Lg. × 9/64" Wd. Diamond Grit Blade for Ceramics and Masonry | 00000000 | 0000000 |