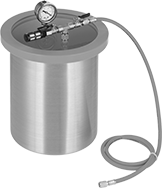

Vacuum Containers

Also known as vacuum degassing chambers, these remove trapped air from mixtures such as paint and mold resins. The fittings on the hose contain a gasket that allows you to connect the hose to flared fittings.

Aluminum containers are lightweight, corrosion resistant, and good for general use.

304 stainless steel containers have excellent corrosion resistance and are commonly used in laboratories.

Soda-lime glass containers are clear, so the material inside is visible from all angles.

PVC containers are lightweight and resist corrosion from harsh solvents. Because they’re taller than other containers, they’re often used for applications that require wood stabilization.

Containers with a side-mount gauge allow you to see the material inside of them when looking from the top.

Glass lids resist corrosion. They’re primarily used to eliminate air bubbles in woodworking projects that use harsh chemicals, which would deteriorate plastic lids. Glass lids are less durable than acrylic lids.

Acrylic lids are more durable than glass lids. They’re commonly used to eliminate air bubbles in hard setting materials, such as silicone and polyurethane.

Replacement lids do not include hardware or seal.

Replacement manifold assemblies include a manifold, vacuum gauge, washer, O-ring, and hex nut.

Containers | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Gauge | Hose | Replacement Lids | |||||||||||||||||

| Cap. | Dia. | Ht. | Bottom ID | Vacuum Range, in. of Hg | Accuracy | Grad. Marks, in. of Hg | Lg. | Thread Size | Gender | For Connection Style | For Flared Angle | For Tube OD | Max. Temp., °F | Removes Particle Size Down To | Includes | Each | Each | ||

Aluminum with Top-Mount Gauge | |||||||||||||||||||

Acrylic Plastic Lid with Silicone Rubber Seal | |||||||||||||||||||

| 2 gal. | 10 3/4" | 7 1/2" | 10" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 0000000 | 0000000 | 0000000 |

| 3 gal. | 10 3/4" | 9" | 10" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 0000000 | 000000 |

| 5 gal. | 12 3/4" | 11 1/2" | 12" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 0000000 | 000000 |

| 7 gal. | 16 3/4" | 9 3/4" | 16" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 0000000 | 000000 |

| 10 gal. | 15 1/4" | 17" | 14" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 0000000 | 000000 |

| 15 gal. | 16 3/4" | 18 1/2" | 16 1/8" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 0000000 | 000000 |

Aluminum with Side-Mount Gauge | |||||||||||||||||||

Glass Lid with Silicone Rubber Seal | |||||||||||||||||||

| 2 gal. | 10 3/4" | 7 1/2" | 10" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 0000000 | 00000 |

| 3 gal. | 10 1/4" | 9 3/4" | 10" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 000000 | 00 |

| 5 gal. | 12 3/8" | 11 1/2" | 12" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 0000000 | 000000 |

Acrylic Plastic Lid with Silicone Rubber Seal | |||||||||||||||||||

| 2 gal. | 10 3/4" | 7 1/2" | 10" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 0000000 | 00000 |

| 3 gal. | 10 3/4" | 9" | 10" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 0000000 | 00000 |

| 10 gal. | 15 1/4" | 17" | 14" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 0000000 | 000000 |

Soda-Lime Glass with Top-Mount Gauge | |||||||||||||||||||

Soda-Lime Glass Lid with Silicone Rubber Seal | |||||||||||||||||||

| 56 fl. oz. | 8 1/4" | 3 1/2" | 6" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 0000000 | 000000 |

PVC Plastic with Top-Mount Gauge | |||||||||||||||||||

PVC Plastic Lid with Silicone Rubber Seal | |||||||||||||||||||

| 1 3/8 gal. | 7" | 16" | 6" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 000000 | 00 |

304 Stainless Steel with Top-Mount Gauge | |||||||||||||||||||

Acrylic Plastic Lid with Silicone Rubber Seal | |||||||||||||||||||

| 1 gal. | 11 1/4" | 4" | 10 1/4" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 0000000 | 000000 |

| 1 1/2 gal. | 8 1/4" | 9 1/4" | 7 1/8" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 0000000 | 000000 |

| 3 gal. | 10 3/4" | 11" | 9" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 000000 | 00 |

| 3 gal. | 11 1/4" | 8 3/4" | 10 1/2" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 0000000 | 000000 |

| 64 fl. oz. | 5 3/4" | 7 1/2" | 4 3/4" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 0000000 | 000000 |

304 Stainless Steel with Side-Mount Gauge | |||||||||||||||||||

Glass Lid with Silicone Rubber Seal | |||||||||||||||||||

| 1 1/2 gal. | 8 1/4" | 9 1/4" | 7 1/8" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 0000000 | 00000 |

| 3 gal. | 10 3/4" | 11" | 10" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 0000000 | 00000 |

| 3 gal. | 11 1/4" | 8 3/4" | 10 1/2" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 0000000 | 00000 |

Acrylic Plastic Lid with Silicone Rubber Seal | |||||||||||||||||||

| 3 gal. | 11 1/4" | 8 3/4" | 10 1/2" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 0000000 | 00000 |

| Gauge Mounting Location | Each | |

| Side | 0000000 | 000000 |

| Removes Particle Size Down To | Each | |

| 50 microns | 0000000 | 00000 |

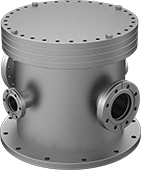

High-Vacuum Chambers

Analyze gases, test for leaks, and check the effects of high altitudes on electronic components with these chambers. They remove air and gases to create a space void of molecules.

Acrylic chambers are clear, so the material inside is visible from all angles. Acrylic releases air at a faster rate than steel, so these chambers cannot reach vacuum levels as high as those of stainless steel chambers.

Stainless steel chambers reach and maintain significantly higher vacuum levels than acrylic vacuum chambers, and they work at higher temperatures. They are more chemical resistant than acrylic chambers, making them appropriate for use with lab substances such as acetone and isopropyl alcohol.

Quick- and claw-clamp connections allow you to connect and disconnect components easily. The clamps join two flanged ends and a rubber O-ring. Quick-clamp connections are also known as ISO-KF; you'll need a ring and quick clamp to complete the connection. Claw-clamp connections are also known as ISO-K; they require a ring and multiple claw clamps to secure.

Flanged connections create a seal that is tighter than clamp connections. Also known as CF connections, the flanges have sharp edges that press into a copper gasket as you tighten the bolts. The tighter seal means chambers with flanged connections can reach a higher vacuum level than chambers with clamp connections. Choose flanged connections for applications that require ultra-high vacuum, such as surface analysis experiments.

Maximum vacuum is measured in torr. The lower the torr value, the higher the level of vacuum.

For technical drawings and 3-D models, click on a part number.

Connection | Inside | Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Vacuum | Style | No. of | High Vacuum Connection Type | High-Vacuum Flange Size | Flange OD | For Tube OD | Ht. | Wd. | Lg. | Ht. | Wd. | Lg. | Temp. Range, °F | Includes | Each | |

| 7.5 × 10 -2 torr @ 72° F | Quick Clamp | 3 | ISO-KF | 25 | 1.57" | 1" | 12" | 12" | 12" | 18" | 15" | 23" | -40° to 100° | Connection Clamps, Rings | 0000000 | 000000000 |

Connection | Inside | Overall | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Vacuum | Style | No. of | High Vacuum Connection Type | High-Vacuum Flange Size | Flange OD | For Tube OD | Bolt Hole Dia. (No. of) | Bolt Circle Dia. | Dia. | Ht. | Dia. | Ht. | Temp. Range, °F | Each | |

| 1 × 10 -7 torr @ 72° F | Claw Clamp Claw Clamp Quick Clamp Quick Clamp | 4 | ISO-KF ISO-KF ISO-K ISO-K | 25 40 63 100 | 1.57" 2.16" 3.74" 5.12" | 1" 1 1/2" 2 1/2" 4" | __ | __ | 9 3/4" | 9 3/8" | 13" | 13.63" | -10° to 240° | 0000000 | 000000000 |

| 1 × 10 -11 torr @ 72° F | Flanged | 4 | CF | 25 40 63 100 | 2 1/8" 2 3/4" 4 1/2" 6" | 1" 1 1/2" 2 1/2" 4" | 17/64" (4) 17/64" (6) 21/64" (8) 21/64" (16) | 1 5/8" 2 5/16" 3 5/8" 5 1/8" | 9 3/4" | 9 1/2" | 13" | 11.26" | -320° to 570° | 0000000 | 00000000 |

Glove Bags

More flexible and portable than glove boxes, these glove bags are temporary enclosures that protect you while you work with hazardous or unknown material and isolate the material from outside air and moisture. They come with built-in gloves to shield your hands and prevent hand oils from getting inside. All have one or two zipper openings for depositing material and equipment. They collapse for storage and are sturdy enough to be used again, but replace them if they become contaminated.

PVC bags have a support frame for assembling them. To fill them with inert gas, use their barbed gas port fitting. They come with butyl gloves, which have excellent resistance to chemicals, vapors, and gases.

Overall | Glove | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Openings | Opening Width | Height | Width | Depth | Thickness, mil | Size | Port Diameter | Closure Type | Maximum Temperature, °F | Includes | Features | Each | |

| 1 | 23 5/8" | 28 1/2" | 33 7/8" | 22" | 60 | 9 3/4 | 4 1/2" | Zipper | 110° | One 29" long piece of 5/16" ID Tubing | 5/16" OD Barbed Gas Port Fitting | 0000000 | 0000000 |

Glove Boxes

Safely handle hazardous and sensitive material in an enclosed space that keeps out air and moisture. These boxes have built-in gloves for protecting your hands and a viewing window for seeing your work. Position them on any flat work surface.

Use boxes with gas port fittings to exhaust the gas within and replace it with a different gas that works for your application.

Polyethylene boxes are lightweight, so they’re easy to move around your facility. They have a side door for inserting material and equipment.

Steel boxes are durable and stand up to frequent use. To deposit material and equipment without letting in air and moisture, they have a side chamber with one interior and one exterior door. There’s also a front door in case you need a bigger opening. Use the included humidity meter to make sure that sensitive material isn’t exposed to too much moisture.

Inside | Overall | Glove | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | Ht. | Wd. | Dp. | Side Door Opening Dia. | Size | Port Dia. | Max. Temp., °F | Includes | Features | Each | |

| 14" | 24 1/2" | 10" | 22" | 27" | 13" | 8" | 10 | 6" | 175° | Clamping Rings | Two 1/4"-3/8" OD Barbed Gas Port Fittings | 0000000 | 000000000 |

Inside | Overall | Front Door | Side Door | Glove | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | Ht. | Wd. | Dp. | Opening Ht. | Opening Wd. | Opening Ht. | Opening Wd. | Size | Port Dia. | Max. Temp., °F | Includes | Features | Each | |

| 19 7/8" | 31 7/8" | 23 7/8" | 24" | 32" | 25" | 20" | 32" | 8 1/4" | 8 3/8" | 10 | 6" | 150° | Humidity Meter | Two 1/4" ID Push-to-Connect Gas Port Fittings | 0000000 | 000000000 |

| Clamp ID | Material | Clamp Type | Pkg. Qty. | Pkg. | |

| 6" | Zinc-Plated Steel | Worm Drive | 2 | 0000000 | 000000 |