About Vacuum Pumps

More

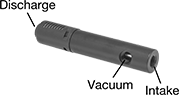

Steam-Powered Jet Pumps

Use plant steam to pump liquids and gases, prime pumps, and remove fumes. When high-pressure steam enters the intake, it creates suction that draws a second liquid or gas into the pump body and discharges a pressurized blend of the two. The discharge pressure is greater than the suction flow but lower than the intake pressure. Gas suction flow is calculated using steam at atmospheric pressure. They have no moving parts or seals, eliminating downtime for lubrication and repairs. They're also known as eductors, ejectors, and injectors.

Note: Liquid suction flow rate is calculated using 80 psi steam at 0-40 feet of discharge head.

Bronze is more corrosion resistant than cast iron.

316 stainless steel pumps provide the most corrosion resistance.

Liquid Suction Flow Rate, gpm | Gas Suction Flow, cfm | Intake Pressure, psi | Suction | Intake | Discharge | Overall | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 5 ft. of Lift | 10 ft. of Lift | @ 20 ft. of Lift | @ 20 psi Steam | @ 50 psi Steam | @ 80 psi Steam | Max. Suction Lift, ft. | For Liquids | For Gases | Temp. Range, °F | Pipe Size | Thread Type | Pipe Size | Thread Type | Pipe Size | Thread Type | Lg. | Wd. | Each | |

For Use With Air, Inert Gas, Steam, Water | |||||||||||||||||||

Cast Iron | |||||||||||||||||||

| 6 | 5 | 3 | 5 | 4 | 3 | 20 | 35-150 | 20-80 | -20° to 150° | 1/2 | NPT | 3/8 | NPT | 1/2 | NPT | 4 1/2" | 1 1/8" | 0000000 | 0000000 |

| 10 | 9 | 5 | 8 | 6 | 6 | 20 | 35-150 | 20-80 | -20° to 150° | 3/4 | NPT | 1/2 | NPT | 3/4 | NPT | 5 7/8" | 1 1/4" | 0000000 | 000000 |

| 17 | 15 | 9 | 14 | 11 | 10 | 20 | 35-150 | 20-80 | -20° to 150° | 1 | NPT | 3/4 | NPT | 1 | NPT | 7 1/8" | 1 3/4" | 0000000 | 000000 |

| 31 | 27 | 15 | 24 | 20 | 17 | 20 | 35-150 | 20-80 | -20° to 150° | 1 1/4 | NPT | 1 | NPT | 1 1/4 | NPT | 9" | 2 3/8" | 0000000 | 000000 |

| 51 | 44 | 25 | 40 | 32 | 28 | 20 | 35-150 | 20-80 | -20° to 150° | 1 1/2 | NPT | 1 | NPT | 1 1/2 | NPT | 11" | 2 5/8" | 0000000 | 000000 |

| 93 | 80 | 46 | 73 | 58 | 51 | 20 | 35-150 | 20-80 | -20° to 150° | 2 | NPT | 1 1/4 | NPT | 2 | NPT | 14 3/8" | 3 1/2" | 0000000 | 000000 |

Bronze | |||||||||||||||||||

| 6 | 5 | 3 | 5 | 4 | 3 | 20 | 35-150 | 20-80 | -20° to 150° | 1/2 | NPT | 3/8 | NPT | 1/2 | NPT | 4 1/2" | 1 1/8" | 0000000 | 000000 |

| 10 | 9 | 5 | 8 | 6 | 6 | 20 | 35-150 | 20-80 | -20° to 150° | 3/4 | NPT | 1/2 | NPT | 3/4 | NPT | 5 7/8" | 1 1/4" | 0000000 | 000000 |

| 17 | 15 | 9 | 14 | 11 | 10 | 20 | 35-150 | 20-80 | -20° to 150° | 1 | NPT | 3/4 | NPT | 1 | NPT | 7 1/8" | 1 3/4" | 0000000 | 000000 |

| 31 | 27 | 15 | 24 | 20 | 17 | 20 | 35-150 | 20-80 | -20° to 150° | 1 1/4 | NPT | 1 | NPT | 1 1/4 | NPT | 9" | 2 3/8" | 0000000 | 000000 |

| 51 | 44 | 25 | 40 | 32 | 28 | 20 | 35-150 | 20-80 | -20° to 150° | 1 1/2 | NPT | 1 | NPT | 1 1/2 | NPT | 11" | 2 5/8" | 0000000 | 000000 |

| 93 | 80 | 46 | 73 | 58 | 51 | 20 | 35-150 | 20-80 | -20° to 150° | 2 | NPT | 1 1/4 | NPT | 2 | NPT | 14 3/8" | 3 1/2" | 0000000 | 00000000 |

316 Stainless Steel | |||||||||||||||||||

| 6 | 5 | 3 | 5 | 4 | 3 | 20 | 35-150 | 20-80 | -150° to 150° | 1/2 | NPT | 3/8 | NPT | 1/2 | NPT | 4 1/2" | 1 1/8" | 0000000 | 000000 |

| 10 | 9 | 5 | 8 | 6 | 6 | 20 | 35-150 | 20-80 | -150° to 150° | 3/4 | NPT | 1/2 | NPT | 3/4 | NPT | 5 7/8" | 1 1/4" | 0000000 | 000000 |

| 17 | 15 | 9 | 14 | 11 | 10 | 20 | 35-150 | 20-80 | -150° to 150° | 1 | NPT | 3/4 | NPT | 1 | NPT | 7 1/8" | 1 3/4" | 0000000 | 00000000 |

| 51 | 44 | 25 | 40 | 32 | 28 | 20 | 35-150 | 20-80 | -150° to 150° | 1 1/2 | NPT | 1 | NPT | 1 1/2 | NPT | 11" | 2 5/8" | 0000000 | 00000000 |

| 93 | 80 | 46 | 73 | 58 | 51 | 20 | 35-150 | 20-80 | -150° to 150° | 2 | NPT | 1 1/4 | NPT | 2 | NPT | 14 3/8" | 3 1/2" | 0000000 | 00000000 |

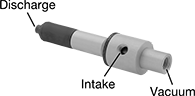

Metal Liquid-Powered Jet Pumps

Powered by liquid, use these to pump a second liquid or to produce emulsions, elevate water, and transport grains and other small particles. When high-pressure liquid enters the intake, it creates suction that draws a second liquid into the pump body and discharges a pressurized blend of the two. The discharge pressure is greater than the suction flow but lower than the intake pressure. They have no moving parts or seals, eliminating downtime for lubrication and repairs. They're also known as eductors, ejectors, and injectors.

Note: Liquid suction flow rate is calculated using water at 100 psi with no feet of discharge head.

Bronze is more corrosion resistant than cast iron.

316 stainless steel pumps are the most corrosion-resistant metal option.

For technical drawings and 3-D models, click on a part number.

Liquid Suction Flow Rate, gpm | Suction | Intake | Discharge | Overall | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 5 ft. of Lift | @ 10 ft. of Lift | @ 20 ft. of Lift | Max. Suction Lift, ft. | Operating Pressure, psi | Temp. Range, °F | Pipe Size | Thread Type | Pipe Size | Thread Type | Pipe Size | Thread Type | Lg. | Wd. | Each | |

For Use With Grain, Slurry, Water | |||||||||||||||

Cast Iron | |||||||||||||||

| 8 | 7 | 5 | 27 | 80 | -20° to 150° | 3/4 | NPT | 3/8 | NPT | 3/4 | NPT | 5 7/8" | 1 1/4" | 0000000 | 0000000 |

| 8 | 7 | 5 | 27 | 80 | -20° to 150° | 3/4 | NPT | 1/2 | NPT | 3/4 | NPT | 5 7/8" | 1 1/4" | 0000000 | 000000 |

| 14 | 12 | 9 | 27 | 80 | -20° to 150° | 1 | NPT | 1/2 | NPT | 1 | NPT | 7 1/8" | 1 3/4" | 0000000 | 000000 |

| 24 | 22 | 16 | 27 | 80 | -20° to 150° | 1 1/4 | NPT | 3/4 | NPT | 1 1/4 | NPT | 9" | 2 3/8" | 0000000 | 000000 |

| 40 | 36 | 27 | 27 | 80 | -20° to 150° | 1 1/2 | NPT | 1 | NPT | 1 1/2 | NPT | 11" | 2 5/8" | 0000000 | 000000 |

| 73 | 66 | 49 | 27 | 80 | -20° to 150° | 2 | NPT | 1 1/4 | NPT | 2 | NPT | 14 3/8" | 3 1/2" | 0000000 | 000000 |

| 127 | 114 | 86 | 27 | 80 | -20° to 150° | 2 1/2 | NPT | 1 1/2 | NPT | 2 1/2 | NPT | 18 1/8" | 4 1/2" | 0000000 | 00000000 |

| 237 | 213 | 160 | 27 | 80 | -20° to 150° | 3 | NPT | 2 | NPT | 3 | NPT | 23 7/8" | 6 1/8" | 0000000 | 00000000 |

Bronze | |||||||||||||||

| 8 | 7 | 5 | 27 | 15-200 | -20° to 150° | 3/4 | NPT | 3/8 | NPT | 3/4 | NPT | 5 7/8" | 1 1/4" | 0000000 | 000000 |

| 8 | 7 | 5 | 27 | 15-200 | -20° to 150° | 3/4 | NPT | 1/2 | NPT | 3/4 | NPT | 5 7/8" | 1 1/4" | 0000000 | 000000 |

| 14 | 12 | 9 | 27 | 15-200 | -20° to 150° | 1 | NPT | 1/2 | NPT | 1 | NPT | 7 1/8" | 1 3/4" | 0000000 | 000000 |

| 24 | 22 | 16 | 27 | 15-200 | -20° to 150° | 1 1/4 | NPT | 3/4 | NPT | 1 1/4 | NPT | 9" | 2 3/8" | 0000000 | 000000 |

| 40 | 36 | 27 | 27 | 15-200 | -20° to 150° | 1 1/2 | NPT | 1 | NPT | 1 1/2 | NPT | 11" | 2 5/8" | 0000000 | 000000 |

| 73 | 66 | 49 | 27 | 15-200 | -20° to 150° | 2 | NPT | 1 1/4 | NPT | 2 | NPT | 14 3/8" | 3 1/2" | 0000000 | 00000000 |

| 127 | 114 | 86 | 27 | 15-200 | -20° to 150° | 2 1/2 | NPT | 1 1/2 | NPT | 2 1/2 | NPT | 18 1/8" | 4 1/2" | 0000000 | 00000000 |

| 237 | 213 | 160 | 27 | 15-200 | -20° to 150° | 3 | NPT | 2 | NPT | 3 | NPT | 23 7/8" | 6 1/8" | 0000000 | 00000000 |

316 Stainless Steel | |||||||||||||||

| 8 | 7 | 5 | 27 | 15-200 | -150° to 150° | 3/4 | NPT | 3/8 | NPT | 3/4 | NPT | 5 7/8" | 1 1/4" | 0000000 | 000000 |

| 8 | 7 | 5 | 27 | 15-200 | -150° to 150° | 3/4 | NPT | 1/2 | NPT | 3/4 | NPT | 5 7/8" | 1 1/4" | 0000000 | 000000 |

| 14 | 12 | 9 | 27 | 15-200 | -150° to 150° | 1 | NPT | 1/2 | NPT | 1 | NPT | 7 1/8" | 1 3/4" | 0000000 | 000000 |

| 24 | 22 | 16 | 27 | 15-200 | -150° to 150° | 1 1/4 | NPT | 3/4 | NPT | 1 1/4 | NPT | 9" | 2 3/8" | 0000000 | 00000000 |

| 40 | 36 | 27 | 27 | 15-200 | -150° to 150° | 1 1/2 | NPT | 1 | NPT | 1 1/2 | NPT | 11" | 2 5/8" | 0000000 | 00000000 |

| 73 | 66 | 49 | 27 | 15-200 | -150° to 150° | 2 | NPT | 1 1/4 | NPT | 2 | NPT | 14 3/8" | 3 1/2" | 0000000 | 00000000 |

| 127 | 114 | 86 | 27 | 15-200 | -150° to 150° | 2 1/2 | NPT | 1 1/2 | NPT | 2 1/2 | NPT | 18 1/8" | 4 1/2" | 0000000 | 00000000 |

| 237 | 213 | 160 | 27 | 15-200 | -150° to 150° | 3 | NPT | 2 | NPT | 3 | NPT | 23 7/8" | 6 1/8" | 0000000 | 00000000 |

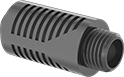

Chemical-Resistant Plastic Liquid-Powered Jet Pumps

Made from PVC, these pumps are highly corrosion resistant and lightweight. Use them to produce emulsions, elevate water, and transport grains and other small particles. When high-pressure liquid enters the intake, it creates suction that draws a second liquid or gas into the pump body and discharges a pressurized blend of the two. The discharge pressure is greater than the suction flow but lower than the intake pressure. They have no moving parts or seals, eliminating downtime for lubrication and repairs. They're also known as eductors, ejectors, and injectors.

Note: Liquid suction flow rate is calculated using water at 100 psi with no feet of discharge head.

For technical drawings and 3-D models, click on a part number.

Liquid Suction Flow Rate, gpm | Suction | Intake | Discharge | Overall | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 5 ft. of Lift | @ 10 ft. of Lift | @ 20 ft. of Lift | Max. Suction Lift, ft. | Operating Pressure, psi | Max. Temp., °F | Pipe Size | Thread Type | Pipe Size | Thread Type | Pipe Size | Thread Type | Lg. | Wd. | Each | |

For Use With Grain, Slurry, Water | |||||||||||||||

PVC Plastic | |||||||||||||||

| 8 | 7 | 5 | 27 | 100 | 70° | 3/4 | NPT | 1/2 | NPT | 3/4 | NPT | 5 3/4" | 2" | 0000000 | 0000000 |

| 14 | 12 | 9 | 27 | 100 | 70° | 1 | NPT | 1/2 | NPT | 1 | NPT | 6 7/8" | 2 1/2" | 0000000 | 000000 |

| 24 | 22 | 16 | 27 | 100 | 70° | 1 1/4 | NPT | 3/4 | NPT | 1 1/4 | NPT | 9 1/8" | 3" | 0000000 | 000000 |

| 40 | 36 | 27 | 27 | 100 | 70° | 1 1/2 | NPT | 1 | NPT | 1 1/2 | NPT | 11" | 3 1/2" | 0000000 | 000000 |

| 73 | 66 | 49 | 27 | 100 | 70° | 2 | NPT | 1 1/4 | NPT | 2 | NPT | 14 1/4" | 4" | 0000000 | 000000 |

| 127 | 114 | 86 | 27 | 100 | 70° | 2 1/2 | NPT | 1 1/2 | NPT | 2 1/2 | NPT | 18 1/2" | 5" | 0000000 | 00000000 |

| 237 | 213 | 160 | 27 | 100 | 70° | 3 | NPT | 2 | NPT | 3 | NPT | 24 1/4" | 6" | 0000000 | 00000000 |

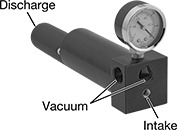

Fixed-Flow Air-Powered Vacuum Pumps

Also known as venturi pumps, these compressed-air-powered pumps are commonly used in vacuum packaging, pick-and-place operations, and end-of-arm robotic tooling. They have no seals or moving parts that can wear down or overheat, and they don’t require lubrication, so there's no downtime for maintenance. The compact body allows inline installation close to your vacuum point. Maximum flow rate is the rate at which air is pumped before a vacuum is created. Flow rate steadily decreases as the pump generates the vacuum. The larger the tank, the longer it will take to form a vacuum. Tube and fitting ID will also affect flow. A higher maximum vacuum value indicates a stronger vacuum.

For technical drawings and 3-D models, click on a part number.

Pumps | Replacement Mufflers | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Vacuum, in. of Hg | Max. Flow Rate, cfm | Operating Pressure, psi | Temp. Range, °F | Air Consumption, cfm | Volume | Intake Pipe Size | Discharge Pipe Size | Vacuum Pipe Size | Dia. | Overall Lg. | Each | Each | ||

| 20 | 0.5 | 80 | -100° to 400° | 0.5 | 64 dB | 1/8 BSPP | 1/4 BSPP | 1/8 BSPP | 3/4" | 4 1/4" | 00000000 | 0000000 | 00000000 | 000000 |

| 20 | 0.5 | 80 | -100° to 400° | 0.5 | 64 dB | 1/8 NPT | 1/4 NPT | 1/8 NPT | 3/4" | 4 1/4" | 00000000 | 000000 | 00000000 | 00000 |

| 20 | 1.4 | 80 | -100° to 400° | 1.4 | 64 dB | 1/8 BSPP | 1/4 BSPP | 1/8 BSPP | 3/4" | 4 1/4" | 000000 | 000000 | 00000000 | 00000 |

| 20 | 1.4 | 80 | -100° to 400° | 1.4 | 64 dB | 1/8 NPT | 1/4 NPT | 1/8 NPT | 3/4" | 4 1/4" | 00000000 | 000000 | 00000000 | 00000 |

| 20 | 2.1 | 80 | -100° to 400° | 1.8 | 64 dB | 1/8 BSPP | 1/4 BSPP | 1/8 BSPP | 3/4" | 4 1/4" | 00000000 | 000000 | 00000000 | 00000 |

| 20 | 2.1 | 80 | -100° to 400° | 1.8 | 64 dB | 1/8 NPT | 1/4 NPT | 1/8 NPT | 3/4" | 4 1/4" | 00000000 | 000000 | 00000000 | 00000 |

| 20 | 3.5 | 80 | -100° to 400° | 2.8 | 64 dB | 1/8 BSPP | 1/4 BSPP | 1/8 BSPP | 3/4" | 4 1/4" | 00000000 | 000000 | 00000000 | 00000 |

| 20 | 3.5 | 80 | -100° to 400° | 2.8 | 64 dB | 1/8 NPT | 1/4 NPT | 1/8 NPT | 3/4" | 4 1/4" | 00000000 | 000000 | 00000000 | 00000 |

| 20 | 6 | 80 | -100° to 400° | 4.8 | 70 dB | 1/4 BSPP | 3/8 BSPP | 3/8 BSPP | 1 1/4" | 5 7/8" | 00000000 | 000000 | 00000000 | 00000 |

| 20 | 6 | 80 | -100° to 400° | 4.8 | 70 dB | 1/4 NPT | 3/8 NPT | 3/8 NPT | 1 1/4" | 5 7/8" | 00000000 | 000000 | 00000000 | 00000 |

| 20 | 9.5 | 80 | -100° to 400° | 7.8 | 70 dB | 1/4 NPT | 3/8 NPT | 3/8 NPT | 1 1/4" | 5 7/8" | 00000000 | 000000 | 00000000 | 00000 |

| 20 | 20 | 80 | -100° to 400° | 12.5 | 72 dB | 3/8 NPT | 3/8 NPT | 3/8 NPT | 1 1/4" | 9 7/8" | 00000000 | 000000 | 00000000 | 00000 |

| 20 | 28 | 80 | -100° to 400° | 22 | 76 dB | 1/2 NPT | 1/2 NPT | 1/2 NPT | 1 1/2" | 10 7/8" | 00000000 | 000000 | 00000000 | 00000 |

| 26 | 0.95 | 75 | 35° to 125° | 1.6 | 65 dBA | 1/8 NPT | 1/8 NPT | 1/8 NPT | 2" | 5 3/8" | 00000000 | 000000 | 00000000 | 00000 |

| 27 | 2.2 | 75 | 35° to 125° | 3.5 | 65 dBA | 1/8 NPT | 1/4 NPT | 1/4 NPT | 1 3/4" | 7 3/8" | 00000000 | 000000 | 000000 | 00 |

| 27 | 4 | 75 | 35° to 125° | 6.4 | 65 dBA | 1/8 NPT | 3/8 NPT | 3/8 NPT | 1 3/4" | 8 1/4" | 00000000 | 000000 | 00000000 | 00000 |

| 28 | 0.5 | 80 | -100° to 400° | 0.5 | 64 dB | 1/8 BSPP | 1/4 BSPP | 1/8 BSPP | 3/4" | 4 1/4" | 00000000 | 000000 | 00000000 | 00000 |

| 28 | 0.5 | 80 | -100° to 400° | 0.8 | 64 dB | 1/8 NPT | 1/4 NPT | 1/8 NPT | 3/4" | 4 1/4" | 0000000 | 000000 | 00000000 | 00000 |

| 28 | 1.2 | 80 | -100° to 400° | 1.8 | 64 dB | 1/8 NPT | 1/4 NPT | 1/8 NPT | 3/4" | 4 1/4" | 0000000 | 000000 | 00000000 | 00000 |

| 28 | 2 | 80 | -100° to 400° | 2.8 | 64 dB | 1/8 BSPP | 1/4 BSPP | 1/8 BSPP | 3/4" | 4 1/4" | 00000000 | 000000 | 00000000 | 00000 |

| 28 | 2 | 80 | -100° to 400° | 2.8 | 64 dB | 1/8 NPT | 1/4 NPT | 1/8 NPT | 3/4" | 4 1/4" | 0000000 | 000000 | 00000000 | 00000 |

| 28 | 3.2 | 80 | -100° to 400° | 4.8 | 64 dB | 1/8 NPT | 1/4 NPT | 1/8 NPT | 3/4" | 4 1/4" | 0000000 | 000000 | 00000000 | 00000 |

| 28 | 5.4 | 80 | -100° to 400° | 7.8 | 70 dB | 1/4 BSPP | 3/8 BSPP | 3/8 BSPP | 1 1/4" | 5 7/8" | 00000000 | 000000 | 00000000 | 00000 |

| 28 | 5.4 | 80 | -100° to 400° | 7.8 | 70 dB | 1/4 NPT | 3/8 NPT | 3/8 NPT | 1 1/4" | 5 7/8" | 0000000 | 000000 | 00000000 | 00000 |

| 28 | 9 | 80 | -100° to 400° | 12.5 | 76 dB | 1/4 NPT | 3/8 NPT | 3/8 NPT | 1 1/4" | 8 7/8" | 0000000 | 000000 | 00000000 | 00000 |

| 28 | 20 | 80 | -100° to 400° | 22 | 72 dB | 3/8 BSPP | 3/8 BSPP | 3/8 BSPP | 1 1/4" | 9 7/8" | 00000000 | 000000 | 00000000 | 00000 |

| 28 | 20 | 80 | -100° to 400° | 22 | 72 dB | 3/8 NPT | 3/8 NPT | 3/8 NPT | 1 1/4" | 9 7/8" | 0000000 | 000000 | 00000000 | 00000 |

| 28 | 28 | 80 | -100° to 400° | 28 | 76 dB | 1/2 NPT | 1/2 NPT | 1/2 NPT | 1 1/2" | 10 7/8" | 0000000 | 000000 | 00000000 | 00000 |

Adjustable-Flow Air-Powered Vacuum Pumps

Use the rotating diffuser to alter flow rate. Also known as venturi pumps, these compressed-air-powered pumps are commonly used in vacuum packaging, pick-and-place operations, and end-of-arm robotic tooling. They have no seals or moving parts that can wear down or overheat, and they don’t require lubrication, so there's no downtime for maintenance. The compact body allows inline installation close to your vacuum point. Maximum flow rate is the rate at which air is pumped before a vacuum is created. Flow rate steadily decreases as the pump generates the vacuum. The larger the tank, the longer it will take to form a vacuum. Tube and fitting ID will also affect flow.

For technical drawings and 3-D models, click on a part number.

Pumps | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Intake, NPT | Discharge, NPT | Vacuum Connection, NPT | Replacement Mufflers | ||||||||||||||

| Max. Vacuum, in. of Hg | Max. Flow Rate, cfm | Operating Pressure, psi | Temp. Range, °F | Air Consumption, cfm | Volume, dB | Pipe Size | Gender | Pipe Size | Gender | Pipe Size | Gender | Dia. | Overall Lg. | Each | Each | ||

| 25 | 2 | 80 | -100° to 400° | 1.3 | 70 | 1/8 | Female | 1/4 | Female | 1/4 | Female | 1 1/4" | 5 5/8" | 00000000 | 0000000 | 00000000 | 000000 |

| 25 | 3.2 | 80 | -100° to 400° | 2.4 | 74 | 1/8 | Female | 1/4 | Female | 1/4 | Female | 1 1/4" | 5 5/8" | 00000000 | 000000 | 00000000 | 00000 |

| 25 | 6 | 80 | -100° to 400° | 4.7 | 78 | 1/8 | Female | 1/4 | Female | 1/4 | Female | 1 1/4" | 5 5/8" | 00000000 | 000000 | 00000000 | 00000 |

| 25 | 10 | 80 | -100° to 400° | 8.3 | 84 | 1/8 | Female | 1/4 | Female | 1/4 | Female | 1 1/4" | 6 1/4" | 00000000 | 000000 | 00000000 | 00000 |

| 25 | 30 | 80 | -100° to 400° | 17 | 88 | 3/8 | Female | 1/2 | Female | 1/2 | Female | 1 3/4" | 10 7/8" | 00000000 | 000000 | 00000000 | 00000 |

| 25 | 60 | 80 | -100° to 400° | 28 | 82 | 3/8 | Female | 3/4 | Female | 1/2 | Female | 2" | 13" | 00000000 | 000000 | 00000000 | 000000 |

| 25 | 120 | 80 | -100° to 400° | 44 | 98 | 1/2 | Female | 1 | Female | 3/4 | Female | 2 1/4" | 13 7/8" | 00000000 | 000000 | 00000000 | 000000 |

High-Efficiency Fixed-Flow Air-Powered Vacuum Pumps

A multistage design generates a high vacuum flow with less air consumption than other air-powered vacuum pumps. Also known as venturi pumps, these pumps are commonly used in vacuum packaging, pick-and-place operations, and end-of-arm robotic tooling. They have no seals or moving parts that can wear down or overheat, and they don’t require lubrication, so there's no downtime for maintenance. The compact body allows inline installation close to your vacuum point. Maximum flow rate is the rate at which air is pumped before a vacuum is created. Flow rate steadily decreases as the pump generates the vacuum. The larger the tank, the longer it will take to form a vacuum. Tube and fitting ID will also affect flow. A higher maximum vacuum value indicates a stronger vacuum.

For technical drawings and 3-D models, click on a part number.

Intake | Discharge | Vacuum Connection | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Vacuum, in. of Hg | Max. Flow Rate, cfm | Operating Pressure, psi | Temp. Range, °F | Air Consumption, cfm | Volume, dBA | Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Dia. | Overall Lg. | Each | |

| 26 | 17 | 68 | 35° to 125° | 7 | 65 | 1/8 | NPT | Female | 3/8 | NPT | Female | 1/2 | NPT | Female | 3" | 10 1/4" | 00000000 | 0000000 |

| 27 | 6.8 | 68 | 35° to 125° | 2.7 | 65 | 1/8 | NPT | Female | 1/4 | NPT | Female | 1/2 | NPT | Female | 3" | 8 1/4" | 00000000 | 000000 |

Water Aspirator Pumps

Pick up chemical spills and remove liquids in vacuum filtering systems—these pumps create suction to draw up liquids and gases as water flows through them. They’re made of HDPE and polyethylene, so they won’t break down when exposed to highly corrosive chemicals and acids. The suction end has a barbed tube connector, which attaches to your vacuum tubing. The connector stays attached to your vacuum tubing and connects to the pump when you’re ready to use it again. These pumps also have an internal check valve to prevent backflow.

Suction | Intake | Discharge | Overall | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Rate, gpm | Maximum Vacuum, in. of Hg | Minimum Operating Pressure, psi | Temperature Range, °F | For Tube ID | Gender | Pipe Size | Thread Type | Gender | Outlet Connection Type | Gender | Length | Width | Includes | Each | |

| 1.5 | 27 | 11 | -140° to 240° | 1/4", 5/16", 3/8" | Male | 3/8 | NPT | Male | Open | Female | 3" | 3" | 4 1/2" Length of 3/8" OD Polyethylene Tubing | 00000000 | 000000 |