About Plastic

More

How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Plastic and Rubber Tubing

More

UV-Resistant Firm Plastic Tubing for Air and Water

- Flexible

- Compatible with Barbed Tube Fittings

- Firm (Durometer 85A)

- Temperature Range: -10° to 220° F

With a unique combination of UV resistance and clarity, this PVC tubing won’t degrade from the damaging effects of ultraviolet light exposure, and allows you to monitor flow through the line. Tubing is flexible, so it can easily bend around objects.

For technical drawings and 3-D models, click on a part number.

| ID | OD | Wall Thick. | Bend Radius | Max. Pressure | Color | Lengths, ft. | Per Ft. | |

Clear PVC Plastic | ||||||||

|---|---|---|---|---|---|---|---|---|

Inch | ||||||||

| 1/16" | 1/8" | 1/16" | 1/8" | 90 psi @ 72° F | Clear | 100 | 0000000 | 00000 |

| 1/8" | 1/4" | 1/16" | 1/4" | 90 psi @ 72° F | Clear | 000000 | 000 | |

| 3/16" | 5/16" | 1/16" | 3/8" | 60 psi @ 72° F | Clear | 100 | 0000000 | 000 |

| 1/4" | 3/8" | 1/16" | 3/4" | 45 psi @ 72° F | Clear | 000000 | 000 | |

| 1/4" | 7/16" | 1/16" | 1/2" | 70 psi @ 72° F | Clear | 100 | 0000000 | 0000 |

| 1/4" | 1/2" | 1/8" | 1/4" | 90 psi @ 72° F | Clear | 50 | 0000000 | 0000 |

| 5/16" | 7/16" | 1/16" | 1 1/8" | 35 psi @ 72° F | Clear | 00000000 | 000 | |

| 3/8" | 1/2" | 1/16" | 1 5/8" | 30 psi @ 72° F | Clear | 000000 | 0000 | |

| 3/8" | 5/8" | 1/8" | 3/4" | 60 psi @ 72° F | Clear | 50 | 0000000 | 0000 |

| 1/2" | 5/8" | 1/16" | 2 7/8" | 25 psi @ 72° F | Clear | 25 | 0000000 | 0000 |

| 1/2" | 3/4" | 1/8" | 1 1/4" | 45 psi @ 72° F | Clear | 000000 | 0000 | |

| 5/8" | 7/8" | 1/8" | 2" | 35 psi @ 72° F | Clear | 25 | 0000000 | 0000 |

| 3/4" | 1" | 1/8" | 3" | 30 psi @ 72° F | Clear | 000000 | 0000 | |

| 3/4" | 1 1/8" | 3/16" | 1 5/8" | 45 psi @ 72° F | Clear | 25 | 0000000 | 0000 |

Metric | ||||||||

| 1mm | 3mm | 1mm | 2mm | 180 psi @ 72° F | Clear | 00000000 | 000 | |

| 1mm | 4mm | 1.5mm | 2mm | 270 psi @ 72° F | Clear | 00000000 | 000 | |

| 2mm | 5mm | 1.5mm | 3mm | 135 psi @ 72° F | Clear | 00000000 | 000 | |

| 2mm | 6mm | 2mm | 3mm | 180 psi @ 72° F | Clear | 00000000 | 000 | |

| 2mm | 7mm | 2.5mm | 3mm | 235 psi @ 72° F | Clear | 00000000 | 000 | |

| 3mm | 5mm | 1mm | 6mm | 60 psi @ 72° F | Clear | 0000000 | 000 | |

| 3mm | 6mm | 1.5mm | 5mm | 90 psi @ 72° F | Clear | 00000000 | 000 | |

| 3mm | 7mm | 2mm | 4mm | 120 psi @ 72° F | Clear | 00000000 | 000 | |

| 3mm | 8mm | 2.5mm | 3mm | 150 psi @ 72° F | Clear | 00000000 | 000 | |

| 4mm | 7mm | 1.5mm | 8mm | 70 psi @ 72° F | Clear | 00000000 | 000 | |

| 4mm | 8mm | 2mm | 6mm | 90 psi @ 72° F | Clear | 00000000 | 000 | |

| 4mm | 9mm | 2.5mm | 5mm | 115 psi @ 72° F | Clear | 00000000 | 0000 | |

| 6mm | 8mm | 1mm | 25mm | 30 psi @ 72° F | Clear | 00000000 | 000 | |

| 6mm | 9mm | 1.5mm | 17mm | 45 psi @ 72° F | Clear | 00000000 | 000 | |

| 6mm | 10mm | 2mm | 12mm | 60 psi @ 72° F | Clear | 00000000 | 0000 | |

| 7mm | 9mm | 1mm | 34mm | 25 psi @ 72° F | Clear | 0000000 | 000 | |

| 7mm | 10mm | 1.5mm | 24mm | 40 psi @ 72° F | Clear | 00000000 | 000 | |

| 7mm | 11mm | 2mm | 17mm | 55 psi @ 72° F | Clear | 00000000 | 0000 | |

| 9mm | 11mm | 1mm | 56mm | 20 psi @ 72° F | Clear | 00000000 | 000 | |

| 9mm | 13mm | 2mm | 28mm | 40 psi @ 72° F | Clear | 00000000 | 0000 | |

| 9mm | 15mm | 3mm | 17mm | 60 psi @ 72° F | Clear | 00000000 | 0000 | |

| 10mm | 13mm | 1.5mm | 49mm | 30 psi @ 72° F | Clear | 00000000 | 0000 | |

| 10mm | 15mm | 2.5mm | 27mm | 45 psi @ 72° F | Clear | 00000000 | 0000 | |

| 10mm | 17mm | 3.5mm | 17mm | 65 psi @ 72° F | Clear | 00000000 | 0000 | |

| 15mm | 20mm | 2.5mm | 62mm | 30 psi @ 72° F | Clear | 00000000 | 0000 | |

| 15mm | 22mm | 3.5mm | 39mm | 45 psi @ 72° F | Clear | 0000000 | 0000 | |

UV-Resistant Soft Plastic and Rubber Tubing for Air and Water

This tubing won’t degrade when exposed to the damaging effects of ultraviolet light. It is opaque, so you can’t see what’s flowing through the line.

PVC plastic tubing is the most economical option.

For technical drawings and 3-D models, click on a part number.

- Flexible

- Compatible with Barbed Tube Fittings

- Soft (Durometer 70A)

- Temperature Range: -5° to 160° F

| ID | OD | Wall Thick. | Bend Radius | Max. Pressure | Color | Lengths, ft. | Specifications Met | Per Ft. | |

| 1/16" | 1/8" | 1/32" | 1/2" | 65 psi @ 72° F | Black | UL 94 HB, UL 94 V-1 | 0000000 | 00000 | |

| 3/32" | 5/32" | 1/32" | 3/4" | 55 psi @ 72° F | Black | UL 94 HB, UL 94 V-1 | 0000000 | 000 | |

| 3/32" | 7/32" | 1/16" | 1" | 60 psi @ 72° F | Black | UL 94 HB, UL 94 V-1 | 0000000 | 000 | |

| 1/8" | 3/16" | 1/32" | 15/16" | 45 psi @ 72° F | Black | 100 | UL 94 HB, UL 94 V-1 | 000000 | 000 |

| 1/8" | 1/4" | 1/16" | 1 1/4" | 65 psi @ 72° F | Black | UL 94 HB, UL 94 V-1 | 0000000 | 000 | |

| 5/32" | 9/32" | 1/16" | 1 1/4" | 50 psi @ 72° F | Black | UL 94 HB, UL 94 V-1 | 0000000 | 000 | |

| 3/16" | 1/4" | 1/32" | 1 1/4" | 30 psi @ 72° F | Black | UL 94 HB, UL 94 V-1 | 0000000 | 000 | |

| 3/16" | 5/16" | 1/16" | 1 1/2" | 50 psi @ 72° F | Black | UL 94 HB, UL 94 V-1 | 0000000 | 000 | |

| 3/16" | 3/8" | 3/32" | 1 3/4" | 70 psi @ 72° F | Black | UL 94 HB, UL 94 V-1 | 0000000 | 000 | |

| 1/4" | 3/8" | 1/16" | 1 3/4" | 45 psi @ 72° F | Black | UL 94 HB, UL 94 V-1 | 0000000 | 000 | |

| 1/4" | 7/16" | 3/32" | 2" | 55 psi @ 72° F | Black | UL 94 HB, UL 94 V-1 | 0000000 | 000 | |

| 1/4" | 1/2" | 1/8" | 2 1/2" | 70 psi @ 72° F | Black | UL 94 HB, UL 94 V-1 | 0000000 | 000 | |

| 5/16" | 7/16" | 1/16" | 2" | 40 psi @ 72° F | Black | UL 94 HB, UL 94 V-1 | 0000000 | 000 | |

| 3/8" | 1/2" | 1/16" | 2 1/2" | 30 psi @ 72° F | Black | UL 94 HB, UL 94 V-1 | 000000 | 000 | |

| 3/8" | 5/8" | 1/8" | 3" | 55 psi @ 72° F | Black | UL 94 HB, UL 94 V-1 | 000000 | 0000 | |

| 1/2" | 5/8" | 1/16" | 3" | 25 psi @ 72° F | Black | UL 94 HB, UL 94 V-1 | 0000000 | 000 | |

| 1/2" | 3/4" | 1/8" | 3 3/4" | 40 psi @ 72° F | Black | UL 94 HB, UL 94 V-1 | 0000000 | 0000 | |

| 5/8" | 7/8" | 1/8" | 4 1/4" | 35 psi @ 72° F | Black | UL 94 HB, UL 94 V-1 | 0000000 | 0000 | |

| 3/4" | 1" | 1/8" | 5" | 30 psi @ 72° F | Black | UL 94 HB, UL 94 V-1 | 0000000 | 0000 | |

| 1" | 1 1/4" | 1/8" | 6 1/4" | 25 psi @ 72° F | Black | UL 94 HB, UL 94 V-1 | 0000000 | 0000 | |

| 1" | 1 3/8" | 3/16" | 1 3/8" | 45 psi @ 72° F | Black | 50 | UL 94 HB, UL 94 V-1 | 000000 | 0000 |

| 1 1/4" | 1 5/8" | 3/16" | 1 5/8" | 45 psi @ 72° F | Black | 50 | UL 94 HB, UL 94 V-1 | 000000 | 0000 |

| 1 1/2" | 1 7/8" | 3/16" | 1 7/8" | 45 psi @ 72° F | Black | 50 | UL 94 HB, UL 94 V-1 | 000000 | 0000 |

| 1 1/2" | 2" | 1/4" | 10" | 35 psi @ 72° F | Black | UL 94 HB, UL 94 V-1 | 0000000 | 0000 | |

| 2" | 2 1/2" | 1/4" | 12 1/2" | 25 psi @ 72° F | Black | UL 94 HB, UL 94 V-1 | 0000000 | 00000 | |

| 2 1/2" | 3" | 1/4" | 15" | 20 psi @ 72° F | Black | UL 94 HB, UL 94 V-1 | 0000000 | 00000 | |

| 3" | 3 1/2" | 1/4" | 17 1/2" | 20 psi @ 72° F | Black | UL 94 HB, UL 94 V-1 | 0000000 | 00000 |

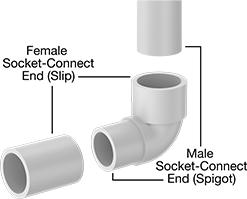

UV-Resistant Standard-Wall PVC Pipe Fittings for Water

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

Use these fittings in outdoor environments—the material has an additive that protects against the damaging effects of ultraviolet light. Fittings meet NSF/ANSI Standard 61 for drinking water. Also known as Schedule 40 fittings, they are typically used in residential and commercial low-pressure plumbing and water supply applications. They are PVC, which has good corrosion resistance. Fittings meet ASTM D1784 specifications and testing requirements for material quality.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

For technical drawings and 3-D models, click on a part number.

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Pipe Size | ||||||||

|---|---|---|---|---|---|---|---|---|

| (A) | (B) | Schedule | OD | ID | Socket Depth | Color | Each | |

| 3/4 | 1/2 | 40 | 1 3/64" | 0.78" | 25/32" | Red | 0000000 | 00000 |

| 1 | 3/4 | 40 | 1 5/16" | 0.99" | 15/16" | Red | 0000000 | 0000 |

| 1 1/2 | 1 | 40 | 1 29/32" | 1.24" | 1 3/32" | Red | 0000000 | 00000 |

| 2 | 1 | 40 | 2 3/8" | 1.26" | 1 1/32" | Red | 0000000 | 00000 |

| 2 | 1 1/2 | 40 | 2 3/8" | 1.775" | 1 5/16" | Red | 0000000 | 00000 |

| 3 | 1 | 40 | 3 1/2" | 3.033" | 1 1/16" | Beige | 00000000 | 00000 |

| 3 | 1 1/2 | 40 | 3 1/2" | 1.783" | 1 5/16" | Beige | 00000000 | 00000 |

| 3 | 2 | 40 | 3 1/2" | 2.291" | 1 21/32" | Beige | 00000000 | 00000 |

| 4 | 3 | 40 | 4 1/2" | 2.227" | 1 7/8" | Beige | 00000000 | 000000 |

| Pipe Cement (8 fl. oz. Can) | 000000000 | Each | 00000 |

UV-Resistant Thick-Wall PVC Pipe for Water

- For Use With: Water

- Temperature Range: -10° to 140° F

- Specifications Met: ASTM D1784, FDA Compliant 21 CFR 175.300

- Fittings: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

Use this pipe in outdoor environments–it’s made with an additive that protects against the damaging effects of ultraviolet light. Also known as Schedule 80 pipe, it has thicker, stronger walls than standard-wall pipe so it can handle heavy duty industrial plumbing and water supply applications, such as water processing, waste water treatment, and irrigation. Pipe is PVC, which has good corrosion resistance. Connect to unthreaded female socket-connect fittings using a PVC primer and cement (also known as solvent weld). Pipe meets ASTM D1784 specifications and testing requirements for material quality.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

4ft. | 8ft. | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | OD | ID | Wall Thick. | Color | Max. Pressure | Each | Each | ||

| 1/4 | 35/64" | 0.302" | 0.119" | Black | 570 psi @ 72° F | 0000000 | 000000 | 0000000 | 000000 |

| 3/8 | 43/64" | 0.423" | 0.126" | Black | 460 psi @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 1/2 | 27/32" | 0.546" | 0.147" | Black | 420 psi @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 3/4 | 1 3/64" | 0.742" | 0.154" | Black | 340 psi @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 1 | 1 5/16" | 0.957" | 0.179" | Black | 320 psi @ 72° F | 0000000 | 00000 | 0000000 | 000000 |

| 1 1/2 | 1 29/32" | 1.5" | 0.2" | Black | 240 psi @ 72° F | 0000000 | 00000 | 0000000 | 000000 |

| 2 | 2 3/8" | 1.939" | 0.218" | Black | 200 psi @ 72° F | 0000000 | 000000 | 0000000 | 000000 |

| 3 | 3 1/2" | 2.9" | 0.3" | Black | 190 psi @ 72° F | 00000000 | 000000 | 00000000 | 000000 |

| 4 | 4 1/2" | 3.826" | 0.337" | Black | 160 psi @ 72° F | 00000000 | 000000 | 00000000 | 000000 |

| Pipe Cement (8 fl. oz. Can) | 000000000 | Each | 00000 |

UV-Resistant Standard-Wall PVC Pipe for Water

- For Use With: Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784

- Fittings: Use Schedule 40 PVC Plastic

Made with an additive that protects against the damaging effects of ultraviolet light, this pipe won’t degrade in outdoor environments. Also known as Schedule 40 pipe, it’s typically used in low-pressure residential and commercial plumbing and water supply applications. Pipe is PVC, which has good corrosion resistance. Connect to unthreaded female socket-connect fittings using a PVC primer and cement (also known as solvent weld). Pipe meets ASTM D1784 specifications and testing requirements for material quality.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

5ft. | 10ft. | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | OD | ID | Wall Thick. | Color | Max. Pressure | Each | Each | ||

| 1/2 | 27/32" | 0.622" | 0.109" | Black | 300 psi @ 72° F | 0000000 | 000000 | 0000000 | 000000 |

| 3/4 | 1 3/64" | 0.824" | 0.113" | Black | 240 psi @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 1 | 1 5/16" | 1.049" | 0.133" | Black | 220 psi @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 1 1/2 | 1 29/32" | 1.61" | 0.145" | Black | 170 psi @ 72° F | 0000000 | 00000 | 0000000 | 000000 |

| 2 | 2 3/8" | 2.067" | 0.154" | Black | 140 psi @ 72° F | 0000000 | 000000 | 0000000 | 000000 |

| 3 | 3 1/2" | 3.042" | 0.229" | Black | 130 psi @ 72° F | 00000000 | 000000 | 00000000 | 000000 |

| 4 | 4 1/2" | 3.998" | 0.251" | Black | 110 psi @ 72° F | 00000000 | 000000 | 00000000 | 000000 |

| Pipe Cement (8 fl. oz.Can) | 000000000 | Each | 00000 |

Impact- and Chemical-Resistant PVC 90° Angles

- Color: Black

- Temperature Range: See table

- Tensile Strength: 5,600 psi (Good)

- Impact Strength: 20 ft.-lbs./in. (Excellent)

- Hardness: Durometer 80D (Hard)

- For Use Outdoors: Yes

- Specifications Met: UL 94 V-0, NSF/ANSI 51

Made of PVC Type 2 plastic, these 90° angles resist impact and chemicals. More impact resistant than PVC Type 1, PVC Type 2 is commonly used where protection from bumps and strikes is needed. It’s also more impact resistant than silicone, although not as resistant to heat. Since it stands up to acids and alkalies, it’s often used to make parts for chemical processing applications.

For technical drawings and 3-D models, click on a part number.

Outside | Inside | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Ht. Tolerance | Wd. | Wd. Tolerance | Ht. | Wd. | Temperature Range, °F | 2 ft. Lg. | 4 ft. Lg. | 8 ft. Lg. | |

0.06" Wall Thickness (-0.01" to 0.01") | ||||||||||

| 1/2" | -0.01" to 0.01" | 1/2" | -0.01" to 0.01" | 0.44" | 0.44" | 40° to 140° | 00000000 | |||

| 1" | -0.02" to 0.02" | 1" | -0.02" to 0.02" | 0.94" | 0.94" | 40° to 140° | 00000000 | |||

0.06" Wall Thickness (-0.008" to 0.008") | ||||||||||

| 3/4" | -0.015" to 0.015" | 3/4" | -0.015" to 0.015" | 0.69" | 0.69" | 40° to 140° | 0000000 | |||

0.065" Wall Thickness (-0.01" to 0.01") | ||||||||||

| 1 1/2" | -0.025" to 0.025" | 1 1/2" | -0.025" to 0.025" | 1.435" | 1.435" | 40° to 140° | 00000000 | |||

| 2" | -0.02" to 0.02" | 2" | -0.02" to 0.02" | 1.935" | 1.935" | -20° to 140° | 00000000 | |||

0.1" Wall Thickness (-0.015" to 0.015") | ||||||||||

| 3/4" | -0.015" to 0.015" | 3/4" | -0.015" to 0.015" | 0.65" | 0.65" | 40° to 140° | 00000000 | |||

| 1" | -0.02" to 0.02" | 1" | -0.02" to 0.02" | 0.9" | 0.9" | 40° to 140° | 00000000 | |||

| 2" | -0.025" to 0.025" | 2" | -0.025" to 0.025" | 1.9" | 1.9" | 40° to 140° | 00000000 | |||

| 3" | -0.03" to 0.03" | 3" | -0.03" to 0.03" | 2.885" | 2.885" | -20° to 140° | 00000000 | |||

0.1" Wall Thickness (-0.01" to 0.01") | ||||||||||

| 1 1/2" | -0.02" to 0.02" | 1 1/2" | -0.02" to 0.02" | 1.39" | 1.39" | -20° to 140° | 00000000 | |||

3/16" Wall Thickness (-0.02" to 0.02") | ||||||||||

| 1 1/2" | -0.025" to 0.025" | 1 1/2" | -0.025" to 0.025" | 1.312" | 1.312" | 40° to 140° | 00000000 | |||

| 2" | -0.025" to 0.025" | 2" | -0.025" to 0.025" | 1.812" | 1.812" | 40° to 140° | 00000000 | |||

3/16" Wall Thickness (-0.0195" to 0.0195") | ||||||||||

| 3/4" | -0.02" to 0.02" | 3/4" | -0.02" to 0.02" | 0.542" | 0.542" | -20° to 140° | 00000000 | |||

| 1" | -0.02" to 0.02" | 1" | -0.02" to 0.02" | 0.792" | 0.792" | -20° to 140° | 00000000 | |||

1/4" Wall Thickness (-0.02" to 0.02") | ||||||||||

| 1 1/2" | -0.02" to 0.02" | 1 1/2" | -0.02" to 0.02" | 1.23" | 1.23" | -20° to 140° | 00000000 | |||

| 2" | -0.025" to 0.025" | 2" | -0.025" to 0.025" | 1.73" | 1.73" | -20° to 140° | 00000000 | |||