Filter by

Hardness

Maximum Temperature

Weight

Volume

DFARS Specialty Metals

Food Industry Standard

Environment

Casting Compounds

Hardness | Time to Harden, min. | Time to Cure, hr. | Time to Demold, hr. | Cure Temp., ° F | Max. Temp., ° F | Shrinkage | Color | Mixing Req. | Volume, cu. in. | Wt., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Urethane Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Soft | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 20A | 15 | 168 | 5 | 77 | 180 | 0.1% | Black | Yes | 25 | 1 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 20A | 15 | 168 | 5 | 77 | 180 | 0.1% | Black | Yes | 250 | 10 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Medium | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 40A | 15 | 168 | 5 | 77 | 180 | 0.1% | Black | Yes | 25 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 40A | 15 | 168 | 5 | 77 | 180 | 0.1% | Black | Yes | 250 | 10 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 60A | 15 | 168 | 2 | 77 | 180 | 0.1% | Black | Yes | 25 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 60A | 15 | 168 | 2 | 77 | 180 | 0.1% | Black | Yes | 250 | 10 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 60D | 15 | 168 | 2 | 77 | 180 | 0.1% | Black | Yes | 25 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 60D | 15 | 168 | 2 | 77 | 180 | 0.1% | Black | Yes | 250 | 10 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hard | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 80A | 15 | 168 | 3 | 77 | 180 | 0.1% | Black | Yes | 25 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 80A | 15 | 168 | 3 | 77 | 180 | 0.1% | Black | Yes | 250 | 10 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 94A | 15 | 168 | 2 | 77 | 180 | 0.1% | Black | Yes | 25 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 94A | 15 | 168 | 2 | 77 | 180 | 0.1% | Black | Yes | 250 | 10 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 75D | 15 | 168 | 2 | 77 | 180 | 0.1% | Black | Yes | 25 | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 75D | 15 | 168 | 2 | 77 | 180 | 0.1% | Black | Yes | 250 | 10 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 85D | 5 | 2 | 1.5 | 77 | 180 | 0.1% | Green | Yes | 80 | 5 | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 85D | 5 | 2 | 1.5 | 77 | 180 | 0.1% | Green | Yes | 320 | 20 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Quick-Set Casting Compounds

Casting Compounds

Hardness | Time to Harden, min. | Time to Cure, min. | Time to Demold, min. | Cure Temp., ° F | Max. Temp., ° F | Shrinkage | Color | Mixing Req. | Volume, cu. in. | Wt., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Acrylic Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hard | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 85D | 2 | 11 | 11 | 69 | 350 | 0% | Light Blue | Yes | 20 | 1 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 85D | 2 | 11 | 11 | 69 | 350 | 0% | Light Blue | Yes | 62 | 3 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Silicone Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Soft | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 27A | 2 | 15 | 15 | 70 | 650 | 0% | Light Blue | Yes | 4 | 0.2 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 27A | 2 | 15 | 15 | 70 | 650 | 0% | Light Blue | Yes | 46 | 2.2 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 30A | 2 | 10 | 10 | 69 | 250 | 0% | Green | Yes | 8 | 0.5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 30A | 2 | 10 | 10 | 69 | 250 | 0% | Green | Yes | 23 | 1.1 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Medium | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 40A | 2 | 15 | 15 | 70 | 600 | 0% | Green | Yes | 4 | 0.2 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 40A | 2 | 15 | 15 | 70 | 600 | 0% | Green | Yes | 46 | 2.2 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 50A | 2 | 10 | 10 | 69 | 250 | 0% | Light Blue | Yes | 13 | 0.8 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 50A | 2 | 10 | 10 | 69 | 250 | 0% | Light Blue | Yes | 32 | 1.75 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

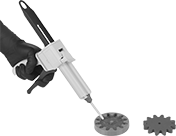

Casting Compounds with Dispensing Gun

Hardness Rating | Hardness | Time to Harden, min. | Time to Cure | Time to Demold | Cure Temp., ° F | Max. Temp., ° F | Shrinkage | Color | Mixing Req. | Wt., lb. | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Silicone Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Soft | Durometer 30A | 2 | 10 min. | 10 min. | 69 | 250 | 0% | Green | No | 4 | Carrying Case, Six each 3 cu. in. Disposable Cartridges | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Soft Medium | Durometer 30A Durometer 55A | 2 | 10 min. 6 min. | 10 min. 6 min. | 69 | 250 | 0% | Green Orange | No | 4 | Carrying Case, Six each 3 cu. in. Disposable Cartridges | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Medium | Durometer 55A | 2 | 6 min. | 6 min. | 69 | 250 | 0% | Orange | No | 4 | 15 Disposable Nozzles, 2 Snap-On Nozzles, Carrying Case, Six each 3 cu. in. Disposable Cartridges | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

See-Through Casting Compounds

Hardness | Time to Harden, min. | Time to Cure | Time to Demold | Cure Temp. | Max. Temp., ° F | Shrinkage | Color | Mixing Req. | Volume, cu. in. | Wt., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Urethane Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Medium | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 40A | 6 | 144 hr. | 2 hr. | 77° F | 180 | 0.8% | Clear | Yes | 25 | 1 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 60A | 6 | 144 hr. | 2 hr. | 77° F | 180 | 0.8% | Clear | Yes | 25 | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hard | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 80A | 6 | 144 hr. | 2 hr. | 77° F | 180 | 0.8% | Clear | Yes | 25 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 75D | 6 | 144 hr. | 2 hr. | 77° F | 180 | 0.8% | Clear | Yes | 25 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Silicone Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Medium | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 40A | 10 | 1.5 hr. 30 min. | 1.5 hr. 30 min. | 77° F 120° F | 570 | 0% | Blue | Yes | 57 | 2.2 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chemical-Resistant Casting Compounds

Food and Beverage Casting Compounds

Hardness | Time to Harden, min. | Time to Cure, hr. | Time to Demold, hr. | Cure Temp., ° F | Max. Temp., ° F | Shrinkage | Color | Mixing Req. | Food Industry Std. | Volume, cu. in. | Wt., lb. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Urethane Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Medium | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 40A | 8 | 12 | 2 | 120 | 180 | 5% | White | Yes | FDA Compliant 21 CFR 175.105, FDA Compliant 21 CFR 177.1680 | 25 | 1 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 60A | 8 | 12 | 2 | 120 | 180 | 5% | White | Yes | FDA Compliant 21 CFR 175.105, FDA Compliant 21 CFR 177.1680 | 25 | 1 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 60A | 8 | 12 | 2 | 120 | 180 | 5% | White | Yes | FDA Compliant 21 CFR 175.105, FDA Compliant 21 CFR 177.1680 | 250 | 10 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hard | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 78A | 4 | 12 | 2 | 120 | 180 | 5% | White | Yes | FDA Compliant 21 CFR 175.105, FDA Compliant 21 CFR 177.1680 | 25 | 1 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 88A | 4 | 12 | 2 | 120 | 180 | 5% | White | Yes | FDA Compliant 21 CFR 175.105, FDA Compliant 21 CFR 177.1680 | 25 | 1 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 88A | 4 | 12 | 2 | 120 | 180 | 5% | White | Yes | FDA Compliant 21 CFR 175.105, FDA Compliant 21 CFR 177.1680 | 250 | 10 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 75D | 5 | 12 | 2 | 120 | 180 | 5% | White | Yes | FDA Compliant 21 CFR 175.105, FDA Compliant 21 CFR 177.1680 | 25 | 1 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Foam Casting Compounds

Foam Expansion | Density, lb/ft³ | Time to Harden, min. | Time to Cure, min. | Time to Demold, min. | Cure Temp., ° F | Max. Temp., ° F | Shrinkage | Color | Mixing Req. | Wt., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Polyurethane Foam | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

White | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flexible—Not Machinable | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4X | 12 | 3 | 25 | 25 | 80 | 125 | Not Rated | White | Yes | 3 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4X | 12 | 3 | 25 | 25 | 80 | 125 | Not Rated | White | Yes | 12 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8X | 8 | 3 | 25 | 25 | 80 | 125 | Not Rated | White | Yes | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8X | 8 | 3 | 25 | 25 | 80 | 125 | Not Rated | White | Yes | 12 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15X | 4 | 3 | 25 | 25 | 80 | 125 | Not Rated | White | Yes | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15X | 4 | 3 | 25 | 25 | 80 | 125 | Not Rated | White | Yes | 12 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Beige | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rigid—Machinable | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2X | 20 | 3 | 15 | 15 | 75 | 85 | Not Rated | Beige | Yes | 16 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7X | 12 | 3 | 15 | 15 | 75 | 85 | Not Rated | Beige | Yes | 4 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7X | 12 | 3 | 15 | 15 | 75 | 85 | Not Rated | Beige | Yes | 16 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19X | 4 | 3 | 15 | 15 | 75 | 85 | Not Rated | Beige | Yes | 4 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19X | 4 | 3 | 15 | 15 | 75 | 85 | Not Rated | Beige | Yes | 16 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Long-Life Casting Compounds

Hardness | Time to Harden, min. | Time to Cure, hr. | Time to Demold, hr. | Cure Temp., ° F | Max. Temp., ° F | Shrinkage | Color | Mixing Req. | Volume, cu. in. | Wt., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Urethane Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Medium | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 45A | 60 | 24 | 16 | 77 | 200 | 0% | Yellow | Yes | 58 | 2.2 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Easy-Form Casting Compounds

Hardness | Time to Harden, min. | Time to Cure, hr. | Time to Demold, hr. | Cure Temp., ° F | Max. Temp., ° F | Shrinkage | Color | Mixing Req. | Volume, cu. in. | Wt., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Urethane Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Medium | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 60A | 15 | 168 | 3 | 75 | 180 | Not Rated | Dark Gray | Yes | 25 | 1 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 60A | 15 | 168 | 3 | 75 | 180 | Not Rated | Dark Gray | Yes | 100 | 4 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 60D | 15 | 168 | 3 | 75 | 180 | Not Rated | Dark Gray | Yes | 25 | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 60D | 15 | 168 | 3 | 75 | 180 | Not Rated | Dark Gray | Yes | 100 | 4 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hard | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 85A | 15 | 168 | 3 | 75 | 180 | Not Rated | Black | Yes | 25 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 85A | 15 | 168 | 3 | 75 | 180 | Not Rated | Black | Yes | 100 | 4 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Machinable Casting Compounds

High-Temperature Casting Compounds

Time to Harden, min. | Time to Cure, hr. | Time to Demold, hr. | Cure Temp., ° F | Max. Temp., ° F | Shrinkage | Color | Mixing Req. | Volume, cu. in. | Wt., lb. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Aluminum Oxide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 24 | 24 | 77 | 3,000 | 1% | White | Yes | 38 | 4 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 24 | 24 | 77 | 3,000 | 1% | White | Yes | 96 | 10 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Purity Ceramic Alumina | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 24 | 24 | 77 | 3,200 | 1.3% | White | Yes | 98 | 10 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Silicon Carbide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 24 | 24 | 77 | 2,700 | 1.5% | Black | Yes | 47 | 4 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 24 | 24 | 77 | 2,700 | 1.5% | Black | Yes | 119 | 10 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Silica | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 24 | 24 | 77 | 2,700 | 1.3% | White | Yes | 62 | 4 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 24 | 24 | 77 | 2,700 | 1.3% | White | Yes | 155 | 10 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zirconium Oxide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 24 | 24 | 77 | 4,000 | 1% | Beige | Yes | 27 | 4 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 24 | 24 | 77 | 4,000 | 1% | Beige | Yes | 69 | 10 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||