How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Nickel-Plated Brass Push-to-Connect Tube Fittings for Air

- For Use With: Air, Lubricated Air

- Temperature Range: 0° to 140° F

- Tubing: Fittings with Release Ring and Fittings with no Release Type: Use with firm or hard (Durometer 95A-60D) nylon plastic, polyethylene plastic or polyurethane rubber

Fittings with Release Sleeve: Use with firm or hard (Durometer 95A-60D) polyethylene plastic or polyurethane rubber

Made of nickel-plated brass, these fittings have better corrosion resistance than unplated brass fittings. Also known as instant fittings, they connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. To disconnect, push on the release ring or sleeve and pull the tubing out of the fitting.

Fittings with release sleeve are easier to disconnect than fittings with a release ring because they are seamless and won't collect dirt and debris.

Fittings with thread sealant offer extra protection against leaks.

For technical drawings and 3-D models, click on a part number.

Release Sleeve | ||||||

|---|---|---|---|---|---|---|

| For Tube OD | Pipe Size | Material | Max. Pressure | Features | Each | |

NPT Threads | ||||||

| 20mm | 3/4 | Nickel-Plated Brass | 230 psi @ 72° F | Thread Sealant | 00000000 | 000000 |

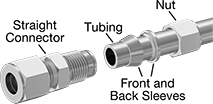

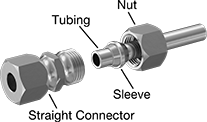

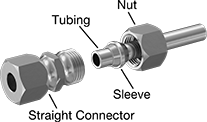

Yor-Lok Fittings for Stainless Steel Tubing

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

316 stainless steel fittings have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

- For Use With:

Inch:

NPT and BSPT Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

BSPP Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Mineral Oil, Water

UN/UNF (SAE Straight) Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil

Metric:

NPT, BSPT, and UN/UNF (SAE Straight) Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water - Tubing:

Inch:

NPT and UN/UNF (SAE Straight) Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

BSPP and BSPT Threads: Use with seamless 304 or 316 stainless steel that meets ASTM A269

Metric:

NPT, BSPT, and UN/UNF (SAE Straight) Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing:

Inch:

NPT Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

BSPP and BSPT Threads: Use with seamless 304 or 316 stainless steel that meets ASTM A269

Metric:

NPT Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | |||||||

| 20mm | 1.5 to 2.5 mm | 1/2 | 316 Stainless Steel | 2,600 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

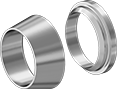

Couple these sleeves with Yor-Lok nuts and fittings to create an extra-strong seal on stainless steel tubing. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

For Tube | Front Sleeve | Back Sleeve | |||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

Sleeves | |||||||||

| 20mm | 1.5 to 2.5 mm | 316 Stainless Steel | 7mm | 1 | 4mm | 1 | 2,600 psi @ 72° F | 0000000 | 000000 |

Front and Back Sleeves for Yor-Lok Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -420° to 1200° F

- Tubing: Use with seamless or welded 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Compatible With: Let-Lok, Parker A-Lok, Swagelok®

Couple these sleeves with Yor-Lok nuts and fittings to create an extra-strong seal on stainless steel tubing. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

For technical drawings and 3-D models, click on a part number.

For Tube | Front Sleeve | Back Sleeve | |||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

Sleeves | |||||||||

| 20mm | 1.5 to 2.5 mm | 316 Stainless Steel | 7mm | 1 | 4mm | 1 | 2,600 psi @ 72° F | 0000000 | 000000 |

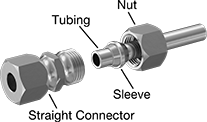

High-Pressure Compression Fittings for Stainless Steel Tubing

- Tubing: Use with seamless 304 or 316/316L/316Ti stainless steel that meets DIN EN 10216-5 or DIN EN 10305-1

- Specifications Met: DIN 2353, ISO 8434

The thick walls of these fittings can withstand more than twice the pressure of standard compression fittings. A single sleeve (ferrule) bites into tubing as you tighten the nut, creating a strong seal. The nut and sleeve are included. Made from 316 stainless steel, these fittings won’t corrode from water, chemicals, or salt spray. They are also known as flareless fittings. They meet ISO 8434 (formerly DIN 2353), an international standard for tube fitting dimensions and materials.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -75° to 750° F

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Pipe Size | Material | Maximum Pressure | Each | |

NPT Threads | ||||||

| 20 | 2-3 | 1 | 316 Stainless Steel | 6,000 psi @ 72° F | 00000000 | 000000 |

- For Use With: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -75° to 750° F

For Tube | |||||

|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Material | Maximum Pressure | Each | |

| 20 | 2-3 | 316 Stainless Steel | 6,000 psi @ 72° F | 00000000 | 000000 |

- For Use With: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -75° to 750° F

For Tube | |||||

|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Nut Material | Maximum Pressure | Each | |

| 20 | 2-3 | 316 Stainless Steel | 6,000 psi @ 72° F | 00000000 | 000000 |

- For Use With: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -75° to 750° F

For Tube | |||||

|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Sleeve Material | Maximum Pressure | Each | |

| 20 | 2-3 | 316 Stainless Steel | 6,000 psi @ 72° F | 00000000 | 00000 |

Sleeves for High-Pressure Compression Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -75° to 750° F

- Tubing: Use with seamless 304 or 316/316L/316Ti stainless steel that meets DIN EN 10216-5 or DIN EN 10305-1

- Specifications Met: DIN 2353, ISO 8434

When used with high-pressure compression fittings and nuts, these sleeves bite into stainless steel tubing to form a strong seal. Made from 316 stainless steel, they won’t corrode from water, chemicals, or salt spray. These nuts meet ISO 8434 (formerly DIN 2353), which is an international standard for tube fitting dimensions and materials.

For technical drawings and 3-D models, click on a part number.

For Tube | |||||

|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Sleeve Material | Maximum Pressure | Each | |

| 20 | 2-3 | 316 Stainless Steel | 6,000 psi @ 72° F | 00000000 | 00000 |

Nuts for High-Pressure Compression Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -75° to 750° F

- Tubing: Use with seamless 304 or 316/316L/316Ti stainless steel that meets DIN EN 10216-5 or DIN EN 10305-1

- Specifications Met: DIN 2353, ISO 8434

Tighten these nuts onto high-pressure compression sleeves and fittings to create a strong seal on stainless steel tubing. Made from 316 stainless steel, they won’t corrode from water, chemicals, or salt spray. These nuts meet ISO 8434 (formerly DIN 2353), which is an international standard for tube fitting dimensions and materials.

For technical drawings and 3-D models, click on a part number.

For Tube | |||||

|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Nut Material | Maximum Pressure | Each | |

| 20 | 2-3 | 316 Stainless Steel | 6,000 psi @ 72° F | 00000000 | 000000 |

High-Polish Metal Quick-Clamp Sanitary Tube Fittings

- Temperature Range: See Gaskets

The smooth finish inside these fittings makes it easy to remove product residue. Also known as aseptic and tri-clamp fittings, they connect with a gasket, a clamp, and another quick-clamp fitting for a fast and easy way to access your line. The pressure rating of the fitting will vary depending on the clamp you choose, and the temperature rating will vary based on the gasket material you choose.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

Fittings that meet DIN standards adhere to international requirements for sanitary quick-clamp fittings. 3-A certified fittings comply with sanitary standards.

Note: To complete a connection, you’ll need two quick-clamp fittings, a clamp, and a gasket (all sold separately).

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Beverage, Dairy, Food, Water

- Tubing:

Inch Fittings: Use with welded 304/304L or 316/316L stainless steel that meets ASTM A269 or ASTM 270

Metric Fittings: Use with welded 304/304L or 316/316L stainless steel - Specifications Met: See table

Fittings with butt-weld end are also known as ferrules; they weld to tubing for a permanent, flush connection.

| For Tube OD | For Flange OD | Max. Pressure | Specifications Met | Each | |

| 10mm, 16mm, 20mm | 34mm | 90 psi @ 72° F | DIN 32676 | 0000000 | 000000 |

EPDM gaskets resist water and steam and work well in humid environments.

| For Tube OD | ID | OD | Thick. | Temp. Range, °F | Color | Specifications Met | Each | |

EPDM Rubber | ||||||||

|---|---|---|---|---|---|---|---|---|

| 20mm | 20.200mm | 34.000mm | 0.205" | -50° to 275° | Black | DIN 32676 | 0000000 | 000000 |

Silicone Rubber | ||||||||

| 20mm | 20.200mm | 36.170mm | 5.2mm | -40° to 450° | Clear | DIN 32676, FDA Compliant 21 CFR 177.2600 | 00000000 | 0000 |

PTFE Plastic | ||||||||

| 20mm | 20.200mm | 34.000mm | 5.2mm | -100° to 500° | White | DIN 32676, FDA Compliant 21 CFR 177.1550 | 000000000 | 00000 |

Clamps for High-Polish Metal Quick-Clamp Sanitary Tube Fittings

- Temperature Range: See Gaskets or O-Rings

- Tubing:

Inch 304 Stainless Steel and Nylon Plastic: Use with welded 304/304L and 316/316L stainless steel that meets ASTM A269 or ASTM A270, except ASME BPE: Use with welded or seamless 304/304L stainless steel that meets ASTM A269 or ASTM A270

Metric 304 Stainless Steel: Use with welded 304/304L and 316/316L stainless steel

Inch 316 Stainless Steel: Use with welded 304/304L and 316/316L stainless steel

Metric 316 Stainless Steel: Use with welded 316/316L stainless steel

Connect quick-clamp sanitary tube fittings—also known as aseptic fittings—for a fast and easy way to access your line.

Wing nut—These clamps tighten by hand, no tools required.

304 stainless steel clamps have very good corrosion resistance. 316 stainless steel clamps are more corrosion resistant than 304 stainless steel clamps.

Clamps that meet DIN 11864 or DIN 32676 adhere to international standards for sanitary quick-clamp fittings.

| For Tube OD | For Flange OD | Max. Pressure | Specifications Met | Each | |

| 10mm, 16mm, 20mm | 34mm | 90 psi @ 72° F | DIN 32676 | 0000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Specifications Met | Each | |

| 20mm, 25mm | 50.5mm | 725 psi @ 300° F | DIN 11864 | 0000000 | 000000 |

The temperature rating of the fitting will vary depending on the gasket or O-ring material you choose. EPDM resists water and steam and works well in humid environments. Fluoroelastomer stands up to fuel, oil, and acid condensates. PTFE withstands harsh chemicals, with the exception of molten alkali metal and elemental fluorine.

| For Tube OD | ID | OD | Thick. | Temp. Range, °F | Color | Specifications Met | Each | |

Gaskets | ||||||||

|---|---|---|---|---|---|---|---|---|

EPDM Rubber | ||||||||

| 10mm | 10.200mm | 34.000mm | 0.205" | -50° to 275° | Black | DIN 32676 | 0000000 | 000000 |

| 16mm | 16.200mm | 34.000mm | 0.205" | -50° to 275° | Black | DIN 32676 | 0000000 | 00000 |

| 20mm | 20.200mm | 34.000mm | 0.205" | -50° to 275° | Black | DIN 32676 | 0000000 | 00000 |

Silicone Rubber | ||||||||

| 10mm | 10.200mm | 36.170mm | 5.2mm | -40° to 450° | Clear | DIN 32676, FDA Compliant 21 CFR 177.2600 | 00000000 | 0000 |

| 16mm | 16.200mm | 36.170mm | 5.2mm | -40° to 450° | Clear | DIN 32676, FDA Compliant 21 CFR 177.2600 | 00000000 | 0000 |

| 20mm | 20.200mm | 36.170mm | 5.2mm | -40° to 450° | Clear | DIN 32676, FDA Compliant 21 CFR 177.2600 | 00000000 | 0000 |

PTFE Plastic | ||||||||

| 10mm | 10.200mm | 34.000mm | 5.2mm | -100° to 500° | White | DIN 32676, FDA Compliant 21 CFR 177.1550 | 000000000 | 00000 |

| 16mm | 16.200mm | 34.000mm | 5.2mm | -100° to 500° | White | DIN 32676, FDA Compliant 21 CFR 177.1550 | 000000000 | 00000 |

| 20mm | 20.200mm | 34.000mm | 5.2mm | -100° to 500° | White | DIN 32676, FDA Compliant 21 CFR 177.1550 | 000000000 | 00000 |

O-Rings | ||||||||

EPDM Rubber | ||||||||

| 10mm | 12.000mm | 19.000mm | __ | 32° to 280° | Black | 3-A Certified 18-00 | 0000000 | 00000 |

| 20mm | 22.000mm | 29.000mm | __ | 32° to 280° | Black | 3-A Certified 18-00 | 0000000 | 00000 |

Viton® Fluoroelastomer Rubber | ||||||||

| 10mm | 12.000mm | 19.000mm | __ | 32° to 300° | Black | 3-A Certified 18-00 | 0000000 | 00000 |

| 20mm | 22.000mm | 29.000mm | __ | 32° to 300° | Black | 3-A Certified 18-00 | 0000000 | 00000 |

PTFE Plastic | ||||||||

| 10mm | 12.000mm | 19.000mm | __ | 32° to 280° | White | 3-A Certified 18-00 | 0000000 | 00000 |

| 20mm | 22.000mm | 29.000mm | __ | 32° to 280° | White | 3-A Certified 18-00 | 0000000 | 00000 |

Sleeves for Compression Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -65° to 200° F, except metric fittings are -40° to 250° F

- Tubing: Use with copper

- Specifications Met: UL listed, except for metric fittings

For technical drawings and 3-D models, click on a part number.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Max. Pressure | Pkg. Qty. | Pkg. | |

| 20mm | Not Rated | Brass | Not Rated | 1 | 0000000 | 00000 |

Sleeves for 37° Flared Fittings for Steel Tubing

- For Use With: Air, Fuel Oil, Hydraulic Fluid, Mineral Oil

- Temp. Range: -60° to 400° F

- Tubing: Use with seamless steel

- Specifications Met: SAE J514

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on steel tubing that is flared to 37°. Sleeves are zinc-plated steel for fair corrosion resistance. They are also known as ferrules.

Inch × metric sleeve adapters convert the fitting from inch to metric.

For technical drawings and 3-D models, click on a part number.

For Tube OD | |||||

|---|---|---|---|---|---|

| Inch | Metric, mm | Sleeve Material | Max. Pressure | Each | |

Inch × Metric Sleeve Adapters | |||||

| 7/8" | 20 | Zinc-Plated Steel | 2,500 psi @ 72° F | 000000000 | 00000 |

High-Pressure Compression Fittings for Steel Tubing

- For Use With: Hydraulic Fluid

- Specifications Met: DIN 2353, ISO 8434

Thicker walls make these fittings—sometimes called flareless or bite fittings—withstand about twice as much pressure as standard compression fittings, so they’re good for hydraulic power applications. Their single sleeve, or ferrule, bites into tubing as you tighten the nut, creating a seal that is leak tight even at high heat. The nut and sleeve are included. All meet ISO 8434 (formerly DIN 2353), which is an international standard for tube fitting pressures.

For technical drawings and 3-D models, click on a part number.

- Temperature Range: See table

- Tubing: Use with seamless steel

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD, mm | Wall Thickness | Pipe Size | Material | Maximum Pressure | Temperature Range, °F | Each | |

NPT Threads | |||||||

| 20 | Not Rated | 3/4 | Steel | 5,800 psi @ 72° F | -75° to 750° | 00000000 | 000000 |

- Temperature Range: See table

- Tubing: See table

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD, mm | Wall Thickness | Material | Maximum Pressure | Temperature Range, °F | For Tube Material | Each | |

| 20 | Not Rated | Steel | 6,000 psi @ 72° F | -75° to 750° | Steel | 00000000 | 000000 |

- Temperature Range: See table

- Tubing: See table

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD, mm | Wall Thickness | Material | Maximum Pressure | Temperature Range, °F | For Tube Material | Each | |

| 20 | Not Rated | Steel | 6,000 psi @ 72° F | -75° to 750° | Steel | 00000000 | 000000 |

- Temperature Range: -75° to 750° F

- Tubing: Use with seamless steel

| For Tube OD, mm | Material | Maximum Pressure | Each | |

| 20 | Steel | 6,000 psi @ 72° F | 00000000 | 000000 |

- Temperature Range: -75° to 750° F

- Tubing: Use with seamless steel

| For Tube OD, mm | Nut Material | Maximum Pressure | Each | |

| 20 | Steel | 6,000 psi @ 72° F | 0000000 | 00000 |

- Temperature Range: -75° to 750° F

- Tubing: Use with seamless steel

| For Tube OD, mm | Sleeve Material | Maximum Pressure | Each | |

| 20 | Steel | 6,000 psi @ 72° F | 0000000 | 00000 |

Nuts for High-Pressure Compression Fittings for Steel Tubing

- For Use With: Hydraulic Fluid

- Temperature Range: -75° to 750° F

- Tubing: Use with seamless steel

- Specifications Met: ISO 8434, DIN 2353

Pair these nuts with compression sleeves and high-pressure fittings. They withstand about twice as much pressure as nuts for standard compression fittings, so they’re good for hydraulic power applications. As you tighten the nut, the fitting’s sleeve, or ferrule, bites into the steel tubing and creates a strong seal. All meet ISO 8434 (formerly DIN 2353), which is an international standard for tube fitting pressures.

For technical drawings and 3-D models, click on a part number.

| For Tube OD, mm | Nut Material | Maximum Pressure | Each | |

| 20 | Steel | 6,000 psi @ 72° F | 0000000 | 00000 |

Sleeves for High-Pressure Compression Fittings for Steel Tubing

- For Use With: Hydraulic Fluid

- Temperature Range: -75° to 750° F

- Tubing: Use with seamless steel

- Specifications Met: ISO 8434, DIN 2353

Use these sleeves—also known as ferrules—with high-pressure compression nuts and fittings. They withstand about twice as much pressure as sleeves for standard compression fittings, so they’re good for hydraulic power applications. These sleeves bite into the steel tubing as you tighten the nut, creating a strong seal. All meet ISO 8434 (formerly DIN 2353), which is an international standard for tube fitting pressures.

For technical drawings and 3-D models, click on a part number.

| For Tube OD, mm | Sleeve Material | Maximum Pressure | Each | |

| 20 | Steel | 6,000 psi @ 72° F | 0000000 | 00000 |

Ultra-Chemical-Resistant PTFE Gaskets for Quick-Clamp Tube Fittings

Made of PTFE, these gaskets are chemically inert (except to molten alkali metal and elemental fluorine). They ensure a tight seal in quick-clamp stainless steel sanitary tube fittings.

Gaskets that meet DIN 32676 adhere to international standards for sanitary quick-clamp fittings.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | ID | OD | Thick. | Temperature Range, °F | Hardness | Hardness Rating | Color | Specifications Met | Each | |

| 10mm | 10.20mm | 34.00mm | 5.2mm | -100° to 500° | Durometer 63D | Extra Hard | White | DIN 32676, FDA Compliant 21 CFR 177.1550 | 000000000 | 000000 |

| 16mm | 16.20mm | 34.00mm | 5.2mm | -100° to 500° | Durometer 63D | Extra Hard | White | DIN 32676, FDA Compliant 21 CFR 177.1550 | 000000000 | 00000 |

| 20mm | 20.20mm | 34.00mm | 5.2mm | -100° to 500° | Durometer 63D | Extra Hard | White | DIN 32676, FDA Compliant 21 CFR 177.1550 | 000000000 | 00000 |

High-Temperature Silicone Gaskets for Quick-Clamp Tube Fittings

Even as temperatures rise, these silicone gaskets ensure a tight seal in quick-clamp stainless steel sanitary tube fittings. They withstand temperatures up to 450° F. These gaskets also resist water and salts.

Gaskets that meet DIN 32676 adhere to international standards for sanitary quick-clamp fittings.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | ID | OD | Thick. | Temperature Range, °F | Hardness | Hardness Rating | Color | Specifications Met | Each | |

| 10mm | 10.20mm | 36.17mm | 5.2mm | -40° to 450° | Durometer 75A | Hard | Clear | DIN 32676, FDA Compliant 21 CFR 177.2600 | 00000000 | 00000 |

| 16mm | 16.20mm | 36.17mm | 5.2mm | -40° to 450° | Durometer 75A | Hard | Clear | DIN 32676, FDA Compliant 21 CFR 177.2600 | 00000000 | 0000 |

| 20mm | 20.20mm | 36.17mm | 5.2mm | -40° to 450° | Durometer 75A | Hard | Clear | DIN 32676, FDA Compliant 21 CFR 177.2600 | 00000000 | 0000 |

Water- and Steam-Resistant EPDM Gaskets for Quick-Clamp Tube Fittings

When working in moist environments, these EPDM gaskets ensure a tight seal in quick-clamp stainless steel sanitary tube fittings.

Gaskets that meet DIN 32676 adhere to international standards for sanitary quick-clamp fittings.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | ID | OD | Thickness | Temperature Range, °F | Hardness | Hardness Rating | Color | Specifications Met | Each | |

| 10mm | 10.20mm | 34.00mm | 0.205" | -50° to 275° | Durometer 70A | Hard | Black | DIN 32676 | 0000000 | 000000 |

| 16mm | 16.20mm | 34.00mm | 0.205" | -50° to 275° | Durometer 70A | Hard | Black | DIN 32676 | 0000000 | 00000 |

| 20mm | 20.20mm | 34.00mm | 0.205" | -50° to 275° | Durometer 70A | Hard | Black | DIN 32676 | 0000000 | 00000 |