About On/Off Valves

More

How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

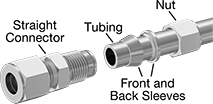

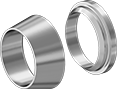

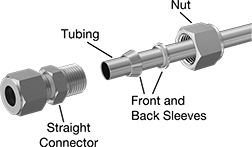

Yor-Lok Fittings for Stainless Steel Tubing

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

316 stainless steel fittings have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

- For Use With:

Inch:

NPT and BSPT Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

BSPP Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Mineral Oil, Water

UN/UNF (SAE Straight) Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil

Metric:

NPT, BSPT, and UN/UNF (SAE Straight) Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water - Tubing:

Inch:

NPT and UN/UNF (SAE Straight) Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

BSPP and BSPT Threads: Use with seamless 304 or 316 stainless steel that meets ASTM A269

Metric:

NPT and BSPT Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

UN/UNF (SAE Straight) Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | |||||||

| 1/16" | 0.02" | 1/16 | 316 Stainless Steel | 9,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

| 1/16" | 0.02" | 1/8 | 316 Stainless Steel | 9,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/16" | 0.01" to 0.028" | 1/4 | 316 Stainless Steel | 7,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing:

Inch:

NPT Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

BSPP and BSPT Threads: Use with seamless 304 or 316 stainless steel that meets ASTM A269

Metric:

NPT Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through your wall or panel to create an inlet or outlet.

For Tube | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Temp. Range, °F | For Hole Dia. | For Max. Wall Thick. | Each | |

NPT Threads | |||||||||

| 1/16" | 0.01" to 0.028" | 1/16 | 316 Stainless Steel | 9,000 psi @ 72° F | -420° to 1200° | 3/16" | 1/8" | 00000000 | 000000 |

| 1/16" | 0.01" to 0.028" | 1/8 | 316 Stainless Steel | 9,000 psi @ 72° F | -420° to 1200° | 3/16" | 1/8" | 00000000 | 00000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube (Metric) | For Tube (Inch) | |||||||

|---|---|---|---|---|---|---|---|---|

| OD, mm | Wall Thick., mm | OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Each | |

| 6 | 1 to 1.5 | 1/16" | 0.01" to 0.02" | 316 Stainless Steel | 6,000 psi @ 72° F | -420° to 1200° | 0000000 | 000000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

Fittings with tube stem insert into the tube end of another fitting in place of a length of tubing.

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/16" | 0.02" | 316 Stainless Steel | 9,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Bore Dia. | Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/16" | 0.02" | 0.013" | 316 Stainless Steel | 9,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through your wall or panel to create an inlet or outlet.

For Tube | ||||||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | For Hole Dia. | For Max. Wall Thick. | Each | |

| 1/16" | 0.02" | 316 Stainless Steel | 9,000 psi @ 72° F | -420° to 1200° | 3/16" | 1/8" | 00000000 | 000000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube (A) | For Tube (B) | |||||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/8" | 0.035" | 1/16" | 0.035" | 316 Stainless Steel | 6,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

| 3/16" | 0.035" | 1/16" | 0.035" | 316 Stainless Steel | 5,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/4" | 0.035" | 1/16" | 0.035" | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/8" | 0.035" | 1/16" | 0.035" | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

- For Use With:

NPT and BSPT Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

BSPP Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Mineral Oil, Water

UN/UNF (SAE Straight) Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil - Tubing:

NPT and UN/UNF (SAE Straight) Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

BSPP and BSPT Threads: Use with seamless 304 or 316 stainless steel that meets ASTM A269

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/16" | 0.02" | 316 Stainless Steel | 9,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/16" | 0.02" | 316 Stainless Steel | 9,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/16" | 0.02" | 316 Stainless Steel | 9,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

Caps for tubing have a nut and a sleeve so you can close off the end of your tubing in place of a fitting. Caps for fittings replace the nut and sleeve of an existing fitting.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/16" | 0.02" | 316 Stainless Steel | 9,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/8" | 0.035" | 316 Stainless Steel | 6,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 3/16" | 0.035" | 316 Stainless Steel | 5,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 1/4" | 0.035" | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 3/8" | 0.035" | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 6mm | 1mm | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/16" | 0.02" | 316 Stainless Steel | 9,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/8" | 0.035" | 316 Stainless Steel | 6,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 3/16" | 0.035" | 316 Stainless Steel | 5,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 1/4" | 0.035" | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 3/8" | 0.035" | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 6mm | 1mm | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

PTFE sleeves are plastic instead of stainless steel, so they won’t damage tubing.

| For Tube OD | Sleeve Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/16" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 000000 |

| 1/8" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 0000 |

| 3/16" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 00000 |

| 1/4" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 0000 |

| 3/8" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 0000 |

Tube supports are recommended for soft plastic tubing to prevent the tube from collapsing.

Front and Back Sleeves for Yor-Lok Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -420° to 1200° F

- Tubing: Use with seamless or welded 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Compatible With: Let-Lok, Parker A-Lok, Swagelok®

Use these sleeves with Yor-Lok nuts and fittings to create an extra-strong seal on stainless steel tubing. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

For technical drawings and 3-D models, click on a part number.

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Max. Pressure | Each | |

| 1/16" | 0.02" | 316 Stainless Steel | 9,000 psi @ 72° F | 00000000 | 00000 |

| 1/8" | 0.035" | 316 Stainless Steel | 6,000 psi @ 72° F | 00000000 | 0000 |

| 3/16" | 0.035" | 316 Stainless Steel | 5,500 psi @ 72° F | 00000000 | 0000 |

| 1/4" | 0.035" | 316 Stainless Steel | 4,000 psi @ 72° F | 00000000 | 0000 |

| 3/8" | 0.035" | 316 Stainless Steel | 2,500 psi @ 72° F | 00000000 | 0000 |

| 6mm | 1mm | 316 Stainless Steel | 4,000 psi @ 72° F | 00000000 | 0000 |

Nuts for Yor-Lok Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -420° to 1200° F

- Tubing: Use with seamless or welded 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Compatible With: Let-Lok, Parker A-Lok, Swagelok®

Use these nuts with Yor-Lok sleeves and fittings to create an extra-strong seal on stainless steel tubing. They are 316 stainless steel for excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Each | |

| 1/16" | 0.02" | 316 Stainless Steel | 9,000 psi @ 72° F | 00000000 | 00000 |

| 1/8" | 0.035" | 316 Stainless Steel | 6,000 psi @ 72° F | 00000000 | 0000 |

| 3/16" | 0.035" | 316 Stainless Steel | 5,500 psi @ 72° F | 00000000 | 0000 |

| 1/4" | 0.035" | 316 Stainless Steel | 4,000 psi @ 72° F | 00000000 | 0000 |

| 3/8" | 0.035" | 316 Stainless Steel | 2,500 psi @ 72° F | 00000000 | 0000 |

| 6mm | 1mm | 316 Stainless Steel | 4,000 psi @ 72° F | 00000000 | 0000 |

PTFE Sleeves for Yor-Lok Fittings

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -65° to 350° F

- Tubing: Use with firm or hard acetal plastic, EVA plastic, HDPE plastic, nylon plastic, PEEK plastic, polycarbonate plastic, polyethylene plastic, polypropylene plastic, PTFE plastic, PVC plastic, PVDF plastic, or THV plastic

- Compatible With: Let-Lok, Parker A-Lok, Swagelok®

Made of plastic, these sleeves create a strong seal without damaging tubing.

For technical drawings and 3-D models, click on a part number.

Compression Fittings for Stainless Steel Tubing

A single sleeve (ferrule) bites into tubing as you tighten the nut, creating a strong seal. The nut and sleeve are included. Fittings are also known as flareless fittings or bite fittings. Use them in low- to medium-pressure applications.

303 stainless steel fittings and 360 brass fittings have good corrosion resistance. Metric and UN/UNF (SAE Straight) male threads have a gasket to protect against leaks. UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

For technical drawings and 3-D models, click on a part number.

(SAE Straight) Male

Threads with Gasket

- For Use With:

303 Stainless Steel, 316 Stainless Steel with 17-4 PH Stainless Steel Sleeve, and 360 Brass: Air, Water, Hydraulic Fluid

316 Stainless Steel: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water - Temperature Range: See table

- Tubing: See table

- Specifications Met:

316 Stainless Steel: ISO 8434, DIN 2353

316 Stainless Steel with 17-4 PH Stainless Steel Sleeve: SAE J514

For Tube | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Thread Size | Material | Gasket Material | Sleeve Material | Max. Pressure | Temp. Range, °F | For Tube Material | For Tube Fabrication | Each | |

Metric Threads | |||||||||||

| 1/16" | 0.01" | M3 × 0.5 mm | 303 Stainless Steel | Fluoroelastomer Rubber | 303 Stainless Steel | 2,000 psi @ 72° F | -4° to 400° | 304 Stainless Steel, 316 Stainless Steel | Seamless, Welded | 0000000 | 000000 |

| 1/16" | 0.01" | M5 × 0.8 mm | 303 Stainless Steel | Fluoroelastomer Rubber | 303 Stainless Steel | 2,000 psi @ 72° F | -4° to 400° | 304 Stainless Steel, 316 Stainless Steel | Seamless, Welded | 0000000 | 00000 |

UN/UNF (SAE Straight) Threads | |||||||||||

| 1/16" | 0.01" | 10-32 | 303 Stainless Steel | Fluoroelastomer Rubber | 303 Stainless Steel | 2,000 psi @ 72° F | -4° to 400° | 304 Stainless Steel, 316 Stainless Steel | Seamless, Welded | 0000000 | 00000 |

| 1/16" | 0.01" | 10-32 | Nickel-Plated 360 Brass | Buna-N Rubber | 360 Brass | 2,000 psi @ 72° F | -40° to 250° | 304 Stainless Steel, 316 Stainless Steel | Seamless, Welded | 0000000 | 00000 |

Precision Compression Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -420° to 1200° F

- Tubing: Use with welded or seamless 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Compatible With: Parker CPI

Made to tighter tolerances than other compression fittings, these are designed for high-precision applications. Also known as instrumentation fittings and flareless fittings. They come with a nut and a single sleeve (ferrule). The sleeve bites into tubing as you tighten the nut to create a strong seal. Fittings are 316 stainless steel for excellent corrosion resistance. A molybdenum disulfide coating on the nut acts as a lubricant for easy installation.

For technical drawings and 3-D models, click on a part number.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Each | |

| 1/16" | 0.02" | 1/16 | 316 Stainless Steel | 7,500 psi @ 72° F | 0000000 | 000000 |

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Each | |

| 1/16" | 0.02" | 1/16 | 316 Stainless Steel | 7,500 psi @ 72° F | 00000000 | 000000 |

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Each | |

| 1/16" | 0.02" | 316 Stainless Steel | 7,500 psi @ 72° F | 0000000 | 000000 |

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Each | |

| 1/16" | 0.02" | 1/16 | 316 Stainless Steel | 7,500 psi @ 72° F | 0000000 | 000000 |

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Each | |

| 1/16" | 0.02" | 316 Stainless Steel | 7,500 psi @ 72° F | 0000000 | 000000 |

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Each | |

| 1/16" | 0.02" | 316 Stainless Steel | 7,500 psi @ 72° F | 0000000 | 000000 |

Caps for tubing have a nut and a sleeve so you can close off the end of your tubing in place of a fitting. Caps for fittings replace the nut and sleeve of an existing fitting.

For Tube | ||||

|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | |

| 1/16" | 0.02" | Molybdenum-Disulfide-Coated 316 Stainless Steel | 7,500 psi @ 72° F | 00000000 |

For Tube | ||||

|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Max. Pressure | |

| 1/16" | 0.02" | 316 Stainless Steel | 7,500 psi @ 72° F | 00000000 |

Sleeves for Precision Compression Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -420° to 1200° F

- Tubing: Use with seamless or welded 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Compatible With: Parker CPI

Use these sleeves with precision compression nuts and fittings to create a strong seal on stainless steel tubing. Made to tighter tolerances than other sleeves, these are designed for high-precision applications. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

For technical drawings and 3-D models, click on a part number.

For Tube | ||||

|---|---|---|---|---|

| OD | Wall Thick. | Max. Pressure | Each | |

| 1/16" | 0.02" | 7,500 psi @ 72° F | 00000000 | 00000 |

Nuts for Precision Compression Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -420° to 1200° F

- Tubing: Use with seamless or welded 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Compatible With: Parker CPI

Use these nuts with precision compression sleeves and fittings to create a strong seal on stainless steel tubing. Made to tighter tolerances than other nuts, these are designed for high-precision applications. Nuts are 316 stainless steel for excellent corrosion resistance. They have a molybdenum disulfide coating that acts as a lubricant for easy installation.

For technical drawings and 3-D models, click on a part number.

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Each | |

| 1/16" | 0.02" | 316 Stainless Steel | 7,500 psi @ 72° F | 00000000 | 00000 |

Quick-Turn Couplings for Stainless Steel Tubing

- For Use With: Air

- Temperature Range: 32° to 350° F

- Tubing: Use with 304/304L or 316/316L stainless steel

Also known as luer lock couplings, these consist of a plug and socket that connect to small-diameter tubing with a half turn. They have a compact body for easy installation in tight spaces. Insert tubing into the plug or socket and tighten the nut to form a seal. Couplings are open-flow style, so there is no shut-off valve to stop the flow when the coupling is separated. They are 316 stainless steel for excellent corrosion resistance.

Note: For a complete coupling, order a plug and a socket.

For technical drawings and 3-D models, click on a part number.

Precision Compression Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -40° to 350° F

- Tubing: Use with seamless copper that meets ASTM B68, ASTM B75, or ASTM B88

- Compatible With: Parker CPI

Made to tighter tolerances than other compression fittings, these are designed for high-precision applications. They are also known as instrumentation fittings and flareless fittings. They come with a nut and a single sleeve (ferrule). The sleeve bites into tubing as you tighten the nut to create a strong seal. The nut has a molybdenum disulfide coating that acts as a lubricant for easy installation. Fittings are brass for good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Each | |

NPT Threads | ||||||

| 1/16" | 0.014" | 1/16 | Brass | 2,600 psi @ 72° F | 0000000 | 000000 |

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Each | |

NPT Threads | ||||||

| 1/16" | 0.02" | 1/16 | Brass | 3,800 psi @ 72° F | 00000000 | 00000 |

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Each | |

| 1/16" | 0.02" | Brass | 3,800 psi @ 72° F | 00000000 | 000000 |

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Each | |

| 1/16" | 0.02" | Brass | 3,800 psi @ 72° F | 00000000 | 00000 |

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Max. Pressure | Each | |

| 1/16" | 0.02" | Brass | 3,800 psi @ 72° F | 00000000 | 00000 |

Nuts for Precision Compression Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -40° to 350° F

- Tubing: Use with seamless copper that meets ASTM B68, ASTM B75, or ASTM B88

- Compatible With: Parker CPI

Use these nuts with precision compression sleeves and fittings to create a strong seal on copper tubing. Made to tighter tolerances than other nuts, they are designed for high-precision applications. Nuts have a molybdenum disulfide coating that acts as a lubricant for easy installation. They are brass for good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Each | |

| 1/16" | 0.02" | Brass | 3,800 psi @ 72° F | 00000000 | 00000 |

Sleeves for Precision Compression Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -40° to 350° F

- Tubing: Use with seamless copper that meets ASTM B68, ASTM B75, or ASTM B88

- Compatible With: Parker CPI

Use these sleeves with precision compression nuts and fittings to create a strong seal on copper tubing. Made to tighter tolerances than other sleeves, they are designed for high-precision applications. Sleeves are brass for good corrosion resistance. They are also known as ferrules.

For technical drawings and 3-D models, click on a part number.

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Max. Pressure | Each | |

| 1/16" | 0.02" | Brass | 3,800 psi @ 72° F | 00000000 | 00000 |

Yor-Lok Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -40° to 400° F

- Tubing: Use with seamless copper

- Specifications Met: ASME B31.3

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. Fittings are brass for good corrosion resistance. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

For technical drawings and 3-D models, click on a part number.

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Each | |

| 1/16" | 0.028" | Brass | 5,400 psi @ 72° F | 00000000 | 000000 |

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through your wall or panel to create an inlet or outlet.

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Each | |

| 1/16" | 0.028" | Brass | 5,400 psi @ 72° F | 00000000 | 000000 |

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Each | |

| 1/16" | 0.028" | Brass | 5,400 psi @ 72° F | 00000000 | 000000 |

Caps for fittings replace the nut and sleeve of an existing fitting.

For Tube | For Fitting | ||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Each | |

| 1/16" | 0.028" | Brass | 5,400 psi @ 72° F | 00000000 | 00000 |

Nuts for Yor-Lok Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -40° to 400° F

- Tubing: Use with seamless copper

- Specifications Met: ASME B31.3

- Compatible With: Let-Lok, Parker A-Lok, Swagelok®

Use these nuts with Yor-Lok sleeves and fittings to create an extra-strong seal on copper tubing. They are brass for good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Front and Back Sleeves for Yor-Lok Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -40° to 400° F

- Tubing: Use with seamless copper

- Specifications Met: ASME B31.3

- Compatible With: Let-Lok, Parker A-Lok, Swagelok®

Use these sleeves with Yor-Lok nuts and fittings to create an extra-strong seal on copper tubing. Sleeves are brass for good corrosion resistance. They are also known as ferrules.

For technical drawings and 3-D models, click on a part number.

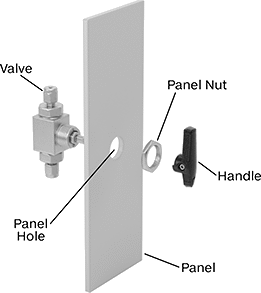

Panel-Mount On/Off Valves with Yor-Lok Fittings

Easily access the handle of these valves while protecting your line behind an instrument panel. Threads and a hex nut below the handle allow you to install these valves in instrument panels. For extra gripping power and a strong seal, they have Yor-Lok fittings with two sleeves that bite into tubing as you tighten the nut. All are compatible with Swagelok®, Let-Lok, and Parker A-Lok fittings. Valves are standard port, so they slightly restrict flow.

316 stainless steel valves are more corrosion resistant than brass valves.

PTFE seals are the best choice for valves that are opened and closed often. The PTFE material forms a seal while remaining slippery, so you can open and close the valve frequently without the seal wearing down and failing.

PFA seals withstand high pressures and temperature changes. The plastic of the seal is nonporous, so it won’t trap gases or liquids that would weaken these seals.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Ball

- For Use With: See Table

| For Tube OD | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | Panel Cutout Dia. | For Use With | Each | |

316 Stainless Steel Body—PFA Plastic Seal | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Yor Lok × Yor Lok | ||||||||||

| 1/16" | 0.03 | 1000 psi @ 300° F | 50 psi @ 300° F | -65° to 300° | Not Rated | 1 11/16" | 19/32" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | 0000000 | 0000000 |

316 Stainless Steel Body—PTFE Plastic Seal | ||||||||||

Yor Lok × Yor Lok | ||||||||||

| 1/16" | 0.1 | 6000 psi @ 125° F | __ | -30° to 280° | 29 | 2 3/4" | 3/4" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | 00000000 | 000000 |