How to Measure Threaded Pipe Size

More

How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

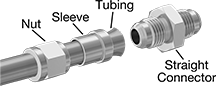

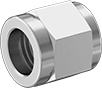

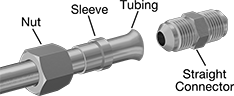

Yor-Lok Fittings for Stainless Steel Tubing

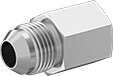

(SAE Straight) Male

Threads with Gasket

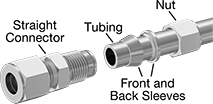

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

316 stainless steel fittings have excellent corrosion resistance.

BSPP and UN/UNF (SAE Straight) male threads have a gasket to protect against leaks. UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

For technical drawings and 3-D models, click on a part number.

(SAE Straight) Male

Threads with Gasket

- For Use With:

Inch:

NPT and BSPT Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

BSPP Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Mineral Oil, Water

UN/UNF (SAE Straight) Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil

Metric:

NPT, BSPT, and UN/UNF (SAE Straight) Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water - Tubing:

Inch:

NPT and UN/UNF (SAE Straight) Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

BSPP and BSPT Threads: Use with seamless 304 or 316 stainless steel that meets ASTM A269

Metric:

NPT and BSPT Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

UN/UNF (SAE Straight) Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube | ||||||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Thread Size | Material | Gasket Material | Max. Pressure | Temp. Range, °F | Each | |

UN/UNF (SAE Straight) Threads | ||||||||

| 1/8" | 0.035" | 5/16"-24 | 316 Stainless Steel | Fluoroelastomer Rubber | 6,000 psi @ 72° F | -15° to 400° | 00000000 | 000000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Specifications Met: SAE J514

For Tube (Yor-Lok) | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | For Tube OD (Flared) | Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/8" | 0.035" | 1/8" | 316 Stainless Steel | 6,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

For Tube | ||||||

|---|---|---|---|---|---|---|

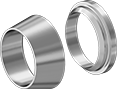

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/8" | 0.035" | 316 Stainless Steel | 6,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/8" | 0.035" | 316 Stainless Steel | 6,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| For Tube OD | Sleeve Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/8" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 00000 |

Tube supports are recommended for soft plastic tubing to prevent the tube from collapsing.

For Tube | |||||

|---|---|---|---|---|---|

| OD | ID | Tube Support Material | Temp. Range, °F | Each | |

| 1/4" | 1/8" | 316 Stainless Steel | -420° to 1200° | 00000000 | 00000 |

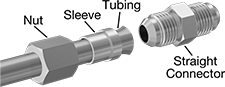

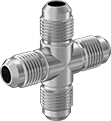

37° Flared Fittings for Stainless Steel Tubing

- Tubing: Use with welded or seamless 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Specifications Met: ISO 8434, SAE J514, except fittings with BSPP and BSPT threads meet SAE J514 only

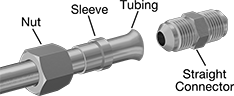

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They withstand high pressure, so they’re often used in hydraulic applications. Made from 316 stainless steel, they resist corrosion from water and chemicals. A complete fitting requires a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

BSPP threads and UN/UNF (SAE Straight) male threads have a gasket to protect against leaks. UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

For technical drawings and 3-D models, click on a part number.

- For Use With: See table

- Temperature Range: See table

| For Tube OD | Pipe Size | Thread Size | For Use With | Material | Gasket Material | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/8" | 1/8 | __ | Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water | 316 Stainless Steel | __ | 6,000 psi @ 72° F | -420° to 1200° | 000000000 | 000000 |

UN/UNF (SAE Straight) Threads | |||||||||

| 1/8" | __ | 5/16"-24 | Air, Hydraulic Fluid, Isopropyl Alcohol, Water | 316 Stainless Steel | Fluoroelastomer Rubber | 6,000 psi @ 72° F | -15° to 400° | 000000000 | 00000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: See table

| For Tube OD | Pipe Size | Material | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | ||||||

|---|---|---|---|---|---|---|

| 1/8" | 1/8 | 316 Stainless Steel | 6,000 psi @ 72° F | -420° to 1200° | 000000000 | 000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: See Table

| For Tube OD | Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/8" | 316 Stainless Steel | 6,000 psi @ 72° F | -420° to 1200° | 000000000 | 000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: See table

Fittings that swivel until tightened have a built-in nut that rotates 360° for easy installation.

Fittings with female tube end have an internal flare that mates with the male tube end of another fitting.

| For Tube OD | Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/8" | 316 Stainless Steel | 6,000 psi @ 72° F | -420° to 1200° F | 000000000 | 0000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: See table

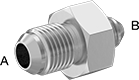

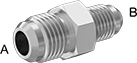

| For Tube OD (A) | For Tube OD (B) | Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/4" | 1/8" | 316 Stainless Steel | 5,000 psi @ 72° F | -380° to 800° | 000000000 | 00000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1200°

Fittings with female tube end have an internal flare that mates with the male tube end of another fitting.

| For Tube OD (A) | For Tube OD (B) | Material | Max. Pressure | Each | |

| 1/4" | 1/8" | 316 Stainless Steel | 6,000 psi @ 72° F | 000000000 | 000000 |

- For Use With: See table

- Temperature Range: See table

| For Tube OD | Pipe Size | For Use With | Material | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/8" | 1/8 | Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water | 316 Stainless Steel | 5,000 psi @ 72° F | -420° to 1200° | 000000000 | 000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: See table

| For Tube OD | Pipe Size | Material | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | ||||||

|---|---|---|---|---|---|---|

| 1/8" | 1/8 | 316 Stainless Steel | 5,000 psi @ 72° F | -420° to 1200° | 000000000 | 0000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

| For Tube OD | Material | Max. Pressure | Each | |

| 1/8" | 316 Stainless Steel | 5,000 psi @ 72° F | 000000000 | 0000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: See table

| For Tube OD | Material | Temp. Range, °F | Each | |

| 1/8" | 316 Stainless Steel | -420° to 1200° | 000000000 | 000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: See table

| For Tube OD | Material | Temp. Range, °F | Each | |

| 1/8" | 316 Stainless Steel | -420° to 1200° | 000000000 | 000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on stainless steel tubing that is flared to 37°. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

Inch × metric sleeve adapters convert the fitting from inch to metric.

Nuts for 37° Flared Fittings for Stainless Steel Tubing

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

- Tubing: Use with seamless or welded 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Specifications Met: ISO 8434, SAE J514

Use these nuts with a sleeve and fitting to provide a tight metal-to-metal seal on stainless steel tubing that is flared to 37°. Nuts are 316 stainless steel for excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

37° Flared Fittings with Thread Sealant for Stainless Steel Tubing

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range:

Adapters: -420° to 450° F

Sleeves and Nuts: -420° to 1,200° F - Tubing: Use with seamless or welded 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Specifications Met: ISO 8434, SAE J514, except fittings with BSPT threads meet SAE J514 only

The male pipe threads on these fittings have a sealant applied for extra protection against leaks. Also known as JIC (Joint Industrial Council) fittings, they provide a tight metal-to-metal seal on tubing that is flared to 37°. They’re often used in hydraulic applications. Made from 316 stainless steel, these fittings have excellent corrosion resistance. A complete fitting requires a nut and a sleeve (ferrule) for each tube end—tighten the nut to create a secure seal that withstands high pressure. Nuts and sleeves are sold separately.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | Pipe Size | Material | Max. Pressure | Each | |

NPT Threads | |||||

|---|---|---|---|---|---|

| 1/8" | 1/8 | 316 Stainless Steel | 6,000 psi @ 72° F | 000000000 | 000000 |

| For Tube OD | Pipe Size | Material | Max. Pressure | Each | |

NPT Threads | |||||

|---|---|---|---|---|---|

| 1/8" | 1/8 | 316 Stainless Steel | 5,000 psi @ 72° F | 000000000 | 000000 |

| For Tube OD | Pipe Size | Material | Max. Pressure | Each | |

NPT Threads | |||||

|---|---|---|---|---|---|

| 1/8" | 1/8 | 316 Stainless Steel | 5,000 psi @ 72° F | 000000000 | 0000000 |

| For Tube OD | Nut Material | Each | |

| 1/8" | 316 Stainless Steel | 000000000 | 000000 |

| For Tube OD | Sleeve Material | Each | |

| 1/8" | 316 Stainless Steel | 000000000 | 00000 |

Precision AN 37° Flared Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -320° to 1200° F

- Tubing: Use with seamless 304 or 316 stainless steel

- Specifications Met: See Table

The threads on the tube end of these fittings are Class 3A or 3B and adhere to tighter tolerances than other 37° flared fittings. They are made to exact AS (formerly AN) specifications and provide a tight metal-to-metal seal on tubing that is flared to 37°. Fittings require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through your wall or panel to create an inlet or outlet.

| For Tube OD | Max. Pressure | Specifications Met | For Hole Dia. | For Max. Wall Thick. | Each | |

304 Stainless Steel | ||||||

|---|---|---|---|---|---|---|

| 1/8" | 3,000 psi @ 72° F | AN832-2J, ASTM A380, SAE AS4841 | 5/16" | 3/32" | 00000000 | 000000 |

| For Tube OD | Pipe Size | Max. Pressure | Specifications Met | Each | |

304 Stainless Steel | |||||

|---|---|---|---|---|---|

ANPT Threads | |||||

| 1/8" | 1/8 | 3,000 psi @ 72° F | ASTM A380, MS20822-2J, SAE AS4841, SAE AS9100D, SAE AS9104/1 | 00000000 | 000000 |

| For Tube OD | Max. Pressure | Specifications Met | Each | |

304 Stainless Steel | ||||

|---|---|---|---|---|

| 1/8" | 3,000 psi @ 72° F | AN821-2J, ASTM A380, SAE AS4841 | 0000000 | 000000 |

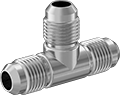

Inline tees are also known as branch tees.

| For Tube OD | Pipe Size | Max. Pressure | Specifications Met | Each | |

304 Stainless Steel | |||||

|---|---|---|---|---|---|

ANPT Threads | |||||

| 1/8" | 1/8 | 3,000 psi @ 72° F | ASTM A380, SAE AS4841, SAE AS9104/1, MS20825-2J, SAE AS9100D | 00000000 | 000000 |

| For Tube OD | Max. Pressure | Specifications Met | Each | |

304 Stainless Steel | ||||

|---|---|---|---|---|

| 1/8" | 3,000 psi @ 72° F | AN827-2J, ASTM A380, SAE AS4841 | 00000000 | 0000000 |

| For Tube OD | Max. Pressure | Specifications Met | Each | |

304 Stainless Steel | ||||

|---|---|---|---|---|

| 1/8" | 3,000 psi @ 72° F | AN818-2J, ASTM A380, SAE AS4841 | 0000000 | 00000 |

| 1/4" | 3,000 psi @ 72° F | AN818-4J, ASTM A380, SAE AS4841 | 0000000 | 0000 |

316 Stainless Steel | ||||

| 1/8" | 3,000 psi @ 72° F | AN818-2K, ASTM A380, SAE AS4841 | 00000000 | 00000 |

| 1/4" | 3,000 psi @ 72° F | AN818-4K, ASTM A380, SAE AS4841 | 00000000 | 00000 |

| For Tube OD | Max. Pressure | Specifications Met | Each | |

304 Stainless Steel | ||||

|---|---|---|---|---|

| 1/8" | 3,000 psi @ 72° F | AN819-2J, ASTM A380, MS20819, SAE AS4841, SAE AS5176 | 0000000 | 00000 |

| 1/4" | 3,000 psi @ 72° F | AN819-4J, ASTM A380, MS20819, SAE AS4841, SAE AS5176 | 0000000 | 0000 |

316 Stainless Steel | ||||

| 1/8" | 3,000 psi @ 72° F | AN819-2K, ASTM A380, MS20819, SAE AS4841, SAE AS5176 | 00000000 | 0000 |

| 1/4" | 3,000 psi @ 72° F | AN819-4K, ASTM A380, MS20819, SAE AS4841, SAE AS5176 | 00000000 | 0000 |

Nuts for Precision AN 37° Flared Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -320° to 1200° F

- Tubing: Use with seamless 304 or 316 stainless steel

- Specifications Met: See Table

Use these nuts with precision AN sleeves and fittings to provide a tight metal-to-metal seal on stainless steel tubing that is flared to 37°. The threads are Class 3B and adhere to tighter tolerances than other nuts. They are made to exact AS (formerly AN) specifications.

304 stainless steel nuts have very good corrosion resistance. 316 stainless steel nuts have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | Max. Pressure | Specifications Met | Each | |

304 Stainless Steel | ||||

|---|---|---|---|---|

| 1/8" | 3,000 psi @ 72° F | AN818-2J, ASTM A380, SAE AS4841 | 0000000 | 00000 |

| 1/4" | 3,000 psi @ 72° F | AN818-4J, ASTM A380, SAE AS4841 | 0000000 | 0000 |

316 Stainless Steel | ||||

| 1/8" | 3,000 psi @ 72° F | AN818-2K, ASTM A380, SAE AS4841 | 00000000 | 00000 |

| 1/4" | 3,000 psi @ 72° F | AN818-4K, ASTM A380, SAE AS4841 | 00000000 | 00000 |

45° Flared Fittings for Copper and Brass Tubing

- Temperature Range: -65° to 250° F

- Tubing: Use with seamless brass and copper that meets ASTM B280

No sleeve is required to assemble these fittings, which makes for a faster, more convenient installation compared to 37° flared fittings. They require a nut (sold separately) for each tube end. Fittings are also known as refrigeration and SAE fittings. They are brass for good corrosion resistance.

NPTF (Dryseal) threads are compatible with NPT threads.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water; except adapters for 1/8" and 1" tube OD are not for use with fuel oil

- Specifications Met: See table

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Specifications Met | Each | |

NPTF Threads | |||||||

| 1/8" | 0.03" | 1/8 | Brass | 2,800 psi @ 73° F | SAE J512, SAE J513 | 000000000 | 00000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water; except adapters for 5/8" and 3/4" tube OD are not for use with fuel oil

- Specifications Met: See table

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Specifications Met | Each | |

NPTF Threads | |||||||

| 1/8" | 0.03" | 1/8 | Brass | 2,800 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 000000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: SAE J512, SAE J513, UL Listed

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Each | |

| 1/8" | 0.03" | Brass | 2,800 psi @ 72° F | 000000000 | 00000 |

- For Use With:

Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water - Specifications Met: SAE J512, SAE J513, UL Listed

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Each | |

NPTF Threads | ||||||

| 1/8" | 0.03" | 1/8 | Brass | 2,800 psi @ 72° F | 000000000 | 00000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: SAE J512, SAE J513, UL Listed

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Each | |

| 1/8" | 0.03" | Brass | 2,800 psi @ 72° F | 000000000 | 000000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: SAE J512, SAE J513, UL Listed

Inline tees are also known as branch tees.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Each | |

NPTF Threads | ||||||

| 1/8" | 0.03" | 1/8 | Brass | 2,800 psi @ 72° F | 000000000 | 000000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water;

except caps for 1/8" tube OD are only for use with refrigerant - Specifications Met: See table

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Each | |

| 1/8" | 0.03" | Brass | 2,800 psi @ 73° F | 000000000 | 00000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water; except nuts for 1" tube OD are not for use with fuel oil

- Specifications Met: SAE J512, SAE J513, UL Listed; except nuts for 1" tube OD meet SAE J512 and SAE J513 only

Nuts for 45° Flared Fittings for Copper and Brass Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water; except nuts for 1" tube OD are not for use with fuel oil

- Temperature Range: -65° to 250° F

- Tubing: Use with seamless brass and copper that meets ASTM B280

- Specifications Met: SAE J512, SAE J513, UL Listed; except nuts for 1" tube OD meet SAE J512 and SAE J513 only

Use these nuts with 45° flared tube fittings to provide a tight metal-to-metal seal on flared copper and brass tubing. Nuts are brass for good corrosion resistance. They don’t require a sleeve, which makes for a fast, convenient installation.

Long nuts support more of the tube’s surface area than short nuts for a strong grip in high-vibration applications.

For technical drawings and 3-D models, click on a part number.

37° Flared Fittings for Copper Tubing

- For Use With: Air, Fuel Oil, Mineral Oil, Water

- Temperature Range: -40° to 400° F

- Tubing: Use with seamless copper

- Specifications Met: ISO 8434, MIL-F-18866, SAE J514

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They can handle higher pressures than 45° flared fittings. Fittings are brass for good corrosion resistance. They require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | Lg. | Material | Max. Pressure | Each | |

| 1/8" | 1 11/64" | 360 Brass | 3,300 psi @ 72° F | 000000000 | 00000 |

Nuts for 37° Flared Fittings for Copper Tubing

- For Use With: Air, Fuel Oil, Mineral Oil, Water

- Temperature Range: -40° to 400° F

- Tubing: Use with seamless copper

- Specifications Met: ISO 8434, MIL-F-18866, SAE J514

Use these nuts with a sleeve and fitting to provide a tight metal-to-metal seal on copper tubing that is flared to 37°. They are brass for good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | Nut Material | Each | |

| 1/8" | 360 Brass | 00000000 | 00000 |

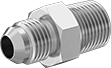

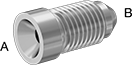

37° Flared Fittings for Steel Tubing

Male Threads

with Gasket

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil

- Tubing: Use with seamless steel

- Specifications Met: SAE J514

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately. Fittings are zinc-plated steel for fair corrosion resistance.

NPTF (Dryseal) threads are compatible with NPT threads.

To prevent leaks, UN/UNF (SAE Straight) male threads have a gasket. Metric and BSPP male threads have either a gasket or a gasket and washer. UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

For technical drawings and 3-D models, click on a part number.

Male Threads

with Gasket

- Temperature Range: See table

- Temperature Range: -60° to 400° F

| For Tube OD | Pipe Size | Material | Max. Pressure | Each | |

NPTF Threads | |||||

|---|---|---|---|---|---|

| 1/8" | 1/8 | Zinc-Plated Steel | 5,000 psi @ 72° F | 00000000 | 000000 |

- Temperature Range: -60° to 400° F

| For Tube OD | Material | Max. Pressure | Each | |

| 1/8" | Zinc-Plated Steel | 5,000 psi @ 72° F | 000000000 | 000000 |

- Temperature Range: -60° to 400° F

| For Tube OD (A) | For Tube OD (B) | Material | Max. Pressure | Each | |

| 1/4" | 1/8" | Zinc-Plated Steel | 7,500 psi @ 72° F | 000000000 | 00000 |

- Temperature Range: -60° to 400° F

| For Tube OD | Material | Max. Pressure | Each | |

| 1/8" | Zinc-Plated Steel | 1,250 psi @ 72° F | 000000000 | 00000 |

- Temperature Range: -60° to 400° F

| For Tube OD | Material | Max. Pressure | Each | |

| 1/8" | Zinc-Plated Steel | 1,250 psi @ 72° F | 000000000 | 00000 |

- Temperature Range: -60° to 400° F

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on steel tubing that is flared to 37°. Sleeves are zinc-plated steel for fair corrosion resistance. They are also known as ferrules.

Inch × metric sleeve adapters convert the fitting from inch to metric.

Nuts for 37° Flared Fittings for Steel Tubing

- For Use With: Air, Fuel Oil, Hydraulic Fluid, Mineral Oil

- Temp. Range: -60° to 400° F

- Tubing: Use with seamless steel

- Specifications Met: SAE J514

Use these nuts with a sleeve and fitting to provide a tight metal-to-metal seal on steel tubing that is flared to 37°. They are zinc-plated steel for fair corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Crimp-On Hose Fittings for Hydraulic Fluid

Crimp these fittings onto hydraulic hose for a permanent, leak-tight connection. Since they crimp on, they handle higher pressure than screw-on fittings. To install, use Parker crimping tools and dies (not included).

Fittings with a female end swivel 360° until tightened without you needing to move or twist the entire hose, making them easy to install.

Fittings with a 37° flared end are also known as JIC (Joint Industrial Council) fittings.

Note: Fittings are only for use with hydraulic hose.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: See table

- Temperature Range: -40° to 210° F

- For Hose Manufacturer Series:

Parker 43 Series Fittings: 302 SAE J517 100R2AT, 422 SAE J517 100R1AT, 487 ISO17582-AC, 777 ISO17582-CC

Parker 56 Series Fittings: 510D J517 SAE 100R7, 518D J517 SAE 100R7

For Hose | |||||||

|---|---|---|---|---|---|---|---|

| ID | OD | For Tube OD | Thread Size | Dash Size | Max. Pressure | Each | |

Zinc-Plated Steel—Parker 56 Series | |||||||

| 1/8" | 5/16" | 1/8" | 5/16"-24 | 02 | 3,000 psi @ 72° F | 0000000 | 000000 |

Straight-Flow Rectangular Manifolds

Unlike other manifolds, which have an inlet on either end, these have one inlet on the opposite side from the outlets. This design allows fluid or air to follow a straight path, improving flow through your system. It also frees up the ends of the manifold, so you can mount it in corners and in narrow spaces. Manifolds are also known as headers. They have mounting holes, so you can mount from the top or side.

Anodized aluminum manifolds are the industry standard for the most common types of applications. They are lighter in weight than other metal manifolds and have good corrosion resistance. These manifolds are anodized for a black finish.

Use a plug (sold separately) to close off any unused inlets and outlets.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water, Hydraulic Fluid

- Temperature Range: -10° to 200° F

- Maximum Pressure:

Air: 1,000 psi @ 72° F

Water: 1,000 psi @ 72° F

Hydraulic Fluid: 3,000 psi @ 72° F

Inlet | Outlet | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Thread Size | Dash Size | Thread Size | Dash Size | Lg. | Wd. | Ht. | Outlet Ctr.-to-Ctr. | Color | Each | |

Standard Outlet Spacing | |||||||||||

| 8 | 7/16"-20 | 4 | 5/16"-24 | 2 | 6 1/4" | 1" | 1" | 3/4" | Black | 00000000 | 000000 |

| Thread Size | Drive | Pressure Class | Max. Pressure | Each | |

Aluminum—UNF | |||||

|---|---|---|---|---|---|

| 7/16"-20 | External Hex | 150 | 150 psi @ 72° F | 00000000 | 00000 |

Low-Profile Square Manifolds

With outlets on the side instead of on top, these manifolds have a lower profile than rectangular manifolds and fit well in cramped spaces. Use them to distribute air, water, or hydraulic fluid to three locations from a single supply source. Manifolds have mounting holes, so you can mount from the top.

Anodized aluminum manifolds are the industry standard for the most common types of applications. They are lighter in weight than other metal manifolds and have good corrosion resistance. These manifolds are anodized for a black finish.

Use a plug (sold separately) to close off any unused inlets and outlets.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water, Hydraulic Fluid

- Temperature Range: -10° to 200° F

- Maximum Pressure: 1,000 psi @ 72° F

- Maximum Vacuum: 27 in. of Hg @ 72° F

Inlet | Outlet | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Thread Size | Dash Size | Thread Size | Dash Size | Lg. | Wd. | Ht. | Color | Each | |

| 3 | 7/16"-20 | 04 | 5/16"-24 | 02 | 1 1/2" | 1 1/2" | 3/4" | Black | 0000000 | 000000 |

| Thread Size | Drive | Length | Max. Pressure | Each | |

Aluminum—UNF | |||||

|---|---|---|---|---|---|

| 7/16"-20 | External Hex | 1/2" | 150 psi @ 72° F | 00000000 | 00000 |