Selecting and Measuring Expansion Joints

For information about selecting pipe size, see Selecting and Measuring Pipe & Fittings.

More

How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Vacuum Fittings for Steel Tubing

- For Use With: Air, Glass, Plastic Pellets, Resins, Wood Chips

- Temperature Range: -10° to 180° F

- Tubing: Galvanized Steel: Use with steel, galvanized steel

Steel: Use with steel

Use these fittings to create an air vacuum system without the hassle of brazing and welding. Insert two fittings into a clamp (sold separately) and tighten to form a secure seal.

Galvanized steel fittings have fair corrosion resistance. Fittings without a finish should only be used in noncorrosive environments.

For technical drawings and 3-D models, click on a part number.

Easy-Fit Barbed Hose Fittings for Air and Water

Low-profile barbs and a longer first barb allow for a smoother, easier installation than other barbed fittings. Slide the barbed end into rubber hose and secure with a clamp.

Steel fittings are stronger and more durable than other metal fittings. They should be used in noncorrosive environments. Zinc-plated steel fittings have slightly better corrosion resistance than unplated steel fittings. Fittings with a threaded end are also known as hose nipples.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: 125 psi @ 72° F, except For 5" to 8" Hose IDs: 100 psi @ 72° F

- Maximum Vacuum: For 1/2" to 4" Hose IDs: 26 in. of Hg @ 72° F

- Temperature Range: -20° to 200° F

- Attachment Type: Use Worm-Drive Clamps, Bolt Clamps or Band-and-Buckle Clamps

- Specifications Met: See table

Metal Cam-and-Groove Hose Couplings for Water

A complete coupling consists of a plug and a socket (both sold separately) that allow you to quickly connect and disconnect medium-to large-diameter hose lines. To connect, insert the plug into the socket and press the levers down. The levers fit snugly into the groove on the plug’s body and force the plug against the gasket to form a tight seal. To disconnect, lift both levers and pull out the plug.

Plugs with male threaded end are also known as F adapters.

Plugs with female threaded end are also known as A adapters.

Couplings with locking levers prevent accidental disconnection. The locks engage automatically when the coupling is connected. Press the locks simultaneously to disengage.

Straight sockets with female threaded end are also known as D couplers.

Aluminum couplings are lighter in weight than brass plugs and sockets. They have good abrasion and corrosion resistance. Brass couplings are softer than aluminum plugs and sockets, so they’re easier to thread together. They have good corrosion resistance.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

Warning: Relieve all pressure before disconnecting the couplings. Do not use cam-and-groove couplings with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Specifications Met: Fed. Spec. A-A-59326

- Compatible With: Andrews Cam-and-Groove Couplings, Dixon Cam-and-Groove Couplings, Ever-Tite Cam-and-Groove Couplings, PT Coupling Cam-and-Groove Couplings

| Coupling Size | Plug OD | Pipe Size | Max. Pressure | Each | |

Anodized Aluminum | |||||

|---|---|---|---|---|---|

| 5 | 5 3/4" | 5 | 75 psi @ 72° F | 00000000 | 0000000 |

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Specifications Met: Fed. Spec. A-A-59326

- Compatible With: Andrews Cam-and-Groove Couplings, Dixon Cam-and-Groove Couplings, Ever-Tite Cam-and-Groove Couplings, PT Coupling Cam-and-Groove Couplings

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Specifications Met: Fed. Spec. A-A-59326

- Compatible With: Andrews Cam-and-Groove Couplings, Dixon Cam-and-Groove Couplings, Ever-Tite Cam-and-Groove Couplings, PT Coupling Cam-and-Groove Couplings

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Specifications Met: Fed. Spec. A-A-59326

- Compatible With: Andrews Cam-and-Groove Couplings, Dixon Cam-and-Groove Couplings, Ever-Tite Cam-and-Groove Couplings, PT Coupling Cam-and-Groove Couplings

Easy-Fit Barbed Hose Fittings for Chemicals

Low-profile barbs and a longer first barb allow for a smoother, easier installation than other barbed fittings. Slide the barbed end into rubber hose and secure with a clamp. Fittings are 316 stainless steel, which has excellent corrosion resistance to withstand a variety of chemicals.

Adapters are also known as hose nipples; they adapt a barbed end to a threaded end.

For technical drawings and 3-D models, click on a part number.

- For Use With: Acetone, Isopropyl Alcohol, Mineral Oil, Sodium Hydroxide

- Maximum Pressure: See table

- Maximum Vacuum: 26 in. of Hg @ 72° F

- Temperature Range: -20° to 200° F

- Attachment Type: Use Worm-Drive Clamps, Bolt Clamps or Band-and-Buckle Clamps

- Specifications Met: ASME B1.20.1, ASTM A312

| For Hose ID | Pipe Size | Body Shape | Max. Pressure | Each | |

316 Stainless Steel | |||||

|---|---|---|---|---|---|

| 5" | 5 | Round | 45 psi @ 72° F | 0000000 | 0000000 |

Metal Cam-and-Groove Hose Couplings for Chemicals and Petroleum

Made of metal, these couplings have better durability than plastic cam-and-groove couplings. A complete coupling consists of a plug and a socket (both sold separately) that allow you to quickly connect and disconnect medium-to large-diameter hose lines. To connect, insert the plug into the socket and press the levers down. The levers fit snugly into the groove on the plug’s body and force the plug against the gasket to form a tight seal. To disconnect, lift both levers and pull out the plug. Couplings are compatible with Andrews, Dixon, Ever-Tite, and PT cam-and-groove couplings.

Plugs with male threaded end are also known as F adapters.

Plugs with female threaded end are also known as A adapters.

Sockets with locking levers prevent accidental disconnection. The locks engage automatically when the coupling is connected. Press the locks simultaneously to disengage.

Sockets with male threaded end are also known as B couplers.

Straight sockets with female threaded end are also known as D couplers.

Aluminum plugs and sockets are lighter in weight than 316 stainless steel plugs and sockets. They have good corrosion resistance. 316 stainless steel plugs and sockets have excellent corrosion resistance.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

Warning: Relieve all pressure before disconnecting the couplings. Do not use cam-and-groove couplings with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Citric Acid, Diesel Fuel, Gasoline, Hydraulic Fluid

- Temperature Range: -65° to 250° F

- Compatible With: Andrews Cam-and-Groove, Dixon Cam-and-Groove, Ever-Tite Cam-and-Groove, PT Coupling Cam-and-Groove

- Specifications Met: 6 Coupling Size and smaller: Fed. Spec. A-A-59326

- For Use With: Citric Acid, Diesel Fuel, Gasoline, Hydraulic Fluid

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Compatible With: Andrews Cam-and-Groove, Dixon Cam-and-Groove, Ever-Tite Cam-and-Groove, PT Coupling Cam-and-Groove

- Specifications Met: 6 Coupling Size and smaller: Fed. Spec. A-A-59326

- For Use With: Citric Acid, Diesel Fuel, Gasoline, Hydraulic Fluid

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Compatible With: Andrews Cam-and-Groove, Dixon Cam-and-Groove, Ever-Tite Cam-and-Groove, PT Coupling Cam-and-Groove

- Specifications Met: Fed. Spec. A-A-59326

| Coupling Size | Plug OD | Pipe Size | Max. Pressure | Each | |

316 Stainless Steel | |||||

|---|---|---|---|---|---|

| 5 | 5 3/4" | 5 | 75 psi @ 72° F | 000000000 | 0000000 |

- For Use With: Citric Acid, Diesel Fuel, Gasoline, Hydraulic Fluid

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Compatible With: Andrews Cam-and-Groove, Dixon Cam-and-Groove, Ever-Tite Cam-and-Groove, PT Coupling Cam-and-Groove

- Specifications Met: Fed. Spec. A-A-59326

- For Use With: Citric Acid, Diesel Fuel, Gasoline, Hydraulic Fluid

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Compatible With: Andrews Cam-and-Groove, Dixon Cam-and-Groove, Ever-Tite Cam-and-Groove, PT Coupling Cam-and-Groove

- Specifications Met: 6 Coupling Size and smaller: Fed. Spec. A-A-59326

- For Use With: Citric Acid, Diesel Fuel, Gasoline, Hydraulic Fluid

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Compatible With: Andrews Cam-and-Groove, Dixon Cam-and-Groove, Ever-Tite Cam-and-Groove, PT Coupling Cam-and-Groove

- Specifications Met: 6 Coupling Size and smaller: Fed. Spec. A-A-59326

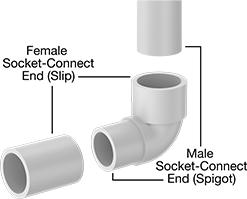

Standard-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 40 plastic pipe–they are the industry standard for residential and commercial low-pressure plumbing and water supply applications. They are plastic for good corrosion resistance.

Fittings for drinking water meet NSF/ANSI Standard 61.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a sealant to the male threads. Threaded connections can be taken apart as needed for maintenance and repair. For plastic threads, apply a non-hardening, plastic-compatible sealant. Tape or sealants with PTFE are not recommended for plastic-to-plastic connections. Fittings that meet ASTM D1784, ASTM D1785, and ASTM D4066 adhere to specifications and testing requirements for material quality.

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

| Pipe Size | Socket Depth | Material | Color | Each | |

| 5 | 3" | PVC Plastic | White | 00000000 | 000000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: See table

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

| Pipe Size | Socket Depth | Material | Color | Max. Pressure | Specifications Met | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 5 | 3" | PVC Plastic | White | Not Rated | ASTM D1784, NSF/ANSI 61 | 00000000 | 000000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: See table

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

| Pipe Size | Socket Depth | Material | Color | Max. Pressure | Specifications Met | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 5 | 3 1/32" | PVC Plastic | White | Not Rated | ASTM D1784, NSF/ANSI 61 | 00000000 | 000000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

| Pipe Size | Socket Depth | Material | Color | Each | |

| 5 | 3" | PVC Plastic | White | 00000000 | 000000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

| Pipe Size | Socket Depth | Material | Color | Each | |

| 5 | 3" | PVC Plastic | White | 00000000 | 000000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

| Pipe Size | Socket Depth | Material | Color | Each | |

| 5 | 3" | PVC Plastic | White | 00000000 | 000000 |

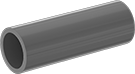

Standard-Wall Plastic Pipe for Water

Connect this pipe to standard-wall plastic pipe fittings for a variety of residential and commercial low-pressure plumbing and water supply applications. It’s made of PVC, which has good corrosion resistance. Pipe meets NSF/ANSI Standard 61 for drinking water. It also meets ASTM D1784 and ASTM D1785 specifications and testing requirements for material quality. Connect this pipe to unthreaded female socket-connect fittings using a PVC primer and cement (also known as solvent weld).

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, ASTM D1785, NSF/ANSI 61

- Fittings: Use Schedule 40 PVC Plastic

- Flanges: Use Schedule 40 PVC Plastic

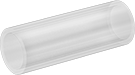

Clear-View Standard-Wall Plastic Pipe for Water

See inside your line with this clear pipe, which works in a variety of residential and commercial low-pressure plumbing and water supply applications. It connects to standard-wall plastic pipe fittings. Made of PVC, it has good corrosion resistance. Join this pipe to unthreaded female socket-connect fittings using a PVC primer and cement (also known as solvent weld).

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, ASTM D1785, NSF/ANSI 61

- Fittings: Use Schedule 40 PVC Plastic

- Flanges: Use Schedule 40 PVC Plastic

Rigid pipe meets NSF/ANSI 61 for use with drinking water systems. It also meets ASTM D1784 and ASTM D1785 specifications and testing requirements for material quality.

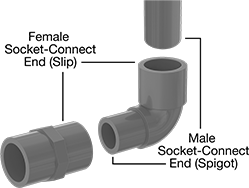

Thick-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 80 pipe. With thicker, stronger walls than standard-wall fittings, they can handle heavy duty supply applications, such as water processing, wastewater treatment, and irrigation. Fittings are plastic for good corrosion resistance. They meet ASTM specifications and testing requirements for material quality.

Fittings for drinking water meet NSF/ANSI Standard 61.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

| Pipe Size | Socket Depth | Material | Color | Each | |

| 5 | 2 5/8" | PVC Plastic | Dark Gray | 00000000 | 000000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

| Pipe Size | Socket Depth | Material | Color | Each | |

| 5 | 2 3/4" | PVC Plastic | Dark Gray | 00000000 | 000000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

| Pipe Size | Socket Depth | Material | Color | Each | |

| 5 | 2 9/16" | PVC Plastic | Dark Gray | 00000000 | 0000000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

| Pipe Size | Socket Depth | Material | Color | Each | |

| 5 | 2 5/8" | PVC Plastic | Dark Gray | 00000000 | 0000000 |

Thick-Wall Plastic Pipe for Water

With thicker, stronger walls than standard-wall pipe, this Schedule 80 pipe can handle heavy duty industrial plumbing and water supply applications, such as water processing, waste water treatment, and irrigation. It’s made of PVC, which has good corrosion resistance. Pipe meets ASTM D1784 and ASTM D1785 specifications and testing requirements for material quality.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, ASTM D1785, NSF/ANSI 61

- Fittings: Use Schedule 80 PVC Plastic

- Flanges; : Use Class 150 PVC Plastic

Pipe for drinking water meets NSF/ANSI Standard 61.

Connect unthreaded pipe to unthreaded female socket-connect fittings using a PVC primer and cement (also known as solvent weld).

High-Temperature All-Metal Expansion Joints with Flanged Ends

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Temperature Range: -20° to 800° F

- Maximum Pressure: 150 psi @ 72° F

- Maximum Vacuum: 29 in. of Hg @ 72° F

These all-metal expansion joints can handle higher temperatures than rubber expansion joints. They reduce stress, vibration, and noise in piping systems by providing a point of flexibility to absorb movement. Joints are made of 304 stainless steel for very good corrosion resistance. The flanged ends rotate for easy bolt hole alignment during installation. Flanges mate with a same-size flat-surface Class 150 flange with a gasket (sold separately).

Liners (sold separately) slide into the expansion joint to provide a smooth interior for unrestricted flow.

For technical drawings and 3-D models, click on a part number.

Expansion Joints with Sealing Flanged Ends for Metal Pipe

Because the flanges are molded into the body for a wide sealing surface, these joints provide a tighter seal than other expansion joints. Each flange is supported by a zinc-plated steel plate. Flanges mate with a same-size flat-surface Class 150 flange without the need for a gasket. Joints reduce stress, vibration, and noise in metal piping systems by providing a point of flexibility to absorb movement. They have a flexible body that is reinforced with cord for added strength.

Mount these expansion joints as close as possible to anchor points. Attach limit rod sets (sold separately) to the flanges to prevent overextension where anchoring is insufficient. To accommodate the thickness of the limit rod mounting plate, use bolts that are 7/8" longer than the bolts connecting the expansion joint to the pipe flange. Each set of limit rods requires eight bolts (not included).

For technical drawings and 3-D models, click on a part number.

- For Use With: Coolant, Grease, Hydraulic Fluid, Water

- Temperature Range: -65° to 220° F

- Maximum Pressure: 210 psi @ 72° F

- Maximum Vacuum: 29 in. of Hg @ 72° F

Expansion Joints with Flanged Ends for High Vibration

These expansion joints have a double-bulb design for extra movement and vibration absorption. The flanged ends rotate for easy bolt hole alignment during installation. They mate with a same-size flat-surface Class 150 flange without the need for a gasket. Joints have a flexible body that is reinforced with nylon for added strength.

Attach limit rod sets (sold separately) to the flanges to prevent overextension where anchoring is insufficient. To accommodate the thickness of the limit rod mounting plate, use bolts that are 7/8" longer than the bolts connecting the expansion joint to the pipe flange. Each set of limit rods requires eight bolts (not included).

For technical drawings and 3-D models, click on a part number.

- For Use With: Grain Alcohol, Nonabrasive Slurry, Water

- Temperature Range: -10° to 220° F

- Maximum Pressure: 220 psi @ 72° F

- Maximum Vacuum: 26 in. of Hg @ 72° F

- For Use With: Alcohol, Water

- Temperature Range: -20° to 250° F

- Maximum Pressure: 220 psi @ 72° F

- Maximum Vacuum: 26 in. of Hg @ 72° F

Expansion Joints with Flanged Ends

These joints reduce stress, vibration, and noise in piping systems by providing a point of flexibility to absorb movement. The flanged ends rotate for easy bolt hole alignment during installation. They mate with a same-size flat-surface Class 150 flange without the need for a gasket. Joints have a flexible body that is reinforced with nylon for added strength.

Position the expansion joints as close as possible to anchor points. Attach limit rod sets (sold separately) to the flanges to prevent overextension where anchoring is insufficient. To accommodate the thickness of the limit rod mounting plate, use bolts that are 7/8" longer than the bolts connecting the expansion joint to the pipe flange. Each set of limit rods requires eight bolts (not included).

For technical drawings and 3-D models, click on a part number.

- For Use With: Nonabrasive Slurry, Water

- Temperature Range: -10° to 220° F

- Maximum Pressure: 220 psi @ 72° F

- Maximum Vacuum: 26 in. of Hg @ 72° F

- For Use With: Alcohol, Water

- Temperature Range: -20° to 250° F

- Maximum Pressure: 220 psi @ 72° F

- Maximum Vacuum: 26 in. of Hg @ 72° F

Clamp-On Expansion Joints

- For Use With: Calcium Chloride, Oil, Petroleum, Sewage, Sludge, Sodium Carbonate (20% in Water), Water

- Temperature Range:

Neoprene Rubber: -20° to 220° F

Silicone Rubber: -75° to 500° F - Maximum Pressure: 150 psi @ 72° F

- Maximum Vacuum: 20 in. of Hg @ 72° F

Slip these joints over your pipe ends and tighten the band clamps for a secure hold. Joints have a triple-bulb design that provides excellent vibration absorption to reduce stress on your piping system. They also have reinforcing rings for extra support during pressure surges and in vacuum applications.

Neoprene rubber joints are more abrasion resistant than silicone rubber joints.

For technical drawings and 3-D models, click on a part number.

Distance | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Pipe OD | Pipe Size | Lg. | Compression | Expansion | Offset | Expansion Joint Type | Reinforcement Material | Band Clamp Material | Each | |

Neoprene Rubber | ||||||||||

| 5 9/16" | 5 | 7" | 1" | 1/2" | 1 1/8" | Triple Bulb | Nylon Plastic | 300 Series Stainless Steel | 0000000 | 0000000 |

Silicone Rubber | ||||||||||

| 5 9/16" | 5 | 7" | 1" | 1/2" | 1 1/8" | Triple Bulb | Fiberglass | 300 Series Stainless Steel | 00000000 | 000000 |

Expansion Joints with Butt-Weld Ends

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Temperature Range: -20° to 800° F

- Maximum Pressure: 150 psi @ 72° F

- Maximum Vacuum: 29 in. of Hg @ 72° F

These joints weld to unthreaded pipe or another butt-weld fitting for a leak-resistant, permanent connection. They reduce stress, vibration, and noise in metal piping systems by providing a point of flexibility to absorb movement.

For technical drawings and 3-D models, click on a part number.

Distance | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Pipe OD | Pipe Size | Lg. | Compression | Expansion | Offset | Expansion Joint Type | Butt Weld End Material | Each | |

321 Stainless Steel | |||||||||

| 5 9/16" | 5 | 7 1/2" | 5/8" | 1/4" | 1/16" | Bellow | Steel | 0000000 | 0000000 |

Low-Pressure Clamp-On Connectors for Drain, Waste, and Vent

To make installing and maintaining systems easy, these connectors come with clamps that form a strong seal on pipe and fittings once tightened.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water

- Temperature Range: -40° to 120° F

- Specifications Met: ASTM D5926

- For Pipe Material: Cast Iron, Steel, Copper, Lead, PVC Plastic, CPVC Plastic, Polyethylene Plastic

| For Pipe OD | For Pipe Size | Max. Pressure | Material | Clamp Material | Flexibility | Each | |

Pipe | |||||||

|---|---|---|---|---|---|---|---|

| 5.6" | 5 | 4 psi @ 72° F | PVC Plastic | 300 Series Stainless Steel | Flexible | 00000000 | 000000 |