How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Butt-Weld Fittings for Stainless Steel Tubing

- For Use With: See table

- Temperature Range: See table

- Tubing:

304 Stainless Steel: Use with 304/304L stainless steel that meets ASTM A213, ASTM A269, or ASTM A270, except DIN EN 10357 fittings with only ASTM A269 or ASTM A270

316 Stainless Steel: Use with 316/316L stainless steel that meets ASTM A213, ASTM A269, or ASTM A270, except ASME BPE and DIN EN 10357 fittings with only ASTM A269 or ASTM A270 - Specifications Met: See table

Weld these fittings to tubing for a permanent, flush connection that permits smooth flow through a line.

316 stainless steel fittings have excellent corrosion resistance.

ASME BPE fittings are polished to a 20 Ra finish for an extra-smooth interior that prevents product buildup and bacteria growth. Use them in pharmaceutical and bioprocessing applications.

For technical drawings and 3-D models, click on a part number.

316/316L Stainless Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Tube OD | Max. Pressure | Temp. Range Min., °F | Temp. Range Max., °F | Wall Thick. | For Use With | Specifications Met | Each | |

Polished | ||||||||

| 3/8" | 200 psi @ 72° F | -65° | 200° | 0.035" | Air, Deionized Water, Pharmaceuticals, Water | ASME BPE | 000000000 | 000000 |

High-Polish Metal Quick-Clamp Sanitary Tube Fittings

- Temperature Range: See Gaskets

The smooth finish inside these fittings makes it easy to remove product residue. Also known as aseptic and tri-clamp fittings, they connect with a gasket, a clamp, and another quick-clamp fitting for a fast and easy way to access your line. The pressure rating of the fitting will vary depending on the clamp you choose, and the temperature rating will vary based on the gasket material you choose.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

3-A certified fittings comply with sanitary standards.

Note: To complete a connection, you’ll need two quick-clamp fittings, a clamp, and a gasket (all sold separately).

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Beverage, Dairy, Food, Water

- Tubing: Use with welded 304/304L or 316/316L stainless steel that meets ASTM A269 or ASTM 270

- Specifications Met: 3-A Certified 63-04

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Each | |

| 1/4", 3/8", 1/2", 5/8", 3/4" | 0.984" | 1,200 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Each | |

| 1/2", 3/4" | 0.984" | 1,200 psi @ 72° F | ASTM A269, ASTM A270 | 0000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1/2", 3/4" | 0.984" | 700 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1/2", 3/4" | 0.984" | 720 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1/2", 3/4" | 0.984" | 720 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Each | |

| 1/2", 3/4" | 0.984" | 150 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 000000 |

Buna-N gaskets are oil resistant. EPDM gaskets resist water and steam and work well in humid environments. Silicone gaskets withstand high temperatures. Fluoroelastomer gaskets stand up to fuel, oil, and acid condensates. PTFE gaskets withstand harsh chemicals, with the exception of molten alkali metal and elemental fluorine.

| For Tube OD | ID | OD | Thick. | Temp. Range, °F | Color | Specifications Met | Each | |

Buna-N Rubber | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2" | 0.380" | 0.860" | 0.178" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

| 3/4" | 0.620" | 0.860" | 0.178" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

EPDM Rubber | ||||||||

| 1/2" | 0.380" | 0.860" | 0.178" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3/4" | 0.620" | 0.860" | 0.178" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

Silicone Rubber | ||||||||

| 1/2" | 0.380" | 0.860" | 0.178" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3/4" | 0.620" | 0.860" | 0.178" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

Fluoroelastomer Rubber | ||||||||

| 1/2" | 0.380" | 0.860" | 0.178" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3/4" | 0.620" | 0.860" | 0.178" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

PTFE Plastic | ||||||||

| 1/2" | 0.380" | 0.860" | 0.178" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 3/4" | 0.620" | 0.860" | 0.178" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

Precision AN 37° Flared Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -320° to 1200° F

- Tubing: Use with seamless 304 or 316 stainless steel

- Specifications Met: See Table

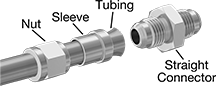

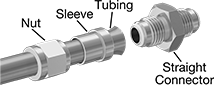

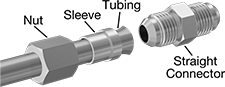

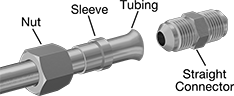

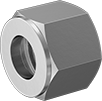

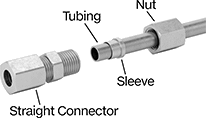

The threads on the tube end of these fittings are Class 3A or 3B and adhere to tighter tolerances than other 37° flared fittings. They are made to exact AS (formerly AN) specifications and provide a tight metal-to-metal seal on tubing that is flared to 37°. Fittings require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Vibration-Resistant Precision AN 37° Flared Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -320° to 500° F

- Tubing: Use with seamless 304 or 316 stainless steel

- Specifications Met: See Table

A PTFE seal on the tube end of these fittings allows for an extra-strong connection in high-vibration applications. The threads on the tube end are Class 3A and adhere to tighter tolerances than other 37° flared fittings. They are made to exact AS (formerly AN) specifications and provide a tight metal-to-metal seal on tubing that is flared to 37°. Fittings are 316 stainless steel for excellent corrosion resistance. They require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | Material | Max. Pressure | Specifications Met | Each | |

| 3/8" | 316 Stainless Steel | 3,000 psi @ 72° F | ASTM A380, SAE AS9100D, SAE AS9104/1 | 00000000 | 000000 |

| For Tube OD | Nut Material | Max. Pressure | Specifications Met | Each | |

| 3/8" | 316 Stainless Steel | 3,000 psi @ 72° F | AN818-6K, ASTM A380, SAE AS4841 | 00000000 | 000000 |

| For Tube OD | Sleeve Material | Max. Pressure | Specifications Met | Each | |

| 3/8" | 316 Stainless Steel | 3,000 psi @ 72° F | AN819-6K, ASTM A380, MS20819, SAE AS4841 | 00000000 | 000000 |

37° Flared Fittings for Stainless Steel Tubing

- Tubing: Use with welded or seamless 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Specifications Met: ISO 8434, SAE J514, except fittings with BSPP and BSPT threads meet SAE J514 only

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They withstand high pressure, so they’re often used in hydraulic applications. Made from 316 stainless steel, they resist corrosion from water and chemicals. A complete fitting requires a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: See table

| For Tube OD | Material | Temp. Range, °F | Each | |

| 3/8" | 316 Stainless Steel | -420° to 1200° | 000000000 | 000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: See table

| For Tube OD | Material | Temp. Range, °F | Each | |

| 3/8" | 316 Stainless Steel | -420° to 1200° | 000000000 | 000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

| For Tube OD | Nut Material | Each | |

| 3/8" | 316 Stainless Steel | 000000000 | 00000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on stainless steel tubing that is flared to 37°. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

Inch × metric sleeve adapters convert the fitting from inch to metric.

Compression Fittings for Stainless Steel Tubing

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Hydraulic Fluid, Water

- Temperature Range: -420° to 1200° F

- Tubing: Use with welded or seamless 304 or 316 stainless steel that meets ASTM A269

- Specifications Met: SAE J514

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Each | |

| 3/8" | 0.035" | 316 Stainless Steel | 2,600 psi @ 72° F | 000000000 | 000000 |

- For Use With: Air, Hydraulic Fluid, Water

- Temperature Range: -420° to 1200° F

- Tubing: Use with seamless 304 or 316 stainless steel that meets ASTM A269

- Specifications Met: SAE J514

Plugs insert into the end of a fitting.

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Each | |

| 3/8" | 0.035" | 316 Stainless Steel | 6,000 psi @ 72° F | 000000000 | 000000 |

- For Use With: See table

- Temperature Range: See table

- Tubing: See table

- Specifications Met: See table

For Tube | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | For Use With | Temp. Range, °F | For Tube Material | For Tube Specifications Met | For Tube Fabrication | Specifications Met | Each | |

| 3/8" | 0.035" | 316 Stainless Steel | 2,600 psi @ 72° F | Air, Hydraulic Fluid, Water | -420° to 1200° | 304 Stainless Steel, 316 Stainless Steel | ASTM A269 | Seamless, Welded | SAE J514 | 000000000 | 00000 |

- For Use With:

17-4 PH Stainless Steel: Air, Hydraulic Fluid, Water

316 Stainless Steel: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water - Temperature Range:

17-4 PH Stainless Steel: -420° to 1200° F

316 Stainless Steel: -75° to 750° F - Tubing:

17-4 PH Stainless Steel: Use with welded or seamless 304 or 316 stainless steel that meets ASTM A269

316 Stainless Steel: Use with seamless 304 or 316/316L/316Ti stainless steel that meets DIN EN 10216-5 or DIN EN 10305-1 - Specifications Met:

17-4 PH Stainless Steel: SAE J514

316 Stainless Steel: ISO 8434-1, DIN 2353

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Max. Pressure | Each | |

| 3/8" | 0.035" | 17-4 PH Stainless Steel | 2,600 psi @ 72° F | 000000000 | 00000 |

Precision Compression Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -420° to 1200° F

- Tubing: Use with welded or seamless 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Compatible With: Parker CPI

Made to tighter tolerances than other compression fittings, these are designed for high-precision applications. Also known as instrumentation fittings and flareless fittings. They come with a nut and a single sleeve (ferrule). The sleeve bites into tubing as you tighten the nut to create a strong seal. Fittings are 316 stainless steel for excellent corrosion resistance. A molybdenum disulfide coating on the nut acts as a lubricant for easy installation.

For technical drawings and 3-D models, click on a part number.

Caps for tubing have a nut and a sleeve so you can close off the end of your tubing in place of a fitting. Caps for fittings replace the nut and sleeve of an existing fitting.

For Tube | ||||

|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | |

| 3/8" | 0.035" | Molybdenum-Disulfide-Coated 316 Stainless Steel | 2,600 psi @ 72° F | 00000000 |

For Tube | ||||

|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Max. Pressure | |

| 3/8" | 0.035" | 316 Stainless Steel | 2,600 psi @ 72° F | 00000000 |

Yor-Lok Fittings for Stainless Steel Tubing

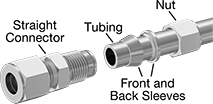

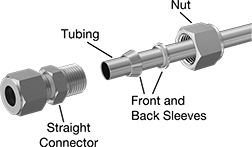

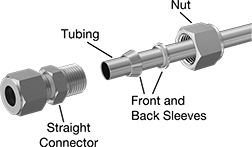

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

316 stainless steel fittings have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

Caps for tubing have a nut and a sleeve so you can close off the end of your tubing in place of a fitting. Caps for fittings replace the nut and sleeve of an existing fitting.

Use these nuts with Yor-Lok sleeves and fittings to create an extra-strong seal on stainless steel tubing. They are 316 stainless steel for excellent corrosion resistance.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Each | |

| 3/8" | 0.035" | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

Couple these sleeves with Yor-Lok nuts and fittings to create an extra-strong seal on stainless steel tubing. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

Save time installing sleeves and nuts—these sets come oriented in the correct direction and order on a dispenser. To install them, slide off a set and place it on your tubing. Each front sleeve, back sleeve, and nut is made of 316 stainless steel for excellent corrosion resistance. Five sets of sleeves and nuts come on each dispenser. Sleeves are also known as ferrules.

For Tube | Front Sleeve | Back Sleeve | Nut | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Lg. | No. Included | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

Sets with Dispenser | |||||||||||

| 3/8" | 0.035" | 316 Stainless Steel | 3/16" | 5 | 7/64" | 5 | 9/16" | 5 | 2,500 psi @ 72° F | 0000000 | 000000 |

PTFE sleeves are plastic instead of stainless steel, so they won’t damage tubing.

| For Tube OD | Sleeve Material | Max. Pressure | Temp. Range, °F | Each | |

| 3/8" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 00000 |

Tube supports are recommended for soft plastic tubing to prevent the tube from collapsing.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | ID | Tube Support Material | Tube Support Style | Temp. Range, °F | Each | |

| 3/8" | 1/4" | 316 Stainless Steel | Smooth | -420° to 1200° | 00000000 | 00000 |

Solder-Connect Fittings for Copper Tubing

- Temperature Range: 32° to 200° F

Solder these fittings to copper tubing or the tube end of another fitting for a permanent, leak-tight connection. They are also known as sweat fittings. Fittings have good corrosion resistance. To adhere to safety standards for drinking water systems, use fittings that meet NSF/ANSI 61 or EN 1057.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water

- Tubing: See table

- Specifications Met: See table

| Copper Tube Size | For Tube OD | Material | Max. Pressure | For Copper Tube Type | Specifications Met | Each | |

| 1/4 | 3/8" | Copper | 400 psi @ 72° F | K, M, L | ASME B16.22, MSS-SP104, NSF/ANSI 61 | 0000000 | 00000 |

Brass Push-to-Connect Fittings for Copper Tubing

- Tubing: Use with K, M, L copper, polyethylene plastic, CPVC

Connect these fittings to copper tubing with a push—no heat, solder, or flux required. They have an internal gripping ring and O-ring that hold the fitting secure. They also come with a tube support or retainer if you want to use them with polyethylene plastic (PEX) tubing. They are also known as instant fittings. Fittings are brass for good corrosion resistance. They are compatible with SharkBite® fittings. To adhere to safety standards for drinking water systems, use fittings that meet NSF/ANSI 61.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Drinking Water

- Temperature Range: 32° to 200° F

- Specifications Met: NSF/ANSI 61

Standard Caps | |||||||

|---|---|---|---|---|---|---|---|

| Copper Tube Size | For Tube OD | Material | Release Ring Material | Release Ring Color | Max. Pressure | Each | |

| 1/4 | 3/8" | Brass | Plastic | Black | 200 psi @ 72° F | 00000000 | 00000 |

Yor-Lok Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -40° to 400° F

- Tubing: Use with seamless copper

- Specifications Met: ASME B31.3

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. Fittings are brass for good corrosion resistance. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

For technical drawings and 3-D models, click on a part number.

Caps for tubing have a nut and a sleeve so you can close off the end of your tubing in place of a fitting. Caps for fittings replace the nut and sleeve of an existing fitting.

| For Tube OD | Nut Material | Max. Pressure | Each | |

| 3/8" | Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

| For Tube OD | Sleeve Material | Front Sleeve Lg. | Back Sleeve Lg. | Max. Pressure | Each | |

| 3/8" | Brass | 3/16" | 3/32" | 1,000 psi @ 72° F | 00000000 | 00000 |

45° Flared Fittings for Copper and Brass Tubing

- Temperature Range: -65° to 250° F

- Tubing: Use with seamless brass and copper that meets ASTM B280

No sleeve is required to assemble these fittings, which makes for a faster, more convenient installation compared to 37° flared fittings. They require a nut (sold separately) for each tube end. Fittings are also known as refrigeration and SAE fittings. They are brass for good corrosion resistance.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water;

except caps for 1/8" tube OD are only for use with refrigerant - Specifications Met: See table

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Specifications Met | Each | |

| 3/8" | 0.032" | Brass | 1,000 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 00000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: SAE J512, SAE J513, UL Listed

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Each | |

| 3/8" | 0.032" | Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water; except nuts for 1" tube OD are not for use with fuel oil

- Specifications Met: SAE J512, SAE J513, UL Listed; except nuts for 1" tube OD meet SAE J512 and SAE J513 only

Precision Compression Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -40° to 350° F

- Tubing: Use with seamless copper that meets ASTM B68, ASTM B75, or ASTM B88

- Compatible With: Parker CPI

Made to tighter tolerances than other compression fittings, these are designed for high-precision applications. They are also known as instrumentation fittings and flareless fittings. They come with a nut and a single sleeve (ferrule). The sleeve bites into tubing as you tighten the nut to create a strong seal. Fittings are brass for good corrosion resistance.

Fittings with a molybdenum-disulfide brass nut are easy to install because the coating acts as a lubricant.

For technical drawings and 3-D models, click on a part number.

Caps for tubing have a nut and a sleeve so you can close off the end of your tubing in place of a fitting. Caps for fittings replace the nut and sleeve of an existing fitting.

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Max. Pressure | Each | |

| 3/8" | 0.035" | Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

37° Flared Fittings for Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil

- Tubing: Use with seamless steel

- Specifications Met: SAE J514

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately. Fittings are zinc-plated steel for fair corrosion resistance.

For technical drawings and 3-D models, click on a part number.

30° Flared Fittings for Steel Tubing

- Specifications Met: See table

Also known as JIS (Japanese Industrial Standard) fittings, these have a 30° flare on one or both ends. Fittings are zinc-plated steel for fair corrosion resistance.

For technical drawings and 3-D models, click on a part number.

- Temperature Range: -65° to 500° F

| For Tube OD | Pipe Size | Material | Max. Pressure | Specifications Met | Each | |

| 3/8" | 1/4 | Zinc-Plated Steel | 5,000 psi @ 72° F | ISO 228-1, JIS B 0202, JIS B 8363 | 0000000 | 00000 |

- Temperature Range: -65° to 500° F

| For Tube OD | Pipe Size | Material | Max. Pressure | Specifications Met | Each | |

| 3/8" | 1/4 | Zinc-Plated Steel | 5,000 psi @ 72° F | ISO 228-1, JIS B 0202, JIS B 8363 | 0000000 | 00000 |

Yor-Lok Fittings for Steel Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil

- Tubing: Use with seamless steel

- Specifications Met: See table

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. Fittings are zinc-plated steel for fair corrosion resistance. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

For technical drawings and 3-D models, click on a part number.

Caps for tubing have a nut and a sleeve so you can close off the end of your tubing in place of a fitting. Caps for fittings replace the nut and sleeve of an existing fitting.

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

| 3/8" | 0.035" | Zinc-Plated Steel | 3,100 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 00000 |

For Tube | ||||||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Front Sleeve Material | Back Sleeve Material | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

| 3/8" | 0.035" | Zinc-Plated Steel | 316 Stainless Steel | 3,100 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 000000 |

Compression Fittings for Steel Tubing

- For Use With: Inch: Air, Hydraulic Fluid, Water

Metric: Hydraulic Fluid - Tubing: Inch: Use with welded steel

Metric: Use with seamless steel - Specifications Met: Inch: SAE J514

Metric: ISO 8434, DIN 2353

A single sleeve (ferrule) bites into tubing as you tighten the nut, creating a strong seal. The nut and sleeve are included. Fittings are also known as flareless and bite fittings.

Zinc-plated steel fittings have fair corrosion resistance.

For technical drawings and 3-D models, click on a part number.

- Temperature Range: See table

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Each | |

| 3/8" | 0.035" | Zinc-Plated Steel | 3,000 psi @ 72° F | -65° to 400° | 000000000 | 00000 |

- Temperature Range: See table

| For Tube OD | Nut Material | Max. Pressure | Temp. Range, °F | Each | |

| 3/8" | Zinc-Plated Steel | 3,000 psi @ 72° F | -65° to 400° | 000000000 | 00000 |

- Temperature Range: See table

| For Tube OD | Sleeve Material | Max. Pressure | Temp. Range, °F | Each | |

| 3/8" | Zinc-Plated Steel | 3,000 psi @ 72° F | -65° to 400° | 000000000 | 00000 |

37° Flared Fittings for Aluminum Tubing

- For Use With: Air, Coolant, Gasoline, Hydraulic Fluid, Water

- Temperature Range: -60° to 400° F

- Tubing: Use with seamless aluminum

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. Fittings are aluminum, which is lightweight with good corrosion resistance. They require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | Material | Max. Pressure | Each | |

| 3/8" | Anodized 2024 Aluminum | 3,000 psi @ 72° F | 0000000 | 00000 |

| For Tube OD | Nut Material | Max. Pressure | Each | |

| 3/8" | Anodized 2024 Aluminum | 3,000 psi @ 72° F | 0000000 | 00000 |

| For Tube OD | Sleeve Material | Max. Pressure | Each | |

| 3/8" | Anodized 2024 Aluminum | 3,000 psi @ 72° F | 0000000 | 00000 |

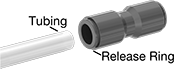

Push-to-Connect Tube Fittings for Air

- Temperature Range: 0° to 170° F, except polybutylene plastic fittings are 32° to 140° F

- Tubing: Use with firm (Durometer 95A-45D) polyethylene plastic or polyurethane rubber

- Specifications Met: ISO 14743, except cartridges and polybutylene plastic fittings

Insert tubing into these fittings and an internal gripping ring and O-ring hold the tubing tight. They are also known as instant fittings. To disconnect, push on the release ring and pull the tubing out of the fitting. Fittings have good corrosion resistance. Use them in low-pressure applications.

Identification rings (sold separately) snap over the release ring so you can color-code your lines.

Clips (sold separately) align and organize your tubing and fittings.

For technical drawings and 3-D models, click on a part number.

Nickel-Plated Brass Push-to-Connect Tube Fittings for Air

- For Use With: Air, Lubricated Air

- Temperature Range: 0° to 140° F

- Tubing: Fittings with Release Ring and Fittings with no Release Type: Use with firm or hard (Durometer 95A-60D) nylon plastic, polyethylene plastic or polyurethane rubber

Fittings with Release Sleeve: Use with firm or hard (Durometer 95A-60D) polyethylene plastic or polyurethane rubber

Made of nickel-plated brass, these fittings have better corrosion resistance than unplated brass fittings. Also known as instant fittings, they connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. To disconnect, push on the release ring or sleeve and pull the tubing out of the fitting.

For technical drawings and 3-D models, click on a part number.

Release Ring | ||||

|---|---|---|---|---|

| For Tube OD | Material | Max. Pressure | Each | |

| 3/8" | Nickel-Plated Brass | 230 psi @ 72° F | 000000000 | 000000 |

Push-to-Connect Tube Fittings for Drinking Water

- Temperature Range: 35° to 150° F

- Tubing: See table

- Specifications Met: NSF/ANSI 61

Made of moisture-resistant acetal, these fittings won't absorb water and lose strength, even in high-humidity environments. Also known as instant fittings, they connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. To disconnect, push on the release ring and pull the tubing out of the fitting. All meet NSF/ANSI 61 for use in drinking water systems.

For technical drawings and 3-D models, click on a part number.

Caps fit over a tube stem end of a fitting or a piece of tubing.

For Tube | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Tube OD | Material | Color | Release Ring Color | Max. Pressure | Material | Hardness Rating | Each | |

| 3/8" | Acetal Plastic | Gray | Gray | 150 psi @ 72° F | Nylon Plastic, Polyethylene Plastic | Firm, Hard | 000000000 | 00000 |

Tube supports are recommended if you want to use fittings with soft nylon, polyethylene, and PVC tubing to prevent the tube from collapsing.

For Tube | Tube Support | |||||||

|---|---|---|---|---|---|---|---|---|

| OD | ID | Material | Color | Max. Pressure | Pkg. Qty. | Environment | Pkg. | |

| 3/8" | 5/16" | Acetal Plastic | Gray | 150 psi @ 72° F | 10 | Food Industry | 000000000 | 00000 |

Locking clips secure the release ring to prevent the fitting from accidentally disconnecting.

| For Tube OD | Material | Color | Pkg. Qty. | Pkg. | |

| 3/8" | Acetal Plastic | Red | 10 | 000000000 | 00000 |

Push-to-Connect Tube Fittings for Hot Drinking Water

- Temperature Range: 35° to 200° F

- Tubing: Use with hard polyethylene plastic

- Specifications Met: NSF/ANSI 51, NSF/ANSI 61

Run hot water through these fittings at temperatures up to 200° F. Also known as instant fittings, they connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. To disconnect, push on the release ring and pull the tubing out of the fitting. Fittings are nylon for excellent impact and abrasion resistance.

For technical drawings and 3-D models, click on a part number.

Caps fit over a tube stem end of a fitting or a piece of tubing.

| For Tube OD | Material | Color | Release Ring Color | Max. Pressure | Each | |

| 3/8" | Nylon Plastic | White | Gray | 190 psi @ 72° F | 00000000 | 00000 |

Compression Fittings for Plastic Tubing—Chemicals

- For Use With: PFA Plastic: Hydrochloric Acid, Sulfuric Acid

PTFE Plastic: Alcohol, Ammonia, Benzoic Acid, Bleach, Bromine, Coolant, Fluoboric Acid, Hydrochloric Acid, Hydrofluoric Acid, Nitric Acid, Organic Solvents, Sodium Carbonate, Sulfuric Acid - Temperature Range: PFA Plastic: 0° to 350° F

PTFE Plastic: -40° to 185° F - Tubing: PFA Plastic: Use with hard (Durometer 50D-65D) PFA or PTFE plastic

PTFE Plastic: Use with hard (Durometer 60D) PFA or PTFE plastic

A sleeve (ferrule) compresses the tubing as you tighten the nut, creating a strong seal. The nut and sleeve are included. Fittings are also known as flareless fittings. Fittings that include a gripper sleeve on the tubing create an even tighter seal.

PFA fittings stand up to harsh substances. They’re made through a melting process.

For technical drawings and 3-D models, click on a part number.

Push-to-Connect Fittings for Food and Beverage

- Temperature Range: 35° to 140° F

- Tubing: See table

- Specifications Met: See table

Also known as instant fittings, these connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. To disconnect fittings with a release ring, push on the release ring and pull the tubing out of the fitting.

Polypropylene fittings have excellent impact and abrasion resistance. They meet NSF/ANSI standards for safe use with food. Some are also FDA compliant for indirect contact with food.

Black fittings have excellent UV resistance and are suitable for outdoor environments.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | Material | Release Ring Color | Max. Pressure | For Tube Hardness Rating | For Tube Hardness | Specifications Met | Each | |

White | ||||||||

|---|---|---|---|---|---|---|---|---|

| 3/8" | Polypropylene Plastic | White | 150 psi @ 72° F | Hard | Durometer 50D-70D | NSF/ANSI 58, NSF/ANSI 372, FDA Compliant 21 CFR 176.170 | 00000000 | 00000 |

Black | ||||||||

| 3/8" | Polypropylene Plastic | Black | 150 psi @ 72° F | Hard | Durometer 50D-70D | NSF/ANSI 58, NSF/ANSI 372, FDA Compliant 21 CFR 176.170 | 00000000 | 0000 |