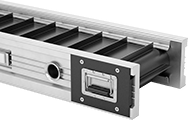

Rough-Top Belting for Slider-Bed Conveyors

The textured surface grips packages and cartons to prevent material from slipping when traveling on inclines and declines. A low-friction bottom surface allows belting to glide along the bed of the conveyor. Use belting with hammer-on hook-style lacing or quick-install hook-style lacing.

Note: The top surface of the belt ends should be removed with a conveyor belt shaver or skiver before installing lacing. Recommended lacing is based on the thickness of the belt after removing the top surface.

PVC resists impact and tears.

Neoprene has a good grip along with superior oil resistance.

Buna-N has a hard textured surface that resists punctures and abrasion.

SBR has good impact resistance and an excellent grip.

For Lace No. | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thick. | For Min. Pulley Dia. | Max. Belt Tension, PIW | Construction | Max. Temp., °F | Quick-Install Hook-Style | Hammer-On Hook-Style | 2" Wd. Per Ft. | 3" Wd. Per Ft. | 4" Wd. Per Ft. | 6" Wd. Per Ft. | 8" Wd. Per Ft. | 10" Wd. Per Ft. | 12" Wd. Per Ft. | 18" Wd. Per Ft. | 24" Wd. Per Ft. | |

Green PVC Plastic | ||||||||||||||||

| 0.210" | 2 1/2" | 46 | 2 Ply | 155° | UCM36LL | 7 | 000000 | |||||||||

Black Neoprene Rubber | ||||||||||||||||

| 0.300" | 3" | 225 | 3 Ply | 250° | 1 | 7 | 000000 | |||||||||

Blue Buna-N Rubber | ||||||||||||||||

| 0.310" | 2 1/2" | 150 | 3 Ply | 250° | 2 | 15 | 000000 | |||||||||

Black SBR Rubber | ||||||||||||||||

| 0.250" | 2" | 150 | 2 Ply | 250° | 1 | 7 | 000000 | |||||||||

Beige SBR Rubber | ||||||||||||||||

| 0.265" | 3" | 200 | 3 Ply | 250° | 2 | 7 | 000000 | |||||||||

Cleated Belting for Slider-Bed Conveyors

Cleats keep material on the belt when traveling along inclines and declines. A low-friction bottom surface allows belting to glide along slider-bed conveyors.

Note: The cleats of the belt should be removed with a conveyor belt shaver or skiver before installing lacing.

White belting is appropriate for food applications when used with stainless steel lacing. It resists animal fats and oils.

Black belting is also known as MOR belting due to its mild oil resistance.

Cleat | For Lace No. | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thick. | For Min. Pulley Dia. | Max. Incline | Max. Belt Tension, PIW | Ht. | Spacing | Construction | Max. Temp., °F | Quick-Install Hook-Style | Hammer-On Hook-Style | 4" Wd. Per Ft. | 6" Wd. Per Ft. | 8" Wd. Per Ft. | 10" Wd. Per Ft. | 12" Wd. Per Ft. | 18" Wd. Per Ft. | 24" Wd. Per Ft. | |

| 0.250" | 2" | 30° | 150 | 1/8" | 1" | 3 Ply | 250° | 2 | 15S | 000000 | |||||||

Cleated Belting for Roller-Bed Conveyors

Cleats keep material on the belt when traveling along inclines and declines. A tough cover on the bottom grips rollers.

Note: The cleats of the belt should be removed with a conveyor belt shaver or skiver before installing lacing.

White belting is appropriate for food applications when used with stainless steel lacing. It resists animal fats and oils.

Black belting is also known as MOR belting due to its mild oil resistance.

Cleat | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thick. | For Min. Pulley Dia. | Max. Incline | Max. Belt Tension, PIW | Ht. | Spacing | Construction | Max. Temp., °F | For Lacing Type | 4" Wd. Per Ft. | 6" Wd. Per Ft. | 8" Wd. Per Ft. | 10" Wd. Per Ft. | 12" Wd. Per Ft. | 18" Wd. Per Ft. | 24" Wd. Per Ft. | 30" Wd. Per Ft. | 36" Wd. Per Ft. | 48" Wd. Per Ft. | |

| 0.225" | 10" | 60° | 220 | 1/4" | 3" | 2 Ply | 200° | Bolt On | 000000 | ||||||||||

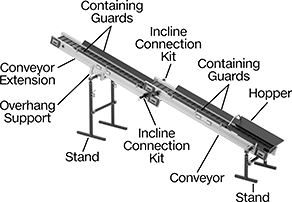

Cleated Belt Conveyors for Inclines

The cleats on these conveyors prevent items from tumbling down as you move them along steep slopes. They are often used to bridge the gap between different elevations in your facility, such as between the floor and a shipping bin. These conveyors keep parts steady as they move, so they're great for moving small, loose, and irregularly shaped parts that might fall through or catch on roller and skate wheel conveyors. They come with an adjustable stand on the higher end and adjustable support bars on the lower end, so you can position the conveyor at the right height and angle for your application.

Note: Capacities are based on an evenly distributed load.

Wd. | Cleat | No. of Stands | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg., ft. | Belt | Frame | Ht. | Spacing | Side Rail Projection | O'all Ht. | Cap., lbs. | Speed, fpm | Climbing Angle | Required | Included | Reversible | Features | Each | |

Powder-Coated Steel Bed with PVC Plastic Belt | |||||||||||||||

120V AC—Single Phase (Plug In) | |||||||||||||||

| 5 | 12" | 16" | 1 1/2" | 12" | 3" | 40"-48" | 150 | 60 | 41°-45° | 1 | 1 | No | On/Off Switch | 0000000 | 000000000 |

| 5 | 16" | 20" | 1 1/2" | 12" | 3" | 40"-48" | 150 | 60 | 41°-45° | 1 | 1 | No | On/Off Switch | 0000000 | 00000000 |

| 7 | 12" | 16" | 1 1/2" | 12" | 3" | 55"-63" | 150 | 60 | 41°-45° | 1 | 1 | No | On/Off Switch | 0000000 | 00000000 |

| 7 | 16" | 20" | 1 1/2" | 12" | 3" | 55"-63" | 150 | 60 | 41°-45° | 1 | 1 | No | On/Off Switch | 0000000 | 00000000 |

| 11 | 12" | 16" | 1 1/2" | 12" | 3" | 85"-93" | 150 | 60 | 41°-45° | 1 | 1 | No | On/Off Switch | 0000000 | 00000000 |

| 11 | 16" | 20" | 1 1/2" | 12" | 3" | 85"-93" | 150 | 60 | 41°-45° | 1 | 1 | No | On/Off Switch | 0000000 | 00000000 |

| Wd. | Ht. | Wire Lead Lg. | Each | |

Hardwire | ||||

|---|---|---|---|---|

| 2 1/2" | 4 1/2" | 2 ft. | 00000000 | 0000000 |

| Motor Enclosure Type | Each | |

120V AC—Single Phase | ||

|---|---|---|

| Open Dripproof | 0000000 | 000000000 |

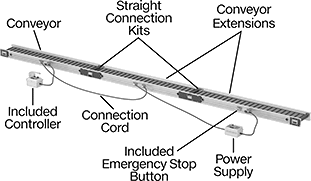

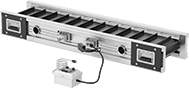

Modular Cleated Belt Conveyors

Create a custom line to convey items up or down steep slopes. The cleats on these conveyors keep items from tumbling down as the belt moves on inclines and declines. The belt moves a wide range of small products, including electronic components, molded plastic parts, and other irregularly shaped parts that would catch on rollers or skate wheels. Since the surface keeps material steady as it moves, these conveyors work well if you need to visually inspect parts as they move by. The belt direction is reversible, so you can cycle material in and out of trucks or return empty totes to the start of your line.

These conveyors are lightweight enough for two people to carry, yet durable enough for environments as tough as mines. Both the motor and the electrical connections are designed to keep water and dust out. Made with an aluminum frame and a stainless steel bed, these conveyors also resist corroding in wet areas.

Straight conveyors come with a controller and an emergency stop, so they’re ready to run once plugged in. To make your line longer, add a conveyor extension. The included controller will work with any extensions you add. For each extension you add, you’ll need a connection cord and a connection kit. If you’re adding two or more extensions, you'll need at least one power supply.

Set these conveyors on the ground, tilt them at an incline, or mount them on stands (sold separately).

Note: Accessories are bolted on. Capacities are based on an evenly distributed load.

Wd. | Cleat | No. of Stands | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Belt | Frame | Ht. | Spacing | Side Rail Projection | O'all Ht. | Cap., lbs. | Max. Climbing Angle | Belt Material | Required | Included | Voltage | Electrical Phase | Reversible | No. of Conveyors Powered | Features | Each | |

5 ft. Lg. | |||||||||||||||||

64 fpm | |||||||||||||||||

| 12" | 15" | 1" | 12" | 1 3/4" | 7 3/4" | 300 | 40° | PVC Plastic | None | None | 120V AC | Single | Yes | 3 | Controller, Emergency Stop, On/Off Switch, Watertight Electrical Connections | 0000000 | 000000000 |

96 fpm | |||||||||||||||||

| 17" | 20" | 1" | 12" | 1 3/4" | 7 3/4" | 450 | 40° | PVC Plastic | None | None | 120V AC | Single | Yes | 2 | Controller, Emergency Stop, On/Off Switch, Watertight Electrical Connections | 0000000 | 00000000 |

10 ft. Lg. | |||||||||||||||||

64 fpm | |||||||||||||||||

| 12" | 15" | 1" | 12" | 1 3/4" | 7 3/4" | 300 | 40° | PVC Plastic | None | None | 120V AC | Single | Yes | 3 | Controller, Emergency Stop, On/Off Switch, Watertight Electrical Connections | 0000000 | 00000000 |

96 fpm | |||||||||||||||||

| 17" | 20" | 1" | 12" | 1 3/4" | 7 3/4" | 450 | 40° | PVC Plastic | None | None | 120V AC | Single | Yes | 2 | Controller, Emergency Stop, On/Off Switch, Watertight Electrical Connections | 0000000 | 00000000 |

Wd. | Cleat | No. of Stands | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Belt | Frame | Ht. | Spacing | Side Rail Projection | O'all Ht. | Cap., lbs. | Max. Climbing Angle | Belt Material | Required | Included | Voltage | Electrical Phase | Reversible | Features | Each | |

5 ft. Lg. | ||||||||||||||||

64 fpm | ||||||||||||||||

| 12" | 15" | 1" | 12" | 1 3/4" | 7 3/4" | 300 | 40° | PVC Plastic | None | None | 120V AC | Single | Yes | Watertight Electrical Connections | 0000000 | 000000000 |

96 fpm | ||||||||||||||||

| 17" | 20" | 1" | 12" | 1 3/4" | 7 3/4" | 450 | 40° | PVC Plastic | None | None | 120V AC | Single | Yes | Watertight Electrical Connections | 0000000 | 00000000 |

10 ft. Lg. | ||||||||||||||||

64 fpm | ||||||||||||||||

| 12" | 15" | 1" | 12" | 1 3/4" | 7 3/4" | 300 | 40° | PVC Plastic | None | None | 120V AC | Single | Yes | Watertight Electrical Connections | 0000000 | 00000000 |

96 fpm | ||||||||||||||||

| 17" | 20" | 1" | 12" | 1 3/4" | 7 3/4" | 450 | 40° | PVC Plastic | None | None | 120V AC | Single | Yes | Watertight Electrical Connections | 0000000 | 00000000 |

| Voltage | Lg. | Wd. | Ht. | Electrical Connection Type | Power Cord Lg., ft. | Features | Each | |

| 120V AC | 11 1/4" | 10 1/2" | 9 1/4" | Plug In | 10 | 8-ft. Connection Cord, On/Off Switch, Watertight Electrical Connections | 0000000 | 000000000 |

| Voltage | Reset Type | Switch Action | Features | Each | |

| 120V AC | Twist | Stays Switched (Maintained) | Watertight Electrical Connections | 0000000 | 0000000 |

Connection cords connect different conveying sections together, so they run from the same controller.

| Voltage | Current, A | Lg., ft. | No. of Poles | End Type | Color | Features | Each | |

| 120V AC | 15 | 15 | 10 | Plug | Black | Watertight Electrical Connections | 0000000 | 0000000 |

Power supplies send additional power down your line so you can run conveyor extensions. Add one power supply for every three extensions with 12” wide belts; add one power supply for every two extensions with 17” wide belts.

No. of Conveyors Powered | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Voltage | For 12" Belt Wd. | For 17" Belt Wd. | Lg. | Wd. | Ht. | Electrical Connection Type | Power Cord Lg., ft. | Features | Each | |

| 120V AC | 3 | 2 | 11 1/4" | 10 1/2" | 9 1/4" | Plug In | 10 | 15-ft. Connection Cord, 8-ft. Connection Cord, Watertight Electrical Connections | 0000000 | 000000000 |

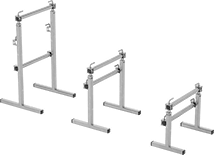

Stands include three sets of legs—short, medium, and tall. All can be adjusted to the height you need.

| Ht. Range | Wd. | Material | No. of Stands Included | Mounting Hardware Included | Each | |

| 16 1/2"-28 1/2" 26"-46 1/2" 46 1/4"-75 1/2" | 32" | Zinc-Plated Steel | 3 | Yes | 0000000 | 000000000 |

Swivel stands pivot these conveyors from one side to another. They’re often paired with wheel kits, so you can quickly adjust the direction of your line.

Wheel kits make it easy for one person to move the conveyor. Pneumatic wheels absorb shock and have better traction than flat-free wheels, so they roll more smoothly. However, you’ll need to fill them with air and check for damage periodically. Flat-free wheels resist punctures from nails, rocks, and other sharp objects, so they’re easy to maintain.

Straight connection kits lock conveyor sections together with plates that mount to each side. When choosing a kit, consider what layout you’ll need and how smooth the flow needs to be. Kits for two belts connect any two lengths of conveyor sections together. They’re also faster to install than kits for one belt because you don’t have to take off the belts or remove rollers. However, they leave a small gap, so the belt and your items will briefly travel over rollers at the end of each conveyor section instead of a conveyor bed. Kits for one belt can only connect two 5 ft. conveyor sections together, but they create a smoother flow than kits for two belts. They include an extension that closes the gap between the two conveyor beds. Because you’ll need to remove the end rollers and replace the belts, these kits take longer to install than kits for two belts.

Incline connection kits lock the end of one conveyor section on top of another at angles up to 40°. The included side guards keep material from falling off.

Overhang supports are useful if you need your conveying line to extend over an area where you’ll be dumping material, and you don’t want stands to get in the way. They give enough support that you can mount stands six feet from the end of a conveyor.

Containing guards keep material from spilling over the sides of the conveyor. They're reversible, so they can be used on either side of your conveyor.

| Lg., ft. | Ht. | Color | Mounting Hardware Included | No. of Guards Included | Each | |

Powder-Coated Steel | ||||||

|---|---|---|---|---|---|---|

| 5 | 4 3/4" | Black | Yes | 1 | 0000000 | 0000000 |

| 6 1/2 | 4 3/4" | Black | Yes | 1 | 0000000 | 000000 |

| 10 | 4 3/4" | Black | Yes | 1 | 0000000 | 000000 |

| 10 | 15" | Black | Yes | 2 | 0000000 | 00000000 |

Stainless Steel | ||||||

| 5 | 4 3/4" | __ | Yes | 1 | 0000000 | 000000 |

| 6 1/2 | 4 3/4" | __ | Yes | 1 | 0000000 | 000000 |

| 10 | 4 3/4" | __ | Yes | 1 | 0000000 | 000000 |

| 10 | 15" | __ | Yes | 2 | 0000000 | 00000000 |

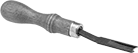

Conveyor Belt Shavers

Also known as skivers, these shavers remove the rough top surface of a conveyor belt for secure lacing connections.

Material | ||||

|---|---|---|---|---|

| Overall Lg. | Blade | Handle | Each | |

| 6 1/2" | Steel | Wood | 0000000 | 000000 |

Battery-Powered Conveyor Belt Shavers

Quickly and accurately remove material from the surface of conveyor belts to prepare them for fastening. These shavers come with rechargeable batteries, so you can take them wherever they’re needed. They’re powered with an attached cordless drill, giving you more control over cuts than manual skivers. Run the drill at low speed for the most control.

Overall | Material | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Belt Thick. | Ht. | Wd. | Dp. | Max. Cutting Wd. | Cutting Dp. | Blade | Body | Battery Charging Time, hrs. | Battery Cap., amp-hrs. | No. of Batteries Included | Battery Charger Included | Includes | Each | |

| 1/4"-1 1/4" | 10" | 10" | 12 1/2" | 2 1/2" | 1/16" to 3/8" | Steel | Steel | 2 | 5 | 2 | Yes | Plastic Carrying Case | 0000000 | 000000000 |

| 7/8"-1 3/4" | 10 1/2" | 10" | 12 1/2" | 2 1/2" | 1/16" to 3/8" | Steel | Steel | 2 | 5 | 2 | Yes | Plastic Carrying Case | 0000000 | 00000000 |