About Electric Motors

When replacing a motor, use the information on your motor’s nameplate to guide your selection.

More

Noncontact-Magnetic Torque Limiters

Using magnetic force instead of friction to transmit torque, these torque limiters won't wear when they slip. Because there's no wear, they give you accurate, repeatable action. Also known as hysteresis clutches, use them to brake, control tension, and prevent torque overload. They are designed to slip during a torque overload while still transmitting the set torque. For example, you can use them to maintain a constant tension while winding and unwinding wire. All are through-shaft torque limiters, so they regulate torque transmission between an input shaft and a mounted component, such as a pulley, sprocket, or gear. Twist the adjustment ring to set the torque limit, then lock the ring into place with the included set screw.

For technical drawings and 3-D models, click on a part number.

Torque, in.-lbs | Mounting Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Min. | Max. | Max. Speed, rpm | OD | Overall Lg. | Drive Direction | Shaft Mount Type | Thread Size | Thread Pitch, mm | For Shaft Dia. | Each | |

| 1 | 25 | 250 | 4 11/16" | 3 1/8" | Clockwise and Counterclockwise | Set Screw | M5 | 0.8 | 7/8" | 000000 | 0000000 |

| 2 | 50 | 200 | 5 1/4" | 3 1/8" | Clockwise and Counterclockwise | Set Screw | M5 | 0.8 | 7/8" | 000000 | 000000 |

| 3 | 70 | 200 | 6 5/16" | 4 1/8" | Clockwise and Counterclockwise | Set Screw | 1/4"-20 | __ | 7/8" | 000000 | 00000000 |

Overload-Protection Spring-Loaded Torque Limiters

Protect your machinery if there is a jam, emergency stop, or other overload by cutting off torque between shafts when a maximum torque is reached. These torque limiters automatically resume transmitting torque once it drops below the set maximum. They should not be used in applications that frequently exceed the maximum torque. Since they come factory-set to a maximum torque, there’s no adjustment required and no risk of unintended changes to the torque setting.

They act as a flexible shaft coupling, so they reduce vibration and protect components from wear by compensating for angular and parallel misalignment. Fasten to your shafts by tightening the set screws, which bite into each shaft to hold it.

Sensor rings help you detect an overload by moving only when the limiter is transmitting torque. Use a sensor (not included) to trigger an alarm or shut down when the ring stops moving.

For technical drawings and 3-D models, click on a part number.

Misalignment Capability | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | For Shaft Type | Max. Speed, rpm | Parallel | Angular | OD | Overall Lg. | Keyway Wd. × Keyway Dp. | Material | Center Material | Drive Direction | Re-Engagement Position | Choose a Max. Torque, in.-lbs. | Each | |

| 7/8" | Keyed | 1,800 | 0.031" | 6° | 3 1/2" | 3" | 3/16" × 3/32" | 6061 Aluminum | Steel | Clockwise and Counterclockwise | Multiple Position | 0000000 | 000000 | |

with Sensor

Ring Installed

| Material | OD | Thickness | Each | |

| Steel | 3 1/2" | 0.06" | 000000 | 000000 |

Torque Limiters for Chain and Belt Drives

Prevent damage from overloading. When overloaded, these limiters cause your sprocket or pulley to slip. Once the overload is removed, the limiters automatically reset. Set the torque within the range listed. Friction discs are between the hub and pressure plate.

Double-spring limiters have a second spring for handling nearly twice the torque of single-spring limiters.

Optional sprockets are designed specifically to fit their corresponding limiters. These hubless sprockets are not interchangeable.

For technical drawings and 3-D models, click on a part number.

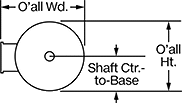

Torque Limiters | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Keyway | Torque | Optional Sprockets | Replacement Friction Discs for Torque Limiters | Replacement Bushings for Optional Sprockets | |||||||||||||||

| For Shaft Dia. | OD | O'all Wd. | Wd. | Dp. | For Max. Sprocket or Pulley Wd. | Friction Disc Thick. | Min., ft.-lbs. | Max., ft.-lbs. | Hub Material | Each | For Roller Chain Trade Size | Each | Each | For Roller Chain Trade Size | Each | ||||

Single Spring | |||||||||||||||||||

| 7/8" | 2 1/2" | 1 3/4" | 3/16" | 3/32" | 11/32" | 1/8" | 25 | 60 | Steel | 00000000 | 000000 | 0000000 | 000000 | 0000000 | 00000 | 000000 | 00000 | ||

| 7/8" | 3 3/8" | 2 1/8" | 3/16" | 3/32" | 1/2" | 1/8" | 11 | 100 | Steel | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 | __ | 000000 | 00 | |

| 7/8" | 3 1/2" | 2 3/16" | 3/16" | 3/32" | 1/2" | 1/8" | 50 | 120 | Steel | 00000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 | 000000 | 0000 | ||

Double Spring | |||||||||||||||||||

| 7/8" | 2 1/2" | 1 3/4" | 3/16" | 3/32" | 11/32" | 1/8" | 30 | 95 | Steel | 00000000 | 000000 | 0000000 | 00000 | 0000000 | 0000 | 000000 | 0000 | ||

| 7/8" | 3 3/8" | 2 1/8" | 3/16" | 3/32" | 7/16" | 1/8" | 13 | 175 | Steel | 00000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 | __ | 000000 | 00 | |

| 7/8" | 3 1/2" | 2 3/16" | 3/16" | 3/32" | 1/2" | 1/8" | 60 | 190 | Steel | 00000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 | 000000 | 0000 | ||

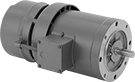

Base/Face-Mount AC Brake Motors

When these motors lose power, a brake engages to hold your equipment’s position, unlike standard AC motors. They’re often used with conveyors to keep items in place after a power loss, and with hoists to stop them from dropping a load. Mount them from the base or face. Rated for continuous duty, these motors can run equipment that never turns off. Their shaft is keyed, and they come with key stock. These motors have a TEFC (totally enclosed fan cooled) enclosure that protects better than an ODP (open dripproof) enclosure. They aren’t airtight, but they can be used in dirty, dusty, and damp environments. To keep the motor cool, the enclosure has an external fan that blows air over the outside of the motor.

For technical drawings and 3-D models, click on a part number.

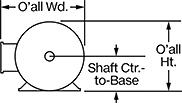

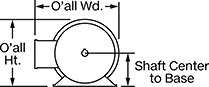

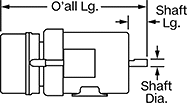

O'all | Shaft | Insulation | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Max. Speed, rpm | Full Load Current, A | Inverter Rated | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Class | Max. Temp., °F | Environmental Rating | Each | |

230/460 Volts AC, Three Phase | |||||||||||||||

NEMA 145TC | |||||||||||||||

| 1 1/2 | 1,750 | 4.8/2.4 | Yes | Totally Enclosed Fan Cooled (TEFC) | 18 1/8" | 8 7/8" | 7 1/4" | 7/8" | 2 1/4" | 3 1/2" | B | 266° | IP43 | 0000000 | 000000000 |

| 2 | 1,740 | 5.8/2.9 | Yes | Totally Enclosed Fan Cooled (TEFC) | 18 5/8" | 8 7/8" | 7 1/4" | 7/8" | 2 1/4" | 3 1/2" | F | 311° | IP43 | 0000000 | 00000000 |

Base-Mount AC Brake Motors

Unlike standard AC motors, these motors have an integrated brake that activates after a power loss to hold your equipment in place. They’re often used with conveyors to stop them from moving backwards after a power loss, and with hoists to prevent them from dropping a load. Mount their base to flat surfaces. Rated for continuous duty, these motors can run equipment that never turns off. Their shaft is keyed, and they come with key stock. These motors have a TEFC (totally enclosed fan cooled) enclosure that protects better than an ODP (open dripproof) enclosure. They aren’t airtight, but they can be used in dirty, dusty, and damp environments. To keep the motor cool, the enclosure has an external fan that blows air over the outside of the motor.

For technical drawings and 3-D models, click on a part number.

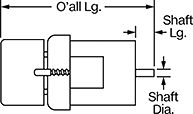

O'all | Shaft | Insulation | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Max. Speed, rpm | Full Load Current, A | Inverter Rated | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Class | Max. Temp., °F | Environmental Rating | Each | |

230/460 Volts AC, Three Phase | |||||||||||||||

NEMA 145 | |||||||||||||||

| 2 | 1,740 | 5.8/2.9 | Yes | Totally Enclosed Fan Cooled (TEFC) | 18 5/8" | 9 1/8" | 7 3/4" | 7/8" | 2 1/4" | 3 1/2" | F | 311° | IP43 | 0000000 | 000000000 |

NEMA 145T | |||||||||||||||

| 1 1/2 | 1,750 | 4.4/2.2 | No | Totally Enclosed Fan Cooled (TEFC) | 18 1/8" | 9 1/8" | 6 3/4" | 7/8" | 2 1/4" | 3 1/2" | B | 266° | IP43 | 0000000 | 00000000 |

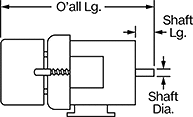

Face-Mount AC Brake Motors

A built-in brake engages to hold your equipment in place when these motors lose power, unlike standard AC motors. These motors are often used with conveyors to keep items in place after a power loss, and with hoists to prevent them from dropping a load. Also known as C-face motors, these bolt directly to your equipment. They’re rated for continuous duty, so they can run equipment that never turns off. Their shaft is keyed, and they come with a key stock. These motors have a TEFC (totally enclosed fan cooled) enclosure that protects better than an ODP (open dripproof) enclosure. They’re not airtight, but they can be used in dirty, damp, and dusty environments. To keep the motor cool, the enclosure has an external fan that blows air over the outside of the motor.

For technical drawings and 3-D models, click on a part number.

O'all | Shaft | Insulation | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Max. Speed, rpm | Full Load Current, A | Inverter Rated | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Class | Max. Temp., °F | Environmental Rating | Each | |

230/460 Volts AC, Three Phase | |||||||||||||||

NEMA 145TC | |||||||||||||||

| 1 1/2 | 1,750 | 4.8/2.4 | Yes | Totally Enclosed Fan Cooled (TEFC) | 18 5/8" | 8 7/8" | 7 1/4" | 7/8" | 2" | 3 1/2" | F | 311° | IP43 | 0000000 | 000000000 |

| 2 | 1,740 | 5.8/2.9 | Yes | Totally Enclosed Fan Cooled (TEFC) | 18 3/4" | 8 7/8" | 7 1/4" | 7/8" | 2" | 3 1/2" | F | 311° | IP43 | 0000000 | 00000000 |