About Torque Tools

More

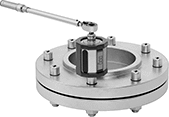

Square Drive Torque Tool Testers

Check the accuracy of torque wrenches and screwdrivers—place your tool onto the tester with the included square drive connector and turn. The main pointer shows torque as it's measured; the memory pointer shows the maximum torque reached. Use these testers with hand tools only.

Note: For the most accurate performance, the maximum torque you apply should fall near the middle of the tester’s torque range.

For technical drawings and 3-D models, click on a part number.

Accuracy | Mounting Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Square Drive Size | Torque Range | Graduations | Torque-Measuring Direction | Clockwise | Counterclockwise | Lg. | Wd. | Ht. | Material | Mounting Fasteners Included | No. of | Dia. | Each | |

With Calibration Certificate Traceable to NIST | ||||||||||||||

in.-lbs. | ||||||||||||||

| 3/8" | 30 to 150 in.-lbs. | 2.5 in.-lbs. | Clockwise and Counterclockwise | ±2% | ±2% | 8" | 4" | 2 1/4" | Steel | No | 4 | 1/4" | 0000000 | 0000000 |

| 3/8" | 60 to 300 in.-lbs. | 5 in.-lbs. | Clockwise and Counterclockwise | ±2% | ±2% | 8" | 4" | 2 1/4" | Steel | No | 4 | 1/4" | 0000000 | 00000000 |

| 3/8" | 120 to 600 in.-lbs. | 10 in.-lbs. | Clockwise and Counterclockwise | ±2% | ±2% | 8" | 4" | 2 1/4" | Steel | No | 4 | 1/4" | 0000000 | 00000000 |

High-Accuracy Torque Tool Testers

Accurate to within ±1%, these torque testers are often used to check the accuracy of torque wrenches and screwdrivers on assembly lines. They come with a calibration certificate traceable to NIST that states they’ve passed a test for accuracy. To test, place your torque wrench or screwdriver onto the tester with the included square drive connection and turn. These testers display torque as it's measured and the maximum torque reached. For accuracy when testing click-style wrenches, they also show the first torque peak reached. They’re not for use with impact or pulse tools.

Note: For the most accurate readings, the maximum torque you're applying should fall near the middle of the tester's torque range.

Bench-top testers can be mounted to your work surface. Those with a gooseneck display can be bent until you can clearly see the test results. Mount these testers to your workbench with a mounting bracket (sold separately). Or, carry them where they’re needed using the included case.

Accuracy | Mounting Holes | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Square Drive Size | Torque Range | Graduations | Torque-Measuring Direction | Clockwise | Counterclockwise | For Tool Type | Ht. | Wd. | Dp. | Mounting Fasteners Included | No. of | Dia. | Batteries Included | Includes | Each | |

With Calibration Certificate with Test Data Traceable to NIST Certificate of Calibration | ||||||||||||||||

in.-lbs., ft.-lbs., Nm | ||||||||||||||||

| 3/8" | 25 to 250 in.-lbs. 2 to 21 ft.-lbs. 2.8 to 28.2 Nm | 0.1 in.-lbs. 0.01 ft.-lbs. 0.01 Nm | Clockwise and Counterclockwise | ±1% | ±1% | Hand Tools Only | 4 1/2" | 6" | 6" | No | 8 | 3/8" | Yes | Female Drive Adapter | 0000000 | 000000000 |

| 3/8" | 60 to 600 in.-lbs. 5 to 50 ft.-lbs. 6.78 to 67.8 Nm | 0.1 in.-lbs. 0.01 ft.-lbs. 0.1 Nm | Clockwise and Counterclockwise | ±1% | ±1% | Hand Tools Only | 4 1/2" | 6" | 6" | No | 8 | 3/8" | Yes | Female Drive Adapter | 0000000 | 00000000 |

Accuracy | Mounting Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Square Drive Size | Torque Range | Graduations | Torque-Measuring Direction | Clockwise | Counterclockwise | For Tool Type | Ht. | Wd. | Dp. | Mounting Fasteners Included | No. of | Dia. | Includes | Each | |

With Calibration Certificate with Test Data Traceable to NIST Certificate of Calibration | |||||||||||||||

in.-lbs., dNm | |||||||||||||||

| 3/8" | 25 to 250 in.-lbs. 28 to 280 dNm | 1 in.-lbs. 1 dNm | Clockwise and Counterclockwise | ±0.5% | ±0.5% | Hand Tools Only | 2 1/2" | 4 1/2" | 14 1/2" | No | 6 | 5/16" | Carrying Case, Female Drive Adapter | 0000000 | 000000000 |

| 3/8" | 100 to 1,000 in.-lbs. 113 to 1,130 dNm | 1 in.-lbs. 1 dNm | Clockwise and Counterclockwise | ±0.5% | ±0.5% | Hand Tools Only | 2 1/2" | 4 1/2" | 14 1/2" | No | 6 | 5/16" | Carrying Case, Female Drive Adapter | 0000000 | 00000000 |

Mounting Holes | ||||||||

|---|---|---|---|---|---|---|---|---|

| Material | Wd. | Ht. | Dp. | Mounting Fasteners Included | No. Of | Dia. | Each | |

| Steel | 4 1/2" | 2 1/2" | 8 3/4" | No | 6 | 5/16" | 0000000 | 0000000 |

Torque Tool Testers for Torque Screwdrivers

Measure the force of hand and non-impact electric torque screwdrivers to keep fasteners from failing due to under or overtightening. A chuck-like adapter simulates your fastener joint during testing. These testers record the first time you reach the maximum torque (peak down), the maximum torque (peak), and torque as it's measured (real-time). For the most accurate performance, the maximum torque you're applying should fall near the middle of the tester's torque range. A track mode lets you monitor fluctuating torque. For quick pass/fail testing, these testers have programmable high/low set points with lights and an alarm. They include a calibration certificate with test data traceable to NIST that states they have passed tests for accuracy.

Testers that meet ISO 17025 have been checked in a laboratory that was evaluated for accuracy.

Testers with automatic screw release reduce time between tests by returning the test screw to its starting position once torque is removed.

Use data acquisition software and a USB cable (each sold separately) to analyze results and connect to computers, laptops, or tablets that run on Microsoft Windows.

Testers cannot be sold to the listed areas due to energy efficiency regulations.

Testers | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Accuracy | USB Output Cables | ||||||||||||

| Screw Drive Size | Square Drive Size | Torque Range | Graduations | Clockwise | Counterclockwise | Features | Battery Type | Includes | Cannot Be Sold To | Each | Each | ||

With Calibration Certificate with Test Data Traceable to NIST Certificate of Calibration | |||||||||||||

lbf-in., kgf-cm, N-cm | |||||||||||||

| No. 2 | 3/8" | 0.02 to 6.97 lbf-in. 0.02 to 8 kgf-cm 0.2 to 78.6 N-cm | 0.001 lbf-in. 0.001 kgf-cm 0.01 N-cm | ±0.5% | ±0.5% | Automatic Screw Release | Rechargeable | 2 Joints (High- and Low-Torque), Carrying Case | CA, OR | 000000 | 000000000 | 000000 | 000000 |

lbf-in., kgf-cm, N-cm, Nm | |||||||||||||

| No. 2, No. 3 | 3/8" | 0.2 to 69.70 lbf-in. 0.2 to 80.00 kgf-cm 2 to 786.00 N-cm 0.02 to 7.86 Nm | 0.01 lbf-in. 0.01 kgf-cm 0.1 N-cm 0.001 Nm | ±0.5% | ±0.5% | Automatic Screw Release | Rechargeable | 2 Joints (High- and Low-Torque), Carrying Case | CA, OR | 000000 | 00000000 | 000000 | 00000 |

lbf-in., kgf-cm, Nm | |||||||||||||

| No. 4 | 3/8" | 1.8 to 221.2 lbf-in. 2 to 255 kgf-cm 0.2 to 25 Nm | 0.01 lbf-in. 0.1 kgf-cm 0.01 Nm | ±0.5% | ±0.5% | __ | Rechargeable | 2 Joints (High- and Low-Torque), Carrying Case | CA, OR | 00000000 | 00000000 | 000000 | 00000 |

With Calibration Certificate with Test Data Traceable to NIST Certificate of Calibration—ISO 17025 | |||||||||||||

lbf-in., kgf-cm, N-cm | |||||||||||||

| No. 2 | 3/8" | 0.02 to 6.97 lbf-in. 0.02 to 8 kgf-cm 0.2 to 78.6 N-cm | 0.001 lbf-in. 0.001 kgf-cm 0.01 N-cm | ±0.5% | ±0.5% | Automatic Screw Release | Rechargeable | 2 Joints (High- and Low-Torque), Carrying Case | CA, OR | 000000 | 00000000 | 000000 | 00000 |

lbf-in., kgf-cm, N-cm, Nm | |||||||||||||

| No. 2, No. 3 | 3/8" | 0.2 to 69.70 lbf-in. 0.2 to 80.00 kgf-cm 2 to 786.00 N-cm 0.02 to 7.86 Nm | 0.01 lbf-in. 0.01 kgf-cm 0.1 N-cm 0.001 Nm | ±0.5% | ±0.5% | Automatic Screw Release | Rechargeable | 2 Joints (High- and Low-Torque), Carrying Case | CA, OR | 000000 | 00000000 | 000000 | 00000 |

lbf-in., kgf-cm, Nm | |||||||||||||

| No. 4 | 3/8" | 1.8 to 221.2 lbf-in. 2 to 255 kgf-cm 0.2 to 25 Nm | 0.01 lbf-in. 0.1 kgf-cm 0.01 Nm | ±0.5% | ±0.5% | __ | Rechargeable | 2 Joints (High- and Low-Torque), Carrying Case | CA, OR | 00000000 | 00000000 | 000000 | 00000 |

| Data Acquisition Software | 000000 | Each | 0000000 |

Square Drive Connectors for Torque Tool Testers

Use these connectors to test male square drive tools on torque testers that have a male square drive.

For technical drawings and 3-D models, click on a part number.

| Square Drive Size (Gender) | Material | Each | |

| 3/8" (Female) × 3/8" (Female) | Steel | 00000000 | 000000 |

Rotary Torque Testers

Monitor torque as you apply it—these testers mount between your torque tool and your fastener. Engage the fastener to track both torque and the angle of rotation for each crank of your tool (snug torque) before you've reached the final torque. This gives you a better idea if fasteners are consistently tightened than measuring torque alone. These testers are often used with nutrunners and click-style torque wrenches in the automotive and aerospace industries. Store up to 999 maximum torque (peak) and rotation values, including the date and time of each test, or transfer to your computer to view in an Excel file. CE marked, they meet European safety standards.

For the most accurate readings, the maximum torque you're applying should fall near the middle of the tester's torque range. They are not for use with impact tools.

Testers with a USB connection transfer data directly to your computer with the included cord. These testers last up to 10 hours on a single charge.

Testers with a Bluetooth connection wirelessly transmit data to a computer as you measure. You can also remotely set snug torque, or when these testers starting measuring the torque applied with each rotation. They last up to 8 hours on a single charge with Bluetooth on and 10 hours with it off.

For technical drawings and 3-D models, click on a part number.

Accuracy | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Square Drive Size | Torque Range | Graduations | Clockwise | Counterclockwise | Lg. | OD | Features | Battery Type | Battery Charger Included | Includes | Each | |

USB-B Data Connection | ||||||||||||

| 3/8" | 560 to 2,800 in.-oz. 35 to 175 in.-lbs. 3 to 14.5 ft.-lbs. 40 to 200 kgf-cm 0.4 to 2 kgf-m 400 to 2,000 cNm 4 to 20 Nm | 2 in.-oz. 0.2 in.-lbs. 0.02 ft.-lbs. 0.2 kgf-cm 0.002 kgf-m 2 cNm 0.02 Nm | ±1% | ±1% | 2 15/16" | 1 13/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | 6 1/2-ft. Long USB Cord, AC Adapter | 0000000 | 000000000 |

| 3/8" | 1,400 to 7,000 in.-oz. 88 to 440 in.-lbs. 7.5 to 36.5 ft.-lbs. 100 to 500 kgf-cm 1 to 5 kgf-m 1,000 to 5,000 cNm 10 to 50 Nm | 5 in.-oz. 0.5 in.-lbs. 0.05 ft.-lbs. 0.5 kgf-cm 0.005 kgf-m 5 cNm 0.05 Nm | ±1% | ±1% | 2 15/16" | 1 13/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | 6 1/2-ft. Long USB Cord, AC Adapter | 0000000 | 00000000 |

Bluetooth Data Connection | ||||||||||||

| 3/8" | 560 to 2,800 in.-oz. 35 to 175 in.-lbs. 3 to 14.5 ft.-lbs. 40 to 200 kgf-cm 0.4 to 2 kgf-m 400 to 2,000 cNm 4 to 20 Nm | 2 in.-oz. 0.2 in.-lbs. 0.02 ft.-lbs. 0.2 kgf-cm 0.002 kgf-m 2 cNm 0.02 Nm | ±1% | ±1% | 2 15/16" | 1 15/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | AC Adapter | 0000000 | 00000000 |

| 3/8" | 1,400 to 7,000 in.-oz. 88 to 440 in.-lbs. 7.5 to 36.5 ft.-lbs. 100 to 500 kgf-cm 1 to 5 kgf-m 1,000 to 5,000 cNm 10 to 50 Nm | 5 in.-oz. 0.5 in.-lbs. 0.05 ft.-lbs. 0.5 kgf-cm 0.005 kgf-m 5 cNm 0.05 Nm | ±1% | ±1% | 2 15/16" | 1 15/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | AC Adapter | 0000000 | 00000000 |

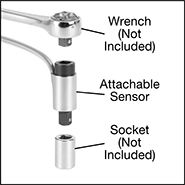

Data-Recording Torque Gauges

Wrench-attachable sensors fit between your wrench and socket. Use with hand tools only.

Accuracy | |||||||

|---|---|---|---|---|---|---|---|

| Square Drive Size (Gender) | Torque Range | Torque-Measuring Direction | Clockwise | Counterclockwise | Cord Lg., ft. | Each | |

in.-oz., in.-lbs., ft.-lbs., Nm, cNm, m-kg, cm-kg | |||||||

| 3/8" (Female) × 3/8" (Male) | 120 to 1,200 in.-lbs. 10 to 100 ft.-lbs. 13.6 to 136 Nm 1,356 to 13,560 cNm 1.38 to 13.8 m-kg 138 to 1,383 cm-kg | Clockwise and Counterclockwise | ±1% | ±1% | 4 | 0000000 | 0000000 |