Filter by

Cooling Method

Torch Body Type

Welding Process

TIG Welding Type

TIG Industry Number

Cable Material

Gas Valve Included

Application

Head Movement

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Duty Cycle

TIG Torches

With many of the parts you need for TIG welding, these torches include a torch body and a cable and hose assembly.

Rigid-Neck Torch Body

|

Gas Valve Not Included |

Gas Valve Not Included—Torches without a gas valve require a welder with a built-in gas valve.

Water Cooled—Water-cooled torches cool more efficiently than air-cooled torches, which keeps your torch from overheating even when welding continuously or for long periods of time.

Flexible-Neck Torch Body

|

Gas Valve Not Included |

Flexible-neck torch bodies bend so you can weld in hard-to-reach areas. A copper coil allows the neck to flex, but it will loosen over time.

Gas Valve Not Included—Torches without a gas valve require a welder with a built-in gas valve.

Water Cooled—Water-cooled torches cool more efficiently than air-cooled torches, which keeps your torch from overheating even when welding continuously or for long periods of time.

12 ft. Long Cable | 25 ft. Long Cable | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Torch Series No. | Head Movement | Max. Current, amp | Includes | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gas Valve Not Included | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Water Cooled—Rubber Cable | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | Rigid | 225 | Torch Body Cable and Hose Assembly Torch Handle Medium Back Cap | 0000000 | 0000000 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Water Cooled—Vinyl Plastic Cable | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | Rigid | 225 | Torch Body Cable and Hose Assembly Torch Handle Medium Back Cap | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TIG Torch Nozzles

|

Standard |

|

Gas Saving |

|

|  |

Aluminum Oxide Ceramic for Narrow Gas Coverage | Aluminum Oxide Ceramic for Wide Gas Coverage |

|  |

Silicon Nitride Ceramic for Narrow Gas Coverage | Borosilicate Glass for Narrow Gas Coverage |

|  |

Borosilicate Glass for Wide Gas Coverage | Quartz Glass for Narrow Gas Coverage |

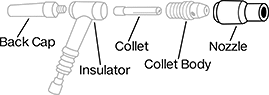

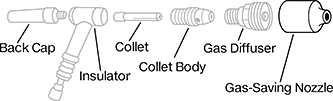

Direct the flow of shielding gas to your weld with these nozzles. When choosing a nozzle size, consider the thickness of the material you’re welding. In general, the thicker the material, the higher the nozzle size you should use. All nozzles require a compatible collet in order to connect to your TIG torch.

Aluminum Oxide Ceramic—Aluminum oxide ceramic nozzles are the most common nozzles. They’re more durable than borosilicate glass nozzles but can limit visibility since they aren’t clear. Use them for general purpose welding applications.

Borosilicate Glass—Borosilicate glass nozzles are clear, so you can see what you’re working on even in tight corners, but they break more easily than other nozzles. These nozzles require a push-on collet body.

Quartz Glass—Quartz glass nozzles are clear like borosilicate glass nozzles, but they’re more durable and withstand higher temperatures. They also won’t turn yellow over time like borosilicate glass nozzles. If you're using them as standard nozzles, you'll need an adapter ring (sold separately) to connect to a threaded collet body.

Silicon Nitride Ceramic—Silicon nitride ceramic nozzles are just as durable as aluminum oxide ceramic nozzles, and they’ll work at higher temperatures. However, they also limit visibility because they aren’t clear. Use standard nozzles with a threaded collet body.

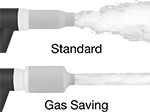

For Narrow Gas Coverage—Nozzles for narrow gas coverage are good for welding most metals.

For Wide Gas Coverage—Nozzles for wide gas coverage produce a large cloud of shielding gas, so they’re a good choice when working with metals that are difficult to weld, such as titanium and Inconel. However, they’re harder to fit into corners than standard nozzles.

Standard TIG Welding—Standard nozzles require a threaded collet body.

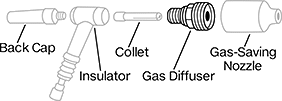

Gas-Saving TIG Welding—Gas-saving nozzles use less gas than standard nozzles but won’t compromise the quality of your weld. These nozzles require a gas diffuser, which prevents oxidation and pitting in the weld by reducing gas turbulence and improving shielding.

For Torch Series No. | TIG Torch Nozzle Size | For Electrode Dia. | TIG Industry No. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Aluminum Oxide Ceramic for Narrow Gas Coverage | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 4 | — | 13N08 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 5 | — | 13N09 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 6 | — | 13N10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 7 | — | 13N11 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 8 | — | 13N12 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 10 | — | 13N13 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gas-Saving TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 4 | — | 53N58 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 5 | — | 53N59 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 6 | — | 53N60 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 7 | — | 53N61 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 8 | — | 53N61S | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum Oxide Ceramic for Wide Gas Coverage | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gas-Saving TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | — | 0.063" | 53N6CN2-16 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | — | 0.094" | 53N6CN2-32 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | — | 0.125" | 53N6CN2-18 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Silicon Nitride Ceramic for Narrow Gas Coverage | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 4 | — | 13N08SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 5 | — | 13N09SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 6 | — | 13N10SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 7 | — | 13N11SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 8 | — | 13N12SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 10 | — | 13N13SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gas-Saving TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 4 | — | 53N58SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 5 | — | 53N59SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 6 | — | 53N60SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 7 | — | 53N61SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 8 | — | 53N61SSC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Borosilicate Glass for Narrow Gas Coverage | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gas-Saving TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | — | 0.063", 0.094", 0.125" | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Borosilicate Glass for Wide Gas Coverage | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gas-Saving TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | — | 0.063", 0.094", 0.125" | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Quartz Glass for Narrow Gas Coverage | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard TIG Welding, Gas-Saving TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 5 | — | 13NQ-5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 5 | — | 13NQ-5L | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 7 | — | 13NQ-7 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 9 | — | 13NQ-9 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 17, 18, 20, 25, 26 | 7 | — | 10NQ-7L | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 17, 18, 20, 25, 26 | 9 | — | 10NQ-9L | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TIG Torch Bodies

Replace worn torch bodies on your TIG torch.

Rigid-Neck Torch Bodies

Gas Valve Not Included |

Water Cooled—Water-cooled torch bodies cool more efficiently than air-cooled torch bodies, which keeps your torch from overheating, even when welding continuously and for long periods of time.

Gas Valve Not Included—Use torch bodies without a gas valve with a machine that has a built-in gas valve.

Gas Valve Not Included | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Torch Series No. | Head Movement | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Water Cooled | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | Rigid | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flexible-Neck Torch Bodies

|

Gas Valve Not Included |

Torch bodies with a flexible neck have a copper coil that bends, so you can weld in hard-to-reach areas. However, the copper coil will loosen over time.

Water Cooled—Water-cooled torch bodies cool more efficiently than air-cooled torch bodies, which keeps your torch from overheating, even when welding continuously and for long periods of time.

Gas Valve Not Included—Use torch bodies without a gas valve with a machine that has a built-in gas valve.

Gas Valve Not Included | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Torch Series No. | Head Movement | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Water Cooled | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | Rigid | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TIG Torch Gas Diffusers

|

Smooth the flow of shielding gas coming out of your TIG torch nozzle, so you have more control and less waste. These mesh diffusers reduce turbulence so that the gas stays where you need it, shielding the weld and preventing oxidation and pitting, which cause weak welds. All require a TIG torch insulator.

For Aluminum Oxide Ceramic Nozzles and Silicon Nitride Ceramic Nozzles

|

Diffusers for ceramic nozzles are commonly called gas lenses.

For Narrow Gas Coverage | For Narrow or Wide Gas Coverage | |||||

|---|---|---|---|---|---|---|

For Torch Series No. | For Electrode Diameter (TIG Industry Number) | Each | Each | |||

| 9, 20, 25 | 0.020" (45V41) | 000000000 | 000000 | ——— | 0 | |

| 9, 20, 25 | 0.040" (45V42) | 000000000 | 00000 | ——— | 0 | |

| 9, 20, 25 | 0.063" (45V43) | ——— | 0 | 000000000 | 000000 | |

| 9, 20, 25 | 0.094" (45V44) | ——— | 0 | 000000000 | 00000 | |

| 9, 20, 25 | 0.125" (45V45) | ——— | 0 | 000000000 | 00000 | |

For Borosilicate Glass Nozzles

|

Diffusers for borosilicate glass nozzles are commonly called screens.

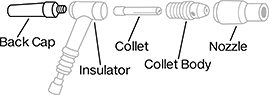

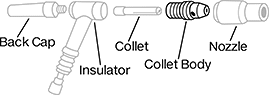

TIG Torch Back Caps

|

|  |

Short | Medium |

| |

Long |

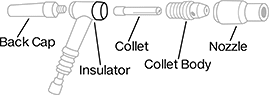

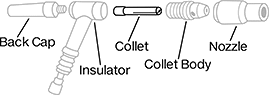

Tighten these caps to the back of your TIG torch, so the collet grips the electrode. They also cover the part of the electrode sticking out the back of your TIG torch.

TIG Torch Accessory Kits

|

All the TIG torch accessories you need to get started in one kit, including collets, collet bodies, and nozzles.

Borosilicate Glass Nozzle—Kits with borosilicate glass nozzles are clear, so you'll be able to see what you're working on, even when space is cramped. However, these nozzles break more easily than other nozzles. Instead of threads, the collet bodies have O-rings; push the nozzle onto the collet body, and the O-ring holds it in place.

Aluminum Oxide Ceramic Nozzle—Kits with aluminum oxide ceramic nozzles are durable and economical—a good choice for most applications, although they do limit visibility, unlike glass. The nozzles thread directly onto the collet bodies.

Gas-Saving TIG Welding—Gas-saving nozzles include a gas diffuser, so they use less gas than standard nozzles but won't compromise the quality of your weld. The gas diffuser smooths the flow of shielding gas, so it goes where you want it and isn't wasted. Shielding gas prevents oxidation and pitting, which weaken welds. Having reliable gas coverage means your electrode can stick out farther and reach into tight spots while staying inside the cloud of gas.

For Narrow Gas Coverage—Narrow nozzles work well with most metals.

For Wide Gas Coverage—Wide nozzles spray a large cloud of shielding gas that helps with tough-to-weld metals, such as titanium and Inconel. Because of their size, they’re harder to fit into corners than standard nozzles.

For Narrow Gas Coverage | For Wide Gas Coverage | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Torch Series No. | For Electrode Dia. | Includes | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Borosilicate Glass Nozzle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gas-Saving TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 0.063" | Gas Lens Insulator 0.063" Collet 0.063" Collet Body 0.063" Gas Diffuser Borosilicate Glass Nozzle | 0000000 | 000000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 0.094" | Gas Lens Insulator 0.094" Collet 0.094" Collet Body 0.094" Gas Diffuser Borosilicate Glass Nozzle | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 0.125" | Gas Lens Insulator 0.125" Collet 0.125" Collet Body 0.125" Gas Diffuser Borosilicate Glass Nozzle | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum Oxide Ceramic Nozzle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 0.063", 0.094", 0.125" | Long Back Cap 0.063" Collet 0.094" Collet 0.125" Collet 0.063" Collet Body 0.094" Collet Body 0.125" Collet Body Size 5 Aluminum Oxide Ceramic Nozzle Size 6 Aluminum Oxide Ceramic Nozzle Size 7 Aluminum Oxide Ceramic Nozzle 7" Long 2% Ceriated Tungsten Electrode with 0.063" Diameter 7" Long 2% Ceriated Tungsten Electrode with 0.094" Diameter 7" Long 2% Ceriated Tungsten Electrode with 0.125" Diameter | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gas-Saving TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 0.063" | Aluminum Oxide Ceramic Nozzle Gas Lens Insulator 0.063" Collet 0.063" Collet Body 0.063" Gas Diffuser | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 0.094" | Aluminum Oxide Ceramic Nozzle Gas Lens Insulator 0.094" Collet 0.094" Collet Body 0.094" Gas Diffuser | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 0.125" | Aluminum Oxide Ceramic Nozzle Gas Lens Insulator 0.125" Collet 0.125" Collet Body 0.125" Gas Diffuser | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TIG Torch Collet Bodies

|

Attach TIG torch nozzles to TIG torches with these collet bodies. Holes in the collet body route shielding gas to the nozzle to protect your weld from oxidation and pitting. Use them with a split or wedge collet to hold a tungsten electrode. All collet bodies require a TIG torch insulator.

For Aluminum Oxide Ceramic and Silicon Nitride Ceramic Nozzles

|

Collet bodies for aluminum oxide ceramic and silicon nitride ceramic nozzles have threads for connecting to nozzles. Use an adapter ring (sold separately) to connect quartz glass nozzles to these collet bodies.

TIG Torch Collet Bodies | TIG Torch Adapter Rings for Quartz Glass Nozzles | ||||||

|---|---|---|---|---|---|---|---|

For Narrow Gas Coverage | |||||||

For Torch Series No. | Choose an Electrode Diameter (Industry Number) | Each | Nozzle Connection | Each | |||

| 9, 20, 25 | 0.020" (13N25) , 0.040" (13N26) , 0.063" (13N27) , 0.094" (13N28) , 0.125" (13N29) | 00000000 | 00000 | Threaded × Push On | 000000000 | 00000 | |

For Borosilicate Glass Nozzles

TIG Torch Insulators

|  |

Prevent shielding gas from escaping and protect torch components from excessive heat—these insulators form a seal between nozzle and torch. When choosing an insulator, you'll want to match your torch's series number and your nozzle's material, as well as whether or not your nozzle is gas saving.

For Torch Series No. | For Nozzle Material | For Gas Coverage | TIG Industry No. | Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Standard TIG Welding/Gas-Saving TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | Aluminum Oxide Ceramic, Quartz Glass | Narrow, Wide | 598882 | PTFE | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | Silicon Nitride Ceramic | Narrow | — | Nylon | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gas-Saving TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | Aluminum Oxide Ceramic, Borosilicate Glass | Narrow | — | PTFE | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | Aluminum Oxide Ceramic, Borosilicate Glass | Wide | — | PTFE | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TIG Torch Collets

|

Hold your tungsten electrode in place during TIG welding with these collets. Slide them into a collet body or gas lens, and secure by screwing the back cap onto your torch.

Split TIG Collet—Split collets are split into two sides. When you tighten the back cap, the sides squeeze together to grip the tungsten. These are the most common collet style, but the split is a weak area where they deform over time.

Wedge TIG Collet—Wedge collets have a wedge-shaped head that presses against the collet body when the back cap is tightened, holding the tungsten steady. This single-piece design is more durable than split collets.

For Torch Series No. | For Nozzle Material | For Gas Coverage | Choose an Electrode Diameter (Industry Number) | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Split TIG Collet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | Aluminum Oxide Ceramic, Silicon Nitride Ceramic, Quartz Glass | Narrow | 0.020" (13N20) , 0.040" (13N21) | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | Aluminum Oxide Ceramic, Silicon Nitride Ceramic, Quartz Glass | Narrow, Wide | 0.063" (13N22) , 0.094" (13N23) , 0.125" (13N24) | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wedge TIG Collet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | Silicon Nitride Ceramic, Borosilicate Glass | Narrow | 0.063" , 0.094" , 0.125" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TIG Torch Power Cable Adapters

|

Connect your power cable to your argon hose for TIG welding.

For Torch Series No. | TIG Industry No. | Each | ||

|---|---|---|---|---|

| 18, 20, 22, 25 | 45V11 | 0000000 | 000000 |