TIG Torch Nozzles

|

Standard |

|

Gas Saving |

|

|  |  |

Aluminum Oxide Ceramic for Narrow Gas Coverage | Silicon Nitride Ceramic for Narrow Gas Coverage | Borosilicate Glass for Narrow Gas Coverage |

|  | |

Borosilicate Glass for Wide Gas Coverage | Quartz Glass for Narrow Gas Coverage |

Direct the flow of shielding gas to your weld with these nozzles. When choosing a nozzle size, consider the thickness of the material you’re welding. In general, the thicker the material, the higher the nozzle size you should use. All nozzles require a compatible collet in order to connect to your TIG torch.

Aluminum Oxide Ceramic—Aluminum oxide ceramic nozzles are the most common nozzles. They’re more durable than borosilicate glass nozzles but can limit visibility since they aren’t clear. Use them for general purpose welding applications.

Borosilicate Glass—Borosilicate glass nozzles are clear, so you can see what you’re working on even in tight corners, but they break more easily than other nozzles. These nozzles require a push-on collet body.

Quartz Glass—Quartz glass nozzles are clear like borosilicate glass nozzles, but they’re more durable and withstand higher temperatures. They also won’t turn yellow over time like borosilicate glass nozzles. If you're using them as standard nozzles, you'll need an adapter ring (sold separately) to connect to a threaded collet body.

Silicon Nitride Ceramic—Silicon nitride ceramic nozzles are just as durable as aluminum oxide ceramic nozzles, and they’ll work at higher temperatures. However, they also limit visibility because they aren’t clear. Use standard nozzles with a threaded collet body.

For Narrow Gas Coverage—Nozzles for narrow gas coverage are good for welding most metals.

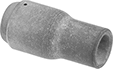

For Wide Gas Coverage—Nozzles for wide gas coverage produce a large cloud of shielding gas, so they’re a good choice when working with metals that are difficult to weld, such as titanium and Inconel. However, they’re harder to fit into corners than standard nozzles.

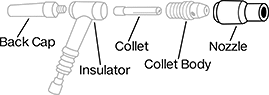

Standard TIG Welding—Standard nozzles require a threaded collet body.

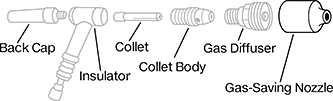

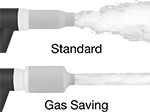

Gas-Saving TIG Welding—Gas-saving nozzles use less gas than standard nozzles but won’t compromise the quality of your weld. These nozzles require a gas diffuser, which prevents oxidation and pitting in the weld by reducing gas turbulence and improving shielding.

For Torch Series No. | TIG Torch Nozzle Size | For Electrode Dia. | TIG Industry No. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Aluminum Oxide Ceramic for Narrow Gas Coverage | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 4 | — | 10N50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 5 | — | 10N49 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 6 | — | 10N48 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 7 | — | 10N47 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 8 | — | 10N46 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 10 | — | 10N45 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 12 | — | 10N44 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gas-Saving TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 4 | — | 54N18 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 5 | — | 54N17 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 6 | — | 54N16 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 7 | — | 54N15 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 8 | — | 54N14 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Silicon Nitride Ceramic for Narrow Gas Coverage | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 4 | — | 10N50SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 5 | — | 10N49SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 6 | — | 10N48SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 7 | — | 10N47SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 8 | — | 10N46SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 10 | — | 10N45SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 12 | — | 10N44SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gas-Saving TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 4 | — | 54N18SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 5 | — | 54N17SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 6 | — | 54N16SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 7 | — | 54N15SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 8 | — | 54N14SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Borosilicate Glass for Narrow Gas Coverage | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gas-Saving TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | — | 0.063", 0.094", 0.125" | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Borosilicate Glass for Wide Gas Coverage | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gas-Saving TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | — | 0.063", 0.094", 0.125" | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Quartz Glass for Narrow Gas Coverage | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 17, 18, 20, 25, 26 | 7 | — | 10NQ-7L | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 17, 18, 20, 25, 26 | 9 | — | 10NQ-9L | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||