Telescoping Weld-Together Rails

Create posts of varying lengths. To telescope rails, slide one length of rail into the next larger size rail (for example, a 1 3/4" height rail fits into a 2" height rail and a 3/4" dia. rail fits into a 1" dia. rail). Weld the rails together at the desired length to create strong structures. These rails are not compatible with weld-together framing and fittings.

Aluminum rails are about half the weight of steel and resist corrosion in wet environments.

For technical drawings and 3-D models, click on a part number.

Rail | ||||||||

|---|---|---|---|---|---|---|---|---|

| Ht. | Wd. | Wall Thick. | Lg. Tolerance | 2 ft. | 4 ft. | 6 ft. | 8 ft. | |

6000 Series Aluminum | ||||||||

| 3/4" | 3/4" | 0.08" | -2" to +2" | 0000000 | ||||

| 1" | 1" | 0.08" | -2" to +2" | 0000000 | ||||

| 1 1/2" | 1 1/2" | 0.11" | 0" to +0.065" | 00000000 | ||||

| 1 3/4" | 1 3/4" | 0.11" | 0" to +0.065" | 00000000 | ||||

| 2" | 2" | 0.11" | 0" to +0.065" | 00000000 | ||||

| 3 1/2" | 3 1/2" | 0.25" | 0" to +0.065" | 00000000 | ||||

| 4" | 4" | 0.25" | 0" to +0.065" | 00000000 | ||||

Light Duty Aluminum Telescoping Framing and Fittings

Create lightweight adjustable structures. With telescoping aluminum rails, this framing is often used to make folding stands, extension poles, and sign frames. To telescope rails, slide one length of rail into the next larger size and connect using the corresponding locks.

For technical drawings and 3-D models, click on a part number.

Tolerance | |||||||

|---|---|---|---|---|---|---|---|

| Rail OD | Wall Thick. | Wall Thick. | Lg. | 3 ft. | 4 ft. | 6 ft. | |

Anodized Aluminum | |||||||

| 5/8" | 0.038" | -0.005" to 0.005" | -0.0625" to 0.0625" | 00000000 | |||

| 3/4" | 0.038" | -0.005" to 0.005" | -0.0625" to 0.0625" | 00000000 | |||

| 7/8" | 0.038" | -0.005" to 0.005" | -0.0625" to 0.0625" | 00000000 | |||

| 1" | 0.038" | -0.005" to 0.005" | -0.0625" to 0.0625" | 00000000 | |||

| 1 1/8" | 0.038" | -0.005" to 0.005" | -0.0625" to 0.0625" | 00000000 | |||

| 1 1/4" | 0.038" | -0.005" to 0.005" | -0.0625" to 0.0625" | 00000000 | |||

| 1 3/8" | 0.038" | -0.005" to 0.005" | -0.0625" to 0.0625" | 00000000 | |||

| 1 1/2" | 0.038" | -0.005" to 0.005" | -0.0625" to 0.0625" | 00000000 | |||

Aluminum Bolt-Together Framing and Fittings

Half the weight of steel, this aluminum framing resists corrosion in wet environments. Rails are drilled with consistently spaced holes for multiple mounting options that do not require machining. Use this bolt-together framing to build guards, tables, and racks.

For technical drawings and 3-D models, click on a part number.

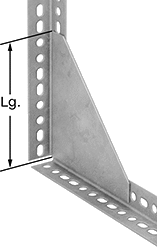

Surface brackets connect rails.

Corner brackets connect rails.

Lg. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Bracket Style | For Rail Ht. | (A) | (B) | Thick. | Material | Mounting Fasteners Included | For Screw Size | Each | |

| Corner | 1 1/2", 1 3/4", 2" | 1 1/2" | 1 1/2" | 1/4" | Anodized Aluminum | Yes | 5/16" | 0000000 | 00000 |

Connectors fit inside the rail and are hidden to connect rails to rails with a finished look.

Use the 2 15/16" long connector to connect rails that have been cut and no longer have the standard 3/4" distance between the end of the rail and the center of the first hole.

Fixed-height mounting feet have a flange to attach to floors, walls, and ceilings.

| Mounting Foot Type | For Rail Ht. | Lg. | Material | Mounting Fasteners Included | For Screw Size | Each | |

| Fixed Height | 1 1/2" | 5" | Anodized Aluminum | Yes | 5/16" | 0000000 | 000000 |

Flat and Angled Bolt-Together Framing and Fittings

Rails are drilled with consistently spaced holes for multiple mounting options that do not require machining. Use this bolt-together framing to build guards, tables, and racks.

For technical drawings and 3-D models, click on a part number.

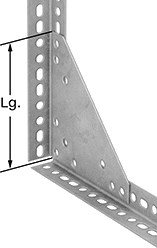

Surface brackets connect rails. These brackets do not have mounting holes already drilled, so you can drill holes where you need them or weld the brackets in place.

Aluminum brackets are half the weight of steel brackets, and they resist corrosion in wet environments.

| Lg. | Thick. | Material | Mounting Fasteners Included | Each | |

| 6" | 0.08" | Aluminum | No | 00000000 | 000000 |

Surface brackets connect rails.

Aluminum brackets are half the weight of steel brackets, and they resist corrosion in wet environments.

| Lg. | Thick. | Material | Mounting Hole Shape | For Screw Size | Mounting Fasteners Included | Each | |

| 6" | 0.08" | Aluminum | Round | 5/16" | No | 00000000 | 000000 |

Telescoping Architectural 6063 Aluminum Round Tubes

- Yield Strength:

0.038" Wall Thick.: 36,000 psi

0.058" Wall Thick.: 35,000 psi - Hardness: Not Rated

- Temper: T832

- Fabrication: Cold Drawn

- Specifications Met: ASTM B483

Sized to fit into the next larger size, use these tubes to create telescoping railings and frames. More corrosion resistant and easier to form than multipurpose 6061 aluminum, 6063 is often used for architectural applications. It is lightweight yet moderately strong and can be machined or formed.

For technical drawings and 3-D models, click on a part number.

| OD | ID | Heat Treatment | Temperature Range, °F | 1 ft. Lg. | 3 ft. Lg. | 6 ft. Lg. | |

0.038" Wall Thick. | |||||||

|---|---|---|---|---|---|---|---|

| 3/8" | 0.299" | Hardened | -320° to 212° | 00000000 | |||

| 1/2" | 0.424" | Hardened | -320° to 212° | 00000000 | |||

| 5/8" | 0.549" | Hardened | -320° to 212° | 00000000 | |||

| 3/4" | 0.674" | Hardened | -320° to 212° | 00000000 | |||

| 7/8" | 0.799" | Hardened | -320° to 212° | 00000000 | |||

| 1" | 0.924" | Hardened | -320° to 212° | 00000000 | |||

| 1 1/8" | 1.049" | Hardened | -320° to 212° | 00000000 | |||

| 1 1/4" | 1.174" | Hardened | -320° to 212° | 00000000 | |||

| 1 3/8" | 1.299" | Hardened | -320° to 212° | 00000000 | |||

| 1 1/2" | 1.424" | Hardened | -320° to 212° | 00000000 | |||

0.058" Wall Thick. | |||||||

| 3/4" | 0.634" | Hardened | -320° to 212° | 00000000 | |||

| 7/8" | 0.759" | Hardened | -320° to 212° | 00000000 | |||

| 1" | 0.884" | Hardened | -320° to 212° | 00000000 | |||

| 1 1/8" | 1.009" | Hardened | -320° to 212° | 00000000 | |||

| 1 1/4" | 1.134" | Hardened | -320° to 212° | 00000000 | |||

| 1 3/8" | 1.259" | Hardened | -320° to 212° | 00000000 | |||

| 1 1/2" | 1.384" | Hardened | -320° to 212° | 00000000 | |||

| 1 5/8" | 1.509" | Hardened | -320° to 212° | 00000000 | |||

| 1 3/4" | 1.634" | Hardened | -320° to 212° | 00000000 | |||

| 1 7/8" | 1.759" | Hardened | -320° to 212° | 00000000 | |||

| 2" | 1.884" | Hardened | -320° to 212° | 00000000 | |||

Telescoping Corrosion-Resistant 3003 Aluminum Tubes

- Yield Strength: 21,000 psi

- Hardness: Brinell 40 (Soft)

- Temper: H14 (1/2 Hard)

- Fabrication: Cold Drawn

- Specifications Met: ASTM B210

These tubes are sized so that each tube fits into the next larger size. 3003 aluminum stands up to outdoor use, as well as exposure to chemicals. It offers a good combination of strength, formability, and weldability. It's often used for storage tanks, heat exchangers, and general sheet metal work.

For technical drawings and 3-D models, click on a part number.

1 ft. Lg. | 6 ft. Lg. | ||||||

|---|---|---|---|---|---|---|---|

| OD | ID | Temperature Range, °F | Pkg. Qty. | Pkg. | Each | ||

0.014" Wall Thick. (-0.002" to 0.002" Tolerance) | |||||||

| 1/16" | 0.035" | -300° to 300° | 3 | 0000000 | 00000 | 0000000 | 00000 |

| 3/32" | 0.066" | -300° to 300° | 3 | 0000000 | 0000 | 0000000 | 0000 |

| 1/8" | 0.097" | -300° to 300° | 3 | 0000000 | 0000 | 0000000 | 0000 |

| 5/32" | 0.128" | -300° to 300° | 1 | 0000000 | 0000 | 0000000 | 0000 |

| 3/16" | 0.159" | -300° to 300° | 1 | 0000000 | 0000 | 0000000 | 0000 |

| 7/32" | 0.191" | -300° to 300° | 1 | 0000000 | 0000 | 0000000 | 0000 |

| 1/4" | 0.222" | -300° to 300° | 1 | 0000000 | 0000 | 0000000 | 0000 |

| 9/32" | 0.253" | -300° to 300° | 1 | 0000000 | 0000 | 0000000 | 0000 |

| 5/16" | 0.284" | -300° to 300° | 1 | 0000000 | 0000 | 0000000 | 00000 |

Temporary Partition Poles

Use these telescoping poles with tarps, drop cloths, and plastic sheeting up to 8 mils thick to create a sturdy, temporary wall and control dust and debris. Poles have a head plate with a nonskid pad to protect your ceiling.

Replace head plates with dust seals (sold separately) for extra protection. These aluminum bars with foam padding press tightly to the ceiling.

Zippered doorway kits (sold separately) include two zippers and a knife to cut sheeting. Use one zipper for a narrow opening; use both to create a larger, roll-up entryway.