About Nuts, Materials, and Finishes

More

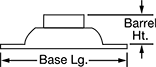

Steel Split-Resistant Tee Nut Inserts for Hardwood

Fewer prongs than other tee nut inserts reduce the risk of splitting hardwood—these inserts have three short prongs. Hammer them into a drilled hole to install. Installed length includes the flange.

Zinc-plated steel inserts are mildly corrosion resistant in wet environments.

For technical drawings and 3-D models, click on a part number.

Barrel | Flange | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Installed Lg. | Dia. | Lg. | Dia. | Thick. | Drill Bit Size | For Max. Hole Dia. | Pkg. Qty. | Pkg. | |

Zinc-Plated Steel | ||||||||||

| 4-40 | 0.149" | 0.13" | 1/8" | 23/64" | 0.024" | 9/64" | 9/64" | 100 | 000000000 | 000000 |

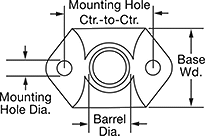

Stainless Steel Narrow-Base Weld Nuts

Slim at the base, these weld nuts fit in channels and other spaces too tight for round-base weld nuts. Weld them to stainless steel surfaces to add strong, permanent threads that resist corroding from chemicals. With a barrel that’s twice as long as low-profile narrow-base weld nuts, more threads engage the fastener for a strong hold. Their base is smooth on both sides, allowing you to weld them either flush to a surface or with the barrel through a hole. Compared to rivet nuts, they stand up to higher torque and pull force.

For technical drawings and 3-D models, click on a part number.

Base | Barrel | |||||||

|---|---|---|---|---|---|---|---|---|

| Thread Size | Lg. | Wd. | Thick. | Dia. | Ht. | Pkg. Qty. | Pkg. | |

18-8 Stainless Steel | ||||||||

| 4-40 | 9/16" | 9/32" | 1/32" | 9/64" | 1/8" | 25 | 000000000 | 000000 |

Steel Round-Base Weld Nuts

A smooth base provides more contact with the mating surface than weld nuts with projections. Both sides of the weld nut base are flat, so it can be welded flush to a surface or with the barrel through the hole. Use them to add strong, permanent threads to uncoated steel surfaces. Its barrel is twice as long as low-profile weld nuts for added thread engagement. Because they’re welded on, they can stand up to more torque and pull force than rivet nuts.

Uncoated steel weld nuts can be welded on with minimal preparation.

Zinc-plated steel weld nuts are corrosion resistant in wet environments. They require some preparation before welding, such as grinding off the plating from the part of the nut you intend to weld.

For technical drawings and 3-D models, click on a part number.

Stainless Steel Round-Base Weld Nuts

Weld these nuts to stainless steel surfaces to add strong, permanent threads that distribute force evenly. Their round base acts as a flange. Made of stainless steel, they resist corroding from chemicals. With a barrel that’s twice as long as low-profile round-base weld nuts, more threads engage with the fastener for a strong hold. A smooth base on both sides gives you the flexibility to weld them flush to a surface or with the barrel through a hole. Compared to rivet nuts, they stand up to higher torque and pull force.

For technical drawings and 3-D models, click on a part number.

Base | Barrel | ||||||

|---|---|---|---|---|---|---|---|

| Thread Size | Dia. | Thick. | Dia. | Ht. | Pkg. Qty. | Pkg. | |

18-8 Stainless Steel | |||||||

| 4-40 | 3/8" | 1/32" | 1/8" | 1/8" | 25 | 000000000 | 000000 |

Stainless Steel Low-Profile Round-Base Weld Nuts with Projections

Add corrosion-resistant threads to stainless steel sheets, even in spaces with low clearance. These nuts have a short collar to fit in confined spaces. To make welding easier, their collar pilot guides them into the hole and aligns them with the surface. It also shields the threads from weld spatter. The round base acts as a flange to evenly distribute force, while the projections concentrate your weld. This makes room for heat to dissipate, protecting the threads from deforming. These weld nuts stand up to high torque and pull force better than rivet and press-fit nuts, making them the strongest way to add permanent threads to sheet metal. You can also weld them to thick metal surfaces.

For technical drawings and 3-D models, click on a part number.

Base | Collar | |||||||

|---|---|---|---|---|---|---|---|---|

| Thread Size | Dia. | Thick. | Dia. | Ht. | No. of Projections | Pkg. Qty. | Pkg. | |

18-8 Stainless Steel | ||||||||

| 4-40 | 19/64" | 1/16" | 11/64" | 1/32" | 3 | 25 | 000000000 | 00000 |

Steel Low-Profile Round-Base Weld Nuts with Projections

These nuts have a short collar to fit in low-clearance areas. Made of steel, they weld to uncoated steel surfaces with minimal preparation. The collar pilot helps guide them into the hole and aligns them with the surface, making them easier to weld. It also protects the threads from weld spatter. To distribute force evenly, they have a round base that acts as a flange. Projections on the base concentrate your weld to create room for heat to dissipate, protecting threads from deforming. These weld nuts stand up to high torque and pull force better than rivet and press-fit nuts, making them the strongest way to add permanent threads to sheet metal. You can also install them on thick metal surfaces.

For technical drawings and 3-D models, click on a part number.

Base | Collar | |||||||

|---|---|---|---|---|---|---|---|---|

| Thread Size | Dia. | Thick. | Dia. | Ht. | No. of Projections | Pkg. Qty. | Pkg. | |

Steel | ||||||||

| 4-40 | 5/16" | 1/16" | 11/64" | 1/32" | 3 | 25 | 000000000 | 00000 |

Stainless Steel Adhesive-Ready Nuts

Add strong threads to material that’s too difficult to drill or too thin to grip a threaded insert. These nuts are ideal for brittle plastics or tough composites, such as acrylic or carbon fiber. They have large holes in the base so that adhesive or resin can flow through, spread out, and create an extra-strong hold. You can also mold them into the surface of your material. Made of 316 stainless steel, they resist corrosion from salt water and harsh chemicals.

The base of these nuts acts like a flange, distributing pressure evenly across the mounting surface. The larger the base, the more that pressure is spread out; the smaller the base, the tighter the space these nuts can fit into. Taller nuts engage more of a screw’s threads than shorter nuts. Shorter nuts fit in low-clearance areas.

For technical drawings and 3-D models, click on a part number.

Stainless Steel Closed-End Adhesive-Ready Nuts

Adhere or mold these nuts onto a surface without gunking up the threads—the closed end blocks out adhesive, resin, and debris. It also acts as a stop, preventing screws from penetrating your material. Use them to add strong threads to material that’s too difficult and brittle to drill, such as acrylic and carbon fiber. They’re also often used when the surface is too thin to grip a threaded insert. To create a secure bond, large holes in the base let adhesive and resin flow and spread along the joint. Made of 316 stainless steel, these nuts resist corrosion from salt water and harsh chemicals.

The base of these nuts acts like a flange, distributing pressure evenly across the mounting surface. The larger the base, the more that pressure is spread out; the smaller the base, the tighter the space these nuts can fit into. Taller nuts engage more of a screw’s threads than shorter nuts. Shorter nuts fit in low-clearance areas.

For technical drawings and 3-D models, click on a part number.

Stainless Steel Narrow-Base Adhesive-Ready Nuts

Add corrosion-resistant threads to channels, corners, and other tight spaces without drilling a hole. Glue these nuts on to thin surfaces and materials too hard and brittle to drill, such as acrylic and carbon fiber. Large holes in the base allow adhesive and resin to flow and spread along the joint for a good bond. You can mold them into plastics or composites. Made of 316 stainless steel, these nuts are excellent at resisting chemicals and salt water.

The base of these nuts acts like a flange, distributing pressure evenly across the mounting surface. Larger bases spread the pressure over more surface for a strong bond, while smaller bases fit better in tight spaces.

For technical drawings and 3-D models, click on a part number.

Steel Narrow-Base Adhesive-Ready Nuts

Fit these nuts into channels, corners, and other tight spaces to add strong threads without drilling a hole. They’re ideal for material that’s too thin or too hard and brittle to drill, such as acrylic and carbon fiber. For a strong hold, large holes in the base let adhesive and resin flow through and spread out. You can also mold these nuts into plastics or composites. Thanks to a zinc plating, they resist rusting in wet environments.

The base of these nuts acts like a flange, distributing pressure evenly across the mounting surface. The larger the base, the more that pressure is spread out; the smaller the base, the tighter the space these nuts can fit into.

For technical drawings and 3-D models, click on a part number.

Mil. Spec. Rivet-Mount Nuts

Create threads in hard-to-work areas—where you can’t reach the back of a workpiece, or material is too thin to be tapped. For a strong grip, these nuts have distorted threads that increase friction with bolts. Because they mount with two rivets, they won’t spin when you’re tightening screws. However, these nuts do move inside their retainers, which lets you install bolts at a slight angle; use them to align with off-center parts. All meet military guidelines for dimensions and material.

Cadmium-plated nuts resist corrosion in industrial and saltwater environments, although will lose their corrosion resistance over 450° F. The cadmium plating also adds lubricity, making these nuts easy to install.

A286 stainless steel nuts are corrosion resistant. Silver-plated stainless steel nuts withstand temperatures up to 800° F. The silver plating also adds lubricity and prevents seizing caused by friction between nuts and bolts.

Lubricated nuts thread onto bolts smoothly.

For technical drawings and 3-D models, click on a part number.

Base | Barrel | Mounting | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Lg. | Wd. | Thick. | Dia. | Ht. | No. of Holes | Hole Dia. | Hole Ctr.-to-Ctr. | Specifications Met | Each | |

Steel—Unlubricated | |||||||||||

| 4-40 | 21/32" | 5/16" | 3/32" | 0.125" | 1/16" | 2 | 0.098" | 13/32" | MS21075-04N | 000000000 | 00000 |

Cadmium-Plated Steel—Lubricated | |||||||||||

| 4-40 | 21/32" | 5/16" | 3/32" | 0.125" | 1/16" | 2 | 0.098" | 13/32" | MS21075L04N | 000000000 | 0000 |

Cadmium-Plated Carbon Steel—Lubricated | |||||||||||

| 4-40 | 61/64" | 13/32" | 1/32" | 0.141" | 9/64" | 2 | 0.098" | 11/16" | MS21059L04 | 000000000 | 0000 |

A286 Stainless Steel—Lubricated | |||||||||||

| 4-40 | 21/32" | 5/16" | 3/32" | 0.125" | 1/16" | 2 | 0.098" | 13/32" | MS21076L04N | 000000000 | 00000 |

Silver-Plated A286 Stainless Steel—Unlubricated | |||||||||||

| 4-40 | 21/32" | 5/16" | 3/32" | 0.125" | 1/16" | 2 | 0.098" | 13/32" | MS21076-04N | 000000000 | 00000 |