Filter by

System of Measurement

Thread Size

Flute Type

Finish

Chamfer Type

Material

Number of Flutes

Sold As

DFARS Specialty Metals

Export Control Classification Number (ECCN)

For Hole Type

For Threading

Number of Tapping Ends

Performance

REACH

RoHS

Drill Bit Decimal Size Equivalent

Thread Length

Shank Type

Thread Direction

Thread Type

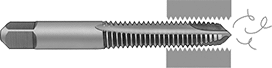

Chip-Clearing Taps

|

Spiral-Point Flute for Through Holes |

Remove long, stringy chips to produce cleaner threads than standard taps. The flute design prevents buildup to protect the quality of the threads and avoid damage to the tap. Since you don’t need to reverse these taps to extract chips, they also create threads faster.

High-Speed Steel—The most versatile taps resist heat and wear to stay sharp. They’re good for most metals and plastic.

Uncoated—The economical choice, these won't last as long as coated taps.

Spiral-Point Flute for Through Holes—Push chips ahead of the tap and out of through holes. Also known as gun taps.

Plug Chamfer—Our go-to chamfer type. With a longer taper than a bottoming chamfer, they are easier to turn but won't thread as close the bottom of a hole.

Drill Bit | Spiral-Point Flute for Through Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Overall Lg. | Thread Type | Size | Decimal Size Equiv. | Shank Type | Chamfer Type | No. of Flutes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4-36 | 9/16" | 1 7/8" | UNC | 44 Ga. | 0.086" | Square | Plug | 2 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

EachDelivers Wednesday | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||