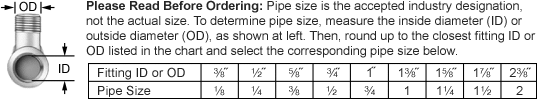

About Pipe Size and Spray Nozzles

More

Rotating Tank-Washing Nozzles

By circulating their spray, these nozzles clean faster with more even coverage and less water than stationary tank-washing nozzles. The force of the liquid flowing through is what causes them to rotate, so the higher the pressure, the faster they will rotate. They spray in multiple directions to effectively rinse down tanks, drums, and small vessels.

316 stainless steel and PVDF nozzles have good resistance to chemicals and corrosion. PTFE nozzles have excellent resistance to chemicals and corrosion.

FDA-compliant nozzles can be used in the food industry.

For technical drawings and 3-D models, click on a part number.

Flow Rate, gpm | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Pattern | Spray Angle | Specifications Met | Environment | Each | ||

1/8 NPT Female | |||||||||||||||

| A | 1.51 | 2.1 | 2.54 | 2 | __ | 5/8" | 1 1/4" | 80 | 200° | Multiple Flat Stream | 360° | __ | __ | 00000000 | 0000000 |

| B | 3.5 | 5 | 6 | 4 1/2 | 0.02" | 11/16" | 1 9/16" | 100 | 480° | Multiple Flat Stream | 360° | __ | __ | 00000000 | 000000 |

| B | 4 | 6 | 7 | 5 | 0.02" | 11/16" | 1 9/16" | 100 | 480° | Multiple Flat Stream | 360° | __ | __ | 00000000 | 000000 |

3/8 NPT Male | |||||||||||||||

| C | 3.5 | 5 | 6 | 5 | __ | 13/16" | 2 1/16" | 85 | 260° | Multiple Flat Stream | 360° | __ | __ | 00000000 | 000000 |

| C | 5 | 7 | 8.5 | 5 | 0.09" | 13/16" | 2" | 70 | 250° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 110.40, FDA Compliant 21 CFR 177.1556, FDA Compliant 21 CFR 211.65 | Food Industry | 000000 | 000000 |

3/8 NPT Female | |||||||||||||||

| A | 12.1 | 17 | 20.8 | 10 | __ | 7/8" | 1 13/16" | 80 | 200° | Multiple Flat Stream | 360° | __ | __ | 00000000 | 000000 |

| B | 6 | 8 | 10 | 5 1/2 | 0.03" | 1 1/16" | 2 3/8" | 100 | 480° | Multiple Flat Stream | 360° | __ | __ | 00000000 | 000000 |

| B | 7 | 10 | 12 | 6 | 0.04" | 1 1/8" | 2 3/8" | 60 | 250° | Multiple Flat Stream | 180° | __ | __ | 00000000 | 000000 |

| B | 8.5 | 12 | 15 | 6 | 0.04" | 1 1/8" | 2 3/8" | 60 | 250° | Multiple Flat Stream | 360° | __ | __ | 00000000 | 000000 |

1/2 NPT Female | |||||||||||||||

| A | 14.3 | 20 | 24.3 | 10 | __ | 1 3/8" | 2 3/8" | 80 | 200° | Multiple Flat Stream | 360° | __ | __ | 00000000 | 000000 |

| A | 18.3 | 26 | 31.9 | 10 | __ | 1 3/8" | 2 3/8" | 80 | 200° | Multiple Flat Stream | 360° | __ | __ | 00000000 | 000000 |

3/4 NPT Female | |||||||||||||||

| D | 11 | 15 | 18 | 6 | __ | 2 5/8" | 4 5/16" | 60 | 250° | Multiple Solid Stream | 270° | FDA Compliant 21 CFR 177.2415 | __ | 000000 | 000000 |

| D | 11 | 15 | 18 | 6 | __ | 2 5/8" | 4 5/16" | 60 | 250° | Multiple Solid Stream | 360° | FDA Compliant 21 CFR 177.2415 | __ | 00000000 | 000000 |

| D | 13 | 18 | 22 | 7 | __ | 2 5/8" | 4 5/16" | 60 | 250° | Multiple Solid Stream | 270° | FDA Compliant 21 CFR 177.2415 | __ | 00000000 | 000000 |

| D | 16 | 22 | 27 | 7 | __ | 2 5/8" | 4 5/16" | 60 | 250° | Multiple Solid Stream | 360° | FDA Compliant 21 CFR 177.2415 | __ | 00000000 | 000000 |

| D | 21 | 30 | 37 | 8 1/2 | __ | 2 5/8" | 4 5/16" | 60 | 250° | Multiple Solid Stream | 270° | FDA Compliant 21 CFR 177.2415 | __ | 00000000 | 000000 |

| D | 21 | 30 | 37 | 8 1/2 | __ | 2 5/8" | 4 5/16" | 60 | 250° | Multiple Solid Stream | 360° | FDA Compliant 21 CFR 177.2415 | __ | 00000000 | 000000 |

| D | 32 | 45 | 55 | 10 | __ | 2 5/8" | 4 5/16" | 60 | 250° | Multiple Solid Stream | 360° | FDA Compliant 21 CFR 177.2415 | __ | 000000 | 000000 |

1 NPT Female | |||||||||||||||

| E | 35.5 | 50 | 61.1 | 11 | 0.17" | 3 7/8" | 2 15/16" | 60 | 190° | Multiple Solid Stream | 360° | __ | __ | 0000000 | 000000 |

Flow Rate, gpm | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Pin Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Pattern | Spray Angle | Each | ||

1/2" Female Tube ID | ||||||||||||||

| B | 6 | 8 | 10 | 5 1/2 | 0.03" | 3/32" | 1 1/16" | 2 1/2" | 100 | 480° | Multiple Flat Stream | 360° | 00000000 | 0000000 |

| B | 7 | 10 | 12 | 6 | 0.04" | 3/32" | 1 1/16" | 2 1/2" | 100 | 480° | Multiple Flat Stream | 180° | 00000000 | 000000 |

| B | 8.5 | 12 | 15 | 6 | 0.04" | 3/32" | 1 1/16" | 2 1/2" | 100 | 480° | Multiple Flat Stream | 360° | 00000000 | 000000 |

Flow Rate, gpm | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Pattern | Spray Angle | Specifications Met | Environment | Each | ||

1/4 NPT Female | |||||||||||||||

| F | 6.31 | 8.96 | 11 | 9 | 0.06" | 1 11/16" | 3 15/16" | 60 | 200° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 177.1550 | Food Industry | 0000000 | 0000000 |

3/8 NPT Female | |||||||||||||||

| F | 6.31 | 8.96 | 11 | 9 | 0.06" | 1 11/16" | 3 15/16" | 60 | 200° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 177.1550 | Food Industry | 0000000 | 000000 |

| F | 13.4 | 19 | 23.4 | 11 | 0.06" | 1 15/16" | 4 1/8" | 60 | 200° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 177.1550 | Food Industry | 0000000 | 000000 |

| F | 15.2 | 21.5 | 26.3 | 14 | 0.06" | 1 15/16" | 4 1/8" | 60 | 200° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 177.1550 | Food Industry | 0000000 | 000000 |

1/2 NPT Female | |||||||||||||||

| F | 6.31 | 8.96 | 11 | 9 | 0.06" | 1 11/16" | 3 15/16" | 60 | 200° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 177.1550 | Food Industry | 0000000 | 000000 |

| F | 13.4 | 19 | 23.4 | 11 | 0.06" | 1 15/16" | 4 1/8" | 60 | 200° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 177.1550 | Food Industry | 0000000 | 000000 |

| F | 15.2 | 21.5 | 26.3 | 14 | 0.06" | 1 15/16" | 4 1/8" | 60 | 200° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 177.1550 | Food Industry | 0000000 | 000000 |

| F | 16.8 | 24.1 | 29.8 | 14 | 0.06" | 3" | 6 3/8" | 60 | 200° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 177.1550 | Food Industry | 0000000 | 000000 |

| F | 21.6 | 30.8 | 37.9 | 16 | 0.06" | 3" | 6 3/8" | 60 | 200° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 177.1550 | Food Industry | 0000000 | 000000 |

3/4 NPT Female | |||||||||||||||

| G | 13 | 18 | 22 | 8 | 0.07" | 2" | 3" | 60 | 200° | Multiple Solid Stream | 360° | __ | __ | 0000000 | 000000 |

| G | 15 | 21 | 26 | 8 | 0.08" | 2" | 3" | 60 | 200° | Multiple Solid Stream | 180° | __ | __ | 0000000 | 000000 |

| G | 22 | 31 | 38 | 8 | 0.14" | 2" | 3" | 60 | 200° | Multiple Solid Stream | 360° | __ | __ | 0000000 | 000000 |

| G | 32 | 45 | 55 | 9 | 0.13" | 2" | 3" | 60 | 200° | Multiple Solid Stream | 180° | __ | __ | 0000000 | 000000 |

| G | 32 | 45 | 55 | 9 | 0.18" | 2" | 3" | 60 | 200° | Multiple Solid Stream | 360° | __ | __ | 0000000 | 000000 |

1 NPT Female | |||||||||||||||

| G | 33 | 47 | 57.5 | 10 | 0.15" | 3" | 4" | 60 | 200° | Multiple Solid Stream | 360° | __ | __ | 0000000 | 000000 |

| G | 49.5 | 70 | 86 | 10 | 0.21" | 3" | 4" | 60 | 200° | Multiple Solid Stream | 360° | __ | __ | 0000000 | 000000 |

| G | 49.5 | 70 | 86 | 10 | 0.28" | 3" | 4" | 60 | 200° | Multiple Solid Stream | 180° | __ | __ | 0000000 | 000000 |

Flow Rate, gpm | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Pattern | Spray Angle | Specifications Met | Environment | Each | ||

1/2 BSPP Female | |||||||||||||||

| H | 4 | 6 | 7 | 5 | 0.03" | 1 3/16" | 3" | 70 | 190° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 177.2510 | Food Industry | 00000000 | 000000 |

High-Impact Rotating Tank-Washing Nozzles

Internal gears create controlled motion as fluid moves through these nozzles, maintaining speed and producing large droplets to efficiently clean heavily soiled or large-diameter tanks. These nozzles rotate, so they produce more even coverage and clean faster than stationary tank nozzles while using less water. A multi-directional spray pattern makes these nozzles good for rinsing.

For technical drawings and 3-D models, click on a part number.

Flow Rate, gpm | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Angle | Each | |

316 Stainless Steel | |||||||||||

1/2 NPT Female | |||||||||||

| 6 | 8 | 10 | 11 1/2 | 1.73" | 2 11/16" | 5 13/16" | 215 | 200° | 360° | 0000000 | 000000000 |

3/4 NPT Female | |||||||||||

| 13 | 18 | 22 | 20 | 1.73" | 2 11/16" | 5 7/8" | 215 | 200° | 360° | 0000000 | 00000000 |

1 NPT Female | |||||||||||

| 30 | 42 | 51 | 26 | 1.73" | 2 11/16" | 5 7/16" | 215 | 200° | 360° | 0000000 | 00000000 |

Foam-Spray Rotating Tank-Washing Nozzles

Use these nozzles with detergent that’s diluted in water to create a rotating, multi-directional foam spray for effectively rinsing tanks, drums, and small vessels. Because they rotate, these nozzles clean faster and produce more even coverage than stationary tank-cleaning spray nozzles, typically while using less liquid. The force of the liquid flowing through these nozzles makes them spin, so they’ll spin faster at higher pressures.

For technical drawings and 3-D models, click on a part number.

Tank-Washing Nozzles

To effectively rinse tanks, drums, and small vessels, these nozzles spray in multiple directions. The simplest style of tank-cleaning nozzle, they don't have any moving parts that will wear or need maintenance.

Brass and nylon nozzles have good corrosion resistance.

303 stainless steel nozzles are more chemical, corrosion, and abrasion resistant than brass nozzles.

316 stainless steel nozzles have excellent chemical and corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Flow Rate, gpm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 30 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Angle | Each | |

1/2 NPT Female | ||||||||||||

| 4 | 5 | 6 | 7 | 10 | 0.03" | 1 1/16" | 1 13/16" | 150 | 400° | 240° | 00000000 | 000000 |

| 6 | 8 | 9 | 11 | 21 | __ | 1" | 1 13/16" | 145 | 390° | 240° | 000000000 | 00000 |

| 13 | 16 | 18 | 22 | 10 | 0.06" | 1 1/16" | 1 13/16" | 150 | 400° | 240° | 00000000 | 00000 |

| 20 | 24 | 28 | 34 | 27 | __ | 1" | 1 13/16" | 145 | 390° | 240° | 000000000 | 00000 |

| 26 | 32 | 37 | 45 | 31 | __ | 1" | 1 13/16" | 145 | 390° | 240° | 000000000 | 00000 |

Flow Rate, gpm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 30 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Angle | Each | |

1/2 NPT Female | ||||||||||||

| 4 | 5 | 6 | 7 | 10 | 0.03" | 1 1/16" | 1 13/16" | 150 | 400° | 240° | 00000000 | 0000000 |

| 6 | 8 | 9 | 11 | 23 | __ | 1" | 1 13/16" | 145 | 390° | 240° | 000000000 | 000000 |

| 13 | 16 | 18 | 22 | 10 | 0.06" | 1 1/16" | 1 13/16" | 150 | 400° | 240° | 00000000 | 000000 |

| 20 | 24 | 28 | 34 | 27 | 0.08" | 1 1/16" | 1 13/16" | 60 | 390° | 240° | 00000000 | 000000 |

| 26 | 32 | 37 | 45 | 31 | 0.09" | 1 1/16" | 1 13/16" | 60 | 390° | 240° | 000000000 | 000000 |

Flow Rate, gpm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 30 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Angle | Each | |

1/8 NPT Female | ||||||||||||

| 3.5 | 4 | 5 | 6 | 7 | 0.03" | 13/16" | 1 1/2" | 60 | 390° | 360° | 000000000 | 0000000 |

1/2 NPT Female | ||||||||||||

| 40 | 48.5 | 56 | 68.5 | 11 | 0.07" | 2 1/2" | 3 5/16" | 60 | 390° | 360° | 000000000 | 000000 |

1 NPT Female | ||||||||||||

| 57 | 70 | 81 | 99 | 17 | 0.08" | 2 1/2" | 3 5/16" | 60 | 390° | 360° | 00000000 | 000000 |

2 NPT Female | ||||||||||||

| 147 | 180 | 208 | 255 | 18 | 0.12" | 3 1/2" | 4 7/16" | 60 | 390° | 360° | 000000000 | 000000 |

Flow Rate, gpm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 30 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Pin Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Angle | Each | |

3/8" Female Tube ID | |||||||||||||

| 11 | 14 | 16 | 19.5 | 7 | 0.04" | 1/16" | 1 1/8" | 1 11/16" | 60 | 390° | 360° | 000000000 | 0000000 |

3/4" Female Tube ID | |||||||||||||

| 22 | 27 | 31 | 38 | 8 | 0.06" | 1/16" | 1 1/8" | 1 11/16" | 60 | 390° | 360° | 000000000 | 000000 |

| 40 | 48.5 | 56 | 68.5 | 11 | 0.07" | 3/32" | 2 9/16" | 3 5/16" | 70 | 390° | 360° | 000000000 | 000000 |

1" Female Tube ID | |||||||||||||

| 57 | 70 | 81 | 99 | 17 | 0.08" | 1/16" | 2 9/16" | 3 5/16" | 60 | 390° | 360° | 000000000 | 000000 |

1 1/2" Female Tube ID | |||||||||||||

| 90 | 110 | 127 | 155.5 | 18 | 0.12" | 1/16" | 2 9/16" | 3 5/16" | 60 | 390° | 360° | 000000000 | 000000 |

2" Female Tube ID | |||||||||||||

| 147 | 180 | 208 | 255 | 18 | 0.13" | 1/16" | 3 9/16" | 4 3/8" | 60 | 390° | 360° | 000000000 | 000000 |

Flow Rate, gpm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 30 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Angle | Each | |

1/2 NPT Female | ||||||||||||

| 3.9 | 4.7 | 5.5 | 6.7 | 5 | 0.03" | 1 3/16" | 1 3/4" | 150 | 200° | 240° | 000000000 | 0000000 |

| 12.5 | 15.1 | 17.7 | 22 | 5 | 0.06" | 1 3/16" | 1 3/4" | 150 | 200° | 240° | 000000000 | 000000 |

3/4 NPT Female | ||||||||||||

| 26 | 31.5 | 37 | 46 | 5 | 0.09" | 1 13/16" | 2 7/16" | 150 | 200° | 240° | 000000000 | 000000 |

Clog-Resistant Tank-Washing Nozzles

and 270°

Spray Angle

Avoid clogs while rinsing tanks, drums, and small vessels. These nozzles have a unique internal and external design, so particles in liquid pass through instead of getting stuck. To effectively rinse down tanks and other containers, they spray in multiple directions. But, compared to standard tank-washing nozzles, they produce larger droplets and have a less precise spray pattern. These nozzles don't have any moving parts that will wear or need maintenance.

Brass nozzles have good corrosion resistance.

316 stainless steel nozzles are more chemical and corrosion resistant than brass nozzles.

For technical drawings and 3-D models, click on a part number.

Flow Rate, gpm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 60 psi | @ 400 psi | For Max. Tank Dia., ft. | Orifice Dia. | For Max. Particle Dia. | Overall Wd. | Max. Pressure, psi | Max. Temp., °F | Lg. | Each | |

180° Spray Angle | ||||||||||||

Brass | ||||||||||||

3/8 NPT Male | ||||||||||||

| 4.2 | 6 | 7.3 | 19 | 2 1/2 | 0.19" | 0.13" | 3/4" | 400 | 450° | 2 7/8" | 0000000 | 000000 |

| 7.5 | 10.6 | 13 | 33.5 | 5 | 0.25" | 0.13" | 3/4" | 400 | 450° | 2 15/16" | 0000000 | 00000 |

| 11.7 | 16.5 | 20.2 | 52.2 | 7 | 0.31" | 0.13" | 3/4" | 400 | 450° | 2 15/16" | 0000000 | 00000 |

316 Stainless Steel | ||||||||||||

3/8 NPT Male | ||||||||||||

| 4.2 | 6 | 7.3 | 19 | 2 1/2 | 0.19" | 0.13" | 3/4" | 400 | 800° | 2 7/8" | 00000000 | 000000 |

| 7.5 | 10.6 | 13 | 33.5 | 5 | 0.25" | 0.13" | 3/4" | 400 | 800° | 2 7/8" | 00000000 | 000000 |

| 11.7 | 16.5 | 20.2 | 52.2 | 7 | 0.31" | 0.13" | 3/4" | 400 | 800° | 2 7/8" | 00000000 | 000000 |

270° Spray Angle | ||||||||||||

Brass | ||||||||||||

3/8 NPT Male | ||||||||||||

| 4.2 | 6 | 7.3 | 19 | 2 1/2 | 0.19" | 0.13" | 3/4" | 400 | 450° | 3 5/8" | 0000000 | 000000 |

| 7.5 | 10.6 | 13 | 33.5 | 5 | 0.25" | 0.13" | 3/4" | 400 | 450° | 3 5/8" | 0000000 | 000000 |

| 11.7 | 16.5 | 20.2 | 52.2 | 7 | 0.31" | 0.13" | 3/4" | 400 | 450° | 3 5/8" | 0000000 | 000000 |

1/2 NPT Male | ||||||||||||

| 17 | 24.1 | 29.5 | 76.2 | 9 | 0.41" | 0.17" | 7/8" | 400 | 450° | 4 1/4" | 0000000 | 000000 |

316 Stainless Steel | ||||||||||||

3/8 NPT Male | ||||||||||||

| 4.2 | 6 | 7.3 | 19 | 2 1/2 | 0.19" | 0.13" | 3/4" | 400 | 800° | 3 5/8" | 00000000 | 000000 |

| 7.5 | 10.6 | 13 | 33.5 | 5 | 0.25" | 0.13" | 3/4" | 400 | 800° | 3 5/8" | 00000000 | 000000 |

| 11.7 | 16.5 | 20.2 | 52.2 | 7 | 0.31" | 0.13" | 3/4" | 400 | 800° | 3 5/8" | 00000000 | 000000 |

1/2 NPT Male | ||||||||||||

| 17 | 24.1 | 29.5 | 76.2 | 9 | 0.41" | 0.17" | 7/8" | 400 | 800° | 4 1/4" | 00000000 | 000000 |

360° Spray Angle | ||||||||||||

316 Stainless Steel | ||||||||||||

3/4 NPT Female | ||||||||||||

| 30 | 42 | Not Rated | Not Rated | 8 | 0.3" | 0.25" | 2 3/8" | 40 | 200° | 3 9/16" | 00000000 | 000000 |

1 NPT Female | ||||||||||||

| 70.6 | 100 | Not Rated | Not Rated | 10 | 0.25" | 0.3" | 2 3/8" | 40 | 200° | 4" | 00000000 | 000000 |

Sanitary Tank-Washing Nozzles

Certified by 3-A to meet sanitary design standards, these nozzles have a 360° spray pattern to effectively rinse tanks and vessels in food, beverage, and pharmaceutical environments. Their one-piece design means there are no moving parts to maintain, making them good for clean-in-place (CIP) systems.

Made from 316 stainless steel, these nozzles will not corrode from frequent washdowns with harsh cleaners and sanitizers. All are self-draining with polished surfaces and a pin connection, which means they have no threads, to reduce the risk of bacteria growth.

These nozzles can be installed in any position. Slip them over your supply tube and secure them in place with the pin. Your supply tube must have a through-hole that matches the pin diameter.

For technical drawings and 3-D models, click on a part number.

Flow Rate, gpm | Smoothness, Ra | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tube Connection Type | @ 15 psi | @ 25 psi | @ 40 psi | For Max. Tank Dia., ft. | Pin Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Angle | Interior | Exterior | Specifications Met | Each | |

316 Stainless Steel | |||||||||||||||

3/4" Female Tube ID | |||||||||||||||

| Pin | 31 | 40 | 51 | 10 | 1/8" | 1 1/2" | 2 1/2" | 40 | 400° | 360° | 32 | 32 | 3-A Certified 78-01 | 0000000 | 0000000 |

1" Female Tube ID | |||||||||||||||

| Pin | 31 | 40 | 51 | 13 | 1/8" | 2" | 3 5/16" | 40 | 400° | 360° | 32 | 32 | 3-A Certified 78-01 | 0000000 | 000000 |

1 1/2" Female Tube ID | |||||||||||||||

| Pin | 31 | 40 | 51 | 13 | 3/16" | 2 1/2" | 4 1/4" | 40 | 400° | 360° | 32 | 32 | 3-A Certified 78-01 | 0000000 | 000000 |

Tank Mixing Nozzles

Circulate tank contents by pumping liquid through these nozzles. For every gallon of liquid that flows through the inlet, suction draws in and mixes about four gallons from the tank. Nozzles should be positioned close to the bottom of your tank.

| Orifice Dia. | Pipe Size | Thread Type | Gender | Inlet Flow Rate | Tank Circulation Rate | Dia. | Lg. | Max. Pressure | Max. Temperature, °F | Material | Color | Each | |

| 0.06" | 1/4 | NPT | Male | 0.7 gpm @ 50 psi | 4.4 gpm @ 50 psi | 11/16" | 1 5/8" | 50 psi @ 70° F | 200° | Polypropylene Plastic | Orange | 0000000 | 000000 |

| 0.08" | 1/4 | NPT | Male | 1.2 gpm @ 50 psi | 6 gpm @ 50 psi | 11/16" | 1 5/8" | 50 psi @ 70° F | 200° | Polypropylene Plastic | Green | 0000000 | 00000 |

| 0.1" | 1/4 | NPT | Male | 2 gpm @ 50 psi | 7.8 gpm @ 50 psi | 11/16" | 1 5/8" | 50 psi @ 70° F | 200° | Polypropylene Plastic | Blue | 0000000 | 00000 |

| 0.12" | 1/4 | NPT | Male | 2.9 gpm @ 50 psi | 10.7 gpm @ 50 psi | 11/16" | 1 5/8" | 50 psi @ 70° F | 200° | Polypropylene Plastic | White | 0000000 | 00000 |

| 3/16" | 1/4 | NPT | Male | 7.8 gpm @ 50 psi | 36.8 gpm @ 50 psi | 1 1/4" | 3" | 50 psi @ 70° F | 200° | Polypropylene Plastic | Black | 0000000 | 00000 |

| 5/16" | 3/8 | NPT | Male | 20 gpm @ 50 psi | 100 gpm @ 50 psi | 1 11/16" | 4 1/16" | 50 psi @ 70° F | 200° | Polypropylene Plastic | Black | 0000000 | 00000 |

| 3/8" | 3/4 | NPT | Male | 30 gpm @ 50 psi | 150 gpm @ 50 psi | 3" | 6 3/8" | 50 psi @ 70° F | 200° | Polypropylene Plastic | Black | 0000000 | 00000 |

| 9/16" | 1 1/2 | NPT | Male | 75 gpm @ 50 psi | 375 gpm @ 50 psi | 4 1/2" | 10" | 50 psi @ 70° F | 200° | Polypropylene Plastic | Black | 0000000 | 000000 |

Organic Drain Cleaners

Made of concentrated bacteria, these cleaners keep clogs from forming by breaking down waste buildup in drains, grease traps, and sewage systems.

Container | ||||

|---|---|---|---|---|

| Size | Net Weight | For Use With | Each | |

Liquid | ||||

| 1 gal. | __ | Floor Drains, Garbage Disposals, Grease Traps, Septic Tanks, Showers/Tubs, Sinks, Toilets, Urinals | 0000000 | 000000 |

| 1 qt. | __ | Floor Drains, Garbage Disposals, Grease Traps, Septic Tanks, Showers/Tubs, Sinks, Toilets, Urinals | 0000000 | 00000 |

Granular | ||||

| __ | 1 lbs. | Floor Drains, Garbage Disposals, Grease Traps, Septic Tanks, Showers/Tubs, Sinks, Toilets, Urinals | 00000000 | 00000 |

| __ | 25 lbs. | Floor Drains, Garbage Disposals, Grease Traps, Septic Tanks, Showers/Tubs, Sinks, Toilets, Urinals | 00000000 | 000000 |

Chemical Drain Cleaners

Remove clogs by dissolving grease and other organic matter with these odorless cleaners.

Granular cleaners activate in hot water.

Water-Powered Drain Cleaners

Flush out clogs with your garden hose. These drain cleaners attach to a hose and expand to form a seal while the water pressure dislodges the blockage.

Flexible cleaners have a bag-style cylinder that can move through pipe curves and elbows.

Cleaners with a 3/8 NPT male nozzle or NH/NST threads can be capped to convert them into a plug for stopping your line (cap sold separately). Thread a plug (sold separately) into cleaners with NPT threads to use them as plug for stopping your line.

Faucet adapters (sold separately) allow your faucet to accept a 3/4 GHT female connector.

Connection | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Use With | For Pipe ID | Pressure Range, psi | Deflated Lg. | Hose Size | Gender | Cylinder Material | Includes | Each | |

Flexible | |||||||||

| Floor Drains, Garbage Disposals, Grease Traps, Septic Tanks, Showers/Tubs, Toilets | 1 3/8"-1 1/2" | 30-80 | 8 3/4" | 3/4 | Female | Fabric | Backflow Preventer | 0000000 | 000000 |

| Floor Drains, Garbage Disposals, Grease Traps, Septic Tanks, Showers/Tubs, Toilets | 1 1/2"-2 1/2" | 30-80 | 9 1/4" | 3/4 | Female | Fabric | Backflow Preventer | 0000000 | 00000 |

| Floor Drains, Garbage Disposals, Grease Traps, Septic Tanks, Showers/Tubs, Toilets | 2 1/2"-3" | 30-80 | 13" | 3/4 | Female | Fabric | Backflow Preventer | 0000000 | 00000 |

| Floor Drains, Garbage Disposals, Grease Traps, Septic Tanks, Showers/Tubs, Toilets | 3"-4" | 30-80 | 14 3/4" | 3/4 | Female | Fabric | Backflow Preventer | 0000000 | 000000 |

| Floor Drains, Garbage Disposals, Grease Traps, Septic Tanks, Showers/Tubs, Toilets | 4"-6" | 30-80 | 20 1/4" | 3/4 | Female | Fabric | 3/8 NPT Male Nozzle | 000000 | 000000 |

Connection | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Use With | For Pipe ID | Pressure Range, psi | Deflated Lg. | Pipe Size | Gender | Cylinder Material | Includes | Each | |

Flexible | |||||||||

| Floor Drains, Garbage Disposals, Grease Traps, Septic Tanks, Showers/Tubs, Toilets | 1 3/8"-1 1/2" | 30-100 | 8 3/4" | 1/8 | Female | Fabric | Backflow Preventer | 00000000 | 000000 |

| Floor Drains, Garbage Disposals, Grease Traps, Septic Tanks, Showers/Tubs, Toilets | 1 3/8"-2 1/2" | 30-100 | 9 1/4" | 1/8 | Female | Fabric | Backflow Preventer | 00000000 | 00000 |

| Floor Drains, Garbage Disposals, Grease Traps, Septic Tanks, Showers/Tubs, Toilets | 2 1/2"-3" | 30-100 | 13" | 1/4 | Female | Fabric | Backflow Preventer | 00000000 | 000000 |

| Floor Drains, Garbage Disposals, Grease Traps, Septic Tanks, Showers/Tubs, Toilets | 3"-4" | 30-100 | 14 3/4" | 1/4 | Female | Fabric | Backflow Preventer | 00000000 | 000000 |

| Floor Drains, Garbage Disposals, Grease Traps, Septic Tanks, Showers/Tubs, Toilets | 4"-6" | 30-100 | 20 1/4" | 1/4 | Female | Fabric | Backflow Preventer | 00000000 | 000000 |

Connection | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Use With | For Pipe ID | Pressure Range, psi | Deflated Lg. | Fire Hose Trade Size | Gender | Swivel Type | Cylinder Material | Each | |

Flexible | |||||||||

| Floor Drains, Garbage Disposals, Grease Traps, Septic Tanks, Showers/Tubs, Toilets | 5"-8" | 30-100 | 25" | 2 1/2 | Female | Swivels Until Tightened | Fabric | 00000000 | 0000000 |

| Floor Drains, Garbage Disposals, Grease Traps, Septic Tanks, Showers/Tubs, Toilets | 5"-10" | 30-100 | 37" | 2 1/2 | Female | Swivels Until Tightened | Fabric | 00000000 | 000000 |

| Stainless Steel Cap for 2623K106 and 2623K107 | 00000000 | Each | 000000 |