How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Strainers and Selecting Screen Size

More

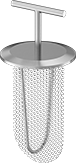

T-Strainers

- Max. Pressure for Water: 150 psi @ 70° F

- Temp. Range: -40° to 125° F

Clean out your strainer less often—these T-strainers have high debris-holding capacity. Install them prior to valves, pumps, and nozzles to protect sensitive equipment. Strainers have a nylon or polypropylene housing for excellent corrosion resistance.

Clear strainers allow you to monitor debris collecting in the screen without disconnecting your pipeline.

Strainers with push-to-connect tube connections make a tight seal around flexible tubing.

Use the optional fluoroelastomer gasket (sold separately) for oil applications.

For technical drawings and 3-D models, click on a part number.

Pipe Connections

(Black Housing)

Pipe Connections

(Clear Housing)

Strainers | Replacement Screens | Replacement EPDM Rubber Gaskets | Optional Fluoroelastomer Rubber Gaskets | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Lg. | Ht. | Gasket Material | Screen Material | Choose a Screen Mesh Size | Each | Each | Pkg. | Pkg. | ||||

Black Polypropylene Plastic Housing | ||||||||||||||

| 1/4 | NPT | 3" | 2 11/16" | EPDM Rubber | 304 Stainless Steel | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 000000 | |

| 3/8 | NPT | 3" | 2 11/16" | EPDM Rubber | 304 Stainless Steel | 00000000 | 0000 | 00000000 | 0000 | 00000000 | 0000 | 00000000 | 00000 | |

| 3/8 | NPT | 3 5/8" | 5 3/8" | EPDM Rubber | 304 Stainless Steel | 00000000 | 0000 | 0000000 | 0000 | 00000000 | 0000 | 00000000 | 0000 | |

| 1/2 | NPT | 3" | 2 11/16" | EPDM Rubber | 304 Stainless Steel | 00000000 | 0000 | 00000000 | 0000 | 00000000 | 0000 | 00000000 | 00000 | |

| 1/2 | NPT | 3 5/8" | 5 3/8" | EPDM Rubber | 304 Stainless Steel | 00000000 | 0000 | 0000000 | 0000 | 00000000 | 0000 | 00000000 | 0000 | |

| 3/4 | NPT | 3 5/8" | 5 3/8" | EPDM Rubber | 304 Stainless Steel | 00000000 | 0000 | 0000000 | 0000 | 00000000 | 0000 | 00000000 | 0000 | |

| 1 | NPT | 5" | 6 7/16" | EPDM Rubber | 304 Stainless Steel | 00000000 | 00000 | 0000000 | 0000 | 00000000 | 0000 | 00000000 | 00000 | |

| 1 1/4 | NPT | 5" | 7 1/8" | EPDM Rubber | 304 Stainless Steel | 00000000 | 00000 | 0000000 | 0000 | 00000000 | 0000 | 00000000 | 00000 | |

| 1 1/2 | NPT | 5 1/8" | 8 1/8" | EPDM Rubber | 304 Stainless Steel | 00000000 | 00000 | 0000000 | 0000 | 00000000 | 0000 | 00000000 | 00000 | |

Clear Nylon Plastic Housing | ||||||||||||||

| 1/4 | NPT | 3" | 2 11/16" | EPDM Rubber | 304 Stainless Steel | 00000000 | 0000 | 00000000 | 0000 | 00000000 | 0000 | 00000000 | 00000 | |

| 3/8 | NPT | 3" | 2 11/16" | EPDM Rubber | 304 Stainless Steel | 00000000 | 0000 | 00000000 | 0000 | 00000000 | 0000 | 00000000 | 00000 | |

| 3/8 | NPT | 3 5/8" | 5 3/8" | EPDM Rubber | 304 Stainless Steel | 00000000 | 00000 | 0000000 | 0000 | 00000000 | 0000 | 00000000 | 0000 | |

| 1/2 | NPT | 3" | 2 11/16" | EPDM Rubber | 304 Stainless Steel | 00000000 | 0000 | 00000000 | 0000 | 00000000 | 0000 | 00000000 | 00000 | |

| 1/2 | NPT | 3 5/8" | 5 3/8" | EPDM Rubber | 304 Stainless Steel | 00000000 | 00000 | 0000000 | 0000 | 00000000 | 0000 | 00000000 | 0000 | |

| 3/4 | NPT | 3 5/8" | 5 3/8" | EPDM Rubber | 304 Stainless Steel | 00000000 | 00000 | 0000000 | 0000 | 00000000 | 0000 | 00000000 | 0000 | |

| 1 | NPT | 5" | 6 7/16" | EPDM Rubber | 304 Stainless Steel | 00000000 | 00000 | 0000000 | 0000 | 00000000 | 0000 | 00000000 | 00000 | |

| 1 1/4 | NPT | 5" | 7 1/8" | EPDM Rubber | 304 Stainless Steel | 00000000 | 00000 | 0000000 | 0000 | 00000000 | 0000 | 00000000 | 00000 | |

| 1 1/2 | NPT | 5 1/8" | 8 1/8" | EPDM Rubber | 304 Stainless Steel | 00000000 | 00000 | 0000000 | 0000 | 00000000 | 0000 | 00000000 | 00000 | |

Screens for T-Strainers

To replace your screen, measure the OD and length and find the corresponding screen listed in the table.

| For Pipe Size | For Tube OD | Screen OD | Screen Length | Screen Material | Choose a Screen Mesh Size | Each | |

Mesh | |||||||

|---|---|---|---|---|---|---|---|

| 1/4, 3/8, 1/2 | 1/4", 3/8" | 15/16" | 1 11/32" | 304 Stainless Steel | 00000000 | 00000 | |

| 3/8, 1/2, 3/4 | __ | 1 31/64" | 3 3/4" | 304 Stainless Steel | 0000000 | 0000 | |

| 1 | __ | 2 15/64" | 4 15/64" | 304 Stainless Steel | 0000000 | 0000 | |

| 1 1/4 | __ | 2 15/64" | 4 17/32" | 304 Stainless Steel | 0000000 | 0000 | |

| 1 1/2 | __ | 2 15/64" | 5 29/64" | 304 Stainless Steel | 0000000 | 0000 | |

Chemical-Resistant T-Strainers

- Max. Pressure for Solvents and Salt Solutions: 150 psi @ 70° F

- Temp. Range: -40° to 125° F

Made of chemical-resistant plastic, these strainers can withstand exposure to salt solutions and solvents that can corrode metals. Use them prior to valves, pumps, and nozzles in your pipeline.

Clear strainers allow you to monitor debris collecting in the screen without disconnecting your pipeline.

Strainers with a polyethylene screen trap particles down to 70 microns, finer than strainers with a polypropylene screen; they’re good for use in vacuum applications.

For technical drawings and 3-D models, click on a part number.

Strainers | Replacement Screens | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Lg. | Ht. | Gasket Material | Screen OD | Screen Lg. | Choose a Screen Mesh Size | Removes Particle Size Down To | Each | Each | ||

Black Polypropylene Plastic Housing | ||||||||||||

Polyethylene Plastic Screen | ||||||||||||

| 1/4 | NPT | 3" | 2 11/16" | EPDM Rubber | 1" | 1 13/32" | __ | 70 microns | 0000000 | 00000 | 0000000 | 00000 |

| 3/8 | NPT | 3" | 2 11/16" | EPDM Rubber | 1" | 1 13/32" | __ | 70 microns | 0000000 | 0000 | 0000000 | 0000 |

| 3/8 | NPT | 3 1/2" | 5 3/8" | EPDM Rubber | 1 1/2" | 3 39/64" | __ | 70 microns | 0000000 | 00000 | 0000000 | 0000 |

| 1/2 | NPT | 3" | 2 11/16" | EPDM Rubber | 1" | 1 13/32" | __ | 70 microns | 0000000 | 0000 | 0000000 | 0000 |

| 1/2 | NPT | 3 1/2" | 5 3/8" | EPDM Rubber | 1 1/2" | 3 39/64" | __ | 70 microns | 0000000 | 00000 | 0000000 | 0000 |

| 3/4 | NPT | 3 9/16" | 5 3/8" | EPDM Rubber | 1 1/2" | 3 39/64" | __ | 70 microns | 0000000 | 00000 | 0000000 | 0000 |

| 1 | NPT | 4 1/8" | 5 11/16" | EPDM Rubber | 1 1/2" | 3 39/64" | __ | 70 microns | 0000000 | 00000 | 0000000 | 0000 |

| 1 | NPT | 4 15/16" | 6 3/8" | EPDM Rubber | 2 5/16" | 4 7/64" | __ | 70 microns | 0000000 | 00000 | 0000000 | 0000 |

| 1 1/2 | NPT | 5 1/16" | 8 1/16" | EPDM Rubber | 2 5/16" | 5 5/16" | __ | 70 microns | 0000000 | 00000 | 0000000 | 0000 |

Clear Nylon Plastic Housing | ||||||||||||

Polyethylene Plastic Screen | ||||||||||||

| 1/4 | NPT | 3" | 2 11/16" | EPDM Rubber | 1" | 1 3/8" | __ | 70 microns | 0000000 | 0000 | 0000000 | 0000 |

| 3/8 | NPT | 3" | 2 11/16" | EPDM Rubber | 1" | 1 13/32" | __ | 70 microns | 0000000 | 0000 | 0000000 | 0000 |

| 3/8 | NPT | 3 1/2" | 5 3/8" | EPDM Rubber | 1 1/2" | 3 39/64" | __ | 70 microns | 0000000 | 00000 | 0000000 | 0000 |

| 1/2 | NPT | 3" | 2 11/16" | EPDM Rubber | 1" | 1 13/32" | __ | 70 microns | 0000000 | 0000 | 0000000 | 0000 |

| 1/2 | NPT | 3 9/16" | 5 3/8" | EPDM Rubber | 1 1/2" | 3 9/16" | __ | 70 microns | 0000000 | 00000 | 0000000 | 0000 |

| 3/4 | NPT | 3 9/16" | 5 3/8" | EPDM Rubber | 1 1/2" | 3 9/16" | __ | 70 microns | 0000000 | 00000 | 0000000 | 0000 |

| 1 | NPT | 4 1/8" | 5 3/8" | EPDM Rubber | 1 1/2" | 3 39/64" | __ | 70 microns | 0000000 | 00000 | 0000000 | 0000 |

| 1 | NPT | 4 15/16" | 6 3/8" | EPDM Rubber | 2 5/16" | 4 7/64" | __ | 70 microns | 0000000 | 00000 | 0000000 | 0000 |

| 1 1/2 | NPT | 5 1/16" | 8 1/16" | EPDM Rubber | 2 5/16" | 5 5/16" | __ | 70 microns | 0000000 | 00000 | 0000000 | 0000 |

Polypropylene Plastic Screen | ||||||||||||

| 3/8 | NPT | 3 1/2" | 5 3/8" | EPDM Rubber | 1 1/2" | 3 45/64" | __ | 0000000 | 00000 | 0000000 | 0000 | |

| 1/2 | NPT | 3 9/16" | 5 3/8" | EPDM Rubber | 1 3/4" | 3 3/4" | __ | 0000000 | 00000 | 0000000 | 0000 | |

| 3/4 | NPT | 3 9/16" | 5 3/8" | EPDM Rubber | 1 3/4" | 3 3/4" | __ | 0000000 | 00000 | 0000000 | 0000 | |

| 1 | NPT | 4 1/8" | 5 11/16" | EPDM Rubber | 1 1/2" | 3 45/64" | __ | 000000 | 00000 | 0000000 | 0000 | |

Screens for Chemical-Resistant T-Strainers

To replace your screen, measure the OD and length and find the corresponding screen listed in the table.

Strainers with a polyethylene screen trap particles down to 70 microns, finer than strainers with a polypropylene screen; they’re good for use in vacuum applications.

| For Pipe Size | Screen OD | Screen Length | Screen Material | Choose a Screen Mesh Size | Removes Particle Size Down To | Each | |

Mesh | |||||||

|---|---|---|---|---|---|---|---|

| 3/8, 1/2, 3/4, 1 | 1 3/4" | 3 3/4" | Polypropylene Plastic | __ | 0000000 | 00000 | |

Perforated | |||||||

| 1/4, 3/8, 1/2 | 1" | 1 3/8" | Polyethylene Plastic | __ | 70 microns | 0000000 | 0000 |

| 3/8, 1/2, 3/4 | 1 1/2" | 3 9/16" | Polyethylene Plastic | __ | 70 microns | 0000000 | 0000 |

| 1, 1 1/4 | 2 5/16" | 4 7/64" | Polyethylene Plastic | __ | 70 microns | 0000000 | 0000 |

| 1 1/2 | 2 5/16" | 5 5/16" | Polyethylene Plastic | __ | 70 microns | 0000000 | 0000 |

High-Capacity T-Strainers

- Max. Pressure for Water, Ethylene Glycol, Acetone, and Sodium Nitrate: 300 psi @ 70° F

- Temp. Range: -20° to 150° F

Well suited for high-flow applications, these strainers have an extra-long housing and screen for greater debris-holding capacity than our other T-strainers. Use them to prevent debris from entering sensitive equipment such as valves, pumps, and nozzles. Strainers have a polypropylene housing for excellent corrosion resistance. They have a threaded drain with a plug that provides access to the screen without disconnecting your line.

Strainers with 3/4 and 1 pipe size have mounting brackets to provide extra stability.

For technical drawings and 3-D models, click on a part number.

Strainers | Replacement Screens | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Lg. | Ht. | Plug Pipe Size | Gasket Material | Screen Material | Screen OD | Screen Lg. | Choose a Screen Mesh Size | Each | Each | ||

Black Polypropylene Plastic Housing | |||||||||||||

| 3/4 | NPT | 3 7/8" | 9 1/16" | 1/2 | EPDM Rubber | 316 Stainless Steel | 1 3/8" | 5 3/4" | 00000000 | 000000 | 0000000 | 000000 | |

| 1 | NPT | 3 7/8" | 9 1/16" | 1/2 | EPDM Rubber | 316 Stainless Steel | 1 3/8" | 5 3/4" | 00000000 | 00000 | 0000000 | 00000 | |

| 1 1/4 | NPT | 5 1/4" | 11 1/4" | 1 | EPDM Rubber | 316 Stainless Steel | 2 7/32" | 7 15/16" | 00000000 | 00000 | 0000000 | 00000 | |

| 1 1/2 | NPT | 5 1/4" | 11 1/4" | 1 | EPDM Rubber | 316 Stainless Steel | 2 7/32" | 7 15/16" | 00000000 | 00000 | 0000000 | 00000 | |

Screens for High-Capacity T-Strainers

To replace your screen, measure the OD and length and find the corresponding screen listed in the table.

Impact-Resistant T-Strainers

- Max. Pressure for Water: 150 psi @ 70° F

- Temp. Range: 0° to 125° F

A nylon housing provides excellent durability and impact-resistance, as well as corrosion resistance. Install strainers prior to valves, pumps, and nozzles to catch particles in your pipeline and protect sensitive equipment.

Clear strainers allow you to monitor debris collecting in the screen without disconnecting your pipeline.

For technical drawings and 3-D models, click on a part number.

Strainers | Replacement Screens | Replacement Buna-N Rubber Gaskets | Optional Fluoroelastomer Rubber Gaskets | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Lg. | Ht. | Gasket Material | Screen Material | Screen OD | Screen Lg. | Choose a Screen Mesh Size | Each | Each | Pkg. | Pkg. | ||||

White Nylon Plastic Housing | ||||||||||||||||

| 1/2 | NPT | 3 5/8" | 5 3/8" | Buna-N Rubber | 304 Stainless Steel | 1 31/64" | 3 3/4" | 00000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 | 00000000 | 00000 | |

| 3/4 | NPT | 3 5/8" | 5 3/8" | Buna-N Rubber | 304 Stainless Steel | 1 31/64" | 3 3/4" | 00000000 | 00000 | 0000000 | 0000 | 0000000 | 0000 | 00000000 | 0000 | |

| 1 | NPT | 5" | 6 7/16" | Buna-N Rubber | 304 Stainless Steel | 2 15/64" | 4 15/64" | 00000000 | 00000 | 0000000 | 0000 | 0000000 | 0000 | 00000000 | 00000 | |

| 1 1/4 | NPT | 5" | 7 1/8" | Buna-N Rubber | 304 Stainless Steel | 2 15/64" | 4 17/32" | 00000000 | 00000 | 0000000 | 0000 | 0000000 | 0000 | 00000000 | 00000 | |

| 1 1/2 | NPT | 5 1/8" | 8 1/8" | Buna-N Rubber | 304 Stainless Steel | 2 15/64" | 5 29/64" | 00000000 | 00000 | 0000000 | 0000 | 0000000 | 0000 | 00000000 | 00000 | |

Clear Nylon Plastic Housing | ||||||||||||||||

| 1/2 | NPT | 3 5/8" | 5 3/8" | Buna-N Rubber | 304 Stainless Steel | 1 31/64" | 3 3/4" | 00000000 | 00000 | 0000000 | 0000 | 0000000 | 0000 | 00000000 | 0000 | |

| 3/4 | NPT | 3 5/8" | 5 3/8" | Buna-N Rubber | 304 Stainless Steel | 1 31/64" | 3 3/4" | 00000000 | 00000 | 0000000 | 0000 | 0000000 | 0000 | 00000000 | 0000 | |

| 1 | NPT | 5" | 6 7/16" | Buna-N Rubber | 304 Stainless Steel | 2 15/64" | 4 15/64" | 00000000 | 00000 | 0000000 | 0000 | 0000000 | 0000 | 00000000 | 00000 | |

| 1 1/4 | NPT | 5" | 7 1/8" | Buna-N Rubber | 304 Stainless Steel | 2 15/64" | 4 17/32" | 00000000 | 00000 | 0000000 | 0000 | 0000000 | 0000 | 00000000 | 00000 | |

| 1 1/2 | NPT | 5 1/8" | 8 1/8" | Buna-N Rubber | 304 Stainless Steel | 2 15/64" | 5 29/64" | 00000000 | 00000 | 0000000 | 0000 | 0000000 | 0000 | 00000000 | 00000 | |

Stainless Steel Quick-Clamp T-Strainers

- Max. Pressure for Beverage, Dairy, Food, Pharmaceuticals, and Water: 150 psi @ 72° F

- Temp. Range: -50° to 275° F

Add these inline T-strainers to your sanitary process line to trap solid particles during clean-in-place (CIP) cycles. They have quick-clamp sanitary tube connections, also known as tri-clamp connections, for use in dairy, food, and other process lines that require frequent cleaning and disassembly. As the high-pressure cleaning fluid flows through your line, the strainer's screen catches particles larger than 1/8" to prevent damage to pumps, valves, and other downstream components. And because the total open area of the screen is larger than the area of the tube itself, the screen will not restrict flow.

Strainers come with a gasket and clamp to secure the screen inside the strainer. Gaskets and clamps for connecting the strainer to your line are sold separately. A handle lets you remove the screen to clean it between runs.

Strainers | Replacement Clamps | Replacement Screens | Replacement EPDM Gaskets | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | Lg. | Ht. | Screen Material | Screen Opening Size | Screen Lg. | Each | Each | Each | Each | ||||

316 Stainless Steel | ||||||||||||||

| 1 1/2" | 1.984" | 5 1/2" | 5 7/8" | 316 Stainless Steel | 1/8" | 3 1/2" | 0000000 | 0000000 | 00000000 | 000000 | 0000000 | 0000000 | 0000000 | 00000 |

| 2" | 2.516" | 7" | 6 7/8" | 316 Stainless Steel | 1/8" | 4 1/2" | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 0000 |

| 2 1/2" | 3.047" | 7" | 7 3/16" | 316 Stainless Steel | 1/8" | 4 3/4" | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 0000 |

| 3" | 3.579" | 7 1/2" | 7 11/16" | 316 Stainless Steel | 1/8" | 5 1/4" | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 0000 |

Screens for Stainless Steel Quick-Clamp T-Strainers

Use these replacement screens with our Stainless Steel Quick-Clamp T-Strainers. Designed for use in dairy, food, and other process lines that use clean-in-place (CIP) systems, they prevent damage to pumps, valves, and other downstream components. Insert the screen into the strainer, then add a gasket and clamp to seal. The screen catches particles larger than 1/8" without restricting flow.

| For Tube OD | For Flange OD | Screen Opening Size | Screen Lg. | Screen Material | For Use With | Each | |

| 1 1/2" | 1.984" | 1/8" | 3 1/2" | 316 Stainless Steel | Beverage, Dairy, Food, Pharmaceuticals, Water | 0000000 | 0000000 |

| 2" | 2.516" | 1/8" | 4 1/2" | 316 Stainless Steel | Beverage, Dairy, Food, Pharmaceuticals, Water | 0000000 | 000000 |

| 2 1/2" | 3.047" | 1/8" | 4 3/4" | 316 Stainless Steel | Beverage, Dairy, Food, Pharmaceuticals, Water | 0000000 | 000000 |

| 3" | 3.579" | 1/8" | 5 1/4" | 316 Stainless Steel | Beverage, Dairy, Food, Pharmaceuticals, Water | 0000000 | 000000 |

Compact T-Strainers

- Max. Pressure for Water: 250 psi @ 70° F

- Temp. Range: 32° to 180° F

With a smaller overall size than T-strainers of the same pipe size, these are well suited to applications in close quarters. Use them to capture debris in your pipeline before it can damage valves, pumps, nozzles, and other sensitive equipment. Unthread the retainer cap to remove debris. Strainers are bronze for good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Strainers | Replacement Screens | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Lg. | Ht. | Screen Material | Screen OD | Screen Lg. | Choose a Screen Mesh Size | Each | Each | ||

Bronze | |||||||||||

| 1/4 | NPT | 2 1/16" | 1 11/16" | 304 Stainless Steel | 47/64" | 49/64" | 0000000 | 0000000 | 0000000 | 000000 | |

| 3/8 | NPT | 2 1/2" | 2 3/16" | 304 Stainless Steel | 25/32" | 1 1/4" | 0000000 | 000000 | 0000000 | 00000 | |

| 1/2 | NPT | 2 3/4" | 2 5/8" | 304 Stainless Steel | 25/32" | 1 35/64" | 0000000 | 000000 | 0000000 | 00000 | |

Screens for Compact T-Strainers

To replace your screen, measure the OD and length and find the corresponding screen listed in the table.