Filter by

Fastener Head Style

Length

Threading

Finish

Material

Tensile Strength

Thread Fit

Thread Direction

Mount Type

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Nose Material

T-Bolts

Also known as tank-strap bolts, these T-bolts are commonly used with a band clamp or a strap to hold fuel tanks and other objects in place. The large T-shaped head provides a secure grip for steady tightening.

Steel—Steel T-bolts without a finish are ready to be painted or finished.

Black-Oxide Steel—Black-oxide steel T-bolts are mildly corrosion resistant in dry environments.

Zinc-Plated Steel—Zinc-plated steel T-bolts resist corrosion in wet environments.

Coarse Thread—Coarse threads are the industry standard; choose these screws if you don’t know the threads per inch.

Fine Thread—Fine threads are closely spaced to prevent loosening from vibration.

Length—Length is measured from the top of the head.

Thread Spacing—Match the thread spacing of mating components.

Head | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg. | Threading | Thread Spacing | Wd. | Thk. | Tensile Strength, psi | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 2 15/16" | Partially Threaded | Coarse | 1 3/4" | 3/8" | 120,000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 3 11/16" | Partially Threaded | Coarse | 2" | 3/8" | 120,000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 3 3/4" | Partially Threaded | Coarse | 2" | 1/2" | 120,000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 3 3/4" | Partially Threaded | Fine | 2" | 1/2" | 120,000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 2 5/8" | Partially Threaded | Coarse | 1 1/4" | 1/4" | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 5 3/16" | Partially Threaded | Coarse | 1 3/4" | 3/8" | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 3 11/16" | Partially Threaded | Fine | 2" | 1/2" | 120,000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 6 1/4" | Partially Threaded | Coarse | 3" | 1/2" | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 2 15/16" | Partially Threaded | Coarse | 1 3/4" | 3/8" | 120,000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 3 11/16" | Partially Threaded | Coarse | 2" | 3/8" | 120,000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 3 11/16" | Partially Threaded | Fine | 2" | 1/2" | 120,000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 3 3/4" | Partially Threaded | Coarse | 2" | 1/2" | 120,000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 3 3/4" | Partially Threaded | Fine | 2" | 1/2" | 120,000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

T-Bolts with Collar

|

Also known as clamping pins, these bolts have a collar that slides along the shaft and can be welded in place to hold work and prevent over torquing. The large T-shaped head provides a secure grip for steady tightening. The black-oxide finish provides corrosion resistance in dry environments.

Length—Length is measured from the top of the head.

Head | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg. | Threading | Thread Spacing | Wd. | Thk. | Tensile Strength, psi | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 3 1/4" | Partially Threaded | Coarse | 1 1/2" | 1/4" | 70,000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 4 3/8" | Partially Threaded | Coarse | 2 1/2" | 3/8" | 70,000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 4 7/16" | Partially Threaded | Coarse | 3" | 7/16" | 70,000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 5" | Partially Threaded | Coarse | 3 1/2" | 1/2" | 70,000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 5 5/8" | Partially Threaded | Coarse | 3 1/2" | 5/8" | 70,000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 7 5/8" | Partially Threaded | Coarse | 3 1/2" | 5/8" | 70,000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 6 3/8" | Partially Threaded | Coarse | 3 1/2" | 7/8" | 70,000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 6 7/8" | Partially Threaded | Coarse | 3 1/2" | 7/8" | 70,000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

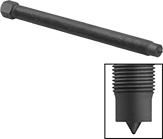

T-Handle Retractable Spring Plungers

|

With the widest grip, T-handles give you the most leverage of all our handles and are the easiest to grab with gloved or slippery hands. A tug manually retracts the nose so you can do everything from latching heavy, frequently-accessed doors to locking large cutting blades in place.

Spring plungers are available with or without a threadlocker. Those with a threadlocker won't wiggle loose from vibration. Spring plungers without a threadlocker are easier to remove.

Steel Nose—The strongest, most wear-resistant noses, these won't deform from stress and vibration. Steel is best for dry environments, however, since moisture will cause it to rust.

18-8 Stainless Steel Nose—The choice for wet and outdoor environments, 18-8 stainless steel resists rusting. It's strong enough for most jobs, but won't withstand stress and vibration as well as steel.

Twist-to-Lock—Free up both hands to adjust your workpiece or switch out parts without the plunger springing back and getting in the way. Pull back the handle and twist to lock the nose in its retracted position.

Extended Nose Force—This is the amount of force needed to start depressing the nose.

Compressed Nose Force—This is the amount of force needed to fully depress the nose into the plunger body, so it releases from a hole, notch, or surface. A lighter compressed nose force with a shallower hole releases more easily, while a heavier compressed nose force with a deeper hole holds more securely.

Nose | Nose Force, lbf | Body | Handle | Twist-to-Lock | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Extended Lg. | Dia. | Extended | Compressed | Material | Lg. | Material | Lg. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 0.8" | 0.25" | 0.155" | 1 | 2.5 | Zinc-Plated Steel | 1.14" | Steel | 1 1/8" | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1.2" | 0.375" | 0.233" | 2 | 4 | Zinc-Plated Steel | 1.68" | Steel | 1 1/2" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1.4" | 0.5" | 0.312" | 2.5 | 5 | Zinc-Plated Steel | 2" | Steel | 2" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 1.7" | 0.625" | 0.375" | 2.5 | 5 | Zinc-Plated Steel | 2.38" | Steel | 2 1/2" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 x 1 mm | 20.3 mm | 6.4 mm | 4 mm | 1 | 2.5 | Zinc-Plated Steel | 29 mm | Steel | 29 mm | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 x 1.5 mm | 30.5 mm | 9.5 mm | 6 mm | 2 | 4 | Zinc-Plated Steel | 43 mm | Steel | 38 mm | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 x 1.75 mm | 35.5 mm | 12.7 mm | 8 mm | 2.5 | 5 | Zinc-Plated Steel | 51 mm | Steel | 51 mm | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 x 2 mm | 43 mm | 16 mm | 10 mm | 2.5 | 5 | Zinc-Plated Steel | 60 mm | Steel | 64 mm | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 0.8" | 0.25" | 0.155" | 1 | 2.5 | 18-8 Stainless Steel | 1.14" | 18-8 Stainless Steel | 1 1/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1.2" | 0.375" | 0.233" | 2 | 4 | 18-8 Stainless Steel | 1.68" | 18-8 Stainless Steel | 1 1/2" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1.4" | 0.5" | 0.312" | 2.5 | 5 | 18-8 Stainless Steel | 2" | 18-8 Stainless Steel | 2" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 1.7" | 0.625" | 0.375" | 2.5 | 5 | 18-8 Stainless Steel | 2.38" | 18-8 Stainless Steel | 2 1/2" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 x 1 mm | 20.3 mm | 6.4 mm | 4 mm | 1 | 2.5 | 18-8 Stainless Steel | 29 mm | 18-8 Stainless Steel | 29 mm | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 x 1.5 mm | 30.5 mm | 9.5 mm | 6 mm | 2 | 4 | 18-8 Stainless Steel | 43 mm | 18-8 Stainless Steel | 38 mm | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 x 1.75 mm | 35.5 mm | 12.7 mm | 8 mm | 2.5 | 5 | 18-8 Stainless Steel | 51 mm | 18-8 Stainless Steel | 51 mm | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 x 2 mm | 43 mm | 16 mm | 10 mm | 2.5 | 5 | 18-8 Stainless Steel | 60 mm | 18-8 Stainless Steel | 64 mm | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||