How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Hose

More

Metal Push-On Barbed Hose Fittings for Air and Water

Fittings have sharper barbs than standard barbed hose fittings to grip rubber push-on hose with no clamps or ferrules required. The more you pull on the fittings, the tighter the hose will grip. 316 stainless steel fittings have excellent corrosion resistance, so they’re the best choice for high-humidity environments.

Fittings that swivel until tightened rotate 360° for easy installation.

Fittings with a flared end meet JIC or SAE standards for dimensions. Fittings with a 37° flared end are also known as JIC (Joint Industrial Council) fittings.The optional installation tool (sold separately) allows you to connect large quantities of barbed fittings to push-on hose. Use the built-in cutter to squarely cut the hose without fraying. Next, lubricate either the push-on hose, fitting or both. Then, clamp the hose into the tool’s vise and apply light pressure on the handle to drive into the fitting.

Note: To ensure proper connection, the barbed end has to be pushed in all the way, with the hose end concealed by the ring.

For technical drawings and 3-D models, click on a part number.

Mounting Hole | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Hose ID Range | Lg. | Ht. | Dp. | Dia. | No. of | Mounting Fasteners Included | Each | |

| 1/4" to 3/4" | 13 1/2" | 7" | 2 3/8" | 5/8" | 4 | No | 00000000 | 0000000 |

Threaded Hose Fittings for Hydraulic Fluid

Fittings are threaded on both ends so you can connect them directly to a threaded hose or to pumps, cylinders, and other equipment in your hydraulic system.

Zinc-plated steel fittings are stronger and more durable than stainless steel fittings. They have fair corrosion resistance. Fittings that swivel until tightened rotate for easy installation.

Fittings with a 37° flared end are also known as JIC (Joint Industrial Council) fittings.

BSPP threads have a gasket or a 60° internal flare to protect against leaks.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: See table

- Temperature Range: -20° to 230° F

- Specifications Met: SAE J514

Continuous-Swivel Threaded Hose Fittings for Hydraulic Fluid

Also known as live swivels, these fittings have ball bearings, so they can swivel continuously 360° before and after installation. This not only makes installation easier, but also eliminates the twisting and kinking that can cause premature hose failure. Fittings are threaded on both ends so you can connect them directly to a threaded hose end or to pumps, cylinders, and other equipment in your hydraulic system. They are zinc-plated steel, which has excellent strength and durability. Fittings have fair corrosion resistance.

Fittings with a 37° flared end are also known as JIC (Joint Industrial Council) fittings and meet JIC standards for dimensions.

UN/UNF (SAE Straight) male threads have a gasket to protect against leaks. They are also known as O-ring boss threads.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: See table

- Temperature Range: -15° to 250° F

Male Tube Connection | Female Tube Connection | |||||||

|---|---|---|---|---|---|---|---|---|

| For Tube OD | Thread Size | Dash Size | For Tube OD | Thread Size | Dash Size | Max. Pressure | Each | |

Zinc-Plated Steel | ||||||||

| 3/8" | 9/16"-18 | 06 | 3/8" | 9/16"-18 | 06 | 5,000 psi @ 72° F | 00000000 | 0000000 |

- Maximum Pressure: 5,000 psi @ 72° F

- Temperature Range: -40° to 250° F

Male Hose Connection | Male Tube Connection | ||||

|---|---|---|---|---|---|

| Thread Size | Dash Size | For Tube OD | Thread Size | Each | |

Zinc-Plated Steel | |||||

| 9/16"-18 | 06 | 3/8" | 9/16"-18 | 0000000 | 0000000 |

Push-On Barbed Hose Fittings for Hydraulic Fluid

These fittings have sharp barbs to grip rubber push-on hose with no clamps or ferrules required. The more you pull on the fittings, the tighter the hose will grip. Use them in low-pressure hydraulic applications up to 350 psi. Also known as hose nipples, they adapt a barbed end to a threaded end, so you can connect to pumps, cylinders, and other equipment in your hydraulic system. Fittings are zinc-plated steel, which has excellent strength and durability. Fittings have fair corrosion resistance.

Fittings that swivel until tightened rotate 360° for easy installation.

Fittings with a 37° flared end are also known as JIC (Joint Industrial Council) fittings.

Note: To ensure proper connection, the barbed end has to be pushed in all the way, with the hose end concealed by the ring.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: See table

- Maximum Vacuum: See Table

- Temperature Range: -40° to 255° F

- For Hose Manufacturer Series: Parker 801

- Specifications Met: See Table

Fittings | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ring Stop | 10-ft. Hose | |||||||||||

| For Hose ID | For Tube OD | Thread Size | Dash Size | Material | Color | Max. Pressure | Max. Vacuum | Manufacturer Series | Each | Each | ||

Zinc-Plated Steel | ||||||||||||

| 3/8" | 3/8" | 9/16"-18 | 06 | Plastic | Yellow | 350 psi @ 72° F | 28 in. of Hg @ 72° F | Parker 82 | 00000000 | 00000 | 0000000 | 000000 |

| 1/2" | 3/8" | 9/16"-18 | 06 | Plastic | Yellow | 300 psi @ 72° F | 28 in. of Hg @ 72° F | Parker 82 | 00000000 | 0000 | 0000000 | 00000 |

- Maximum Pressure: See table

- Maximum Vacuum: See Table

- Temperature Range: -40° to 255° F

- For Hose Manufacturer Series: Parker 801

- Maximum Pressure: See table

- Maximum Vacuum: See Table

- Temperature Range: -40° to 255° F

- For Hose Manufacturer Series: Parker 801

Crimp-On Hose Fittings for Hydraulic Fluid

Crimp these fittings onto hydraulic hose for a permanent, leak-tight connection. Since they crimp on, they handle higher pressure than screw-on fittings. To install, use Parker crimping tools and dies (not included).

Fittings with a female end swivel 360° until tightened without you needing to move or twist the entire hose, making them easy to install.

Fittings with a 37° flared end are also known as JIC (Joint Industrial Council) fittings.

Fittings with an O-ring face seal end are also known as Seal-Lok fittings.

Note: Fittings are only for use with hydraulic hose.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: See table

- Temperature Range: -40° to 210° F

- For Hose Manufacturer Series:

Parker 43 Series Fittings: 302 SAE J517 100R2AT, 422 SAE J517 100R1AT, 487 ISO17582-AC, 777 ISO17582-CC

Parker 56 Series Fittings: 510D J517 SAE 100R7, 518D J517 SAE 100R7

- Maximum Pressure: See table

- Temperature Range: -40° to 210° F

- For Hose Manufacturer Series:

Parker 43 Series Fittings: 302 SAE J517 100R2AT, 422 SAE J517 100R1AT, 487 ISO17582-AC, 777 ISO17582-CC

Parker 56 Series Fittings: 510D J517 SAE 100R7, 518D J517 SAE 100R7

- Maximum Pressure: See table

- Temperature Range: -40° to 210° F

- For Hose Manufacturer Series:

Parker 43 Series Fittings: 302 SAE J517 100R2AT, 422 SAE J517 100R1AT, 487 ISO17582-AC, 777 ISO17582-CC

Parker 56 Series Fittings: 510D J517 SAE 100R7, 518D J517 SAE 100R7

For Hose | |||||||

|---|---|---|---|---|---|---|---|

| ID | OD | For Tube OD | Thread Size | Dash Size | Max. Pressure | Each | |

Zinc-Plated Steel—Parker 43 Series | |||||||

| 1/4" | 1/2" | 3/8" | 9/16"-18 | 06 | 4,000 psi @ 72° F | 0000000 | 000000 |

| 3/8" | 11/16" | 3/8" | 9/16"-18 | 06 | 4,000 psi @ 72° F | 0000000 | 00000 |

Zinc-Plated Steel—Parker 56 Series | |||||||

| 1/4" | 1/2" | 3/8" | 9/16"-18 | 06 | 3,000 psi @ 72° F | 0000000 | 00000 |

| 3/8" | 5/8" | 3/8" | 9/16"-18 | 06 | 2,250 psi @ 72° F | 0000000 | 00000 |

- Maximum Pressure: See table

- Temperature Range: -40° to 210° F

- For Hose Manufacturer Series:

Parker 43 Series Fittings: 302 SAE J517 100R2AT, 422 SAE J517 100R1AT, 487 ISO17582-AC, 777 ISO17582-CC

Parker 56 Series Fittings: 510D J517 SAE 100R7, 518D J517 SAE 100R7

For Hose | |||||||

|---|---|---|---|---|---|---|---|

| ID | OD | For Tube OD | Thread Size | Dash Size | Max. Pressure | Each | |

Zinc-Plated Steel—Parker 43 Series | |||||||

| 1/4" | 1/2" | 3/8" | 9/16"-18 | 06 | 4,000 psi @ 72° F | 0000000 | 000000 |

| 3/8" | 11/16" | 3/8" | 9/16"-18 | 06 | 4,000 psi @ 72° F | 0000000 | 00000 |

Zinc-Plated Steel—Parker 56 Series | |||||||

| 1/4" | 1/2" | 3/8" | 9/16"-18 | 06 | 3,000 psi @ 72° F | 0000000 | 00000 |

| 3/8" | 5/8" | 3/8" | 9/16"-18 | 06 | 2,250 psi @ 72° F | 0000000 | 00000 |

Screw-On Hose Fittings for D.O.T. Hose

Create or repair D.O.T. hose assemblies in the field with just a wrench and a vise, no crimper required. To install, separate the two pieces of these fittings. Screw the hose-end portion onto your hose, then thread the nipple portion into the hose-end portion. When assembled, these fittings compress against the hose to form a strong seal. Also known as reusable fittings, they can be unscrewed from your hose and used on a new one. All meet labeling and performance requirements for motor vehicle brake hose fittings.

Fittings with a flared tube connection swivel 360° until tightened for easy installation. Those with a 37° flared end are also known as JIC (Joint Industrial Council) fittings.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: See table

- Temperature Range: -40° to 300° F

- Specifications Met: D.O.T. FMVSS 106, SAE J517 100R5

- For Hose Manufacturer Series: Parker 201 SAE J517 100R5

For Hose | ||||||||

|---|---|---|---|---|---|---|---|---|

| ID | OD | For Tube OD | Thread Size | Thread Type | Dash Size | Max. Pressure | Each | |

Zinc-Plated Steel—Parker 20 Series | ||||||||

| 5/16" | 11/16" | 3/8" | 9/16"-18 | UN/UNF (JIC) | 06 | 2,250 psi @ 72° F | 0000000 | 000000 |

Screw-On Hose Fittings for Hydraulic Fluid

With just a vise and a wrench, make or repair hose assemblies in the field. These fittings thread directly onto hydraulic hose, so you don't need to crimp. To install, separate the two pieces. Screw the hose end onto your hose first and then thread the two pieces of the fitting back together. These fittings compress against the hose to form a strong seal. Also known as reusable fittings, they can be unscrewed from your hose and used again.

Fittings with a female tube end swivel 360° until tightened for easy installation.

Fittings with a 37° flared end are also known as JIC (Joint Industrial Council) fittings.

Zinc-plated steel fittings are stronger and resist wear and tear better than 316 stainless steel fittings. The zinc plating resists rusting in wet environments.

316 stainless steel fittings resist corroding from harsh chemicals and water better than zinc-plated steel fittings.

Note: Fittings are only for use with hydraulic hose.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: See table

- Temperature Range: -40° to 212° F

- For Hose Manufacturer Series:

Parker 42 Series Fittings: Parker 422 SAE J517 100R1AT

Parker 30 Series Fittings: Parker 302 SAE J517 100R2AT

Parker 51R Series Fittings: Parker 510D and 518D J517 SAE 100R7 - Specifications Met: See table

Fittings | Hose | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Hose | Per Ft. | Vice Jaw Liners | ||||||||||||

| ID | OD | For Tube OD | Thread Size | Thread Type | Dash Size | Max. Pressure | Specifications Met | Each | 1-99 | 100-Up | Each | |||

Zinc-Plated Steel—Parker 42 Series | ||||||||||||||

| 3/8" | 11/16" | 3/8" | 9/16"-18 | UN/UNF (JIC) | 06 | 2,600 psi @ 72° F | SAE J516 | 00000000 | 000000 | 00000000 | 00000 | 00000 | 000000 | 00 |

Zinc-Plated Steel—Parker 30 Series | ||||||||||||||

| 3/8" | 3/4" | 3/8" | 9/16"-18 | UN/UNF (JIC) | 06 | 4,500 psi @ 72° F | SAE J516 | 00000000 | 00000 | 0000000 | 0000 | 0000 | 000000 | 00 |

Zinc-Plated Steel—Parker 51R Series | ||||||||||||||

| 3/8" | 5/8" | 3/8" | 9/16"-18 | UN/UNF (JIC) | 06 | 2,250 psi @ 72° F | __ | 000000000 | 00000 | 0000000 | 0000 | 0000 | 000000000 | 000000 |

316 Stainless Steel—Parker 30 Series | ||||||||||||||

| 3/8" | 3/4" | 3/8" | 9/16"-18 | UN/UNF (JIC) | 06 | 4,500 psi @ 72° F | SAE J514 | 0000000 | 00000 | 0000000 | 0000 | 0000 | 000000 | 00 |

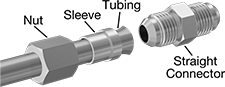

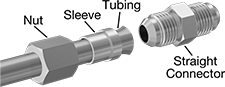

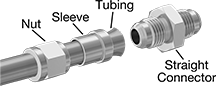

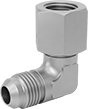

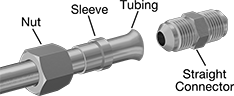

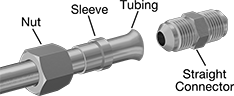

37° Flared Fittings for Stainless Steel Tubing

- Tubing: Use with welded or seamless 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Specifications Met: ISO 8434, SAE J514, except fittings with BSPP and BSPT threads meet SAE J514 only

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They withstand high pressure, so they’re often used in hydraulic applications. Made from 316 stainless steel, they resist corrosion from water and chemicals. A complete fitting requires a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -380° to 800° F

Fittings that swivel until tightened have a built-in nut that rotates 360° for easy installation.

Fittings with female tube end have an internal flare that mates with the male tube end of another fitting.

| For Tube OD | Material | Max. Pressure | Each | |

| 3/8" | 316 Stainless Steel | 5,000 psi @ 72° F | 000000000 | 000000 |

- For Use With: See table

- Temperature Range: See table

Fittings that swivel until tightened have a built-in nut that rotates 360° for easy installation.

Fittings with female tube end have an internal flare that mates with the male tube end of another fitting.

| For Tube OD | Pipe Size | For Use With | Material | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 3/8" | 1/4 | Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water | 316 Stainless Steel | 5,000 psi @ 72° F | -420° to 1200° | 000000000 | 000000 |

| 3/8" | 3/8 | Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water | 316 Stainless Steel | 5,000 psi @ 72° F | -420° to 1200° | 000000000 | 000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: See table

Fittings that swivel until tightened have a built-in nut that rotates 360° for easy installation.

Fittings with female tube end have an internal flare that mates with the male tube end of another fitting.

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: See table

Fittings that swivel until tightened have a built-in nut that rotates 360° for easy installation.

Fittings with female tube end have an internal flare that mates with the male tube end of another fitting.

| For Tube OD | Material | Max. Pressure | Temp. Range, °F | Each | |

| 3/8" | 316 Stainless Steel | 5,000 psi @ 72° F | -420° to 1200° F | 000000000 | 0000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

Fittings that swivel until tightened have a built-in nut that rotates 360° for easy installation.

Fittings with female tube end have an internal flare that mates with the male tube end of another fitting.

| For Tube OD | Material | Max. Pressure | Each | |

| 3/8" | 316 Stainless Steel | 4,500 psi @ 72° F | 000000000 | 000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

Inline tees are also known as branch tees.

Fittings that swivel until tightened have a built-in nut that rotates 360° for easy installation.

Fittings with female tube end have an internal flare that mates with the male tube end of another fitting.

| For Tube OD | Material | Max. Pressure | Each | |

| 3/8" | 316 Stainless Steel | 4,500 psi @ 72° F | 000000000 | 000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

Right-angle tees are also known as run tees.

Fittings that swivel until tightened have a built-in nut that rotates 360° for easy installation.

Fittings with female tube end have an internal flare that mates with the male tube end of another fitting.

| For Tube OD | Material | Max. Pressure | Each | |

| 3/8" | 316 Stainless Steel | 4,500 psi @ 72° F | 000000000 | 000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

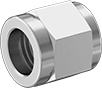

| For Tube OD | Nut Material | Each | |

| 3/8" | 316 Stainless Steel | 000000000 | 00000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on stainless steel tubing that is flared to 37°. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

Inch × metric sleeve adapters convert the fitting from inch to metric.

Cleaned and Bagged 37° Flared Fittings for Stainless Steel Tubing

- For Use With:

NPT Threads: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

UN/UNF (SAE Straight) Threads: Air, Isopropyl Alcohol, Water - Temperature Range:

NPT Threads: -420° to 1200° F

UN/UNF (SAE Straight) Threads: -15° to 400° F - Tubing: Use with seamless or welded 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Specifications Met: SAE J514, ISO 8434

Individually bagged to prevent contamination, these fittings are suitable for applications that require a high level of cleanliness. Also known as JIC (Joint Industrial Council) fittings, they provide a tight metal-to-metal seal on tubing that is flared to 37°. They are 316 stainless steel for excellent corrosion resistance. Fittings require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately and are not cleaned and bagged.

UN/UNF (SAE Straight) male threads have a gasket to protect against leaks. They are also known as O-ring boss threads.

For technical drawings and 3-D models, click on a part number.

Fittings that swivel until tightened have a built-in nut that rotates 360° for easy installation.

Fittings with female tube end have an internal flare that mates with the male tube end of another fitting.

| For Tube OD | Nut Material | Each | |

| 3/8" | 316 Stainless Steel | 000000000 | 00000 |

| For Tube OD | Sleeve Material | Each | |

| 3/8" | 316 Stainless Steel | 000000000 | 00000 |

37° Flared Fittings with Thread Sealant for Stainless Steel Tubing

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range:

Adapters: -420° to 450° F

Sleeves and Nuts: -420° to 1,200° F - Tubing: Use with seamless or welded 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Specifications Met: ISO 8434, SAE J514, except fittings with BSPT threads meet SAE J514 only

The male pipe threads on these fittings have a sealant applied for extra protection against leaks. Also known as JIC (Joint Industrial Council) fittings, they provide a tight metal-to-metal seal on tubing that is flared to 37°. They’re often used in hydraulic applications. Made from 316 stainless steel, these fittings have excellent corrosion resistance. A complete fitting requires a nut and a sleeve (ferrule) for each tube end—tighten the nut to create a secure seal that withstands high pressure. Nuts and sleeves are sold separately.

For technical drawings and 3-D models, click on a part number.

Precision AN 37° Flared Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -320° to 1200° F

- Tubing: Use with seamless 304 or 316 stainless steel

- Specifications Met: See Table

The threads on the tube end of these fittings are Class 3A or 3B and adhere to tighter tolerances than other 37° flared fittings. They are made to exact AS (formerly AN) specifications and provide a tight metal-to-metal seal on tubing that is flared to 37°. Fittings require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

316 stainless steel fittings have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Fittings that swivel until tightened have a built-in nut that rotates 360° for easy installation.

Fittings with female tube end have an internal flare that mates with the male tube end of another fitting.

| For Tube OD | Pipe Size | Max. Pressure | Specifications Met | Each | |

316 Stainless Steel | |||||

|---|---|---|---|---|---|

ANPT Threads | |||||

| 3/8" | 1/4 | 3,000 psi @ 72° F | ASTM A380, SAE AS4841, SAE AS9100D, SAE AS9104/1 | 00000000 | 0000000 |

Fittings that swivel until tightened have a built-in nut that rotates 360° for easy installation.

Fittings with female tube end have an internal flare that mates with the male tube end of another fitting.

| For Tube OD (A) | For Tube OD (B) | Max. Pressure | Specifications Met | Each | |

316 Stainless Steel | |||||

|---|---|---|---|---|---|

UNJ/UNJF (JIC) Threads | |||||

| 3/8" | 3/8" | 3,000 psi @ 72° F | ASTM A380, SAE AS9100D, SAE AS9104/1 | 00000000 | 000000 |

| For Tube OD | Max. Pressure | Specifications Met | Each | |

316 Stainless Steel | ||||

|---|---|---|---|---|

| 3/8" | 3,000 psi @ 72° F | AN818-6K, ASTM A380, SAE AS4841 | 00000000 | 000000 |

| For Tube OD | Max. Pressure | Specifications Met | Each | |

316 Stainless Steel | ||||

|---|---|---|---|---|

| 3/8" | 3,000 psi @ 72° F | AN819-6K, ASTM A380, MS20819, SAE AS4841, SAE AS5176 | 00000000 | 000000 |

O-Ring Face Seal Fittings for Stainless Steel Tubing

(SAE Straight) Male

Threads with Gasket

- For Use With: Air, Hydraulic Fluid, Water

- Temperature Range: -30° to 250° F

- Tubing: Use with welded or seamless 316 stainless steel

- Specifications Met: SAE J1453; flared fittings also meet SAE J514

A tube adapter sits flush against the flat face of the fitting so you can slide the tubing and fitting sideways to disconnect in cramped spaces. Fittings are also known as zero-clearance fittings. To install, weld a tube adapter to the tubing with a brazing ring, then mate the tube adapter to the fitting and screw on the nut. As the nut is tightened, the tube adapter compresses the O-ring, creating a strong seal. Fittings are 316 stainless steel for excellent corrosion resistance. Nuts, tube adapters, and brazing rings are sold separately.

UN/UNF (SAE Straight) threads are also known as O-ring boss threads. Male threads with a gasket provide extra protection against leaks.

For technical drawings and 3-D models, click on a part number.

(SAE Straight) Male

Threads with Gasket

Fittings that swivel until tightened rotate 360° for easy installation.

Female fittings mate with another O-ring face seal fitting without the need for a nut or a tube adapter.

| For Tube OD | Thread Size | Material | Max. Pressure | Each | |

UN/UNF (SAE Straight) Threads | |||||

|---|---|---|---|---|---|

| 3/8" | 9/16"-18 | 316 Stainless Steel | 3,300 psi @ 72° F | 00000000 | 0000000 |

| For Tube OD | Material | Max. Pressure | Each | |

| 3/8" | 316 Stainless Steel | 3,300 psi @ 72° F | 0000000 | 000000 |

Material Composition | |||||||

|---|---|---|---|---|---|---|---|

| For Tube OD | Silver | Cadmium | Copper | Zinc | Nickel | Each | |

| 1/4" | 50% | 16% | 15% | 15% | 3% | 00000000 | 00000 |

| For Tube OD | Nut Material | Max. Pressure | Each | |

| 1/4" | 316 Stainless Steel | 4,000 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | O-Ring Material | Pkg. Qty. | Pkg. | |

| 1/4" | Buna-N Rubber | 5 | 0000000 | 000000 |

37° Flared Fittings for Steel Tubing

Male Threads

with Gasket

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil

- Tubing: Use with seamless steel

- Specifications Met: SAE J514

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately. Fittings are zinc-plated steel for fair corrosion resistance.

NPTF (Dryseal) threads are compatible with NPT threads.

To prevent leaks, UN/UNF (SAE Straight) male threads have a gasket. Metric and BSPP male threads have either a gasket or a gasket and washer. UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

For technical drawings and 3-D models, click on a part number.

- Temperature Range: -60° to 400° F

Fittings that swivel until tightened have a built-in nut that rotates 360° for easy installation.

Fittings with female tube end have an internal flare that mates with the male tube end of another fitting.

Male Threads

with Gasket

- Temperature Range: BSPP: -20° to 212° F

UN/UNF (SAE Straight): -60° to 400° F

Fittings that swivel until tightened have a built-in nut that rotates 360° for easy installation.

Fittings with female tube end have an internal flare that mates with the male tube end of another fitting.

Male Threads

with Gasket

- Temperature Range: -30° to 200° F

Fittings that swivel until tightened have a built-in nut that rotates 360° for easy installation.

| For Tube OD | Thread Size | Material | Max. Pressure | Each | |

UN/UNF (SAE Straight) Threads | |||||

|---|---|---|---|---|---|

| 3/8" | 1/2"-20 | Zinc-Plated Steel | 6,000 psi @ 72° F | 000000000 | 00000 |

- Temperature Range: -60° to 400° F

Fittings that swivel until tightened have a built-in nut that rotates 360° for easy installation.

Fittings with female tube end have an internal flare that mates with the male tube end of another fitting.

| For Tube OD | Material | Max. Pressure | Each | |

| 3/8" | Zinc-Plated Steel | 1,250 psi @ 72° F | 000000000 | 000000 |

- Temperature Range: -60° to 400° F

Fittings that swivel until tightened have a built-in nut that rotates 360° for easy installation.

Fittings with female tube end have an internal flare that mates with the male tube end of another fitting.

| For Tube OD | Material | Max. Pressure | Each | |

| 3/8" | Zinc-Plated Steel | 1,250 psi @ 72° F | 000000000 | 00000 |

- Temperature Range: -60° to 400° F

Fittings that swivel until tightened have a built-in nut that rotates 360° for easy installation.

Fittings with female tube end have an internal flare that mates with the male tube end of another fitting.

Inline tees are also known as branch tees.

| For Tube OD | Material | Max. Pressure | Each | |

| 3/8" | Zinc-Plated Steel | 1,250 psi @ 72° F | 000000000 | 000000 |

- Temperature Range: -60° to 400° F

Fittings that swivel until tightened have a built-in nut that rotates 360° for easy installation.

Fittings with female tube end have an internal flare that mates with the male tube end of another fitting.

Right-angle tees are also known as run tees.

| For Tube OD | Material | Max. Pressure | Each | |

| 3/8" | Zinc-Plated Steel | 1,250 psi @ 72° F | 000000000 | 000000 |

- Temperature Range: -60° to 400° F

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on steel tubing that is flared to 37°. Sleeves are zinc-plated steel for fair corrosion resistance. They are also known as ferrules.

Inch × metric sleeve adapters convert the fitting from inch to metric.

- Temperature Range: -60° to 400° F

| For Tube OD | Nut Material | Max. Pressure | Each | |

| 3/8" | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 00000 |

30° Flared Fittings for Steel Tubing

- Specifications Met: See table

Also known as JIS (Japanese Industrial Standard) fittings, these have a 30° flare on one or both ends. Fittings are zinc-plated steel for fair corrosion resistance.

For technical drawings and 3-D models, click on a part number.

- Temperature Range: -65° to 500° F

Fittings that swivel until tightened have a built-in nut that rotates 360° for easy installation.

Fittings with female tube end have an internal flare that mates with the male tube end of another fitting.

| For Tube OD | Pipe Size | Material | Max. Pressure | Specifications Met | Each | |

| 1/2" | 3/8 | Zinc-Plated Steel | 5,000 psi @ 72° F | ISO 228-1, ISO 263, ISO 8434-2, JIS B 0202, JIS B 8363, SAE J514 | 0000000 | 000000 |

O-Ring Face Seal Fittings for Steel Tubing

(SAE Straight) Male

Threads with Gasket

- For Use With: Air, Hydraulic Fluid

- Temperature Range: -30° to 250° F, except BSPP fittings are -20° to 230° F

- Tubing: Use with seamless steel

- Specifications Met: SAE J1453

A tube adapter sits flush against the flat face of the fitting so you can slide the tubing and fitting sideways to disconnect in cramped spaces. Fittings are also known as zero-clearance fittings. To install, weld a tube adapter to the tubing with a brazing ring (sold separately), then mate the tube adapter to the fitting and screw on the nut. As the nut is tightened, the tube adapter compresses the O-ring, creating a strong seal. Fittings are zinc-plated steel for fair corrosion resistance. Nuts and tube adapters are sold separately.

BSPP and UN/UNF (SAE Straight) male threads have a gasket to prevent leaks. UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

For technical drawings and 3-D models, click on a part number.

(SAE Straight) Male

Threads with Gasket

Fittings that swivel until tightened rotate 360° for easy installation.

| For Tube OD | Thread Size | Material | Gasket Material | Max. Pressure | Each | |

UN/UNF (SAE Straight) Threads | ||||||

|---|---|---|---|---|---|---|

| 3/8" | 9/16"-18 | Zinc-Plated Steel | Buna-N Rubber | 6,000 psi @ 72° F | 00000000 | 000000 |

Material Composition | ||||||

|---|---|---|---|---|---|---|

| For Tube OD | Silver | Cadmium | Zinc | Copper | Each | |

| 3/8" | 45% | 24% | 16% | 15% | 00000000 | 00000 |

| For Tube OD | Nut Material | Max. Pressure | Each | |

| 3/8" | Zinc-Plated Steel | 6,000 psi @ 72° F | 0000000 | 00000 |

| For Tube OD | Max. Pressure | Pkg. Qty. | Pkg. | |

| 3/8" | 6,000 psi @ 72° F | 5 | 0000000 | 00000 |