About Rotating Joints

Rotating joints transfer hot and cold materials from your supply line to a continuously revolving drum, roller, or other rotating equipment.

Pipe size is an industry designation, not the actual size. View information about how to measure pipe size threads.

More

How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Snaps with Swivel Eye

These snaps have an eye that rotates for easy positioning.

Zinc-plated snaps are mildly corrosion resistant.

Brass and nickel-plated snaps are more corrosion resistant than zinc-plated snaps.

| Snap Opening Wd. | Usable Lg. | Eye Inside Wd. | Latch Type | Each | ||

Nickel-Plated Iron | ||||||

|---|---|---|---|---|---|---|

| 1 | 3/8" | 3" | 3/4" | Spring | 0000000 | 00000 |

| 1 | 7/16" | 2 7/8" | 3/4" | Spring | 0000000 | 0000 |

| 1 | 5/8" | 3 7/8" | 13/16" | Spring | 0000000 | 00000 |

| 1 | 3/4" | 4 1/8" | 1" | Spring | 0000000 | 00000 |

| 1 | 3/4" | 5 1/4" | 1 5/16" | Spring | 0000000 | 00000 |

| 2 | 1/2" | 3 3/8" | 7/8" | Spring | 0000000 | 0000 |

| 2 | 1/2" | 4 1/8" | 1" | Spring | 0000000 | 00000 |

| 2 | 9/16" | 4 1/8" | 1 1/8" | Spring | 0000000 | 00000 |

Zinc-Plated Iron | ||||||

| 3 | 3/8" | 3 3/16" | 5/8" | Spring | 0000000 | 00000 |

| 3 | 3/8" | 3 3/4" | 7/8" | Spring | 0000000 | 0000 |

| 3 | 3/4" | 5 1/8" | 1 1/8" | Spring | 0000000 | 00000 |

Slide-Bolt Snaps with Swivel Eye

The slide bolt provides a more secure connection than standard snaps.

Brass and nickel-plated snaps have mild corrosion resistance.

| Snap Opening Wd. | Usable Lg. | Eye Inside Wd. | Latch Type | Each | ||

Nickel-Plated Iron | ||||||

|---|---|---|---|---|---|---|

| 1 | 3/8" | 2 13/16" | 5/8" | Slide Bolt | 00000000 | 00000 |

| 1 | 3/8" | 2 15/16" | 3/4" | Slide Bolt | 00000000 | 0000 |

| 1 | 3/8" | 3 3/16" | 1" | Slide Bolt | 00000000 | 0000 |

| 1 | 3/8" | 3 7/16" | 7/8" | Slide Bolt | 00000000 | 0000 |

| 1 | 3/8" | 3 1/2" | 1 1/8" | Slide Bolt | 00000000 | 0000 |

| 1 | 5/8" | 3 13/16" | 5/8" | Slide Bolt | 0000000 | 0000 |

Slide-Bolt Snaps with Flat Swivel Eye for Webbing

The slide bolt provides a more secure connection than standard snaps.

Brass and nickel-plated snaps have mild corrosion resistance.

For technical drawings and 3-D models, click on a part number.

| Snap Opening Wd. | Usable Lg. | Eye Inside Wd. | Latch Type | Each | |

Nickel-Plated Iron | |||||

|---|---|---|---|---|---|

| 5/16" | 2 1/2" | 1" | Slide Bolt | 0000000 | 00000 |

Overlapping-Arm Snaps with Swivel Eye

The force of the load helps keep the arms closed. Press the trigger for quick connection and disconnection.

Brass and nickel-plated snaps have mild corrosion resistance.

| Style | Snap Opening Wd. | Usable Lg. | Eye Inside Wd. | Latch Type | Locking Latch Type | Each | |

Nickel-Plated Iron | |||||||

|---|---|---|---|---|---|---|---|

| 1 | 3/8" | 2 1/16" | 3/8" | Locking | Overlapping Arm | 00000000 | 00000 |

| 1 | 3/8" | 2 1/4" | 1/2" | Locking | Overlapping Arm | 00000000 | 0000 |

| 1 | 7/16" | 2 3/8" | 5/8" | Locking | Overlapping Arm | 00000000 | 0000 |

| 1 | 1/2" | 2 5/16" | 3/4" | Locking | Overlapping Arm | 00000000 | 0000 |

| 1 | 5/8" | 3 5/16" | 3/4" | Locking | Overlapping Arm | 0000000 | 0000 |

| 1 | 5/8" | 3 5/8" | 1" | Locking | Overlapping Arm | 0000000 | 0000 |

High-Pressure Iron and Steel Threaded Pipe Fittings

These fittings can stand up to high-pressure applications. Use them in noncorrosive environments.

Fittings with intermittent swivel have ball bearings and rotate 360° as needed to allow movement in a rigid metal piping system.

Note: The maximum pressure listed for Class 3000 fittings is for conditions where there are no sudden changes in pressure or velocity. Please refer to ASME B16.11 to determine the specific maximum operating pressure for your application.

For technical drawings and 3-D models, click on a part number.

- For Use With:

Intermittent Swivel: Coolant, Water

Swivels Until Tightened: Air, Coolant, Hydraulic Fluid - Temperature Range: -20° to 225° F

- Specifications Met: See table

- Pipe Nipples and Pipe: Use Schedule 160 steel

- Flanges: Use Class 1500 steel

| Pipe Size | Max. Pressure | Max. Vacuum | Material | Specifications Met | Each | |

NPT Female—Intermittent Swivel | ||||||

|---|---|---|---|---|---|---|

| 1 | 600 psi @ 72° F | 29 in. of Hg @ 72° F | Iron | ASME B16.1, ASTM A536 | 00000000 | 0000000 |

| 1 1/2 | 600 psi @ 72° F | 29 in. of Hg @ 72° F | Iron | ASME B16.1, ASTM A536 | 00000000 | 000000 |

| 2 | 600 psi @ 72° F | 29 in. of Hg @ 72° F | Iron | ASME B16.1, ASTM A536 | 00000000 | 000000 |

| 3 | 600 psi @ 72° F | 29 in. of Hg @ 72° F | Iron | ASME B16.1, ASTM A536 | 00000000 | 000000 |

- For Use With:

Intermittent Swivel: Coolant, Water

Swivels Until Tightened: Air, Coolant, Hydraulic Fluid - Temperature Range: -20° to 225° F

- Specifications Met: See table

- Pipe Nipples and Pipe: Use Schedule 160 steel

- Flanges: Use Class 1500 steel

| Pipe Size | Max. Pressure | Max. Vacuum | Material | Specifications Met | Each | |

NPT Female—Intermittent Swivel | ||||||

|---|---|---|---|---|---|---|

| 1 | 600 psi @ 72° F | 29 in. of Hg @ 72° F | Iron | ASME B16.1, ASTM A536 | 00000000 | 0000000 |

| 1 1/2 | 600 psi @ 72° F | 29 in. of Hg @ 72° F | Iron | ASME B16.1, ASTM A536 | 00000000 | 000000 |

| 2 | 600 psi @ 72° F | 29 in. of Hg @ 72° F | Iron | ASME B16.1, ASTM A536 | 00000000 | 000000 |

| 3 | 600 psi @ 72° F | 29 in. of Hg @ 72° F | Iron | ASME B16.1, ASTM A536 | 00000000 | 000000 |

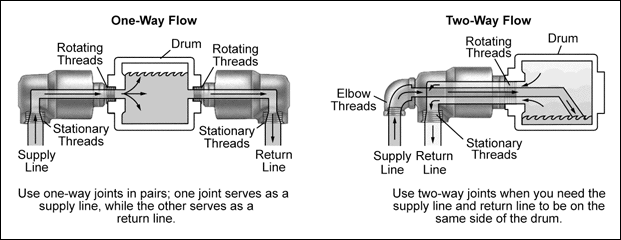

Iron and Steel One-Way-Flow Rotating Joints

These joints have a rotating shaft with threads on one end that connect to a continuously revolving drum, roller, or other rotating equipment. Use them to transfer hot and cold materials from your supply line. Joints are for one-way flow and are meant to be used in pairs—one joint serves as the supply line while the other serves as the return line.

If your drum rotates counterclockwise as you face the connecting end, you should select a rotating joint with right-handed threads. If your drum rotates clockwise as you face the connecting end, you should select a rotating joint with left-handed threads.

For technical drawings and 3-D models, click on a part number.

- For Use With: Oil, Steam, Water

- Maximum Temperature: 370° F

- Maximum Pressure:

Oil: 100 psi @ 72° F

Steam: 150 psi @ 72° F

Water: 250 psi @ 72° F

Rotating Threads | Stationary Threads | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Max. Speed, rpm | Body Dia. | Lg. | Material | Shaft Material | Each | |

Right-Hand Rotating Threads | ||||||||||||

| 1/4 | NPT | Male | 1/4 | NPT | Female | 700 | 1 3/4" | 4 3/8" | Iron | Steel | 0000000 | 0000000 |

| 3/8 | NPT | Male | 3/8 | NPT | Female | 700 | 1 3/4" | 4 3/8" | Iron | Steel | 0000000 | 000000 |

| 1/2 | NPT | Male | 1/2 | NPT | Female | 700 | 2 3/8" | 5" | Iron | Steel | 0000000 | 000000 |

| 3/4 | NPT | Male | 3/4 | NPT | Female | 700 | 2 1/2" | 5 1/2" | Iron | Steel | 0000000 | 000000 |

| 1 | NPT | Male | 1 | NPT | Female | 700 | 3" | 6 1/8" | Iron | Steel | 0000000 | 000000 |

| 1 1/4 | NPT | Male | 1 1/4 | NPT | Female | 700 | 3 3/4" | 9 1/16" | Iron | Steel | 0000000 | 000000 |

| 1 1/2 | NPT | Male | 1 1/2 | NPT | Female | 700 | 4 1/8" | 9 11/16" | Iron | Steel | 0000000 | 000000 |

| 2 | NPT | Male | 2 | NPT | Female | 700 | 5 7/8" | 11 3/4" | Iron | Steel | 0000000 | 00000000 |

Left-Hand Rotating Threads | ||||||||||||

| 1/4 | NPT | Male | 1/4 | NPT | Female | 700 | 1 3/4" | 4 3/8" | Iron | Steel | 0000000 | 000000 |

| 3/8 | NPT | Male | 3/8 | NPT | Female | 700 | 1 3/4" | 4 3/8" | Iron | Steel | 0000000 | 000000 |

| 1/2 | NPT | Male | 1/2 | NPT | Female | 700 | 2 3/8" | 5" | Iron | Steel | 0000000 | 000000 |

| 3/4 | NPT | Male | 3/4 | NPT | Female | 700 | 2 1/2" | 5 1/2" | Iron | Steel | 0000000 | 000000 |

| 1 | NPT | Male | 1 | NPT | Female | 700 | 3" | 6 1/8" | Iron | Steel | 0000000 | 000000 |

| 1 1/4 | NPT | Male | 1 1/4 | NPT | Female | 700 | 3 3/4" | 9 1/16" | Iron | Steel | 0000000 | 000000 |

| 1 1/2 | NPT | Male | 1 1/2 | NPT | Female | 700 | 4 1/8" | 9 11/16" | Iron | Steel | 0000000 | 000000 |

| 2 | NPT | Male | 2 | NPT | Female | 700 | 5 7/8" | 11 3/4" | Iron | Steel | 0000000 | 00000000 |

High-Temperature Iron and Steel One-Way-Flow Rotating Joints

- Maximum Temperature:

Oil: 600° F

Steam: 450° F - Maximum Pressure:

Oil: 100 psi @ 72° F

Steam: 175 psi @ 370° F

Use these rotating joints to transfer high-temperature materials from your supply line. They have a rotating shaft with threads on one end that connect to a continuously revolving drum, roller, or other rotating equipment. Joints are for one-way flow and are meant to be used in pairs—one joint serves as the supply line while the other serves as the return line.

If your drum rotates counterclockwise as you face the connecting end, you should select a rotating joint with right-handed threads.

For technical drawings and 3-D models, click on a part number.

Rotating Threads | Stationary Threads | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Body Dia. | Lg. | Color | Material | Shaft Material | Each | |

For Use With Oil | ||||||||||||

Right-Hand Rotating Threads | ||||||||||||

| 1 | NPT | Male | 1 | NPT | Female | 4 1/2" | 7 1/8" | Gold | Iron | Nickel-Plated Steel | 00000000 | 0000000 |

For Use With Steam | ||||||||||||

Right-Hand Rotating Threads | ||||||||||||

| 1 | NPT | Male | 1 | NPT | Female | 4 1/2" | 7 1/8" | Gold | Iron | Nickel-Plated Steel | 00000000 | 000000 |

Iron Two-Way-Flow Rotating Joints

- For Use With: Oil, Steam, Water

- Maximum Temperature: 370° F

- Maximum Pressure:

Oil: 100 psi @ 72° F

Steam: 150 psi @ 360° F

Water: 250 psi @ 72° F

These joints have a rotating shaft with threads on one end that connect to a continuously revolving drum, roller, or other rotating equipment. Use them to transfer hot and cold materials from your supply line. They are for two-way flow and are meant to be used when you need the supply line and the return line to be on the same side of your equipment.

If your drum rotates counterclockwise as you face the connecting end, you should select a rotating joint with right-handed threads. If your drum rotates clockwise as you face the connecting end, you should select a rotating joint with left-handed threads.

For technical drawings and 3-D models, click on a part number.

Rotating Threads | Stationary Threads | Elbow Threads | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Max. Speed, rpm | Body Dia. | Lg. | Shaft Material | Each | |

Right-Hand Rotating Threads | ||||||||||||||

| 1/2 | NPT | Male | 1/2 | NPT | Female | 1/2 | NPT | Female | 700 | 2 3/8" | 7 1/4" | Steel | 0000000 | 0000000 |

| 3/4 | NPT | Male | 3/4 | NPT | Female | 1/2 | NPT | Female | 700 | 2 1/2" | 7 3/4" | Steel | 0000000 | 000000 |

| 1 | NPT | Male | 1 | NPT | Female | 1/2 | NPT | Female | 700 | 3" | 8 1/2" | Steel | 0000000 | 000000 |

| 1 1/4 | NPT | Male | 1 1/4 | NPT | Female | 1/2 | NPT | Female | 700 | 3 3/4" | 10 5/8" | Steel | 0000000 | 000000 |

| 1 1/2 | NPT | Male | 1 1/2 | NPT | Female | 3/4 | NPT | Female | 700 | 4 1/8" | 11 3/8" | Steel | 0000000 | 00000000 |

| 2 | NPT | Male | 2 | NPT | Female | 1 | NPT | Female | 700 | 5 7/8" | 13 7/8" | Steel | 0000000 | 00000000 |

Left-Hand Rotating Threads | ||||||||||||||

| 1/2 | NPT | Male | 1/2 | NPT | Female | 1/2 | NPT | Female | 700 | 2 3/8" | 7 1/4" | Steel | 0000000 | 000000 |

| 3/4 | NPT | Male | 3/4 | NPT | Female | 1/2 | NPT | Female | 700 | 2 1/2" | 7 3/4" | Steel | 0000000 | 000000 |

| 1 | NPT | Male | 1 | NPT | Female | 1/2 | NPT | Female | 700 | 3" | 8 1/2" | Steel | 0000000 | 000000 |

| 1 1/4 | NPT | Male | 1 1/4 | NPT | Female | 1/2 | NPT | Female | 700 | 3 3/4" | 10 5/8" | Steel | 0000000 | 000000 |

| 1 1/2 | NPT | Male | 1 1/2 | NPT | Female | 3/4 | NPT | Female | 700 | 4 1/8" | 11 3/8" | Steel | 0000000 | 00000000 |

| 2 | NPT | Male | 2 | NPT | Female | 1 | NPT | Female | 700 | 5 7/8" | 13 7/8" | Steel | 0000000 | 00000000 |

Maintenance-Free Square Turntables

The sealed ball bearings will never need additional lubrication. These turntables add rotational positioning to machinery and equipment.

For technical drawings and 3-D models, click on a part number.

Bearing | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Capacity, lbs. | Lg. | Wd. | Overall Ht. | Material | Type | Material | Mounting Fasteners Included | Each | |

Lubricated | |||||||||

| 1,000 | 3.25" | 3.25" | 1.77" | Blue-Painted Iron | Ball | Steel | No | 000000 | 0000000 |

| 2,500 | 3.5" | 3.5" | 1.92" | Blue-Painted Iron | Ball | Steel | No | 0000000 | 000000 |

| 5,000 | 5" | 5" | 2.43" | Blue-Painted Iron | Ball | Steel | No | 0000000 | 000000 |

| 10,000 | 6.5" | 6.5" | 2.72" | Blue-Painted Iron | Ball | Steel | No | 0000000 | 00000000 |

Maintenance-Free Lockable Turntables

The sealed ball bearings will never need additional lubrication. These turntables lock into one of four positions. To unlock, pull the ring on the spring-loaded locking pin and turn it 90°. Turntables add rotational positioning to machinery and equipment.

For technical drawings and 3-D models, click on a part number.

Bearing | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Capacity, lbs. | Lg. | Wd. | Overall Ht. | Material | Type | Material | Mounting Fasteners Included | Each | |

Lubricated | |||||||||

| 1,000 | 3.25" | 3.25" | 1.77" | Blue-Painted Iron | Ball | Steel | No | 000000 | 0000000 |

| 2,500 | 3.5" | 3.5" | 1.92" | Blue-Painted Iron | Ball | Steel | No | 0000000 | 000000 |

| 5,000 | 5" | 5" | 2.43" | Blue-Painted Iron | Ball | Steel | No | 0000000 | 000000 |

| 10,000 | 6.5" | 6.5" | 2.72" | Blue-Painted Iron | Ball | Steel | No | 0000000 | 00000000 |

High-Torque Single U-Joints

With a maximum torque of at least 11,600 in.-lbs., these U-joints handle more torque than any other U-joint in our offering. They’re single U-joints, meaning they connect and transfer torque between shafts that are misaligned at an angle. Often found in continuously running applications, they operate at higher speeds and last longer than other types of joints, thanks to their needle bearings.

Connect these U-joints to shafts using the included set screws. Unlike U-joints that use spring pins, there’s no drilling required. All have a grease fitting, so you can use a grease gun to lubricate all of the bearings at once.

Your shafts’ misalignment will affect the speed and torque the U-joint will be able to transmit. The more the shafts are misaligned, the less speed and torque the U-joint will be able to transmit.

For technical drawings and 3-D models, click on a part number.

For Shaft | O'all | Keyway | Torque | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Dp. | Joint Dia. | Ht. | Lg. | Wd. | Dp. | Max. Operating Angle | Max. Speed, rpm | Max. Torque, in.-lbs. | 3° Operating Angle | 10° Operating Angle | Includes | Each | |

Iron with Steel Bearings | ||||||||||||||

| 3/4" | 1 13/64" | 1 5/8" | 2 3/8" | 5" | 3/16" | 3/32" | 45° | 1,000 | 11,600 | 1,260 in.-lbs. @ 1,000 rpm | 720 in.-lbs. @ 1,000 rpm | Grease Fitting | 000000 | 0000000 |

| 7/8" | 1 13/64" | 1 5/8" | 2 3/8" | 5" | 3/16" 1/4" | 3/32" 1/8" | 45° | 1,000 | 11,600 | 1,260 in.-lbs. @ 1,000 rpm | 720 in.-lbs. @ 1,000 rpm | Grease Fitting | 000000 | 000000 |

| 1" | 1 13/64" | 1 5/8" | 2 3/8" | 5" | 3/16" 1/4" | 3/32" 1/8" | 45° | 1,000 | 11,600 | 1,260 in.-lbs. @ 1,000 rpm | 720 in.-lbs. @ 1,000 rpm | Grease Fitting | 000000 | 000000 |

| 1 1/8" | 1 5/32" | 2 1/4" | 2 5/16" | 5" | 1/4" 5/16" | 1/8" 5/32" | 45° | 1,000 | 11,600 | 1,260 in.-lbs. @ 1,000 rpm | 720 in.-lbs. @ 1,000 rpm | Grease Fitting | 000000 | 000000 |

| 1 1/4" | 1 5/32" | 2 1/4" | 2 5/16" | 5" | 1/4" 5/16" | 1/8" 5/32" | 45° | 1,000 | 11,600 | 1,260 in.-lbs. @ 1,000 rpm | 720 in.-lbs. @ 1,000 rpm | Grease Fitting | 000000 | 000000 |

| Replacement Bearing Assembly for Iron U-Joints | 00000000 | Each | 000000 |

Threaded Rod Eye Nuts

Add an eye nut to threaded rod to hang the rod from rings, hooks, and hangers.

Turnbuckle eye nuts have a swivel eye that allows height adjustment after installation.

Note: Capacity is for the eye nut only. Mounting surface and fastening hardware will affect the ultimate capacity.

For technical drawings and 3-D models, click on a part number.

| For Thread Size | Threaded Hole Dp. | Cap., lbs. | Eye Dia. | Ctr. Ht. | Wd. | Ht. | Threaded Rod Included | Fasteners Required | Each | |

Iron | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Turnbuckle Eye Nut | ||||||||||

| 1/4"-20 | 1 1/4" | 225 | 7/32" | 2 1/2" | 1" | 2 11/16" | No | No | 000000 | 000000 |

| 3/8"-16 | 1 7/8" | 725 | 13/32" | 3 7/8" | 1 1/2" | 4 7/16" | No | No | 000000 | 00000 |

| 1/2"-13 | 1 13/16" | 725 | 13/32" | 3 7/8" | 1 1/2" | 4 7/16" | No | No | 000000 | 00000 |

| 5/8"-11 | 2 5/16" | 725 | 1/2" | 4 7/8" | 1 15/16" | 5 11/16" | No | No | 000000 | 00000 |