Filter by

About Leveling Mounts

Choose the right leveling mounts for your floor conditions, equipment weight, and vibration-control needs.

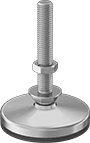

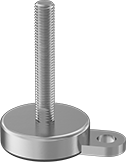

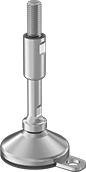

Swivel Leveling Mounts with Threaded Stud

|

With Cushion |

|

Without Cushion |

Keep equipment level on slightly sloped and pitted floors with mounts that have a ball-and-socket joint in the base. For mounting versatility, you can install them in either threaded holes or unthreaded through holes at the bottom of equipment.

303 Stainless Steel Base—The choice for most wet locations, these mounts can withstand repeated washdowns without corroding. However, they won't hold up to cleaning solutions that contain harsh chemicals like 316 stainless steel can.

316 Stainless Steel Base—Our most corrosion-resistant metal mounts, these hold up in just about any environment. They won’t degrade or become pitted, even when exposed to harsh cleaners and chemicals.

Black-Oxide Steel Base—With a matte black appearance, these mounts create a finished look. They offer minimal corrosion resistance, so they're best for dry environments.

Nickel-Plated Steel Base—With a shiny appearance, these mounts create a finished look. They're best for dry environments since the nickel plating offers minimal corrosion resistance.

Plastic Base—These mounts are economical yet resistant to grease, oil, and chemicals that pool on the floor. Often used on small, lightweight machines, they have about 25% the capacity of similarly sized metal mounts.

Zinc-Yellow-Chromate-Plated Steel Base—More corrosion resistant than nickel-plated steel, these mounts are suitable for damp environments. However, they won’t hold up to chemical cleaners, high-pressure washdowns, and other harsh conditions like stainless steel can.

Rubber Cushion—A cushion under the base grips surfaces so vibrating equipment doesn't slide. It also protects floors from scrapes and gouges.

Without Cushion | With Rubber Cushion | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Swivel Range of Motion | Base Dia. | Cap. per Mount, lb. | Overall Ht. | Each | Cap. per Mount, lb. | Overall Ht. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nickel-Plated Steel Base and Stud | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 1" | 7.5° | 3/4" | 700 | 1 1/2" | 0000000 | 00000 | 525 | 1 5/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 2" | 7.5° | 3/4" | 700 | 2 1/2" | 0000000 | 0000 | 525 | 2 5/8" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1 1/4" | 7.5° | 1" | 1,000 | 1 15/16" | 0000000 | 0000 | 750 | 2 1/16" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 2 1/2" | 7.5° | 1" | 1,000 | 3 3/16" | 0000000 | 0000 | 750 | 3 5/16" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 1 1/4" | 7.5° | 1" | 775 | 1 15/16" | 00000000 | 0000 | 580 | 2 1/16" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 2" | 7.5° | 1 1/4" | 2,500 | 2 7/8" | 0000000 | 0000 | 1,875 | 3" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 4" | 7.5° | 1 1/4" | 2,500 | 4 7/8" | 0000000 | 0000 | 1,875 | 5" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 2" | 7.5° | 1 1/4" | 3,750 | 2 7/8" | 0000000 | 0000 | 2,800 | 3" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 4" | 7.5° | 1 1/4" | 3,750 | 4 7/8" | 0000000 | 0000 | 2,800 | 5" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 2" | 7.5° | 1 1/4" | 3,300 | 2 7/8" | 00000000 | 0000 | 2,475 | 3" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 2" | 7.5° | 1 7/8" | 5,000 | 3 1/8" | 0000000 | 00000 | 3,750 | 3 1/4" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 4" | 7.5° | 1 7/8" | 5,000 | 5 1/8" | 0000000 | 00000 | 3,750 | 5 1/4" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 6" | 7.5° | 1 7/8" | 5,000 | 7 1/8" | 00000000 | 00000 | 3,750 | 7 1/4" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 2" | 7.5° | 1 7/8" | 4,000 | 3 1/8" | 00000000 | 00000 | 3,000 | 3 1/4" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 2" | 7.5° | 2 1/2" | 6,000 | 3 1/4" | 0000000 | 00000 | 4,500 | 3 3/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 4" | 7.5° | 2 1/2" | 6,000 | 5 1/4" | 0000000 | 00000 | 4,500 | 5 3/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 6" | 7.5° | 2 1/2" | 6,000 | 7 1/4" | 00000000 | 00000 | 4,500 | 7 3/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-18 | 2" | 7.5° | 2 1/2" | 5,000 | 3 1/4" | 00000000 | 00000 | 3,750 | 3 3/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2" | 7.5° | 3" | 7,400 | 3 1/2" | 0000000 | 00000 | 5,550 | 3 5/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 4" | 7.5° | 3" | 7,400 | 5 1/2" | 0000000 | 00000 | 5,550 | 5 5/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 6" | 7.5° | 3" | 7,400 | 7 1/2" | 00000000 | 00000 | 5,550 | 7 5/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-16 | 2" | 7.5° | 3" | 6,200 | 3 1/2" | 00000000 | 00000 | 4,650 | 3 5/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-9 | 4" | 7.5° | 4" | 15,000 | 5 7/8" | 00000000 | 00000 | 11,250 | 6" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-14 | 4" | 7.5° | 4" | 13,500 | 5 7/8" | 00000000 | 00000 | 10,100 | 6" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 3 1/2" | 7.5° | 4" | 20,000 | 5 3/8" | 0000000 | 00000 | 15,000 | 5 1/2" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 4 1/4" | 7.5° | 4" | 20,000 | 6 1/8" | 00000000 | 00000 | 15,000 | 6 1/4" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 6" | 7.5° | 4" | 20,000 | 7 7/8" | 0000000 | 00000 | 15,000 | 8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 8" | 7.5° | 4" | 20,000 | 9 7/8" | 0000000 | 00000 | 15,000 | 10" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-12 | 3 1/2" | 7.5° | 4" | 18,000 | 5 3/8" | 00000000 | 00000 | 13,500 | 5 1/2" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-7 | 4" | 7.5° | 6" | 43,000 | 6 3/4" | 00000000 | 000000 | 32,250 | 6 7/8" | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-7 | 6" | 7.5° | 6" | 43,000 | 8 3/4" | 00000000 | 000000 | 32,250 | 8 7/8" | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 25 mm | 7.5° | 19 mm | 690 | 38 mm | 00000000 | 0000 | 510 | 41 mm | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 32 mm | 7.5° | 25 mm | 990 | 49 mm | 00000000 | 0000 | 740 | 52 mm | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 51 mm | 7.5° | 32 mm | 3,700 | 73 mm | 00000000 | 0000 | 2,700 | 76 mm | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 51 mm | 7.5° | 48 mm | 4,950 | 79 mm | 00000000 | 00000 | 3,700 | 83 mm | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 51 mm | 7.5° | 64 mm | 5,950 | 83 mm | 00000000 | 00000 | 4,500 | 86 mm | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 2.5 mm | 51 mm | 7.5° | 76 mm | 7,350 | 89 mm | 00000000 | 00000 | 5,500 | 92 mm | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 × 3 mm | 89 mm | 7.5° | 102 mm | 19,500 | 137 mm | 00000000 | 00000 | 14,500 | 140 mm | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 × 3 mm | 108 mm | 7.5° | 102 mm | 19,500 | 156 mm | 00000000 | 00000 | 14,500 | 159 mm | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M30 × 3.5 mm | 102 mm | 7.5° | 152 mm | 42,500 | 172 mm | 00000000 | 000000 | 32,250 | 175 mm | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M30 × 3.5 mm | 152 mm | 7.5° | 152 mm | 42,500 | 222 mm | 00000000 | 000000 | 32,250 | 225 mm | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Yellow-Chromate-Plated Steel Base and Stud | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 1" | 7.5° | 3/4" | 700 | 1 1/2" | 0000000 | 0000 | 525 | 1 5/8" | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 2" | 7.5° | 3/4" | 700 | 2 1/2" | 0000000 | 0000 | 525 | 2 5/8" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1 1/4" | 7.5° | 1" | 1,000 | 1 15/16" | 0000000 | 0000 | 750 | 2 1/16" | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 2 1/2" | 7.5° | 1" | 1,000 | 3 3/16" | 0000000 | 0000 | 750 | 3 5/16" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 1 1/4" | 7.5° | 1" | 775 | 1 15/16" | 00000000 | 0000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 2" | 7.5° | 1 1/4" | 2,500 | 2 7/8" | 0000000 | 0000 | 1,875 | 3" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 4" | 7.5° | 1 1/4" | 2,500 | 4 7/8" | 0000000 | 0000 | 1,875 | 5" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 2" | 7.5° | 1 1/4" | 3,750 | 2 7/8" | 0000000 | 0000 | 2,800 | 3" | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 4" | 7.5° | 1 1/4" | 3,750 | 4 7/8" | 0000000 | 0000 | 2,800 | 5" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 2" | 7.5° | 1 1/4" | 3,300 | 2 7/8" | 00000000 | 00000 | 2,475 | 3" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 2" | 7.5° | 1 7/8" | 5,000 | 3 1/8" | 0000000 | 00000 | 3,750 | 3 1/4" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 4" | 7.5° | 1 7/8" | 5,000 | 5 1/8" | 0000000 | 00000 | 3,750 | 5 1/4" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 6" | 7.5° | 1 7/8" | 5,000 | 7 1/8" | 00000000 | 00000 | 3,750 | 7 1/4" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 2" | 7.5° | 1 7/8" | 4,000 | 3 1/8" | 00000000 | 00000 | 3,000 | 3 1/4" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 2" | 7.5° | 2 1/2" | 6,000 | 3 1/4" | 0000000 | 00000 | 4,500 | 3 3/8" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 4" | 7.5° | 2 1/2" | 6,000 | 5 1/4" | 0000000 | 00000 | 4,500 | 5 3/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 6" | 7.5° | 2 1/2" | 6,000 | 7 1/4" | 00000000 | 00000 | 4,500 | 7 3/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-18 | 2" | 7.5° | 2 1/2" | 5,000 | 3 1/4" | 00000000 | 00000 | 3,750 | 3 3/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2" | 7.5° | 3" | 7,400 | 3 1/2" | 0000000 | 00000 | 5,550 | 3 5/8" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 4" | 7.5° | 3" | 7,400 | 5 1/2" | 0000000 | 00000 | 5,550 | 5 5/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 6" | 7.5° | 3" | 7,400 | 7 1/2" | 00000000 | 00000 | 5,550 | 7 5/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-16 | 2" | 7.5° | 3" | 6,200 | 3 1/2" | 00000000 | 00000 | 4,650 | 3 5/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-9 | 4" | 7.5° | 4" | 15,000 | 5 7/8" | 00000000 | 00000 | 11,250 | 6" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-14 | 4" | 7.5° | 4" | 13,500 | 5 7/8" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 3 1/2" | 7.5° | 4" | 20,000 | 5 3/8" | 0000000 | 00000 | 15,000 | 5 1/2" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 6" | 7.5° | 4" | 20,000 | 7 7/8" | 0000000 | 00000 | 15,000 | 8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 8" | 7.5° | 4" | 20,000 | 9 7/8" | 0000000 | 00000 | 15,000 | 10" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-12 | 3 1/2" | 7.5° | 4" | 18,000 | 5 3/8" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-7 | 4" | 7.5° | 6" | 43,000 | 6 3/4" | 00000000 | 000000 | 32,250 | 6 7/8" | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-7 | 6" | 7.5° | 6" | 43,000 | 8 3/4" | 00000000 | 000000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 25 mm | 7.5° | 19 mm | 690 | 38 mm | 0000000 | 0000 | 515 | 41 mm | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 32 mm | 7.5° | 25 mm | 990 | 49 mm | 0000000 | 0000 | 750 | 52 mm | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 51 mm | 7.5° | 32 mm | 3,740 | 73 mm | 0000000 | 0000 | 2,795 | 76 mm | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 51 mm | 7.5° | 48 mm | 4,950 | 79 mm | 0000000 | 00000 | 3,740 | 83 mm | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 51 mm | 7.5° | 64 mm | 5,940 | 83 mm | 0000000 | 00000 | 4,500 | 86 mm | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 2.5 mm | 51 mm | 7.5° | 76 mm | 7,370 | 89 mm | 0000000 | 00000 | 5,545 | 92 mm | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 × 3 mm | 89 mm | 7.5° | 102 mm | 19,840 | 137 mm | 0000000 | 00000 | 14,990 | 140 mm | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 × 3 mm | 108 mm | 7.5° | 102 mm | 19,840 | 156 mm | 0000000 | 00000 | 14,990 | 159 mm | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M30 × 3.5 mm | 102 mm | 7.5° | 152 mm | 42,990 | 172 mm | 0000000 | 000000 | 32,295 | 175 mm | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M30 × 3.5 mm | 152 mm | 7.5° | 152 mm | 42,990 | 222 mm | 0000000 | 000000 | 32,295 | 225 mm | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel Base and Zinc-Plated Steel Stud | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 1" | 7.5° | 3/4" | 700 | 1 1/2" | 00000000 | 0000 | 525 | 1 5/8" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 2" | 7.5° | 3/4" | 700 | 2 1/2" | 00000000 | 0000 | 525 | 2 5/8" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1 1/4" | 7.5° | 1" | 1,000 | 1 15/16" | 00000000 | 0000 | 750 | 2 1/16" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 2 1/2" | 7.5° | 1" | 1,000 | 3 3/16" | 00000000 | 0000 | 750 | 3 5/16" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 1 1/4" | 7.5° | 1" | 775 | 1 15/16" | 00000000 | 0000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 2" | 7.5° | 1 1/4" | 2,500 | 2 7/8" | 00000000 | 0000 | 1,875 | 3" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 4" | 7.5° | 1 1/4" | 2,500 | 4 7/8" | 00000000 | 00000 | 1,875 | 5" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 2" | 7.5° | 1 1/4" | 3,750 | 2 7/8" | 00000000 | 00000 | 2,800 | 3" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 4" | 7.5° | 1 1/4" | 3,750 | 4 7/8" | 00000000 | 00000 | 2,800 | 5" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 2" | 7.5° | 1 1/4" | 3,300 | 2 7/8" | 00000000 | 00000 | 2,475 | 3" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 2" | 7.5° | 1 7/8" | 5,000 | 3 1/8" | 00000000 | 00000 | 3,750 | 3 1/4" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 4" | 7.5° | 1 7/8" | 5,000 | 5 1/8" | 00000000 | 00000 | 3,750 | 5 1/4" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 6" | 7.5° | 1 7/8" | 5,000 | 7 1/8" | 00000000 | 00000 | 3,750 | 7 1/4" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 2" | 7.5° | 1 7/8" | 4,000 | 3 1/8" | 00000000 | 00000 | 3,000 | 3 1/4" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 2" | 7.5° | 2 1/2" | 6,000 | 3 1/4" | 00000000 | 00000 | 4,500 | 3 3/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 4" | 7.5° | 2 1/2" | 6,000 | 5 1/4" | 00000000 | 00000 | 4,500 | 5 3/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 6" | 7.5° | 2 1/2" | 6,000 | 7 1/4" | 00000000 | 00000 | 4,500 | 7 3/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-18 | 2" | 7.5° | 2 1/2" | 5,000 | 3 1/4" | 00000000 | 00000 | 3,750 | 3 3/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2" | 7.5° | 3" | 7,400 | 3 1/2" | 00000000 | 00000 | 5,550 | 3 5/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 4" | 7.5° | 3" | 7,400 | 5 1/2" | 00000000 | 00000 | 5,550 | 5 5/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 6" | 7.5° | 3" | 7,400 | 7 1/2" | 00000000 | 00000 | 5,550 | 7 5/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-16 | 2" | 7.5° | 3" | 6,200 | 3 1/2" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-9 | 4" | 7.5° | 4" | 15,000 | 5 7/8" | 00000000 | 00000 | 11,250 | 6" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 3 1/2" | 7.5° | 4" | 20,000 | 5 3/8" | 00000000 | 00000 | 15,000 | 5 1/2" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 6" | 7.5° | 4" | 20,000 | 7 7/8" | 00000000 | 00000 | 15,000 | 8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 8" | 7.5° | 4" | 20,000 | 9 7/8" | 00000000 | 00000 | 15,000 | 10" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-12 | 3 1/2" | 7.5° | 4" | 18,000 | 5 3/8" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-7 | 4" | 7.5° | 6" | 43,000 | 6 3/4" | 00000000 | 000000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-7 | 6" | 7.5° | 6" | 43,000 | 8 3/4" | 00000000 | 000000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

303 Stainless Steel Base and Stud | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 1" | 7.5° | 3/4" | 700 | 1 1/2" | 0000000 | 00000 | 525 | 1 5/8" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 2" | 7.5° | 3/4" | 700 | 2 1/2" | 0000000 | 00000 | 525 | 2 5/8" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1 1/4" | 7.5° | 1" | 1,000 | 1 15/16" | 0000000 | 00000 | 750 | 2 1/16" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 2 1/2" | 7.5° | 1" | 1,000 | 3 3/16" | 0000000 | 00000 | 750 | 3 5/16" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 1 1/4" | 7.5° | 1" | 775 | 1 15/16" | 00000000 | 00000 | 580 | 2 1/16" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 2" | 7.5° | 1 1/4" | 2,500 | 2 7/8" | 0000000 | 00000 | 1,875 | 3" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 4" | 7.5° | 1 1/4" | 2,500 | 4 7/8" | 0000000 | 00000 | 1,875 | 5" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 13/16" | 5° | 1 1/4" | 440 | 1 7/16" | 00000000 | 00000 | 85 | 1 7/16" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 13/16" | 5° | 1 9/16" | 700 | 1 7/16" | 00000000 | 00000 | 175 | 1 7/16" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 13/16" | 5° | 2" | 790 | 1 1/2" | 00000000 | 00000 | 220 | 1 1/2" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 2" | 7.5° | 1 1/4" | 3,750 | 2 7/8" | 0000000 | 00000 | 2,800 | 3" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 4" | 7.5° | 1 1/4" | 3,750 | 4 7/8" | 0000000 | 00000 | 2,800 | 5" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 2" | 7.5° | 1 1/4" | 3,300 | 2 7/8" | 00000000 | 00000 | 2,475 | 3" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 2" | 7.5° | 1 7/8" | 5,000 | 3 1/8" | 0000000 | 00000 | 3,750 | 3 1/4" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 4" | 7.5° | 1 7/8" | 5,000 | 5 1/8" | 0000000 | 00000 | 3,750 | 5 1/4" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 6" | 7.5° | 1 7/8" | 5,000 | 7 1/8" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 2" | 7.5° | 1 7/8" | 4,000 | 3 1/8" | 00000000 | 00000 | 3,000 | 3 1/4" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 2" | 7.5° | 2 1/2" | 6,000 | 3 1/4" | 0000000 | 00000 | 4,500 | 3 3/8" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 4" | 7.5° | 2 1/2" | 6,000 | 5 1/4" | 0000000 | 00000 | 4,500 | 5 3/8" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 6" | 7.5° | 2 1/2" | 6,000 | 7 1/4" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-18 | 2" | 7.5° | 2 1/2" | 5,000 | 3 1/4" | 00000000 | 00000 | 3,750 | 3 3/8" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2" | 7.5° | 3" | 7,400 | 3 1/2" | 0000000 | 00000 | 5,550 | 3 5/8" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 4" | 7.5° | 3" | 7,400 | 5 1/2" | 0000000 | 00000 | 5,550 | 5 5/8" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 6" | 7.5° | 3" | 7,400 | 7 1/2" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-16 | 2" | 7.5° | 3" | 6,200 | 3 1/2" | 00000000 | 00000 | 4,650 | 3 5/8" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-9 | 4" | 7.5° | 4" | 15,000 | 5 7/8" | 00000000 | 000000 | 11,250 | 6" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-14 | 4" | 7.5° | 4" | __ | __ | __ | 00 | 10,100 | 6" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 3 1/2" | 7.5° | 4" | 20,000 | 5 3/8" | 0000000 | 00000 | 15,000 | 5 1/2" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 4 1/4" | 7.5° | 4" | __ | __ | __ | 00 | 15,000 | 6 1/4" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 4 1/2" | 7.5° | 4" | 20,000 | 6 1/8" | 00000000 | 000000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 6" | 7.5° | 4" | 20,000 | 7 7/8" | 0000000 | 000000 | 15,000 | 8" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 8" | 7.5° | 4" | 20,000 | 9 7/8" | 0000000 | 000000 | 15,000 | 10" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-12 | 3 1/2" | 7.5° | 4" | __ | __ | __ | 00 | 13,500 | 5 1/2" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-7 | 4" | 7.5° | 6" | __ | __ | __ | 00 | 32,200 | 6 7/8" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-7 | 6" | 7.5° | 6" | 43,000 | 8 3/4" | 00000000 | 000000 | 32,200 | 8 7/8" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 25 mm | 7.5° | 19 mm | 690 | 38 mm | 0000000 | 00000 | 510 | 41 mm | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 32 mm | 7.5° | 25 mm | 990 | 49 mm | 0000000 | 00000 | 740 | 52 mm | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 51 mm | 7.5° | 32 mm | 3,740 | 73 mm | 0000000 | 00000 | 2,790 | 76 mm | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 51 mm | 7.5° | 48 mm | 4,950 | 79 mm | 0000000 | 00000 | 3,740 | 83 mm | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 51 mm | 7.5° | 64 mm | 5,940 | 83 mm | 0000000 | 00000 | 4,500 | 86 mm | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 2.5 mm | 51 mm | 7.5° | 76 mm | 7,370 | 89 mm | 0000000 | 00000 | 5,550 | 92 mm | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 × 3 mm | 89 mm | 7.5° | 102 mm | 19,800 | 137 mm | 0000000 | 00000 | 14,900 | 140 mm | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 × 3 mm | 108 mm | 7.5° | 102 mm | 19,800 | 156 mm | 0000000 | 000000 | 14,900 | 159 mm | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M30 × 3.5 mm | 102 mm | 7.5° | 152 mm | 42,000 | 172 mm | 0000000 | 000000 | 32,200 | 175 mm | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M30 × 3.5 mm | 152 mm | 7.5° | 152 mm | __ | __ | __ | 00 | 32,200 | 225 mm | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Base and Stud | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 1" | 7.5° | 3/4" | 700 | 1 1/2" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 2" | 7.5° | 3/4" | 700 | 2 1/2" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1 1/4" | 7.5° | 1" | 1,000 | 1 15/16" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 2 1/2" | 7.5° | 1" | 1,000 | 3 3/16" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 2" | 7.5° | 1 1/4" | 2,500 | 2 7/8" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 4" | 7.5° | 1 1/4" | 2,500 | 4 7/8" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 2" | 7.5° | 1 1/4" | 3,750 | 2 7/8" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 4" | 7.5° | 1 1/4" | 3,750 | 4 7/8" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 2" | 7.5° | 1 7/8" | 5,000 | 3 1/8" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 4" | 7.5° | 1 7/8" | 5,000 | 5 1/8" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 6" | 7.5° | 1 7/8" | 5,000 | 7 1/8" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 2" | 7.5° | 1 7/8" | 4,000 | 3 1/8" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 2" | 7.5° | 2 1/2" | 6,000 | 3 1/4" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 4" | 7.5° | 2 1/2" | 6,000 | 5 1/4" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 6" | 7.5° | 2 1/2" | 6,000 | 7 1/4" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2" | 7.5° | 3" | 7,400 | 3 1/2" | 00000000 | 000000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 4" | 7.5° | 3" | 7,400 | 5 1/2" | 00000000 | 000000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 6" | 7.5° | 3" | 7,400 | 7 1/2" | 00000000 | 000000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 3 1/2" | 7.5° | 4" | 20,000 | 5 3/8" | 00000000 | 000000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 6" | 7.5° | 4" | 20,000 | 7 7/8" | 00000000 | 000000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 8" | 7.5° | 4" | 20,000 | 9 7/8" | 00000000 | 000000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 25 mm | 7.5° | 19 mm | 690 | 38 mm | 0000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 32 mm | 7.5° | 25 mm | 990 | 49 mm | 0000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 51 mm | 7.5° | 32 mm | 3,740 | 73 mm | 0000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 51 mm | 7.5° | 48 mm | 4,950 | 79 mm | 0000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 51 mm | 7.5° | 64 mm | 5,940 | 83 mm | 0000000 | 000000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 2.5 mm | 51 mm | 7.5° | 76 mm | 7,370 | 89 mm | 0000000 | 000000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 × 3 mm | 89 mm | 7.5° | 102 mm | 19,800 | 137 mm | 0000000 | 000000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic Base and Zinc-Plated Steel Stud | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 1" | 7.5° | 3/4" | 150 | 1 1/2" | 0000000 | 0000 | 150 | 1 5/8" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 2" | 7.5° | 3/4" | 150 | 2 1/2" | 00000000 | 0000 | 150 | 2 5/8" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1 1/4" | 7.5° | 1" | 200 | 1 15/16" | 0000000 | 0000 | 200 | 2 1/16" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 2 1/2" | 7.5° | 1" | 200 | 3 3/16" | 00000000 | 0000 | 200 | 3 5/16" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 1 1/4" | 7.5° | 1" | 200 | 1 15/16" | 00000000 | 0000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 2" | 7.5° | 1 1/4" | 250 | 2 7/8" | 00000000 | 0000 | 250 | 3" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 4" | 7.5° | 1 1/4" | 250 | 4 7/8" | 00000000 | 0000 | 250 | 5" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 2" | 7.5° | 1 1/4" | 300 | 2 7/8" | 0000000 | 0000 | 300 | 3" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 4" | 7.5° | 1 1/4" | 300 | 4 7/8" | 00000000 | 0000 | 300 | 5" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 2" | 7.5° | 1 1/4" | 250 | 2 7/8" | 00000000 | 0000 | 250 | 3" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 2" | 7.5° | 1 7/8" | 700 | 3 1/8" | 0000000 | 00000 | 700 | 3 1/4" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 4" | 7.5° | 1 7/8" | 700 | 5 1/8" | 00000000 | 00000 | 700 | 5 1/4" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 6" | 7.5° | 1 7/8" | 700 | 7 1/8" | 00000000 | 00000 | 700 | 7 1/4" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 2" | 7.5° | 1 7/8" | 625 | 3 1/8" | 00000000 | 00000 | 625 | 3 1/4" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 2" | 7.5° | 2 1/2" | 1,200 | 3 1/4" | 0000000 | 00000 | 1,200 | 3 3/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 4" | 7.5° | 2 1/2" | 1,200 | 5 1/4" | 00000000 | 00000 | 1,200 | 5 3/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 6" | 7.5° | 2 1/2" | 1,200 | 7 1/4" | 00000000 | 00000 | 1,200 | 7 3/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-18 | 2" | 7.5° | 2 1/2" | 1,100 | 3 1/4" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2" | 7.5° | 3" | 1,800 | 3 1/2" | 0000000 | 00000 | 1,800 | 3 5/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 4" | 7.5° | 3" | 1,800 | 5 1/2" | 00000000 | 00000 | 1,800 | 5 5/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 6" | 7.5° | 3" | 1,800 | 7 1/2" | 00000000 | 00000 | 1,800 | 7 5/8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-16 | 2" | 7.5° | 3" | 1,650 | 3 1/2" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-9 | 4" | 7.5° | 4" | 1,700 | 5 7/8" | 00000000 | 00000 | 1,700 | 6" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 3 1/2" | 7.5° | 4" | 2,400 | 5 3/8" | 0000000 | 00000 | 2,400 | 5 1/2" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 6" | 7.5° | 4" | 2,400 | 7 7/8" | 00000000 | 00000 | 2,400 | 8" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 8" | 7.5° | 4" | 2,400 | 9 7/8" | 00000000 | 00000 | 2,400 | 10" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-12 | 3 1/2" | 7.5° | 4" | 2,250 | 5 3/8" | 00000000 | 00000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-7 | 4" | 7.5° | 6" | 3,600 | 6 3/4" | 00000000 | 000000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-7 | 6" | 7.5° | 6" | 3,600 | 8 3/4" | 00000000 | 000000 | __ | __ | __ | 00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

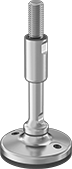

High-Capacity Swivel Leveling Mounts with Threaded Stud

|

Level heavier equipment than other similarly sized swivel mounts. In addition to supporting higher capacities, the broad Acme threads adjust with fewer turns of the stud or jam nut than other threads. These mounts have a ball-and-socket joint in the base that swivels to keep equipment level on slightly sloped and pitted floors. For mounting versatility, you can install them in either threaded holes or unthreaded through holes at the bottom of equipment.

Zinc-Plated Steel Base—These mounts are suitable for damp environments, but they won’t hold up to high-pressure washdowns and cleaners that contain harsh chemicals.

Without Cushion | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Swivel Range of Motion | Base Dia. | Cap. per Mount, lb. | Overall Ht. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel Base and Stud | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-16 | 1 1/4" | 7.5° | 1" | 1,500 | 1 15/16" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-14 | 2" | 7.5° | 1 1/4" | 3,750 | 2 7/8" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-12 | 2" | 7.5° | 1 1/4" | 5,625 | 2 7/8" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-10 | 2" | 7.5° | 1 7/8" | 7,500 | 3 1/8" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-10 | 4" | 7.5° | 1 7/8" | 7,500 | 5 1/8" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-8 | 2" | 7.5° | 2 1/2" | 9,000 | 3 1/4" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-6 | 2" | 7.5° | 3" | 11,100 | 3 1/2" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-5 | 3 1/2" | 7.5° | 4" | 30,000 | 5 3/8" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-5 | 6" | 7.5° | 4" | 30,000 | 7 7/8" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-5 | 4" | 7.5° | 6" | 60,000 | 6 3/4" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

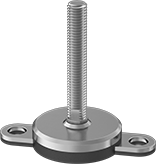

Stay-Put Swivel Leveling Mounts with Threaded Stud

Bolt down machines so they don’t creep across the floor or tip over. These mounts have one or more punch-out holes for securing equipment that you don’t need to move. The ball-and-socket joint in the base swivels to compensate for slightly sloped and pitted floors. For mounting versatility, you can install these mounts in either threaded holes or unthreaded through holes at the bottom of equipment.

Two Mounting Holes

|

Glass-Filled Nylon Base and Zinc-Plated Steel Stud—These mounts are suitable for damp environments, but they won’t hold up to high-pressure washdowns and cleaners that contain harsh chemicals.

Glass-Filled Nylon Base and 303 Stainless Steel Stud—The choice for most wet locations, these mounts can withstand repeated washdowns without corroding. However, they won't hold up to cleaning solutions that contain harsh chemicals.

Rubber Cushion—A cushion under the base protects floors from scrapes and gouges.

Mounting Holes | Without Cushion | With Rubber Cushion | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Swivel Range of Motion | Base Dia. | Mounting Fasteners Included | Dia. | Ctr.-to-Ctr. Lg. | Cap. per Mount, lb. | Overall Ht. | Each | Cap. per Mount, lb. | Overall Ht. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Glass-Filled Nylon Base and Zinc-Plated Steel Stud | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 1" | 7.5° | 2" | No | 1/4" | 1 5/16" | 700 | 2 1/8" | 00000000 | 00000 | 700 | 2 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 2" | 7.5° | 2" | No | 1/4" | 1 5/16" | 700 | 3 1/8" | 00000000 | 0000 | 700 | 3 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1 1/4" | 7.5° | 2" | No | 1/4" | 1 5/16" | 1,000 | 2 3/8" | 00000000 | 0000 | 1,000 | 2 7/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 2 1/2" | 7.5° | 2" | No | 1/4" | 1 5/16" | 1,000 | 3 5/8" | 00000000 | 00000 | 1,000 | 3 11/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 1 1/4" | 7.5° | 2" | No | 1/4" | 1 5/16" | 775 | 2 5/8" | 00000000 | 0000 | __ | __ | __ | 00 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 2" | 7.5° | 2" | No | 1/4" | 1 5/16" | 2,500 | 3 1/8" | 00000000 | 0000 | 2,500 | 3 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 4" | 7.5° | 2" | No | 1/4" | 1 5/16" | 2,500 | 5 1/8" | 00000000 | 00000 | 2,500 | 5 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 2" | 7.5° | 2" | No | 1/4" | 1 5/16" | 3,750 | 3 1/8" | 00000000 | 00000 | 3,750 | 3 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 3" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 4 1/8" | 0000000 | 0000 | 5,000 | 4 3/16" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 4" | 7.5° | 2" | No | 1/4" | 1 5/16" | 4,000 | 5 1/8" | 0000000 | 0000 | 4,000 | 5 3/16" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 4" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 5 1/8" | 0000000 | 0000 | 5,000 | 5 3/16" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 6" | 7.5° | 2" | No | 1/4" | 1 5/16" | 4,000 | 7 1/8" | 0000000 | 0000 | 4,000 | 7 3/16" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 6" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 7 1/8" | 0000000 | 00000 | 5,000 | 7 3/16" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 8" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 9 1/8" | 00000000 | 00000 | 5,000 | 9 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 2" | 7.5° | 2" | No | 1/4" | 1 5/16" | 3,300 | 3 1/8" | 00000000 | 00000 | 3,300 | 3 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 2" | 7.5° | 2" | No | 1/4" | 1 5/16" | __ | __ | __ | 00 | 4,000 | 3 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 3" | 7.5° | 4" | No | 7/16" | 2 11/16" | 5,000 | 4 5/16" | 00000000 | 00000 | 5,000 | 4 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 4" | 7.5° | 2" | No | 1/4" | 1 5/16" | 4,000 | 5 1/8" | 0000000 | 0000 | 4,000 | 5 3/16" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 4" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 5 1/8" | 0000000 | 0000 | 5,000 | 5 3/16" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 4" | 7.5° | 4" | No | 7/16" | 2 11/16" | 5,000 | 5 5/16" | 00000000 | 00000 | 5,000 | 5 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 6" | 7.5° | 2" | No | 1/4" | 1 5/16" | 4,000 | 7 1/8" | 00000000 | 00000 | 4,000 | 7 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 6" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 7 1/8" | 00000000 | 00000 | 5,000 | 7 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 6" | 7.5° | 4" | No | 7/16" | 2 11/16" | 5,000 | 7 5/16" | 00000000 | 00000 | 5,000 | 7 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 8" | 7.5° | 2" | No | 1/4" | 1 5/16" | 4,000 | 9 1/8" | 00000000 | 00000 | 4,000 | 9 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 8" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 9 1/8" | 00000000 | 00000 | 5,000 | 9 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 8" | 7.5° | 4" | No | 7/16" | 2 11/16" | 5,000 | 9 5/16" | 00000000 | 00000 | 5,000 | 9 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 2" | 7.5° | 2" | No | 1/4" | 1 5/16" | 3,800 | 3 1/8" | 00000000 | 0000 | 3,200 | 3 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 2" | 7.5° | 3" | No | 11/32" | 2 3/16" | 4,000 | 3 1/8" | 00000000 | 00000 | __ | __ | __ | 00 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 3" | 7.5° | 2" | No | 1/4" | 1 5/16" | 4,000 | 4 1/8" | 00000000 | 0000 | 4,000 | 4 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 3" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 4 1/8" | 00000000 | 0000 | 5,000 | 4 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 3" | 7.5° | 4" | No | 7/16" | 2 11/16" | 6,000 | 4 5/16" | 00000000 | 00000 | 6,000 | 4 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 4" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 5 1/8" | 0000000 | 0000 | 5,000 | 5 3/16" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 4" | 7.5° | 4" | No | 7/16" | 2 11/16" | 6,000 | 5 5/16" | 00000000 | 00000 | 6,000 | 5 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 6" | 7.5° | 2" | No | 1/4" | 1 5/16" | 4,000 | 7 1/8" | 00000000 | 00000 | 4,000 | 7 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 6" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 7 1/8" | 00000000 | 00000 | 5,000 | 7 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 6" | 7.5° | 4" | No | 7/16" | 2 11/16" | 6,000 | 7 5/16" | 0000000 | 00000 | 6,000 | 7 3/8" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 8" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 9 1/8" | 00000000 | 00000 | 5,000 | 9 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 8" | 7.5° | 4" | No | 7/16" | 2 11/16" | 6,000 | 9 5/16" | 00000000 | 00000 | 6,000 | 9 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 10" | 7.5° | 5" | No | 1/2" | 3 7/8" | 10,000 | 12 1/4" | 00000000 | 00000 | 10,000 | 12 9/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2" | 7.5° | 3" | No | 11/32" | 2 3/16" | __ | __ | __ | 00 | 4,000 | 3 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 4" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 5 1/8" | 00000000 | 00000 | 5,000 | 5 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 4" | 7.5° | 4" | No | 7/16" | 2 11/16" | 7,500 | 5 5/16" | 00000000 | 00000 | 7,500 | 5 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 4" | 7.5° | 5" | No | 1/2" | 3 7/8" | 10,000 | 6 1/4" | 00000000 | 00000 | 10,000 | 6 9/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 6" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 7 1/8" | 00000000 | 00000 | 5,000 | 7 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 6" | 7.5° | 4" | No | 7/16" | 2 11/16" | 7,500 | 7 5/16" | 0000000 | 00000 | 7,500 | 7 3/8" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 6" | 7.5° | 5" | No | 1/2" | 3 7/8" | 10,000 | 8 1/4" | 0000000 | 00000 | 10,000 | 8 9/16" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 8" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 9 1/8" | 00000000 | 00000 | 5,000 | 9 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 8" | 7.5° | 4" | No | 7/16" | 2 11/16" | 7,500 | 9 5/16" | 00000000 | 00000 | 7,500 | 9 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 8" | 7.5° | 5" | No | 1/2" | 3 7/8" | 10,000 | 10 1/4" | 00000000 | 00000 | 10,000 | 10 9/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 10" | 7.5° | 5" | No | 1/2" | 3 7/8" | 10,000 | 12 1/4" | 00000000 | 00000 | 10,000 | 12 9/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 6" | 7.5° | 5" | No | 1/2" | 3 7/8" | 10,000 | 8 1/4" | 0000000 | 00000 | 10,000 | 8 9/16" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 8" | 7.5° | 4 3/8" | No | 13/32" | 2 31/32" | __ | __ | __ | 00 | 2,700 | 9 11/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 76 mm | 7.5° | 51 mm | No | 6.4 mm | 33.8 mm | 4,000 | 105 mm | 0000000 | 00000 | 4,000 | 106.6 mm | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 76 mm | 7.5° | 76 mm | No | 8.9 mm | 55.9 mm | 5,000 | 104 mm | 00000000 | 00000 | 5,000 | 105.6 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 102 mm | 7.5° | 51 mm | No | 6.4 mm | 33.8 mm | 4,000 | 130 mm | 0000000 | 00000 | 4,000 | 131.6 mm | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 102 mm | 7.5° | 76 mm | No | 8.9 mm | 55.9 mm | 5,000 | 130 mm | 0000000 | 0000 | 5,000 | 131.6 mm | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 152 mm | 7.5° | 51 mm | No | 6.4 mm | 33.8 mm | 4,000 | 181 mm | 00000000 | 00000 | 4,000 | 182.6 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 152 mm | 7.5° | 76 mm | No | 8.9 mm | 55.9 mm | 5,000 | 181 mm | 00000000 | 00000 | __ | __ | __ | 00 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 203 mm | 7.5° | 76 mm | No | 8.9 mm | 55.9 mm | 5,000 | 232 mm | 00000000 | 00000 | 5,000 | 233.6 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 76 mm | 7.5° | 51 mm | No | 6.4 mm | 33.8 mm | 4,000 | 105 mm | 0000000 | 0000 | 4,000 | 106.6 mm | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 76 mm | 7.5° | 101.9 mm | No | 12.5 mm | 68.8 mm | 5,000 | 109 mm | 00000000 | 00000 | __ | __ | __ | 00 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 76 mm | 7.5° | 102 mm | No | 11.9 mm | 68.8 mm | __ | __ | __ | 00 | 5,000 | 110.6 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 102 mm | 7.5° | 51 mm | No | 6.4 mm | 33.8 mm | 4,000 | 130 mm | 0000000 | 00000 | 4,000 | 131.6 mm | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 102 mm | 7.5° | 76 mm | No | 8.9 mm | 55.9 mm | 5,000 | 130 mm | 00000000 | 00000 | 5,000 | 131.6 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 102 mm | 7.5° | 102 mm | No | 11.9 mm | 68.8 mm | 5,000 | 135 mm | 00000000 | 00000 | 5,000 | 136.6 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 152 mm | 7.5° | 51 mm | No | 6.4 mm | 33.8 mm | 4,000 | 181 mm | 0000000 | 0000 | 4,000 | 182.6 mm | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 152 mm | 7.5° | 76 mm | No | 8.9 mm | 55.9 mm | 5,000 | 181 mm | 0000000 | 00000 | __ | __ | __ | 00 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 152 mm | 7.5° | 102 mm | No | 11.9 mm | 68.8 mm | 5,000 | 185 mm | 0000000 | 00000 | 5,000 | 186.6 mm | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 203 mm | 7.5° | 51 mm | No | 6.4 mm | 33.8 mm | 4,000 | 232 mm | 00000000 | 00000 | 4,000 | 233.6 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 203 mm | 7.5° | 76 mm | No | 8.9 mm | 55.9 mm | __ | __ | __ | 00 | 5,000 | 233.6 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 203 mm | 7.5° | 102 mm | No | 11.9 mm | 68.8 mm | 5,000 | 236 mm | 00000000 | 00000 | 5,000 | 237.6 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 76 mm | 7.5° | 51 mm | No | 6.4 mm | 33.8 mm | 4,000 | 105 mm | 00000000 | 00000 | __ | __ | __ | 00 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 76 mm | 7.5° | 76 mm | No | 8.9 mm | 55.9 mm | 5,000 | 104 mm | 00000000 | 00000 | 5,000 | 105.6 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 76 mm | 7.5° | 102 mm | No | 11.9 mm | 68.8 mm | 6,000 | 109 mm | 00000000 | 00000 | 6,000 | 110.6 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 102 mm | 7.5° | 76 mm | No | 8.9 mm | 55.9 mm | 5,000 | 130 mm | 0000000 | 00000 | 5,000 | 131.6 mm | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 102 mm | 7.5° | 102 mm | No | 11.9 mm | 68.8 mm | 6,000 | 135 mm | 00000000 | 00000 | 6,000 | 136.6 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 152 mm | 7.5° | 51 mm | No | 6.4 mm | 33.8 mm | 4,000 | 181 mm | 00000000 | 00000 | 4,000 | 182.6 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 152 mm | 7.5° | 76 mm | No | 8.9 mm | 55.9 mm | 5,000 | 181 mm | 00000000 | 00000 | 5,000 | 182.6 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 152 mm | 7.5° | 102 mm | No | 11.9 mm | 68.8 mm | 6,000 | 185 mm | 0000000 | 00000 | 6,000 | 186.6 mm | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 203 mm | 7.5° | 76 mm | No | 8.9 mm | 55.9 mm | 5,000 | 232 mm | 00000000 | 00000 | 5,000 | 233.6 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 203 mm | 7.5° | 102 mm | No | 11.9 mm | 68.8 mm | 6,000 | 236 mm | 00000000 | 00000 | 6,000 | 237.6 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 254 mm | 7.5° | 127 mm | No | 12 mm | 98 mm | 10,000 | 311 mm | 00000000 | 00000 | 10,000 | 312.6 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 2.5 mm | 102 mm | 7.5° | 76 mm | No | 8.9 mm | 55.9 mm | 5,000 | 130 mm | 0000000 | 00000 | 5,000 | 131.6 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 2.5 mm | 102 mm | 7.5° | 102 mm | No | 11.9 mm | 68.8 mm | 7,500 | 135 mm | 0000000 | 00000 | 7,500 | 136.6 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 2.5 mm | 152 mm | 7.5° | 76 mm | No | 8.9 mm | 55.9 mm | 5,000 | 181 mm | 00000000 | 00000 | 5,000 | 182.6 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 2.5 mm | 152 mm | 7.5° | 102 mm | No | 11.9 mm | 68.8 mm | 7,500 | 185 mm | 0000000 | 00000 | 7,500 | 186.6 mm | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 2.5 mm | 152 mm | 7.5° | 127 mm | No | 12 mm | 98 mm | 10,000 | 210 mm | 0000000 | 00000 | __ | __ | __ | 00 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 2.5 mm | 203 mm | 7.5° | 76 mm | No | 8.9 mm | 55.9 mm | 5,000 | 232 mm | 00000000 | 00000 | 5,000 | 233.6 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 2.5 mm | 203 mm | 7.5° | 102 mm | No | 11.9 mm | 68.8 mm | 7,500 | 236 mm | 00000000 | 00000 | 7,500 | 237.6 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 2.5 mm | 203 mm | 7.5° | 127 mm | No | 12 mm | 98 mm | 10,000 | 260 mm | 00000000 | 00000 | __ | __ | __ | 00 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 2.5 mm | 254 mm | 7.5° | 127 mm | No | 12 mm | 98 mm | 10,000 | 311 mm | 00000000 | 00000 | 10,000 | 312.6 mm | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 × 3 mm | 152 mm | 7.5° | 102 mm | No | 11.9 mm | 68.8 mm | 7,500 | 185 mm | 0000000 | 00000 | 7,500 | 186.6 mm | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 × 3 mm | 152 mm | 7.5° | 127 mm | No | 12 mm | 98 mm | 10,000 | 210 mm | 0000000 | 00000 | 10,000 | 211.6 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Glass-Filled Nylon Base and 303 Stainless Steel Stud | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 3" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 4 1/8" | 0000000 | 00000 | 5,000 | 4 3/16" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 4" | 7.5° | 2" | No | 1/4" | 1 5/16" | 4,000 | 5 1/8" | 0000000 | 00000 | 4,000 | 5 3/16" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 4" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 5 1/8" | 0000000 | 00000 | 5,000 | 5 3/16" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 6" | 7.5° | 2" | No | 1/4" | 1 5/16" | 4,000 | 7 1/8" | 0000000 | 00000 | 4,000 | 7 3/16" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 6" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 7 1/8" | 0000000 | 00000 | 5,000 | 7 3/16" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 8" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 9 1/8" | 00000000 | 00000 | 5,000 | 9 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 3" | 7.5° | 4" | No | 7/16" | 2 11/16" | 5,000 | 4 5/16" | 00000000 | 00000 | 5,000 | 4 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 4" | 7.5° | 2" | No | 1/4" | 1 5/16" | 4,000 | 5 1/8" | 0000000 | 00000 | 4,000 | 5 3/16" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 4" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 5 1/8" | 0000000 | 00000 | 5,000 | 5 3/16" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 4" | 7.5° | 4" | No | 7/16" | 2 11/16" | 5,000 | 5 5/16" | 00000000 | 00000 | 5,000 | 5 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 6" | 7.5° | 2" | No | 1/4" | 1 5/16" | 4,000 | 7 1/8" | 00000000 | 00000 | 4,000 | 7 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 6" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 7 1/8" | 00000000 | 00000 | 5,000 | 7 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 6" | 7.5° | 4" | No | 7/16" | 2 11/16" | 5,000 | 7 5/16" | 00000000 | 00000 | 5,000 | 7 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 8" | 7.5° | 2" | No | 1/4" | 1 5/16" | 4,000 | 9 1/8" | 00000000 | 00000 | 4,000 | 9 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 8" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 9 1/8" | 00000000 | 00000 | 5,000 | 9 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 8" | 7.5° | 4" | No | 7/16" | 2 11/16" | 5,000 | 9 5/16" | 00000000 | 00000 | 5,000 | 9 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 3" | 7.5° | 2" | No | 1/4" | 1 5/16" | 4,000 | 4 1/8" | 00000000 | 00000 | 4,000 | 4 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 3" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 4 1/8" | 00000000 | 00000 | 5,000 | 4 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 3" | 7.5° | 4" | No | 7/16" | 2 11/16" | 6,000 | 4 5/16" | 00000000 | 00000 | 6,000 | 4 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 4" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 5 1/8" | 0000000 | 00000 | 5,000 | 5 3/16" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 4" | 7.5° | 4" | No | 7/16" | 2 11/16" | 6,000 | 5 5/16" | 00000000 | 00000 | 6,000 | 5 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 6" | 7.5° | 2" | No | 1/4" | 1 5/16" | 4,000 | 7 1/8" | 00000000 | 00000 | 4,000 | 7 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 6" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 7 1/8" | 00000000 | 00000 | 5,000 | 7 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 6" | 7.5° | 4" | No | 7/16" | 2 11/16" | 6,000 | 7 5/16" | 0000000 | 00000 | 6,000 | 7 3/8" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 8" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 9 1/8" | 00000000 | 00000 | 5,000 | 9 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 8" | 7.5° | 4" | No | 7/16" | 2 11/16" | 6,000 | 9 5/16" | 00000000 | 00000 | 6,000 | 9 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 10" | 7.5° | 5" | No | 1/2" | 3 7/8" | 10,000 | 12 1/4" | 00000000 | 00000 | 10,000 | 12 9/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 4" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 5 1/8" | 00000000 | 00000 | 5,000 | 5 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 4" | 7.5° | 4" | No | 7/16" | 2 11/16" | 7,500 | 5 5/16" | 00000000 | 00000 | 7,500 | 5 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 4" | 7.5° | 5" | No | 1/2" | 3 7/8" | 10,000 | 6 1/4" | 00000000 | 00000 | 10,000 | 6 9/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 6" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 7 1/8" | 00000000 | 00000 | 5,000 | 7 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 6" | 7.5° | 4" | No | 7/16" | 2 11/16" | 7,500 | 7 5/16" | 0000000 | 00000 | 7,500 | 7 3/8" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 6" | 7.5° | 5" | No | 1/2" | 3 7/8" | 10,000 | 8 1/4" | 0000000 | 00000 | 10,000 | 8 9/16" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 8" | 7.5° | 3" | No | 5/16" | 2 3/16" | 5,000 | 9 1/8" | 00000000 | 00000 | 5,000 | 9 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 8" | 7.5° | 4" | No | 7/16" | 2 11/16" | 7,500 | 9 5/16" | 00000000 | 00000 | 7,500 | 9 3/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 8" | 7.5° | 5" | No | 1/2" | 3 7/8" | 10,000 | 10 1/4" | 00000000 | 00000 | 10,000 | 10 9/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 10" | 7.5° | 5" | No | 1/2" | 3 7/8" | 10,000 | 12 1/4" | 00000000 | 00000 | 10,000 | 12 9/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 6" | 7.5° | 5" | No | 1/2" | 3 7/8" | 10,000 | 8 1/4" | 0000000 | 00000 | 10,000 | 8 9/16" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 76 mm | 7.5° | 76 mm | No | 8.9 mm | 55.9 mm | 5,000 | 104 mm | 00000000 | 00000 | __ | __ | __ | 00 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 102 mm | 7.5° | 80 mm | No | 8.9 mm | 55.9 mm | 5,000 | 130 mm | 0000000 | 00000 | 5,000 | 131.6 mm | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 76 mm | 7.5° | 51 mm | No | 6.4 mm | 33.8 mm | 4,000 | 105 mm | 0000000 | 00000 | 4,000 | 106.6 mm | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 102 mm | 7.5° | 76 mm | No | 8.9 mm | 55.9 mm | 5,000 | 130 mm | 00000000 | 00000 | __ | __ | __ | 00 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 102 mm | 7.5° | 102 mm | No | 11.9 mm | 68.8 mm | 5,000 | 135 mm | 00000000 | 00000 | __ | __ | __ | 00 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||