About Strainers and Selecting Screen Size

More

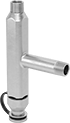

Medium-Pressure Stainless Steel Y-Strainers

- Max. Pressure for Water, Oil, Inert Gas, Natural Gas, and Diesel Fuel: 1,400 psi @ 70° F

Max. Pressure for Steam: 600 psi @ 1125° F - Temp. Range: 35° to 1125° F

316 stainless steel gives these strainers excellent corrosion resistance. Use them in medium-pressure applications to capture debris in your pipeline and protect sensitive equipment. Strainers have a threaded drain with a plug that provides access to the screen without disconnecting your line.

For technical drawings and 3-D models, click on a part number.

Strainers | Replacement Screens | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Lg. | Ht. | Plug Pipe Size | Screen Material | Screen Top OD | Screen Bottom OD | Screen Lg. | Choose a Screen Mesh Size | Choose a Screen Opening Size | Each | Each | ||

With Perforated Screen | ||||||||||||||

| 1/4 | NPT | 2 1/2" | 2 1/2" | 3/8 | 304 Stainless Steel | 3/4" | 7/8" | 1 7/16" | __ | 00000000 | 0000000 | 00000000 | 000000 | |

| 3/8 | NPT | 3 7/8" | 3 3/8" | 1/2 | 304 Stainless Steel | 7/8" | 1 1/8" | 2 3/8" | __ | 00000000 | 000000 | 00000000 | 00000 | |

| 1/2 | NPT | 3 7/8" | 3 1/2" | 1/2 | 304 Stainless Steel | 7/8" | 1 1/8" | 2 3/8" | __ | 00000000 | 000000 | 00000000 | 00000 | |

| 3/4 | NPT | 4" | 3 3/4" | 1/2 | 304 Stainless Steel | 7/8" | 1 1/8" | 2 3/8" | __ | 00000000 | 000000 | 00000000 | 00000 | |

| 1 | NPT | 5" | 5" | 3/4 | 304 Stainless Steel | 1 3/8" | 1 5/8" | 3 1/16" | __ | 00000000 | 000000 | 00000000 | 00000 | |

| 1 1/2 | NPT | 5 5/8" | 6 3/8" | 1 | 304 Stainless Steel | 1 3/4" | 2 1/8" | 4 1/8" | __ | 00000000 | 000000 | 00000000 | 00000 | |

| 2 | NPT | 8" | 7 1/4" | 1 | 304 Stainless Steel | 2 1/4" | 2 9/16" | 5 1/16" | __ | 00000000 | 00000000 | 00000000 | 00000 | |

With Mesh Screen | ||||||||||||||

| 1/4 | NPT | 2 1/2" | 2 1/2" | 3/8 | 304 Stainless Steel | 3/4" | 7/8" | 1 7/16" | __ | 0000000 | 000000 | 0000000 | 00000 | |

| 3/8 | NPT | 3 7/8" | 3 3/8" | 1/2 | 304 Stainless Steel | 7/8" | 1 1/8" | 2 3/8" | __ | 0000000 | 000000 | 0000000 | 00000 | |

| 1/2 | NPT | 3 7/8" | 3 1/2" | 1/2 | 304 Stainless Steel | 7/8" | 1 1/8" | 2 3/8" | __ | 0000000 | 000000 | 0000000 | 00000 | |

| 3/4 | NPT | 4" | 3 3/4" | 1/2 | 304 Stainless Steel | 7/8" | 1 1/8" | 2 3/8" | __ | 0000000 | 000000 | 0000000 | 00000 | |

| 1 | NPT | 5" | 5" | 3/4 | 304 Stainless Steel | 1 3/8" | 1 5/8" | 3 1/16" | __ | 0000000 | 000000 | 0000000 | 00000 | |

| 1 1/2 | NPT | 5 5/8" | 6 3/8" | 1 | 304 Stainless Steel | 1 3/4" | 2 1/8" | 4 1/8" | __ | 0000000 | 000000 | 0000000 | 00000 | |

| 2 | NPT | 8" | 7 1/4" | 1 | 304 Stainless Steel | 2 1/4" | 2 9/16" | 5 1/16" | __ | 0000000 | 00000000 | 0000000 | 000000 | |

Screens for Medium-Pressure Stainless Steel Y-Strainers

Mesh screens typically filter smaller particles than perforated screens. To replace your screen, measure the OD and length and find the corresponding screen listed in the table.

Screen OD | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Pipe Size | Top | Bottom | Screen Length | Screen Material | Choose a Screen Mesh Size | Choose a Screen Opening Size | Each | ||

Mesh | |||||||||

| A | 1/4 | 3/4" | 7/8" | 1 7/16" | 304 Stainless Steel | __ | 0000000 | 000000 | |

| A | 3/8 | 7/8" | 1 1/8" | 2 3/8" | 304 Stainless Steel | __ | 0000000 | 00000 | |

| A | 1/2 | 7/8" | 1 1/8" | 2 3/8" | 304 Stainless Steel | __ | 0000000 | 00000 | |

| A | 3/4 | 7/8" | 1 1/8" | 2 3/8" | 304 Stainless Steel | __ | 0000000 | 00000 | |

| A | 1 | 1 3/8" | 1 5/8" | 3 1/16" | 304 Stainless Steel | __ | 0000000 | 00000 | |

| A | 1 1/2 | 1 3/4" | 2 1/8" | 4 1/8" | 304 Stainless Steel | __ | 0000000 | 00000 | |

| A | 2 | 2 1/4" | 2 9/16" | 5 1/16" | 304 Stainless Steel | __ | 0000000 | 000000 | |

Perforated | |||||||||

| B | 1/4 | 3/4" | 7/8" | 1 7/16" | 304 Stainless Steel | __ | 00000000 | 00000 | |

| B | 3/8 | 7/8" | 1 1/8" | 2 3/8" | 304 Stainless Steel | __ | 00000000 | 00000 | |

| B | 1/2 | 7/8" | 1 1/8" | 2 3/8" | 304 Stainless Steel | __ | 00000000 | 00000 | |

| B | 3/4 | 7/8" | 1 1/8" | 2 3/8" | 304 Stainless Steel | __ | 00000000 | 00000 | |

| B | 1 | 1 3/8" | 1 5/8" | 3 1/16" | 304 Stainless Steel | __ | 00000000 | 00000 | |

| B | 1 1/2 | 1 3/4" | 2 1/8" | 4 1/8" | 304 Stainless Steel | __ | 00000000 | 00000 | |

| B | 2 | 2 1/4" | 2 9/16" | 5 1/16" | 304 Stainless Steel | __ | 00000000 | 00000 | |

ASME-Code Metal Basket Strainers

- Max. Pressure for Water, Oil, Inert Gas, Diesel Fuel, and Natural Gas: 200 psi @ 100° F

- Temp. Range: -20° to 150° F

These basket strainers are constructed for use with boilers and pressure vessels. They are 316 stainless steel for excellent corrosion resistance. Commonly used in high-flow industrial processes, they hold more debris than all of our other strainers. Use them to protect valves, pumps, and nozzles from particles in your pipeline. Strainers have a threaded drain with a plug for easy cleaning.

For technical drawings and 3-D models, click on a part number.

Strainers | Replacement Baskets | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Lg. | Ht. | Material | Gasket Material | Basket Material | Specifications Met | Choose a Basket Opening Size | Each | Each | ||

| 1/2 | NPT | 4 9/16" | 6 1/2" | 316 Stainless Steel | Fluoroelastomer Rubber | 304 Stainless Steel | ASME B16.5, ASME BPVC.VIII | 0000000 | 0000000 | 0000000 | 0000000 | |

| 3/4 | NPT | 4 9/16" | 6 1/2" | 316 Stainless Steel | Fluoroelastomer Rubber | 304 Stainless Steel | ASME B16.5, ASME BPVC.VIII | 0000000 | 000000 | 0000000 | 000000 | |

| 1 | NPT | 5 5/16" | 7 7/16" | 316 Stainless Steel | Fluoroelastomer Rubber | 304 Stainless Steel | ASME B16.5, ASME BPVC.VIII | 0000000 | 000000 | 0000000 | 000000 | |

| 1 1/2 | NPT | 6 5/16" | 9 1/2" | 316 Stainless Steel | Fluoroelastomer Rubber | 304 Stainless Steel | ASME B16.5, ASME BPVC.VIII | 0000000 | 000000 | 0000000 | 000000 | |

| 2 | NPT | 8 1/4" | 11 1/2" | 316 Stainless Steel | Fluoroelastomer Rubber | 304 Stainless Steel | ASME B16.5, ASME BPVC.VIII | 0000000 | 00000000 | 0000000 | 000000 | |

Sediment Traps for Natural Gas

Get ahead of your water heater maintenance—these traps catch debris from natural gas lines before it can enter the tank. Also called a drip leg, these traps are often required by building standards. They’re plated in zinc, so they’re mildly corrosion resistant.

Install them after your shutoff valve and as close to the water heater inlet as possible. To empty the trap, unscrew the cap and dispose of any debris.

For technical drawings and 3-D models, click on a part number.