Hollow-Shaft Stepper Motors

Route light beams, wire, or tubing through the hollow shaft of these stepper motors when space is tight. Often used in robotics and optical equipment, they're good for precise, repetitive movements. Similar to the hands of a clock, their shaft turns in small, equal increments for smooth motion. When the shaft stops, it holds its position even when a counteracting force is applied to the load. You can control the position of the load without having to configure encoders, sensors, or other position feedback devices. All are bipolar hybrid stepper motors, so the current can flow in both directions. This helps them deliver higher torque, precision, and efficiency than unipolar stepper motors.

Holding torque is the force needed to move the shaft out of position when it is stationary. When the shaft is in motion, torque generally decreases as speed increases. Use a torque-speed curve to confirm which motor will work for your application. Click on a part number and select “Product Detail” to view the curve for a motor.

Full step increment is the rotation of the shaft from one position to the next. A smaller full step increment means the rotor has more teeth, producing smoother and more precise motion. 1.8° is considered standard.

All motors require a controller and driver (not included).

For technical drawings and 3-D models, click on a part number.

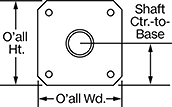

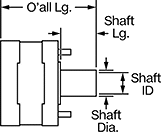

O'all | Shaft | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Holding Torque, in.-oz. | Max. Speed, rpm | Max. Current per Phase, A | Full Step Increment | No. of Wire Leads | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Type | ID | No. of Shafts | Temp. Range, °F | Each | |

NEMA 17 | ||||||||||||||||

| 16.9 | 1,475 | 1.2 | 0.9° | 4 | 1.9" | 1.7" | 1.7" | 1/2" | 3/4" | 0.84" | Hollow | 7/16" | 1 | 0° to 120° | 00000000 | 0000000 |

| 33.9 | 1,700 | 1.4 | 0.9° | 4 | 2.5" | 1.7" | 1.7" | 1/2" | 3/4" | 0.84" | Hollow | 7/16" | 1 | 0° to 120° | 00000000 | 000000 |