About Nuts, Materials, and Finishes

More

Stainless Steel Twist-Resistant Rivet Nuts

Made of 18-8 stainless steel, these rivet nuts withstand water, mild chemicals, and outdoor conditions better than zinc-plated steel nuts. A ribbed body grips surrounding material to hold them in place, keeping them from spinning as you tighten screws. Rivet nuts create permanent threads in sheet metal and other surfaces that are too thin to be tapped. They’re also known as blind inserts—installation requires access to just one side of your material. The flange distributes the load and holds them against the surface.

Secure them in a drilled or punched round hole with a wrench- or power-driven rivet nut tool. The tool collapses the nut, creating a backside flange that holds the nut to the material.

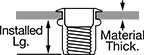

Length is measured from under the flange. Installed length is the maximum length of the barrel when installed.

For technical drawings and 3-D models, click on a part number.

Body | Flange | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Drill Bit Size | For Material Thick. | Type | Dia. | Lg. | Installed Lg. | Dia. | Thick. | Pkg. Qty. | Pkg. | |

18-8 Stainless Steel | |||||||||||

| 6-32 | 17/64" | 0.02" to 0.08" | Ribbed | 0.27" | 0.42" | 0.305" | 0.39" | 0.03" | 10 | 000000000 | 00000 |

| 6-32 | 17/64" | 0.08" to 0.13" | Ribbed | 0.27" | 0.47" | 0.305" | 0.39" | 0.03" | 10 | 000000000 | 0000 |

| 8-32 | 17/64" | 0.02" to 0.08" | Ribbed | 0.27" | 0.42" | 0.305" | 0.39" | 0.03" | 10 | 000000000 | 0000 |

| 8-32 | 17/64" | 0.08" to 0.13" | Ribbed | 0.27" | 0.42" | 0.305" | 0.39" | 0.03" | 10 | 000000000 | 0000 |

| 10-24 | 19/64" | 0.02" to 0.13" | Ribbed | 0.3" | 0.475" | 0.315" | 0.415" | 0.03" | 10 | 000000000 | 0000 |

| 10-24 | 19/64" | 0.13" to 0.225" | Ribbed | 0.3" | 0.585" | 0.315" | 0.415" | 0.03" | 10 | 000000000 | 0000 |

| 10-32 | 19/64" | 0.02" to 0.13" | Ribbed | 0.3" | 0.475" | 0.315" | 0.415" | 0.03" | 10 | 000000000 | 0000 |

| 10-32 | 19/64" | 0.13" to 0.225" | Ribbed | 0.3" | 0.585" | 0.315" | 0.415" | 0.03" | 10 | 000000000 | 0000 |

| 1/4"-20 | 25/64" | 0.027" to 0.165" | Ribbed | 0.39" | 0.58" | 0.38" | 0.5" | 0.03" | 10 | 000000000 | 0000 |

| 1/4"-20 | 25/64" | 0.165" to 0.26" | Ribbed | 0.39" | 0.68" | 0.38" | 0.5" | 0.03" | 10 | 000000000 | 0000 |

| 1/4"-28 | 25/64" | 0.027" to 0.165" | Ribbed | 0.39" | 0.58" | 0.38" | 0.5" | 0.03" | 5 | 000000000 | 00000 |

| 1/4"-28 | 25/64" | 0.165" to 0.26" | Ribbed | 0.39" | 0.68" | 0.38" | 0.5" | 0.03" | 5 | 000000000 | 00000 |

| 5/16"-18 | 17/32" | 0.027" to 0.15" | Ribbed | 0.53" | 0.69" | 0.47" | 0.685" | 0.035" | 5 | 000000000 | 0000 |

| 5/16"-18 | 17/32" | 0.15" to 0.312" | Ribbed | 0.53" | 0.805" | 0.425" | 0.685" | 0.035" | 5 | 000000000 | 00000 |

| 5/16"-24 | 17/32" | 0.027" to 0.15" | Ribbed | 0.53" | 0.69" | 0.47" | 0.685" | 0.035" | 5 | 000000000 | 00000 |

| 5/16"-24 | 17/32" | 0.15" to 0.312" | Ribbed | 0.53" | 0.805" | 0.425" | 0.685" | 0.035" | 5 | 000000000 | 00000 |

| 3/8"-16 | 17/32" | 0.027" to 0.15" | Ribbed | 0.53" | 0.69" | 0.47" | 0.685" | 0.035" | 5 | 000000000 | 00000 |

| 3/8"-16 | 17/32" | 0.15" to 0.312" | Ribbed | 0.53" | 0.805" | 0.425" | 0.685" | 0.035" | 5 | 000000000 | 00000 |

| 3/8"-24 | 17/32" | 0.027" to 0.15" | Ribbed | 0.53" | 0.69" | 0.47" | 0.685" | 0.035" | 5 | 000000000 | 00000 |

| 3/8"-24 | 17/32" | 0.15" to 0.312" | Ribbed | 0.53" | 0.805" | 0.425" | 0.685" | 0.035" | 5 | 000000000 | 00000 |

| 1/2"-13 | 11/16" | 0.063" to 0.2" | Ribbed | 0.69" | 1.15" | 0.85" | 0.865" | 0.047" | 1 | 000000000 | 0000 |

Thread | Body | Flange | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Pitch, mm | Drill Bit Size | For Material Thick., mm | Type | Dia., mm | Lg., mm | Installed Lg., mm | Dia., mm | Thick., mm | Pkg. Qty. | Pkg. | |

18-8 Stainless Steel | ||||||||||||

| M4 | 0.7 | 6 mm | 0.5 to 2.5 | Ribbed | 6 | 11 | 7.5 | 9 | 1 | 10 | 000000000 | 000000 |

| M4 | 0.7 | 6.8 mm | 2 to 3.3 | Ribbed | 6.7 | 11.9 | 7.8 | 9.9 | 0.8 | 10 | 000000000 | 0000 |

| M5 | 0.8 | 7 mm | 0.5 to 3 | Ribbed | 7 | 12 | 8 | 10 | 1 | 10 | 000000000 | 00000 |

| M5 | 0.8 | 7.6 mm | 3.3 to 5.7 | Ribbed | 7.5 | 14.9 | 8 | 10.5 | 0.8 | 5 | 000000000 | 0000 |

| M6 | 1 | 9 mm | 0.5 to 3 | Ribbed | 9 | 14 | 10 | 12 | 1.5 | 5 | 000000000 | 0000 |

| M6 | 1 | 10 mm | 4.2 to 6.6 | Ribbed | 9.9 | 17.3 | 9.7 | 12.7 | 0.8 | 5 | 000000000 | 0000 |

| M8 | 1.25 | 11 mm | 0.7 to 3 | Ribbed | 11 | 16 | 12 | 15 | 1.5 | 5 | 000000000 | 00000 |

| M8 | 1.25 | 13.5 mm | 3.8 to 7.9 | Ribbed | 13.5 | 20.5 | 10.8 | 17.4 | 0.9 | 5 | 000000000 | 00000 |

| M10 | 1.5 | 13.5 mm | 0.7 to 3.8 | Ribbed | 13.5 | 17.5 | 11.9 | 17.4 | 0.9 | 5 | 000000000 | 0000 |

| M10 | 1.5 | 13.5 mm | 3.8 to 7.9 | Ribbed | 13.5 | 20.5 | 10.8 | 17.4 | 0.9 | 5 | 000000000 | 00000 |

| M12 | 1.75 | 17.5 mm | 1.6 to 5.1 | Ribbed | 17.4 | 29.2 | 21.6 | 22 | 1.2 | 1 | 000000000 | 0000 |

Stainless Steel Heavy Duty Twist-Resistant Hex-Shaped Rivet Nuts

Ideal for wet and outdoor environments, these rivet nuts are made of stainless steel. Their hex-shaped body provides the highest twist resistance of any rivet nut. As you tighten screws, the flat sides hold them in place to keep them from spinning. They hold up in heavy duty applications because of their thick walls, making them some of our strongest rivet nuts. To install them, you only need access to one side of your sheet metal. The flange distributes the load and secures these nuts to the surface of your material.

Install them in a hex-shaped punched hole with a rivet nut tool. The tool collapses the nut, creating a backside flange that holds the nut to the material.

Length is measured from under the flange. Installed length is the maximum length of the barrel when installed.

18-8 stainless steel nuts stand up to mild chemicals and water.

316 stainless steel nuts have excellent corrosion resistance. They stand up to salt water and harsh chemicals.

For technical drawings and 3-D models, click on a part number.

Body | Flange | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Wd. Across Flats | For Material Thick. | Type | Dia. | Lg. | Installed Lg. | Dia. | Thick. | Pkg. Qty. | Pkg. | |

18-8 Stainless Steel | |||||||||||

| 5/16"-18 | 7/16" | 0.079" to 0.157" | Hex | 0.432" | 0.689" | 0.457" | 0.591" | 0.059" | 5 | 000000000 | 000000 |

Thread | Body | Flange | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Pitch, mm | Wd. Across Flats, mm | For Material Thick., mm | Type | Dia., mm | Lg., mm | Installed Lg., mm | Dia., mm | Thick., mm | Pkg. Qty. | Pkg. | |

18-8 Stainless Steel | ||||||||||||

| M4 | 0.7 | 6 | 0.5 to 2 | Hex | 5.98 | 11 | 7.9 | 9 | 1 | 10 | 000000000 | 000000 |

| M5 | 0.8 | 7 | 0.5 to 3 | Hex | 6.98 | 11.5 | 7.3 | 10 | 1 | 10 | 000000000 | 00000 |

| M6 | 1 | 9 | 0.5 to 3 | Hex | 8.98 | 14.5 | 9.3 | 12 | 1.5 | 5 | 000000000 | 0000 |

| M8 | 1.25 | 11 | 0.5 to 3 | Hex | 10.98 | 16 | 11.1 | 15 | 1.5 | 5 | 000000000 | 0000 |

316 Stainless Steel | ||||||||||||

| M4 | 0.7 | 6 | 0.5 to 2 | Hex | 5.98 | 11 | 7.9 | 9 | 1 | 5 | 000000000 | 0000 |

| M5 | 0.8 | 7 | 0.5 to 3 | Hex | 6.98 | 11.5 | 7.3 | 10 | 1 | 5 | 000000000 | 0000 |

| M6 | 1 | 9 | 0.5 to 3 | Hex | 8.98 | 14.5 | 9.3 | 12 | 1.5 | 5 | 000000000 | 00000 |

| M8 | 1.25 | 11 | 0.5 to 3 | Hex | 10.98 | 16 | 11.1 | 15 | 1.5 | 5 | 000000000 | 00000 |

Stainless Steel Low-Profile Rivet Nuts

The most corrosion resistant low-profile rivet nuts we offer, these stand up to chemicals. They're often used for light duty fastening in low-clearance applications. The threaded portion is drawn into the sleeve when installed, creating pressure against the hole to secure the nut. The tin-plating provides lubricity allowing the nut to collapse smoothly. Drill bit size listed in the table is for material with a 0.030"-0.090" thickness. These rivet nuts can be installed in thicker material, but may require larger holes. Install them using a hand- or power-driven rivet nut tool. Length is measured from under the flange. Installed length is the maximum length of the barrel when installed.

For technical drawings and 3-D models, click on a part number.

Rivet Nuts | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Body | Flange | Hand-Driven Tools | Mandrels | ||||||||||||

| Thread Size | Drill Bit Size | For Material Thick. | Type | Dia. | Lg. | Installed Lg. | Dia. | Thick. | Pkg. Qty. | Pkg. | Each | Each | |||

Tin-Plated 18-8 Stainless Steel | |||||||||||||||

| 4-40 | 3/16" | 0.030" to 0.090" | Sleeve | 0.187" | 0.355" | 0.175" | 0.211" | 0.015" | 1 | 000000000 | 00000 | 000000000 | 0000000 | 000000000 | 000000 |

| 6-32 | 7/32" | 0.030" to 0.090" | Sleeve | 0.218" | 0.355" | 0.175" | 0.24" | 0.015" | 1 | 000000000 | 0000 | 000000000 | 000000 | 000000000 | 00000 |

| 8-32 | 1/4" | 0.030" to 0.090" | Sleeve | 0.249" | 0.355" | 0.175" | 0.269" | 0.015" | 1 | 000000000 | 0000 | 000000000 | 000000 | 000000000 | 00000 |

| 10-24 | 9/32" | 0.030" to 0.090" | Sleeve | 0.28" | 0.355" | 0.175" | 0.306" | 0.015" | 1 | 000000000 | 0000 | 000000000 | 000000 | 000000000 | 00000 |

| 10-32 | 9/32" | 0.030" to 0.090" | Sleeve | 0.28" | 0.355" | 0.175" | 0.306" | 0.015" | 1 | 000000000 | 0000 | 000000000 | 000000 | 000000000 | 00000 |

| 1/4"-20 | 3/8" | 0.030" to 0.090" | Sleeve | 0.374" | 0.5" | 0.245" | 0.4" | 0.015" | 1 | 000000000 | 0000 | 000000000 | 000000 | 000000000 | 00000 |

| 1/4"-28 | 3/8" | 0.030" to 0.090" | Sleeve | 0.374" | 0.5" | 0.245" | 0.4" | 0.015" | 1 | 000000000 | 0000 | 000000000 | 000000 | 000000000 | 00000 |

| 5/16"-18 | 1/2" | 0.030" to 0.090" | Sleeve | 0.499" | 0.6" | 0.295" | 0.528" | 0.015" | 1 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 00000 |

| 3/8"-16 | 9/16" | 0.030" to 0.090" | Sleeve | 0.561" | 0.73" | 0.360" | 0.588" | 0.015" | 1 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 00000 |

| 3/8"-24 | 9/16" | 0.030" to 0.090" | Sleeve | 0.561" | 0.73" | 0.360" | 0.588" | 0.015" | 1 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 00000 |

Rivet Nuts | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread | Body | Flange | Hand-Driven Tools | Mandrels | ||||||||||||

| Size | Pitch, mm | Drill Bit Size | For Material Thick. | Type | Dia., mm | Lg., mm | Installed Lg., mm | Dia., mm | Thick., mm | Pkg. Qty. | Pkg. | Each | Each | |||

Tin-Plated 18-8 Stainless Steel | ||||||||||||||||

| M3 | 0.5 | 4.8 mm | 0.030" to 0.090" | Sleeve | 4.8 | 9 | 5.124 | 5.36 | 0.4 | 1 | 000000000 | 00000 | 000000000 | 0000000 | 000000000 | 000000 |

| M4 | 0.7 | 6.4 mm | 0.030" to 0.090" | Sleeve | 6.3 | 9 | 5.124 | 6.83 | 0.4 | 1 | 000000000 | 0000 | 000000000 | 000000 | 000000000 | 00000 |

| M5 | 0.8 | 7.1 mm | 0.030" to 0.090" | Sleeve | 7.1 | 9 | 5.124 | 7.77 | 0.4 | 1 | 000000000 | 0000 | 000000000 | 000000 | 000000000 | 00000 |

| M6 | 1 | 9.5 mm | 0.030" to 0.090" | Sleeve | 9.5 | 12.7 | 6.924 | 10.16 | 0.4 | 1 | 000000000 | 0000 | 000000000 | 000000 | 000000000 | 00000 |

| M8 | 1.25 | 12.7 mm | 0.030" to 0.090" | Sleeve | 12.7 | 15.2 | 8.224 | 13.41 | 0.4 | 1 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 00000 |

Stainless Steel Rivet Nuts

Made of stainless steel, these rivet nuts hold up better outdoors than zinc-plated steel rivet nuts. Use them to add corrosion-resistant threads to surfaces that are too thin to be tapped, such as sheet metal. Also known as blind inserts, they require access to just one side of your material for installation. The flange distributes the load and secures these nuts to the surface of your material. Install them in a drilled or punched round hole using a rivet nut tool. The tool collapses the nut, creating a backside flange that also holds them to the material.

Length is measured from under the flange. Installed length is the maximum length of the barrel when installed.

18-8 stainless steel nuts stand up to mild chemicals and water.

316 stainless steel nuts have excellent corrosion resistance. They stand up to salt water and harsh chemicals.

For technical drawings and 3-D models, click on a part number.

Thread | Body | Flange | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Pitch, mm | Drill Bit Size | For Material Thick., mm | Type | Dia., mm | Lg., mm | Installed Lg., mm | Dia., mm | Thick., mm | Pkg. Qty. | Pkg. | |

18-8 Stainless Steel | ||||||||||||

| M4 | 0.7 | 6 mm | 0.5 to 2 | Smooth | 6 | 11 | 7.8 | 9 | 1 | 10 | 000000000 | 00000 |

| M4 | 0.7 | 6 mm | 2 to 3.5 | Smooth | 6 | 12.5 | 7.8 | 9 | 1 | 10 | 000000000 | 0000 |

| M5 | 0.8 | 7 mm | 0.5 to 3 | Smooth | 7 | 11.5 | 7.5 | 10 | 1 | 10 | 000000000 | 00000 |

| M5 | 0.8 | 7 mm | 3 to 5 | Smooth | 7 | 15 | 8.8 | 10 | 1 | 10 | 000000000 | 0000 |

| M6 | 1 | 9 mm | 0.5 to 3 | Smooth | 9 | 14.5 | 10 | 12 | 1.5 | 5 | 000000000 | 0000 |

| M6 | 1 | 9 mm | 3 to 5 | Smooth | 9 | 16.5 | 10 | 12 | 1.5 | 5 | 000000000 | 0000 |

| M6 | 1 | 9 mm | 5 to 7 | Smooth | 9 | 18.5 | 10 | 12 | 1.5 | 5 | 000000000 | 0000 |

| M8 | 1.25 | 11 mm | 0.5 to 3 | Smooth | 11 | 16 | 11.6 | 15 | 1.5 | 5 | 000000000 | 00000 |

| M8 | 1.25 | 11 mm | 3 to 5.5 | Smooth | 11 | 18.5 | 11.4 | 15 | 1.5 | 5 | 000000000 | 00000 |

| M10 | 1.5 | 12 mm | 0.8 to 3 | Smooth | 12 | 18.5 | 14.3 | 15 | 1 | 1 | 000000000 | 0000 |

| M10 | 1.5 | 12 mm | 3 to 5 | Smooth | 12 | 20.5 | 14.1 | 15 | 1 | 1 | 000000000 | 0000 |

| M10 | 1.5 | 13 mm | 0.8 to 3.5 | Smooth | 13 | 21.5 | 16.9 | 17 | 1.5 | 1 | 000000000 | 0000 |

316 Stainless Steel | ||||||||||||

| M4 | 0.7 | 6 mm | 0.5 to 2 | Smooth | 6 | 11 | 7.8 | 9 | 1 | 5 | 000000000 | 0000 |

| M5 | 0.8 | 7 mm | 0.5 to 3 | Smooth | 7 | 11.5 | 7.5 | 10 | 1 | 5 | 000000000 | 0000 |

| M6 | 1 | 9 mm | 0.5 to 3 | Smooth | 9 | 14.5 | 10 | 12 | 1.5 | 5 | 000000000 | 00000 |

| M6 | 1 | 9 mm | 3 to 5 | Smooth | 9 | 16.5 | 10 | 12 | 1.5 | 5 | 000000000 | 00000 |

| M8 | 1.25 | 11 mm | 0.5 to 3 | Smooth | 11 | 16 | 11.6 | 15 | 1.5 | 1 | 000000000 | 0000 |

Rivet Nuts for Sandwich Panels

To grip all layers of a sandwich panel—the top, core, and bottom—these rivet nuts have a two-piece construction. They combine a flanged rivet nut that grasps the top and a threaded insert that bonds to the core and bottom with adhesive. Use them to add strong, reusable threads so you can fasten your panel to other components. They won’t budge when you tighten a screw—between the adhesive and the rivet nut’s ribbed body, these nuts grip onto your material. The flange anchors the rivet nut so it doesn’t pull through, and it also helps distribute load from parts you fasten to the panel. Since these rivet nuts are made of 18-8 stainless steel, they stand up to mild chemicals and water.

Place the rivet nut into a drilled hole. Using a rivet nut tool, collapse the rivet nut against your panel to create a backside flange that holds it tight. With a mixing nozzle and dispensing gun, inject structural adhesive (all sold separately) through the rivet nut so the insert can stick to the bottom and core layer beneath. Add the reusable threads by threading the insert into the rivet nut with a slotted screwdriver. The closed end on the insert keeps the adhesive from leaking into the threads.

For technical drawings and 3-D models, click on a part number.

Rivet Nut Thread | Body | Flange | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Outer Layer Thick. | For Hole Dp. | Threaded Insert Thread Size | Threaded Insert Lg. | Size | Pitch, mm | Drill Bit Size | Type | Dia. | Dia. | Thick. | For Use In | Each | |

18-8 Stainless Steel | |||||||||||||

| 0.02" to 0.079" | 0.375" to 0.512" | 1/4"-20 | 0.394" | M10 | 1.5 | 1/2" | Ribbed | 0.5" | 0.709" | 0.039" | Composite, Metal | 000000000 | 00000 |

| 0.02" to 0.079" | 0.472" to 0.61" | 1/4"-20 | 0.492" | M10 | 1.5 | 1/2" | Ribbed | 0.5" | 0.709" | 0.039" | Composite, Metal | 000000000 | 0000 |

| 0.02" to 0.079" | 0.571" to 0.709" | 1/4"-20 | 0.591" | M10 | 1.5 | 1/2" | Ribbed | 0.5" | 0.709" | 0.039" | Composite, Metal | 000000000 | 0000 |

| 0.02" to 0.079" | 0.669" to 0.807" | 1/4"-20 | 0.689" | M10 | 1.5 | 1/2" | Ribbed | 0.5" | 0.709" | 0.039" | Composite, Metal | 000000000 | 0000 |

| 0.02" to 0.079" | 0.866" to 1.004" | 1/4"-20 | 0.886" | M10 | 1.5 | 1/2" | Ribbed | 0.5" | 0.709" | 0.039" | Composite, Metal | 000000000 | 0000 |

| 0.02" to 0.138" | 0.787" to 1.102" | 1/4"-20 | 0.787" | M10 | 1.5 | 1/2" | Ribbed | 0.5" | 0.63" | 0.059" | Composite, Metal | 000000000 | 0000 |

| 0.02" to 0.138" | 0.866" to 1.181" | 1/4"-20 | 0.886" | M10 | 1.5 | 1/2" | Ribbed | 0.5" | 0.63" | 0.059" | Composite, Metal | 000000000 | 0000 |

Threaded Insert Thread | Rivet Nut Thread | Body | Flange | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Outer Layer Thick., mm | For Hole Dp., mm | Size | Pitch, mm | Threaded Insert Lg., mm | Size | Pitch, mm | Drill Bit Size, mm | Type | Dia., mm | Dia., mm | Thick., mm | For Use In | Each | |

18-8 Stainless Steel | ||||||||||||||

| 0.5 to 2 | 9.5 to 13 | M4 | 0.7 | 10 | M10 | 1.5 | 13 | Ribbed | 13 | 18 | 1 | Composite, Metal | 000000000 | 00000 |

| 0.5 to 2 | 9.5 to 13 | M5 | 0.8 | 10 | M10 | 1.5 | 13 | Ribbed | 13 | 18 | 1 | Composite, Metal | 000000000 | 0000 |

| 0.5 to 2 | 9.5 to 13 | M6 | 1 | 10 | M10 | 1.5 | 13 | Ribbed | 13 | 18 | 1 | Composite, Metal | 000000000 | 0000 |

| 0.5 to 2 | 12 to 15.5 | M6 | 1 | 12.5 | M10 | 1.5 | 13 | Ribbed | 13 | 18 | 1 | Composite, Metal | 000000000 | 0000 |

| 0.5 to 2 | 14.5 to 18 | M6 | 1 | 15 | M10 | 1.5 | 13 | Ribbed | 13 | 18 | 1 | Composite, Metal | 000000000 | 0000 |

| 0.5 to 2 | 17 to 20.5 | M6 | 1 | 17.5 | M10 | 1.5 | 13 | Ribbed | 13 | 18 | 1 | Composite, Metal | 000000000 | 0000 |

| 0.5 to 2 | 17.5 to 20 | M8 | 1.25 | 15 | M12 | 1.75 | 15 | Ribbed | 15 | 18 | 1.5 | Composite, Metal | 000000000 | 0000 |

| 0.5 to 2 | 22 to 25.5 | M6 | 1 | 22.5 | M10 | 1.5 | 13 | Ribbed | 13 | 18 | 1 | Composite, Metal | 000000000 | 0000 |

| 0.5 to 3.5 | 20 to 28 | M6 | 1 | 20 | M10 | 1.5 | 13 | Ribbed | 13 | 16 | 1.5 | Composite, Metal | 000000000 | 0000 |

| 0.5 to 3.5 | 22 to 30 | M6 | 1 | 22.5 | M10 | 1.5 | 13 | Ribbed | 13 | 16 | 1.5 | Composite, Metal | 000000000 | 0000 |

| 0.5 to 3.5 | 25 to 35 | M8 | 1.25 | 25 | M12 | 1.75 | 15 | Ribbed | 15 | 18 | 2 | Composite, Metal | 000000000 | 0000 |

Container | Strength | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Elongation | Temp. Range, °F | Color | Each | |

| 1.58 | Cartridge | 4 min. | 24 hrs. | 3,000 | 35 | 1:1 | Thick Liquid (55,000 cP) | 10% | -65° to 250° | Light Yellow | 00000000 | 000000 |

| For Cartridge Size, oz. | Mix Ratio | Opening ID | Lg. | Mixing Elements | Material | Each | |

Bayonet Connection | |||||||

|---|---|---|---|---|---|---|---|

Taper Tip | |||||||

| 1.58 | 1:1 | 0.07" | 5.9" | 20 | Polypropylene Plastic | 00000000 | 00000 |

| For Cartridge Size, oz. | Includes | Each | |

| 1.58 | 1:1 and 2:1 Mix Ratio Plungers | 00000000 | 000000 |

Flange-Sealing Closed-End Rivet Nuts

With a durable plastic seal around a closed body, these rivet nuts add threads to sheet metal without letting water or dust pass through. They’re often used on surfaces that protect equipment, such as fuse box housings, in wet areas. They help maintain an enclosure’s IP68 rating for protection from water submersion and airborne dust. Made of 18-8 stainless steel, these rivet nuts withstand mild chemicals and resist corrosion in wet and outdoor environments.

Install these rivet nuts in sheet metal and other surfaces that are too thin to be tapped. Also known as blind inserts, installation requires access to just one side of your material. The flange distributes the load and holds these nuts against the surface. They collapse during installation, creating a backside flange that secures them to your material and creates a water-tight seal.

Length is measured from under the flange. Installed length is the maximum length of the barrel when installed.

Smooth-body nuts can be installed in either a drilled or punched hole using a rivet nut tool.

Hex-body nuts are the most twist-resistant style of rivet nut. Their flat sides hold them in place, so they won’t turn as you tighten screws. Install them in a hex-shaped punched hole with a rivet nut tool.

For technical drawings and 3-D models, click on a part number.

Body | Flange | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Drill Bit Size | For Material Thick. | Type | Dia. | Lg. | Installed Lg. | Dia. | Thick. | Seal Material | For Enclosure Environmental Rating | Pkg. Qty. | Pkg. | |

18-8 Stainless Steel | |||||||||||||

| 1/4"-20 | S | 0.02" to 0.079" | Smooth | 0.394" | 0.815" | 0.63" | 0.472" | 0.07" | Polyolefin Plastic | IP68 | 5 | 000000000 | 00000 |

Thread | Body | Flange | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Pitch, mm | Drill Bit Size | For Material Thick., mm | Type | Dia., mm | Lg., mm | Installed Lg., mm | Dia., mm | Thick., mm | Seal Material | For Enclosure Environmental Rating | Pkg. Qty. | Pkg. | |

18-8 Stainless Steel | ||||||||||||||

| M5 | 0.8 | 7 mm | 0.5 to 1.5 | Hex | 8.3 | 16.5 | 12.5 | 10 | 1.5 | Polyolefin Plastic | IP68 | 5 | 000000000 | 00000 |

| M5 | 0.8 | 7 mm | 0.5 to 1.5 | Smooth | 8.2 | 16.3 | 12.5 | 10 | 1.7 | Polyolefin Plastic | IP68 | 5 | 000000000 | 0000 |

| M5 | 0.8 | 7 mm | 2 to 3 | Hex | 8.3 | 18.5 | 12.5 | 10 | 1.5 | Polyolefin Plastic | IP68 | 5 | 000000000 | 00000 |

| M5 | 0.8 | 7 mm | 2 to 3 | Smooth | 8.2 | 18.3 | 12.5 | 10 | 1.7 | Polyolefin Plastic | IP68 | 5 | 000000000 | 00000 |

| M6 | 1 | 9 mm | 0.5 to 2 | Hex | 10 | 20.8 | 16 | 12 | 1.7 | Polyolefin Plastic | IP68 | 5 | 000000000 | 00000 |

| M6 | 1 | 9 mm | 0.5 to 2 | Smooth | 10 | 20.7 | 16 | 12 | 1.8 | Polyolefin Plastic | IP68 | 5 | 000000000 | 00000 |

| M6 | 1 | 9 mm | 2.5 to 4 | Hex | 10 | 23.3 | 16 | 12 | 1.7 | Polyolefin Plastic | IP68 | 5 | 000000000 | 00000 |

| M6 | 1 | 9 mm | 2.5 to 4 | Smooth | 10 | 23.2 | 16 | 12 | 1.8 | Polyolefin Plastic | IP68 | 5 | 000000000 | 00000 |

| M8 | 1.25 | 11 mm | 0.5 to 2.5 | Hex | 12 | 23.1 | 17.5 | 14 | 1.9 | Polyolefin Plastic | IP68 | 5 | 000000000 | 00000 |

| M8 | 1.25 | 11 mm | 0.5 to 2.5 | Smooth | 12.1 | 23 | 17.5 | 14 | 2 | Polyolefin Plastic | IP68 | 5 | 000000000 | 00000 |

| M8 | 1.25 | 11 mm | 3 to 5 | Hex | 12 | 25.6 | 17.5 | 14 | 1.9 | Polyolefin Plastic | IP68 | 5 | 000000000 | 00000 |

| M8 | 1.25 | 11 mm | 3 to 5 | Smooth | 12.1 | 25.5 | 17.5 | 14 | 2 | Polyolefin Plastic | IP68 | 5 | 000000000 | 00000 |

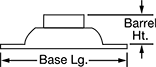

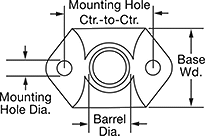

Mil. Spec. Rivet-Mount Nuts

Create threads in hard-to-work areas—where you can’t reach the back of a workpiece, or material is too thin to be tapped. For a strong grip, these nuts have distorted threads that increase friction with bolts. Because they mount with two rivets, they won’t spin when you’re tightening screws. However, these nuts do move inside their retainers, which lets you install bolts at a slight angle; use them to align with off-center parts. All meet military guidelines for dimensions and material.

A286 stainless steel nuts are corrosion resistant. Silver-plated stainless steel nuts withstand temperatures up to 800° F. The silver plating also adds lubricity and prevents seizing caused by friction between nuts and bolts.

Lubricated nuts thread onto bolts smoothly.

For technical drawings and 3-D models, click on a part number.

Base | Barrel | Mounting | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Lg. | Wd. | Thick. | Dia. | Ht. | No. of Holes | Hole Dia. | Hole Ctr.-to-Ctr. | Specifications Met | Each | |

A286 Stainless Steel—Lubricated | |||||||||||

| 4-40 | 21/32" | 5/16" | 3/32" | 0.125" | 1/16" | 2 | 0.098" | 13/32" | MS21076L04N | 000000000 | 000000 |

| 6-32 | 11/16" | 11/32" | 3/32" | 0.172" | 5/64" | 2 | 0.098" | 7/16" | MS21076L06N | 000000000 | 00000 |

| 6-32 | 61/64" | 13/32" | 1/32" | 0.172" | 11/64" | 2 | 0.098" | 11/16" | MS21060L06 | 000000000 | 00000 |

| 8-32 | 45/64" | 23/64" | 3/32" | 0.203" | 5/32" | 2 | 0.098" | 15/32" | MS21076L08N | 000000000 | 0000 |

| 8-32 | 61/64" | 13/32" | 1/32" | 0.203" | 7/32" | 2 | 0.098" | 11/16" | MS21060L08 | 000000000 | 0000 |

| 10-32 | 47/64" | 13/32" | 3/32" | 0.234" | 5/32" | 2 | 0.098" | 1/2" | MS21076L3N | 000000000 | 0000 |

| 10-32 | 61/64" | 13/32" | 1/32" | 0.234" | 7/32" | 2 | 0.098" | 11/16" | MS21060L3 | 000000000 | 0000 |

| 1/4"-28 | 51/64" | 1/2" | 3/32" | 0.313" | 3/16" | 2 | 0.098" | 9/16" | MS21076L4N | 000000000 | 0000 |

| 1/4"-28 | 1 19/64" | 33/64" | 1/32" | 0.313" | 1/4" | 2 | 0.098" | 1" | MS21060L4 | 000000000 | 00000 |

| 5/16"-24 | 1 1/64" | 37/64" | 7/64" | 0.391" | 7/32" | 2 | 0.13" | 23/32" | MS21076L5N | 000000000 | 00000 |

| 5/16"-24 | 1 19/64" | 39/64" | 3/64" | 0.375" | 9/32" | 2 | 0.13" | 1" | MS21060L5 | 000000000 | 00000 |

| 3/8"-24 | 1 19/64" | 43/64" | 1/16" | 0.453" | 19/64" | 2 | 0.13" | 1" | MS21060L6 | 000000000 | 00000 |

Silver-Plated A286 Stainless Steel—Unlubricated | |||||||||||

| 4-40 | 21/32" | 5/16" | 3/32" | 0.125" | 1/16" | 2 | 0.098" | 13/32" | MS21076-04N | 000000000 | 00000 |

| 6-32 | 61/64" | 13/32" | 1/32" | 0.172" | 11/64" | 2 | 0.098" | 11/16" | MS21060-06 | 000000000 | 0000 |

| 8-32 | 45/64" | 23/64" | 3/32" | 0.203" | 5/32" | 2 | 0.098" | 15/32" | MS21076-08N | 000000000 | 00000 |

| 10-32 | 47/64" | 13/32" | 3/32" | 0.234" | 5/32" | 2 | 0.098" | 1/2" | MS21076-3N | 000000000 | 0000 |

| 10-32 | 61/64" | 13/32" | 1/32" | 0.234" | 7/32" | 2 | 0.098" | 11/16" | MS21060-3 | 000000000 | 0000 |

| 1/4"-28 | 51/64" | 1/2" | 3/32" | 0.313" | 3/16" | 2 | 0.098" | 9/16" | MS21076-4N | 000000000 | 00000 |

| 1/4"-28 | 1 19/64" | 33/64" | 1/32" | 0.313" | 1/4" | 2 | 0.098" | 1" | MS21060-4 | 000000000 | 00000 |

| 5/16"-24 | 1 1/64" | 37/64" | 7/64" | 0.391" | 7/32" | 2 | 0.13" | 23/32" | MS21076-5N | 000000000 | 00000 |