About Gears

More

MXL Series Lightweight Timing Belt Pulleys

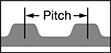

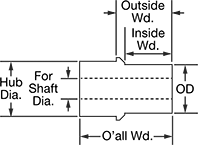

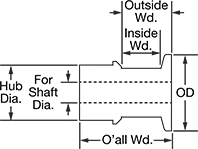

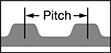

Made from polycarbonate, these pulleys are useful in applications with weight constraints. All are MXL series (miniature extra light) and have trapezoidal teeth. The teeth match up with the grooves along the inside diameter of a timing belt in order to move components forward or backward. Select a pulley with a maximum belt width that’s the same or larger than your timing belt width.

For technical drawings and 3-D models, click on a part number.

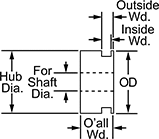

| OD | Number of Teeth | Pitch | For Shaft Dia. | Bore Type | Inside Wd. | Outside Wd. | Overall Wd. | Pitch Dia. | Fabrication | Material | Hub Dia. | Each | |

1 Flange | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For 6 mm Max. Belt Wd. | |||||||||||||

| 11mm | 10 | 2.030mm | 3mm | Finished | 9.5mm | 15.9mm | 17.5mm | 6.5mm | Molded | Polycarbonate | 11mm | 0000000 | 00000 |

2 Flanges | |||||||||||||

For 6 mm Max. Belt Wd. | |||||||||||||

| 11mm | 10 | 2.030mm | 3mm | Finished | 9.5mm | 15.9mm | 17.5mm | 6.5mm | Molded | Polycarbonate | 11mm | 0000000 | 00000 |

MXL Series Corrosion-Resistant Timing Belt Pulleys

Anodized aluminum has good corrosion resistance. Pulleys are MXL series (miniature extra light) and have trapezoidal teeth. The teeth match up with the grooves along the inside diameter of a timing belt in order to move components forward or backward. Select a pulley with a maximum belt width that’s the same or larger than your timing belt width.

For technical drawings and 3-D models, click on a part number.

| OD | Number of Teeth | Pitch | For Shaft Dia. | Bore Type | Inside Wd. | Outside Wd. | Overall Wd. | Pitch Dia. | Number of Flanges | Fabrication | Material | Hub Dia. | Each | |

For 3 mm Max. Belt Wd. | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10.8mm | 10 | 2.030mm | 3mm | Finished | 4mm | 5.1mm | 11.1mm | 6.5mm | 1 | Machined | Anodized Aluminum | 10.8mm | 00000000 | 000000 |

| 11.4mm | 11 | 2.030mm | 3mm | Finished | 4mm | 5.1mm | 11.1mm | 7.1mm | 1 | Machined | Anodized Aluminum | 11.4mm | 00000000 | 00000 |

| 12.2mm | 12 | 2.030mm | 3mm | Finished | 4mm | 5.1mm | 11.1mm | 7.8mm | 1 | Machined | Anodized Aluminum | 12.2mm | 00000000 | 00000 |

| 13.5mm | 14 | 2.030mm | 3mm | Finished | 4mm | 5.1mm | 11.1mm | 9.1mm | 1 | Machined | Anodized Aluminum | 13.5mm | 00000000 | 00000 |

For 6 mm Max. Belt Wd. | ||||||||||||||

| 10.8mm | 10 | 2.030mm | 3mm | Finished | 7.2mm | 8.3mm | 14.3mm | 6.5mm | 1 | Machined | Anodized Aluminum | 10.8mm | 00000000 | 00000 |

| 12.2mm | 12 | 2.030mm | 3mm | Finished | 7.2mm | 8.3mm | 14.3mm | 7.8mm | 1 | Machined | Anodized Aluminum | 12.2mm | 00000000 | 00000 |

| 13.5mm | 14 | 2.030mm | 3mm | Finished | 7.2mm | 8.3mm | 14.3mm | 9.1mm | 1 | Machined | Anodized Aluminum | 13.5mm | 00000000 | 00000 |

For 9 mm Max. Belt Wd. | ||||||||||||||

| 10.8mm | 10 | 2.030mm | 3mm | Finished | 10.4mm | 11.5mm | 17.5mm | 6.5mm | 1 | Machined | Anodized Aluminum | 10.8mm | 00000000 | 00000 |

| 13.5mm | 14 | 2.030mm | 3mm | Finished | 10.4mm | 11.5mm | 17.5mm | 9.1mm | 1 | Machined | Anodized Aluminum | 13.5mm | 00000000 | 00000 |

High-Strength HTD Timing Belt Idler Pulleys

Keep high torque drive (HTD) timing belt systems running tightly with these idler pulleys. Made with built-in, free-spinning ball bearings, they're installed on shafts or belt tensioners (not included) to remove slack from timing belts. By maintaining tension on the belt, these pulleys reduce wear and vibration in 3D printing, machine tool drives, robotics, and other linear motion applications that require precise positioning.

When replacing an idler pulley, be sure the pulley matches your belt's trade size.

Toothed pulleys are shaped to mesh with the teeth on a timing belt, which reduces wear on the belt's teeth.

Smooth pulleys have no teeth; they're used with the smooth side of the belt.

For technical drawings and 3-D models, click on a part number.

| Manufacturer Series | OD | Number of Teeth | For Shaft Dia. | Dia. | Wd. | Groove Dp. | Shaft Mount Type | Bore Type | Number of Flanges | Fabrication | Material | Bearing Type | Each | |

For 6 mm Max. Belt Wd. | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gates PowerGrip 2GT | 15mm | 20 | 3mm | 12.22mm | 10mm | 1.39 mm | Slip Fit | Finished | 2 | Machined | Aluminum | Ball | 00000000 | 00000 |

For 9 mm Max. Belt Wd. | ||||||||||||||

| Gates PowerGrip 2GT | 15mm | 20 | 3mm | 12.22mm | 14mm | 1.39 mm | Slip Fit | Finished | 2 | Machined | Aluminum | Ball | 00000000 | 0000 |

For 12 mm Max. Belt Wd. | ||||||||||||||

| Gates PowerGrip 2GT | 15mm | 20 | 3mm | 12.22mm | 16mm | 1.39 mm | Slip Fit | Finished | 2 | Machined | Aluminum | Ball | 00000000 | 0000 |

| Manufacturer Series | OD, mm | For Shaft Dia., mm | Dia., mm | Wd., mm | Groove Dp., mm | Shaft Mount Type | Bore Type | Number of Flanges | Fabrication | Material | Bearing Type | Each | |

For 6 mm Max. Belt Wd. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gates PowerGrip 2GT | 15 | 3 | 12 | 10 | 1.5 | Slip Fit | Finished | 2 | Machined | Aluminum | Ball | 00000000 | 00000 |

For 9 mm Max. Belt Wd. | |||||||||||||

| Gates PowerGrip 2GT | 15 | 3 | 12 | 14 | 1.5 | Slip Fit | Finished | 2 | Machined | Aluminum | Ball | 00000000 | 0000 |

For 12 mm Max. Belt Wd. | |||||||||||||

| Gates PowerGrip 2GT | 15 | 3 | 12 | 16 | 1.5 | Slip Fit | Finished | 2 | Machined | Aluminum | Ball | 00000000 | 0000 |

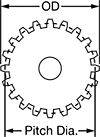

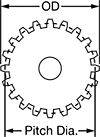

Metal Gears and Gear Racks—20° Pressure Angle

The current industry standard, these 20° pressure angle gears have thicker, stronger teeth than 14½° pressure angle gears. Compared to plastic gears and racks, they’re better for high-load, high-speed, and heavy duty applications. Also known as spur gears.

Combine gears with different numbers of teeth to change speed and torque in your assembly. Combine a gear and rack to convert rotary motion into linear motion. To minimize your footprint, mount one or more standard gears inside of an internal gear.

For components to mesh correctly, they must have the same pressure angle and pitch/module.

Brass gears and racks are easy to machine, so you can add your own mounting holes and make other alterations. They won't rust when exposed to water.

Carbon steel components have hard, strong, and wear-resistant teeth, although they will rust when exposed to moisture and corrosive chemicals. They're best for high-torque machines, like lifting equipment, and heavy duty applications, such as rock crushing. Gears with teeth that are not hardened can be hardened to fit your application.

For technical drawings and 3-D models, click on a part number.

Hub | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Module | Number of Teeth | Gear Pitch Dia., mm | OD, mm | Face Wd., mm | Overall Wd., mm | For Shaft Dia., mm | Material | Teeth Heat Treatment | Dia., mm | Wd., mm | Set Screw Thread Size | Each | |

Round Bore with Set Screw | |||||||||||||

| 0.5 | 15 | 7.5 | 8.5 | 3 | 14 | 3 | Brass | __ | 8.5 | 11 | M3 | 00000000 | 000000 |

| 0.5 | 15 | 7.5 | 8.5 | 5 | 16 | 3 | Black-Oxide 1045 Carbon Steel | Not Hardened | 8.5 | 11 | M3 | 00000000 | 00000 |

| 0.5 | 16 | 8 | 9 | 3 | 14 | 3 | Brass | __ | 9 | 11 | M3 | 00000000 | 00000 |

| 0.5 | 17 | 8.5 | 9.5 | 3 | 14 | 3 | Brass | __ | 9.5 | 11 | M3 | 00000000 | 00000 |

| 0.5 | 20 | 10 | 11 | 3 | 14 | 3 | Brass | __ | 11 | 11 | M3 | 00000000 | 00000 |

| 0.5 | 20 | 10 | 11 | 5 | 16 | 3 | Black-Oxide 1045 Carbon Steel | Not Hardened | 11 | 11 | M3 | 00000000 | 00000 |

| 0.5 | 21 | 10.5 | 11.5 | 3 | 14 | 3 | Brass | __ | 11.5 | 11 | M3 | 00000000 | 00000 |

| 0.5 | 22 | 11 | 12 | 3 | 10 | 3 | Brass | __ | 9 | 7 | M3 | 00000000 | 00000 |

| 0.5 | 24 | 12 | 13 | 3 | 10 | 3 | Brass | __ | 10 | 7 | M3 | 00000000 | 00000 |

| 0.5 | 25 | 12.5 | 13 | 3 | 10 | 3 | Brass | __ | 10 | 7 | M3 | 00000000 | 00000 |

| 0.5 | 30 | 15 | 16 | 3 | 10 | 3 | Brass | __ | 12 | 7 | M3 | 00000000 | 00000 |

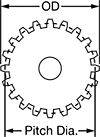

Plastic Gears and Gear Racks—20° Pressure Angle

The current industry standard, these 20° pressure angle gears have thicker, stronger teeth than 14½° pressure angle gears. Made of plastic, they run quieter than metal gears and have good corrosion and chemical resistance. They’re also known as spur gears.

Combine gears with different numbers of teeth to change speed and torque in your assembly. Combine a gear and rack to convert rotary motion into linear motion.

For components to mesh correctly, they must have the same pressure angle and pitch/module.

Acetal gears are best suited for use in light duty machines or for prototyping.

For technical drawings and 3-D models, click on a part number.

Plastic Miter Gears

Connect two shafts at a right angle without changing shaft speed or torque. Made of plastic, these gears run quieter than metal gears and have good corrosion and chemical resistance.

For two gears to mesh correctly, they must have the same pressure angle, pitch/module, and number of teeth.

Acetal gears absorb less moisture than nylon gears and are less prone to dimensional change. They’re best suited for use in light duty applications such as prototyping.

For technical drawings and 3-D models, click on a part number.

Hub | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Module | Number of Teeth | Pressure Angle | Gear Pitch Dia. | OD, mm | Face Wd., mm | Overall Wd., mm | For Shaft Dia., mm | Mounting Distance, mm | Material | Fabrication | Color | Dia., mm | Wd., mm | Each | |

Round Bore | |||||||||||||||

| 0.5 | 20 | 20° | 10mm | 10.7 | 2.5 | 8 | 3 | 11 | Acetal Plastic | Molded | White | 8 | 4 | 000000 | 00000 |