About Gears

More

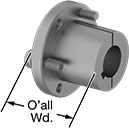

Taper-Lock Bushings

Mount these hubless bushings flush into your sprocket or pulley for a slim profile with no protruding screws. They are for use with taper-lock sprockets of the same bushing style. As you tighten the included set screws, the bushing grips the shaft and pulls it into your sprocket or pulley.

For technical drawings and 3-D models, click on a part number.

Keyway | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Wd. | Wd. | Dp. | Taper | Fastener Tightening Torque, in.-lbs. | Material | Includes | Each | |

1008 Style Bushing | |||||||||

| 14mm | 22mm | 5mm | 2.3mm | 8° | 55 | Steel | Set Screws | 000000000 | 000000 |

| 16mm | 22mm | 5mm | 2.3mm | 8° | 55 | Steel | Set Screws | 000000000 | 00000 |

1108 Style Bushing | |||||||||

| 14mm | 22mm | 5mm | 2.3mm | 8° | 55 | Steel | Set Screws | 000000000 | 00000 |

| 16mm | 22mm | 5mm | 2.3mm | 8° | 55 | Steel | Set Screws | 000000000 | 00000 |

1210 Style Bushing | |||||||||

| 14mm | 25mm | 5mm | 2.3mm | 8° | 175 | Steel | Set Screws | 000000000 | 00000 |

| 16mm | 25mm | 5mm | 2.3mm | 8° | 175 | Steel | Set Screws | 000000000 | 00000 |

1610 Style Bushing | |||||||||

| 14mm | 25mm | 5mm | 2.3mm | 8° | 175 | Steel | Set Screws | 000000000 | 00000 |

| 16mm | 25mm | 5mm | 2.3mm | 8° | 175 | Steel | Set Screws | 000000000 | 00000 |

Split-Tapered Bushings

The tapered barrel on these bushings is split on both sides, allowing them to contract more tightly around the shaft than quick-disconnect and taper-lock bushings. They're for use with split-tapered sprockets and pulleys of the same bushing style. As you tighten the included screws, the bushing grips the shaft and pulls it into the sprocket or pulley.

For technical drawings and 3-D models, click on a part number.

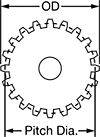

Metal Miter Gears

With straight, conically shaped teeth and a 1:1 speed ratio, miter gears connect two shafts at an angle without changing shaft speed or torque. They're more efficient than spiral miter gears because they create less friction.

For two gears to mesh correctly, they must have the same pressure angle, shaft angle, pitch/module, and number of teeth.

Carbon steel gears have hard, strong, and wear-resistant teeth. They’re best for heavy duty and high-torque applications, such as lifting equipment. However, these gears will rust when exposed to moisture or corrosive chemicals. Some gears have hardened teeth for additional wear resistance; gears with teeth that are not hardened can be hardened to fit your application.

For technical drawings and 3-D models, click on a part number.

Hub | Keyway | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Module | Number of Teeth | For Shaft Angle | Pressure Angle | Gear Pitch Dia., mm | OD, mm | Face Wd., mm | Overall Wd., mm | For Shaft Dia., mm | Mounting Distance, mm | Teeth Heat Treatment | Dia., mm | Wd., mm | Wd., mm | Dp., mm | Set Screw Thread Size | Each | |

Keyed Bore with Set Screw—1045 Carbon Steel | |||||||||||||||||

| 1.5 | 30 | 90° | 20° | 45 | 47.1 | 10 | 28.2 | 15 | 43 | Hardened | 36 | 16 | 5 | 2.3 | M5 | 000000 | 000000 |

| 2 | 20 | 90° | 20° | 40 | 42.8 | 10 | 24.9 | 15 | 37 | Hardened | 34 | 14 | 5 | 2.3 | M5 | 000000 | 00000 |

| 2 | 25 | 90° | 20° | 50 | 52.8 | 12 | 24.3 | 15 | 40 | Hardened | 40 | 10 | 5 | 2.3 | M5 | 0000000 | 00000 |

| 2 | 30 | 90° | 20° | 60 | 62.8 | 12 | 29.4 | 15 | 50 | Hardened | 45 | 12.5 | 5 | 2.3 | M5 | 0000000 | 00000 |