About Gears

More

About Roller Chain and Sprockets

More

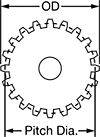

Corrosion-Resistant Sprockets for ANSI Roller Chain

Mount these sprockets onto your shaft and secure with a set screw—no machining necessary. Made of stainless steel, they withstand washdown conditions and harsh environments.

For technical drawings and 3-D models, click on a part number.

Keyway | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Number of Teeth | For Shaft Dia. | OD | Overall Wd. | Hub Dia. | Wd. | Dp. | Material | Includes | Each | |

For ANSI 35 Roller Chain (3/8" Pitch) | ||||||||||

| 10 | 3/8" | 1.38" | 3/4" | 31/32" | 0.094" | 3/64" | 18-8 Stainless Steel | Two Set Screws | 00000000 | 000000 |

| 11 | 3/8" | 1.5" | 3/4" | 1 1/16" | 0.094" | 3/64" | 18-8 Stainless Steel | Two Set Screws | 00000000 | 000000 |

| 12 | 3/8" | 1.63" | 3/4" | 1 7/32" | 0.094" | 3/64" | 18-8 Stainless Steel | Two Set Screws | 00000000 | 00000 |

| 13 | 3/8" | 1.75" | 3/4" | 1 1/4" | 0.094" | 3/64" | 18-8 Stainless Steel | Two Set Screws | 00000000 | 000000 |

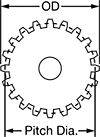

Metal Gears and Gear Racks—14 1/2° Pressure Angle

A former industry standard, 14½° pressure angle gears are often found on older machinery. Made of carbon steel, they have high strength and are better than plastic gears and gear racks for high-load, high-speed, and heavy duty applications.

Combine gears with different numbers of teeth to change speed and torque in your assembly. Combine a gear and rack to convert rotary motion into linear motion.

For components to mesh correctly, they must have the same pressure angle and pitch.

Gears with teeth that are not hardened can be hardened to fit your application. Hardening a gear's teeth increases its wear resistance.

For technical drawings and 3-D models, click on a part number.

Hub | Keyway | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gear Pitch | Number of Teeth | Gear Pitch Dia. | OD | Face Wd. | Overall Wd. | For Shaft Dia. | Material | Teeth Heat Treatment | Dia. | Wd. | Wd. | Dp. | Set Screw Thread Size | Each | |

Keyed Bore with Set Screw | |||||||||||||||

| 24 | 24 | 1" | 1.08" | 1/4" | 0.625" | 3/8" | 1144 Carbon Steel | Not Hardened | 0.875" | 0.375" | 0.094" | 0.047" | 10-24 | 0000000 | 000000 |

| 24 | 36 | 1 1/2" | 1.58" | 1/4" | 0.625" | 3/8" | 1144 Carbon Steel | Not Hardened | 1.125" | 0.375" | 0.094" | 0.047" | 10-24 | 0000000 | 00000 |

| 24 | 48 | 2" | 2.08" | 1/4" | 0.625" | 3/8" | 1144 Carbon Steel | Not Hardened | 1.25" | 0.375" | 0.094" | 0.047" | 10-24 | 0000000 | 000000 |

| 20 | 20 | 1" | 1.1" | 3/8" | 0.75" | 3/8" | 1144 Carbon Steel | Not Hardened | 0.859" | 0.375" | 0.094" | 0.047" | 10-24 | 0000000 | 00000 |

| 20 | 23 | 1.15" | 1.25" | 3/8" | 0.75" | 3/8" | 1144 Carbon Steel | Not Hardened | 0.969" | 0.375" | 0.094" | 0.047" | 10-24 | 0000000 | 00000 |

| 20 | 24 | 1.2" | 1.3" | 3/8" | 0.75" | 3/8" | 1144 Carbon Steel | Not Hardened | 1.063" | 0.375" | 0.094" | 0.047" | 1/4"-20 | 0000000 | 00000 |

| 20 | 25 | 1 1/4" | 1.35" | 3/8" | 0.75" | 3/8" | 1144 Carbon Steel | Not Hardened | 1.109" | 0.375" | 0.094" | 0.047" | 1/4"-20 | 0000000 | 00000 |

| 20 | 32 | 1.6" | 1.7" | 3/8" | 0.875" | 3/8" | 1144 Carbon Steel | Not Hardened | 1.439" | 0.5" | 0.094" | 0.047" | 1/4"-20 | 0000000 | 00000 |

| 20 | 36 | 1.8" | 1.9" | 3/8" | 0.875" | 3/8" | 1144 Carbon Steel | Not Hardened | 1.625" | 0.5" | 0.094" | 0.047" | 1/4"-20 | 0000000 | 00000 |

| 20 | 48 | 2.4" | 2.5" | 3/8" | 0.875" | 3/8" | 1144 Carbon Steel | Not Hardened | 2" | 0.5" | 0.094" | 0.047" | 10-24 | 0000000 | 000000 |

| 20 | 60 | 3" | 3.1" | 3/8" | 0.875" | 3/8" | 1144 Carbon Steel | Not Hardened | 2" | 0.5" | 0.094" | 0.047" | 10-24 | 0000000 | 000000 |

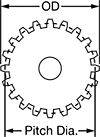

Metal Miter Gears

With straight, conically shaped teeth and a 1:1 speed ratio, miter gears connect two shafts at an angle without changing shaft speed or torque. They're more efficient than spiral miter gears because they create less friction.

For two gears to mesh correctly, they must have the same pressure angle, shaft angle, pitch/module, and number of teeth.

Carbon steel gears have hard, strong, and wear-resistant teeth. They’re best for heavy duty and high-torque applications, such as lifting equipment. However, these gears will rust when exposed to moisture or corrosive chemicals. Some gears have hardened teeth for additional wear resistance; gears with teeth that are not hardened can be hardened to fit your application.

For technical drawings and 3-D models, click on a part number.

Hub | Keyway | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gear Pitch | Number of Teeth | For Shaft Angle | Pressure Angle | Gear Pitch Dia. | OD | Face Wd. | Overall Wd. | For Shaft Dia. | Mounting Distance | Teeth Heat Treatment | Dia. | Wd. | Wd. | Dp. | Set Screw Thread Size | Each | |

Keyed Bore with Set Screw—1144 Carbon Steel | |||||||||||||||||

| 16 | 16 | 90° | 20° | 1" | 1.09" | 0.22" | 0.75" | 3/8" | 1.063" | Hardened | 0.75" | 0.438" | 0.094" | 0.047" | 10-24 | 0000000 | 000000 |

High-Power Metal Miter Gears

Also known as spiral miter gears, these gears have curved teeth that stay in contact longer than straight teeth so they handle heavier loads at higher speeds. They run quieter than standard miter gears because the teeth gradually engage. Use them to transmit motion at a right angle while maintaining shaft speed and torque. Gears are carbon steel for strength. Teeth are hardened for wear resistance.

Gears must be identical in order to mesh correctly; they're sold as a pair.

For technical drawings and 3-D models, click on a part number.

Hub | Keyway | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gear Pitch | Number of Teeth | Pressure Angle | Gear Pitch Dia. | OD | Face Wd. | Overall Wd. | For Shaft Dia. | Mounting Distance | Material | Dia. | Wd. | Wd. | Dp. | Set Screw Thread Size | Pair | |

Keyed Bore with Set Screw | ||||||||||||||||

| 18 | 18 | 20° | 1" | 1.07" | 0.22" | 0.74" | 3/8" | 1.062" | 1117 Carbon Steel | 0.75" | 0.44" | 0.094" | 0.047" | 10-32 | 000000 | 0000000 |