About Roller Chain and Sprockets

More

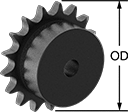

Sprockets for Metric Roller Chain

Designed to meet ISO 606 and DIN 8187 international dimensional standards, these sprockets are for use with compatible ISO and DIN roller chain. They come machined to the shaft diameter size listed and are machinable up to the maximum shaft diameter size.

For technical drawings and 3-D models, click on a part number.

| Number of Teeth | For Shaft Dia., mm | For Max. Shaft Dia., mm | OD, mm | Overall Wd., mm | Hub Dia., mm | Material | Specifications Met | Each | |

For ISO 05B Roller Chain (8 mm Pitch) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 26 | 10 | 22 | 69.5 | 16 | 40 | Steel | DIN 8187, ISO 606 | 0000000 | 000000 |

| 28 | 10 | 22 | 74.8 | 16 | 40 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

| 30 | 10 | 30 | 80.5 | 16 | 40 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

For ISO 06B Roller Chain (9.53 mm Pitch) | |||||||||

| 13 | 10 | 18 | 43 | 25 | 29 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

| 14 | 10 | 16 | 48.01 | 25 | 31 | Steel | DIN 8187, ISO 606 | 000000 | 00000 |

| 15 | 10 | 20 | 51.05 | 25 | 34 | Steel | DIN 8187, ISO 606 | 000000 | 00000 |

| 16 | 10 | 22 | 53.85 | 25 | 37 | Steel | DIN 8187, ISO 606 | 000000 | 00000 |

| 17 | 10 | 25 | 56.9 | 28 | 40 | Steel | DIN 8187, ISO 606 | 000000 | 00000 |

| 18 | 10 | 25 | 59.94 | 28 | 43 | Steel | DIN 8187, ISO 606 | 000000 | 00000 |

| 19 | 10 | 28 | 62.99 | 28 | 46 | Steel | DIN 8187, ISO 606 | 000000 | 00000 |

| 20 | 10 | 30 | 66.04 | 28 | 49 | Steel | DIN 8187, ISO 606 | 000000 | 00000 |

For ISO 08B Roller Chain (12.7 mm Pitch) | |||||||||

| 9 | 10 | 15 | 43.4 | 25 | 21 | Steel | DIN 8187, ISO 606 | 00000000 | 00000 |

| 10 | 10 | 20 | 47.4 | 25 | 26 | Steel | DIN 8187, ISO 606 | 00000000 | 00000 |

| 11 | 10 | 22 | 51.4 | 25 | 30 | Steel | DIN 8187, ISO 606 | 00000000 | 00000 |

| 12 | 10 | 22 | 55.88 | 28 | 34 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

| 13 | 10 | 25 | 59.4 | 28 | 38 | Steel | DIN 8187, ISO 606 | 00000000 | 00000 |

| 14 | 10 | 28 | 64.01 | 28 | 42 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

| 15 | 10 | 30 | 67.82 | 28 | 46 | Steel | DIN 8187, ISO 606 | 0000000 | 00000 |

Machinable-Bore Corrosion-Resistant Sprockets for Metric Roller Chain

Machine the center of these sprockets to fit the exact dimensions of your shaft. They come machined to the shaft diameter size listed and are machinable up to the maximum shaft diameter size. The teeth are sized to fit into metric ISO roller chain. Made from stainless steel, they won’t corrode from humidity or frequent washdowns. The extended hub makes these sprockets more stable and more durable than sprockets with flat hubs. They meet ISO 606 (formerly DIN 8187), which is an international standard for dimensions and materials.

For technical drawings and 3-D models, click on a part number.

| Number of Teeth | For Shaft Dia., mm | For Max. Shaft Dia., mm | OD, mm | Overall Wd., mm | Hub Dia., mm | Material | Specifications Met | Each | |

For ISO 06B Roller Chain (9.53 mm Pitch) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 14 | 10 | 19 | 48.36 | 25 | 31 | Stainless Steel | DIN 8187, ISO 606 | 0000000 | 0000000 |

| 17 | 10 | 25 | 57.39 | 25 | 40 | Stainless Steel | DIN 8187, ISO 606 | 0000000 | 000000 |

For ISO 08B Roller Chain (12.7 mm Pitch) | |||||||||

| 12 | 10 | 22 | 56.44 | 28 | 34 | Stainless Steel | DIN 8187, ISO 606 | 0000000 | 000000 |

| 15 | 10 | 30 | 68.45 | 28 | 46 | Stainless Steel | DIN 8187, ISO 606 | 0000000 | 000000 |

Flat Sprockets for Metric Roller Chain

With metric teeth and slim profile, these sprockets allow your ISO roller chain to reach narrow spaces. They're commonly referred to as A-plate sprockets. Machine the unfinished bore to fit your shaft—sprockets come machined to the shaft diameter listed and are machinable up to the maximum shaft diameter size. Sprockets meet DIN 8187 and ISO 606, international standards for sprockets and roller chains.

For technical drawings and 3-D models, click on a part number.

| Number of Teeth | For Shaft Dia., mm | For Max. Shaft Dia., mm | OD, mm | Overall Wd., mm | Material | Specifications Met | Each | |

For ISO 06B Roller Chain (9.525 mm Pitch) | ||||||||

|---|---|---|---|---|---|---|---|---|

| 16 | 10 | 39 | 53.85 | 6 | Steel | DIN 8187, ISO 606 | 00000000 | 000000 |

| 17 | 10 | 42 | 56.9 | 6 | Steel | DIN 8187, ISO 606 | 00000000 | 00000 |

| 18 | 10 | 45 | 59.94 | 6 | Steel | DIN 8187, ISO 606 | 00000000 | 00000 |

| 20 | 10 | 51 | 66.04 | 6 | Steel | DIN 8187, ISO 606 | 00000000 | 00000 |

| 21 | 10 | 54 | 69.09 | 6 | Steel | DIN 8187, ISO 606 | 00000000 | 00000 |

| 22 | 10 | 57 | 72.14 | 6 | Steel | DIN 8187, ISO 606 | 00000000 | 00000 |

| 26 | 10 | 69 | 84.07 | 6 | Steel | DIN 8187, ISO 606 | 00000000 | 00000 |

| 28 | 10 | 75 | 90.17 | 6 | Steel | DIN 8187, ISO 606 | 00000000 | 00000 |

For ISO 08B Roller Chain (12.7 mm Pitch) | ||||||||

| 13 | 10 | 38 | 59.94 | 8 | Steel | DIN 8187, ISO 606 | 00000000 | 00000 |

| 14 | 10 | 43 | 64.01 | 8 | Steel | DIN 8187, ISO 606 | 00000000 | 00000 |

| 15 | 10 | 47 | 67.82 | 8 | Steel | DIN 8187, ISO 606 | 00000000 | 00000 |

| 16 | 10 | 51 | 71.88 | 8 | Steel | DIN 8187, ISO 606 | 00000000 | 00000 |

| 17 | 10 | 55 | 75.95 | 8 | Steel | DIN 8187, ISO 606 | 00000000 | 00000 |

| 18 | 10 | 59 | 80.01 | 8 | Steel | DIN 8187, ISO 606 | 00000000 | 00000 |

| 20 | 10 | 67 | 88.14 | 8 | Steel | DIN 8187, ISO 606 | 00000000 | 00000 |

Sprockets for Double-Strand Metric Roller Chain

The double row of teeth on these sprockets are designed to fit into metric ISO double-strand roller chain. They have an unfinished bore that’s machined to the shaft diameter size listed. Machine them to fit any shaft up to the maximum shaft diameter size. The extended hub makes these sprockets more stable and more durable than flat sprockets. They meet ISO 606 (formerly DIN 8187), which is an international standard for sprocket and roller chain dimensions and materials.

For technical drawings and 3-D models, click on a part number.

| Number of Teeth | For Shaft Dia., mm | For Max. Shaft Dia., mm | OD, mm | Overall Wd., mm | Hub Dia., mm | Material | Specifications Met | Each | |

For ISO 06B-2 Roller Chain (9.53 mm Pitch) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 12 | 10 | 16 | 42.36 | 25 | 25 | Steel | DIN 8187, ISO 606 | 00000000 | 000000 |

| 14 | 10 | 18 | 48.36 | 25 | 31 | Steel | DIN 8187, ISO 606 | 00000000 | 00000 |

| 15 | 10 | 20 | 51.37 | 25 | 34 | Steel | DIN 8187, ISO 606 | 00000000 | 00000 |

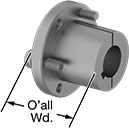

Split-Tapered Bushings

The tapered barrel on these bushings is split on both sides, allowing them to contract more tightly around the shaft than quick-disconnect and taper-lock bushings. They're for use with split-tapered sprockets and pulleys of the same bushing style. As you tighten the included screws, the bushing grips the shaft and pulls it into the sprocket or pulley.

For technical drawings and 3-D models, click on a part number.

| For Shaft Dia. | Overall Wd. | Taper | Fastener Tightening Torque, in.-lbs. | Each | |

Steel | |||||

|---|---|---|---|---|---|

H Style Bushing | |||||

| 10mm | 1 1/4" | 3° | 95 | 00000000 | 000000 |

Hex Flanged Eccentric Bushings

Often used with V-groove wheels or track roller carriages, these off-center bushings create precise mounting clearance. As you turn the bushing’s hex flange with a wrench, it adjusts the distance between the V-groove wheel or carriage and the rail. Tighten the axle bolt in place once you’ve adjusted them. Made of 303 stainless steel, these bushings have very good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

| For Hole Diameter | Overall Width | Flange Height | Hex Size | Material | Each | |

| 15mm | 30mm | 11mm | 22mm | 303 Stainless Steel | 00000000 | 000000 |

Quick-Grip Screw-Clamp Bushings

Also known as Trantorque bushings, these tighten with a twist of the collar nut—no screws needed. As you tighten the collar nut, the inner sleeve contracts onto the shaft and the outer sleeve expands to hold your sprocket, pulley, or gear.

For technical drawings and 3-D models, click on a part number.

| For Shaft Dia. | OD | Overall Wd. | Max. Torque, in.-lbs. | Each | |

Steel | |||||

|---|---|---|---|---|---|

| 10mm | 23mm | 26mm | 600 | 0000000 | 000000 |