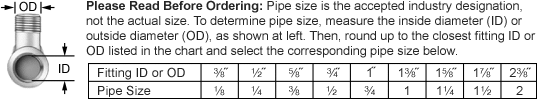

About Pipe Size and Spray Nozzles

More

Rotating Tank-Washing Nozzles

By circulating their spray, these nozzles clean faster with more even coverage and less water than stationary tank-washing nozzles. The force of the liquid flowing through is what causes them to rotate, so the higher the pressure, the faster they will rotate. They spray in multiple directions to effectively rinse down tanks, drums, and small vessels.

316 stainless steel and PVDF nozzles have good resistance to chemicals and corrosion.

FDA-compliant nozzles can be used in the food industry.

For technical drawings and 3-D models, click on a part number.

Flow Rate, gpm | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Pattern | Spray Angle | Specifications Met | Environment | Each | ||

1/2 BSPP Female | |||||||||||||||

| H | 4 | 6 | 7 | 5 | 0.03" | 1 3/16" | 3" | 70 | 190° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 177.2510 | Food Industry | 00000000 | 000000 |

Foam-Spray Rotating Tank-Washing Nozzles

Use these nozzles with detergent that’s diluted in water to create a rotating, multi-directional foam spray for effectively rinsing tanks, drums, and small vessels. Because they rotate, these nozzles clean faster and produce more even coverage than stationary tank-cleaning spray nozzles, typically while using less liquid. The force of the liquid flowing through these nozzles makes them spin, so they’ll spin faster at higher pressures.

For technical drawings and 3-D models, click on a part number.

Rotating High-Pressure Spray Nozzles

These nozzles combine the cleaning ability of a solid stream with a rotating spray action that produces a hollow cone for more coverage. They have good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Flow Rate, gpm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 500 psi | @ 1,000 psi | @ 2,000 psi | @ 3,500 psi | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Cover Material | Spray Angle | Each | |

Brass | ||||||||||||

1/4 BSPP Female | ||||||||||||

| 1.52 | 2.15 | 3.05 | 4.02 | 0.055" | 1 1/2" | 4 1/8" | 3,500 | 200° | Plastic | 0°-40° | 00000000 | 000000 |

| 1.72 | 2.43 | 3.44 | 4.55 | 0.059" | 1 1/2" | 4 1/8" | 3,500 | 200° | Plastic | 0°-40° | 00000000 | 00000 |

| 2.06 | 2.92 | 4.12 | 5.46 | 0.063" | 1 1/2" | 4 1/8" | 3,500 | 200° | Plastic | 0°-40° | 00000000 | 00000 |

Adjustable-Flow/Adjustable Spray-Angle High-Pressure Spray Nozzles

Push the nozzle out for lower pressures and pull it back for higher pressures. Turn the cover to adjust the spray angle from 0° to 25° or 75°. Use with pressure washers and in other high pressure washing and rinsing applications. All have good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Flow Rate, gpm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 500 psi | @ 1,000 psi | @ 2,500 psi | @ 4,050 psi | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Cover Material | Spray Angle | Each | |

Brass | ||||||||||||

1/4 BSPP Female | ||||||||||||

| 0.88 | 1.25 | 1.98 | 2.5 | 0.04" | 1 3/4" | 4 1/2" | 4,050 | 195° | Plastic | 0°-25°; 75° | 00000000 | 000000 |

| 1.06 | 1.5 | 2.37 | 3 | 0.04" | 1 3/4" | 4 1/2" | 4,050 | 195° | Plastic | 0°-25°; 75° | 00000000 | 00000 |

| 1.41 | 2 | 3.16 | 4 | 0.05" | 1 3/4" | 4 1/2" | 4,050 | 195° | Plastic | 0°-25°; 75° | 00000000 | 00000 |

| 2.47 | 3.5 | 5.53 | 7 | 0.07" | 1 3/4" | 4 1/2" | 4,050 | 195° | Plastic | 0°-25°; 75° | 00000000 | 00000 |

Diesel Exhaust Fluid Hose Nozzles

To avoid contaminating diesel exhaust fluid (DEF), these nozzles are made of anodized aluminum and have a stainless steel spout. Similar to pumps at a gas station, these let you control how much DEF flows into your tank at once with the trigger or the hold-open clip. The clip adjusts to two different positions, each with a different flow rate. The design of the tip keeps the flow smooth and steady, reducing spills. When your tank is full, these nozzles stop dispensing automatically. A PVC scuff guard protects them from bumps and scrapes.

Threaded swivels and thread sealants (both sold separately) also won’t contaminate DEF. Threaded swivels install between your hose and these nozzles to prevent your line from twisting, kinking, and wearing prematurely. Splash guards (sold separately) protect your hands from spray.

Splash Guard | |||

|---|---|---|---|

| Material | Color | Each | |

| PVC Plastic | Blue | 0000000 | 00000 |