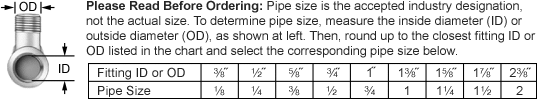

About Pipe Size and Spray Nozzles

More

Tank-Washing Nozzles

To effectively rinse tanks, drums, and small vessels, these nozzles spray in multiple directions. The simplest style of tank-cleaning nozzle, they don't have any moving parts that will wear or need maintenance.

Brass and nylon nozzles have good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Flow Rate, gpm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 30 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Angle | Each | |

1/2 NPT Female | ||||||||||||

| 3.9 | 4.7 | 5.5 | 6.7 | 5 | 0.03" | 1 3/16" | 1 3/4" | 150 | 200° | 240° | 000000000 | 0000000 |

| 12.5 | 15.1 | 17.7 | 22 | 5 | 0.06" | 1 3/16" | 1 3/4" | 150 | 200° | 240° | 000000000 | 000000 |

3/4 NPT Female | ||||||||||||

| 26 | 31.5 | 37 | 46 | 5 | 0.09" | 1 13/16" | 2 7/16" | 150 | 200° | 240° | 000000000 | 000000 |

Wide-Airflow Air Nozzles

The flat nozzle tip distributes air over a wider area than focused-airflow nozzles. Volume (dBA) is measured 3 ft. from the nozzle at 80 psi.

Nozzles that are OSHA Compliant 29 CFR 1910.242 conform to requirements for maximum air outlet pressure.

For technical drawings and 3-D models, click on a part number.

Tip | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Air Consumption | Max. Temp., °F | Volume | Wd. | Thick. | O'all Lg. | Max. Inlet Pressure, psi | Specifications Met | Each | ||

1/4 NPT Male Inlet | ||||||||||

Nylon Plastic | ||||||||||

| B | 24 cfm @ 100 psi | 350° | 84 dBA @ 80 psi | 1 7/8" | 1/4" | 2 9/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 0000000 | 0000000 |

| B | 58 cfm @ 100 psi | 350° | 90 dBA @ 80 psi | 2 3/4" | 1/4" | 2 9/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 0000000 | 000000 |

1/4 BSPP Male Inlet | ||||||||||

Nylon Plastic | ||||||||||

| B | 52 cfm @ 85 psi | 355° | 90 dBA @ 80 psi | 2 3/4" | 1/4" | 2 9/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 0000000 | 000000 |

1/2 NPT Male Inlet | ||||||||||

Nylon Plastic | ||||||||||

| B | 165 cfm @ 100 psi | 350° | 96 dBA @ 80 psi | 5 9/16" | 1/4" | 3 13/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 0000000 | 000000 |

1/2 BSPP Male Inlet | ||||||||||

Nylon Plastic | ||||||||||

| B | 156 cfm @ 85 psi | 355° | 96 dBA @ 80 psi | 5 9/16" | 1/4" | 3 13/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 0000000 | 000000 |

Bend-and-Stay Air Nozzles

Nozzles are attached to a flexible hose that bends and holds its shape until you reposition it. They conform to OSHA 29 CFR 1910.242 requirements for maximum air outlet pressure.

For technical drawings and 3-D models, click on a part number.

Air Inlet | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Air Consumption | Max. Temp., °F | Volume | Tip OD | O'all Lg. | Max. Inlet Pressure, psi | Material | Hose Material | Specifications Met | Each | ||

| C | 1/8 | NPT | Male | 14 cfm @ 100 psi | 100° | 85 dBA @ 80 psi | 1/4" | 7 1/2" | 90 | Nylon Plastic | Nylon Plastic | OSHA Compliant 29 CFR 1910.242 | 0000000 | 000000 |

Cold-Air Nozzles

Often used for simultaneously spot cooling and blowing parts, these nozzles cool compressed air without electricity or refrigerants. One collar on these nozzles adjusts airflow to control how much air they're using and how noisy they are. The other collar adjusts the air temperature.

For technical drawings and 3-D models, click on a part number.

Air Inlet | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cooling Cap., Btu/hr. | Pipe Size | Thread Type | Gender | Air Consumption | Max. Temp., °F | Volume | Tip OD | O'all Lg. | Max. Inlet Pressure, psi | Material | Specifications Met | Each | |

| 79-468 | 1/4 | NPT | Female | 10 cfm-23 cfm @ 100 psi | 245° | 76 dBA @ 80 psi | 11/16" | 6 11/16" | 145 | Nylon Plastic | OSHA Compliant 29 CFR 1910.242; OSHA Compliant 29 CFR 1910.95 | 0000000 | 0000000 |

Air-Powered Tube Cleaners

Launch foam cylinders through hose and tubing to power away dirt and deposits. Unlike cleaners with brushes, these work on flexible, curved, and coiled tubing as well as those with fittings, valves, and 90° bends. Connect the gun to your compressed air with the included quick-disconnect fitting. Attach a nozzle and load a cylinder that matches your tube ID, and then insert the nozzle into your tube and pull the trigger. To thoroughly clean the tubing, you may have to use a second cylinder. Cylinders are single use.