About Actuated On/Off Valves

More

Sealed Linear Solenoids

Spend less time on solenoid maintenance in dirty environments—these have a closed steel housing that keeps dust out.

Pull solenoids exert force when the rod retracts.

Push solenoids exert force when the rod extends.

For technical drawings and 3-D models, click on a part number.

Length | Overall | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Stroke Lg. | Retracted | Extended | Overall | Force @ 50% Stroke Lg., oz. | Choose a Voltage | Power Draw, Watts | On/Off Time, Minutes | Dia. | Wd. | Ht. | Rod Dia. (R) | Each | |

For DC Voltage | |||||||||||||

Pull | |||||||||||||

| 1/4" | 1.6" | 1.9" | 1.9" | 5 | 7.5 | 1/9 | 1/2" | 1/2" | 1/2" | 0.2" | 000000000 | 000000 | |

| 1/2" | 2.4" | 2.9" | 2.9" | 15 | 24 | 1/9 | 3/4" | 3/4" | 3/4" | 1/4" | 000000000 | 00000 | |

| 1" | 2.9" | 3.9" | 3.9" | 29 | 38 | 1/9 | 1" | 1" | 1" | 0.44" | 000000000 | 00000 | |

| 1" | 3.3" | 4.3" | 4.3" | 79 | 59 | 1/9 | 1 1/2" | 1 1/2" | 1 1/2" | 1/2" | 000000000 | 00000 | |

Push | |||||||||||||

| 1/4" | 1.5" | 1.7" | 1.7" | 3 | 7.5 | 1/9 | 1/2" | 1/2" | 1/2" | 0.06" | 000000000 | 00000 | |

| 1/2" | 2.6" | 3.1" | 3.1" | 78 | 41 | 1/9 | 1 1/2" | 1 1/2" | 1 1/2" | 0.19" | 000000000 | 00000 | |

| 1/2" | 2.8" | 3.3" | 3.3" | 25 | 38 | 1/9 | 1" | 1" | 1" | 0.11" | 000000000 | 00000 | |

| 1" | 3.4" | 4.4" | 4.4" | 68 | 59 | 1/9 | 1 1/2" | 1 1/2" | 1 1/2" | 0.19" | 000000000 | 00000 | |

Extended-Life Sealed Linear Solenoids

In addition to a closed steel housing that keeps out dust, these solenoids have a PTFE coating on the rod to minimize friction for a long service life. All are pull solenoids—they exert force when the rod retracts.

For technical drawings and 3-D models, click on a part number.

Length | Overall | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Stroke Lg. | Retracted | Extended | Overall | Force @ 50% Stroke Lg., oz. | Choose a Voltage | Power Draw, Watts | On/Off Time, Minutes | Dia. | Wd. | Ht. | Rod Dia. (R) | Each | |

For DC Voltage | |||||||||||||

Pull | |||||||||||||

| 1/4" | 1.8" | 2" | 2" | 2 | 5.6 | 1.7/5 | 1/2" | 1/2" | 1/2" | 0.16" | 0000000 | 0000000 | |

| 1/2" | 2.4" | 2.9" | 2.9" | 10 | 11 | 1.7/5 | 3/4" | 3/4" | 3/4" | 0.31" | 0000000 | 00000 | |

| 3/4" | 3.1" | 3.9" | 3.9" | 25 | 20.4 | 1.7/5 | 1" | 1" | 1" | 0.44" | 0000000 | 00000 | |

| 1" | 3.4" | 4.4" | 4.4" | 45 | 32.4 | 1.7/5 | 1 1/2" | 1 1/2" | 1 1/2" | 1/2" | 0000000 | 000000 | |

Water-Resistant Sealed Linear Solenoids

Great for use in damp and dirty environments, these solenoids meet IP65 for protection from dust and spraying water. They have two-pin plugs that are compatible with Deutsch-style DC connectors (sold separately). They can be used to pull or push. To pull, install them with the connector pins facing your device; to push, install them facing away.

For technical drawings and 3-D models, click on a part number.

Length | Overall | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Stroke Lg. | Retracted | Extended | Overall | Force @ 50% Stroke Lg., oz. | Choose a Voltage | Power Draw, Watts | On/Off Time, Minutes | Wd. | Ht. | Rod Dia. (R) | Environmental Rating | Each | |

For DC Voltage | |||||||||||||

Pull/Push | |||||||||||||

| 0.39" | 4.6" | 4.6" | 4.6" | 115 | 50 | 1/3 | 2 1/4" | 2 1/4" | 0.2" | IP65 | 00000000 | 0000000 | |

| 0.51" | 4.7" | 4.7" | 4.7" | 177 | 60 | 1/3 | 2 7/8" | 2 3/4" | 0.2" | IP65 | 00000000 | 000000 | |

Linear Solenoids

Create linear motion economically with one of these open-frame solenoids.

Pull solenoids exert force when the rod retracts.

Push solenoids exert force when the rod extends.

Pull/push solenoids exert force when the rod retracts and extends.

For technical drawings and 3-D models, click on a part number.

Length | Overall | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Stroke Lg. | Retracted | Extended | Overall | Force @ 50% Stroke Lg., oz. | Choose a Voltage | Power Draw, Watts | On/Off Time, Minutes | Wd. | Ht. | Rod Dia. (R) | Specifications Met | Each | |

For AC Voltage, 60 Hz | |||||||||||||

Pull | |||||||||||||

| 1/2" | 1.7" | 2.2" | 2.2" | 13 | 120V AC | 18 | 1/3 | 1 1/4" | 1 1/4" | 0.31" | UL Recognized Component | 000000000 | 000000 |

| 1/2" | 2.5" | 3" | 3" | 22 | 120V AC | 40.9 | 1/3 | 1 1/4" | 1 1/4" | 0.31" | UL Recognized Component | 000000000 | 00000 |

| 1" | 3.2" | 4.2" | 4.3" | 34 | 120V AC | 57.6 | 1/3 | 1 3/4" | 1 3/4" | 0.44" | UL Recognized Component | 000000000 | 00000 |

Push | |||||||||||||

| 1/2" | 1.9" | 1.9" | 2" | 13 | 120V AC | 23 | 1/3 | 1 1/4" | 1 1/4" | 0.09" | UL Recognized Component | 000000000 | 00000 |

| 1/2" | 3.1" | 3.1" | 3.3" | 21 | 120V AC | 52.4 | 1/3 | 1 1/4" | 1 1/4" | 0.09" | UL Recognized Component | 000000000 | 00000 |

For DC Voltage | |||||||||||||

Pull | |||||||||||||

| 1/2" | 1.7" | 2.2" | 2.2" | 9 | 11.5 | 1/3 | 1 1/4" | 1 1/4" | 0.31" | UL Recognized Component | 000000000 | 00000 | |

| 1/2" | 2.5" | 3" | 3" | 26 | 19 | 1/3 | 1 1/4" | 1 1/4" | 0.31" | UL Recognized Component | 000000000 | 00000 | |

| 1" | 3.2" | 4.2" | 4.3" | 52 | 38 | 1/3 | 1 3/4" | 1 3/4" | 0.44" | UL Recognized Component | 000000000 | 00000 | |

Pull/Push | |||||||||||||

| 0.19" | 2" | 2.2" | 2.2" | 8 | 7.2 | 0.2/1.5 | 1" | 3/4" | 0.13" | __ | 00000000 | 000000 | |

Push | |||||||||||||

| 1/2" | 3.1" | 3.1" | 3.3" | 26 | 19 | 1/3 | 1 1/4" | 1 1/4" | 0.09" | UL Recognized Component | 000000000 | 00000 | |

| 1" | 3.2" | 3.2" | 3.2" | 13 | 30 | 0.8/2.5 | 1" | 1 1/4" | 0.13" | __ | 00000000 | 00000 | |

Compact Linear Solenoids

A thin profile allows these solenoids to fit well in narrow spaces. You can use them to push or pull—use the side with the unthreaded rod (R) and two mounting studs to push or use the opposite side with the threaded rod to pull.

For technical drawings and 3-D models, click on a part number.

Rod Length (Pulling) | Rod Length (Pushing) | Overall | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Stroke Lg. | Retracted | Extended | Retracted | Extended | Force @ 100% Stroke Lg., oz. | Choose a Voltage | Power Draw, Watts | On/Off Time, Seconds | Dia. | Lg. | Rod Dia. (R) | Each | |

For DC Voltage | |||||||||||||

Pull/Push | |||||||||||||

| 0.2" | 0.5" | 0.7" | 0.3" | 0.5" | 7 | 18 | 30/90 | 1 1/4" | 1 1/2" | 0.16" | 000000 | 0000000 | |

| 0.3" | 0.6" | 0.9" | 0.2" | 0.5" | 1 | 16 | 20/60 | 1" | 1 3/4" | 0.13" | 000000 | 00000 | |

| 0.7" | 1.9" | 2.6" | 0.3" | 1" | 50 | 80 | 90/270 | 2 3/4" | 4 3/4" | 0.38" | 000000 | 000000 | |

High-Force Linear Solenoids

High-force solenoids draw more power than our other open-frame solenoids, so they can deliver higher force. They also have a laminated rod that minimizes friction during operation.

Pull solenoids exert force when the rod retracts.

Push solenoids exert force when the rod extends.

For technical drawings and 3-D models, click on a part number.

Length | Overall | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Stroke Lg. | Retracted | Extended | Overall | Force @ 50% Stroke Lg., oz. | Voltage | Power Draw, Watts | On/Off Time, Minutes | Wd. | Ht. | Rod Dia. (R) | Each | |

For AC Voltage, 60 Hz | ||||||||||||

Pull | ||||||||||||

| 1" | 2.3" | 3" | 3" | 60 | 120V AC | 70 | 2.5/22.5 | 1 1/2" | 1 1/2" | 0.36" | 000000 | 0000000 |

| 1" | 2.7" | 3.4" | 3.4" | 195 | 120V AC | 228 | 3/27 | 1 7/8" | 2 1/8" | 0.49" | 000000 | 00000 |

| 1" | 2.7" | 3.4" | 3.4" | 195 | 240V AC | 228 | 3/27 | 1 7/8" | 2 1/8" | 0.49" | 000000 | 00000 |

Push | ||||||||||||

| 0.82" | 3" | 3" | 3" | 60 | 120V AC | 70 | 2.5/22.5 | 1 1/2" | 1 1/2" | 0.13" | 000000 | 000000 |

| 1" | 3 1/2" | 3.5" | 3.5" | 195 | 120V AC | 228 | 3/27 | 1 7/8" | 2 1/8" | 0.19" | 0000000 | 000000 |

Rotary Solenoids

Convert electricity into rotational motion to actuate switches, valves, and locks. These solenoids have a built-in spring that returns the rod to its original position, making them good for use in valves that require precision to fully open or close.

Intermittent-use solenoids are designed to run for seconds or minutes at a time with rest in between.

For technical drawings and 3-D models, click on a part number.

Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Max. Stroke Rotation | Torque @ 50% Rotation, in.-oz. | Choose a Direction of Force | Power Draw, Watts | On/Off Time, Minutes | Dia. | Lg. | Rod Dia. (R) | Each | |

12V DC | |||||||||

| 40° | 11.2 | 36 | 1/3 | 1 1/2" | 1 3/4" | 0.19" | 0000000 | 0000000 | |

| 40° | 17 | 40 | 1.5/4.5 | 2" | 2 1/4" | 0.24" | 0000000 | 000000 | |

| 40° | 24 | 44 | 1.5/4.5 | 2" | 2 1/4" | 0.24" | 0000000 | 000000 | |

| 40° | 41 | 48 | 3.5/10.5 | 2 3/4" | 2 1/4" | 0.24" | 0000000 | 000000 | |

24V DC | |||||||||

| 40° | 11.2 | 36 | 1/3 | 1 1/2" | 1 3/4" | 0.19" | 0000000 | 000000 | |

| 40° | 17 | 40 | 1.5/4.5 | 2" | 2 1/4" | 0.24" | 0000000 | 000000 | |

| 40° | 24 | 44 | 1.5/4.5 | 2" | 2 1/4" | 0.24" | 0000000 | 000000 | |

| 40° | 41 | 48 | 3.5/10.5 | 2 3/4" | 2 1/4" | 0.24" | 0000000 | 000000 | |

Solenoid Diverting Valves for Chemicals

- For Use With: Acetone, Air, Ammonia, Argon, Chlorine, Citric Acid, Deionized Water, Diesel Fuel, Ethylene Glycol, Fuel Oil, Helium, Hydrochloric Acid, Krypton, Methanol, Neon, Nitric Acid, Oil, Oxygen, Phosphoric Acid, Salt Water, Sulfuric Acid, Water, Xenon, Xylene

- Seal Material: PTFE Plastic

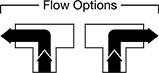

Often used for chemical analysis and other laboratory testing, these valves have a PTFE seal and body to withstand aggressive and corrosive solutions. All operate on electricity to automatically divert flow between ports. They do not require a pressure drop for operation. Any port can be used as an inlet or an outlet. Valves can direct flow from the inlet port to either outlet port. They cannot shut off flow. The actuator is mounted directly to the valve body to minimize movement and reduce wear.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

Mounting Holes | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Size | Flow Pattern | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Min. Pressure Drop Required | Temp. Range, °F | Actuation Time | Valve Lg. | O'all Ht. | Mounting Fasteners Included | No. of | Thread Size | Each | |

PTFE Plastic Body with Wire Leads—12V DC | |||||||||||||||

NPSM Female × NPSM Female × NPSM Female | |||||||||||||||

| 1/8 | __ | L-Pattern | 15.85 | 30 psi @ 70° F | Zero Pressure Drop | None | 35° to 155° | 0.04 sec. | 1 3/4" | 2" | No | 7 | 4-40 | 0000000 | 0000000 |

UNF Female × UNF Female × UNF Female | |||||||||||||||

| __ | 1/4"-28 | L-Pattern | 10.57 | 30 psi @ 70° F | Zero Pressure Drop | None | 35° to 155° | 0.02 sec. | 1 1/2" | 1 13/16" | No | 7 | 4-40 | 0000000 | 000000 |

| __ | 10-32 | L-Pattern | 2.64 | 30 psi @ 70° F | Zero Pressure Drop | None | 35° to 155° | 0.02 sec. | 3/4" | 1 3/16" | No | 5 | 2-56 | 0000000 | 000000 |

PTFE Plastic Body with Wire Leads—24V DC | |||||||||||||||

NPSM Female × NPSM Female × NPSM Female | |||||||||||||||

| 1/8 | __ | L-Pattern | 15.85 | 30 psi @ 70° F | Zero Pressure Drop | None | 35° to 155° | 0.04 sec. | 1 3/4" | 2" | No | 7 | 4-40 | 0000000 | 000000 |

UNF Female × UNF Female × UNF Female | |||||||||||||||

| __ | 1/4"-28 | L-Pattern | 10.57 | 30 psi @ 70° F | Zero Pressure Drop | None | 35° to 155° | 0.02 sec. | 1 1/2" | 1 13/16" | No | 7 | 4-40 | 0000000 | 000000 |

| __ | 10-32 | L-Pattern | 2.64 | 30 psi @ 70° F | Zero Pressure Drop | None | 35° to 155° | 0.02 sec. | 3/4" | 1 3/16" | No | 5 | 2-56 | 0000000 | 000000 |