About Actuated On/Off Valves

More

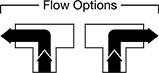

Matching Flow Diagrams to Replace an Air Directional Control Valve

More

Choosing an Air Directional Control Valve

More

Compact Solenoid On/Off Valves with Push-to-Connect Fittings

- For Use With: Water, Air, Argon, Helium, Neon, Xenon, Krypton

- Seal Material: Buna-N Rubber

- Specifications Met: CSA Certified

Insert tubing into the fittings on these valves—no heat, solder, or flux required. They operate on electricity to automatically start and stop flow.

Valves are normally closed unless actuated. They don’t require a minimum pressure drop between the inlet and outlet for operation. The actuator is directly mounted to the valve body to minimize movement and reduce wear.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | Gender | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Temp. Range, °F | Valve Lg. | O'all Ht. | Quick-Disconnect Tab Wd. | Each | |

Polycarbonate Plastic Body with Quick-Disconnect Terminals | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Normally Closed—24V DC | ||||||||||

| 1/4" | Female | 0.31 | 80 psi @ 70° F | Zero Pressure Drop | -10° to 100° | 2" | 3" | 1/4" | 00000000 | 0000000 |

| 1/4" | Female | 0.37 | 40 psi @ 70° F | Zero Pressure Drop | -10° to 100° | 2" | 3" | 1/4" | 00000000 | 000000 |

| 3/8" | Female | 1 | 5 psi @ 70° F | Zero Pressure Drop | -10° to 100° | 2 3/8" | 3" | 1/4" | 00000000 | 000000 |

Normally Closed—120V AC | ||||||||||

| 1/4" | Female | 0.31 | 80 psi @ 70° F | Zero Pressure Drop | -10° to 100° | 2" | 3" | 1/4" | 00000000 | 000000 |

| 1/4" | Female | 0.37 | 40 psi @ 70° F | Zero Pressure Drop | -10° to 100° | 2" | 3" | 1/4" | 00000000 | 000000 |

| 3/8" | Female | 1 | 5 psi @ 70° F | Zero Pressure Drop | -10° to 100° | 2 3/8" | 3" | 1/4" | 00000000 | 000000 |

Polysulfone Plastic Body with Quick-Disconnect Terminals | ||||||||||

Normally Closed—24V DC | ||||||||||

| 1/4" | Female | 0.23 | 120 psi @ 70° F | Zero Pressure Drop | -10° to 100° | 2" | 3" | 1/4" | 00000000 | 000000 |

Normally Closed—120V AC | ||||||||||

| 1/4" | Female | 0.23 | 120 psi @ 70° F | Zero Pressure Drop | -10° to 100° | 2" | 3" | 1/4" | 00000000 | 000000 |

Solenoid On/Off Valves with Flow Adjustment

- For Use With: Water

- Seal Material: EPDM Rubber

Turn the knob to adjust how much these valves will open or close when actuated. They are often used in irrigation and landscaping applications. All operate on electricity to automatically start and stop flow.

These valves require a minimum pressure drop between the inlet and the outlet for operation; the upstream pressure must be greater than the downstream pressure. The actuator is directly mounted to the valve body to minimize movement and reduce wear.

Normally closed valves are closed unless actuated. Normally open valves are open unless actuated.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Gender | Thread Type | Max. Pressure | Pressure Drop | Temp. Range, °F | Valve Lg. | O'all Ht. | Each | |

Nylon Plastic Body with Wire Leads | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Normally Closed—24V AC | |||||||||

| 1 | Female | NPT | 175 psi @ 70° F | Pressure Drop Assisted | 35° to 150° | 4 1/4" | 5 1/2" | 00000000 | 000000 |

| 1 1/2 | Female | NPT | 160 psi @ 70° F | Pressure Drop Assisted | 35° to 150° | 5 13/16" | 7 1/16" | 00000000 | 000000 |

| 2 | Female | NPT | 160 psi @ 70° F | Pressure Drop Assisted | 35° to 150° | 6 1/2" | 8 1/2" | 00000000 | 000000 |

Normally Closed—120V AC | |||||||||

| 1 | Female | NPT | 175 psi @ 70° F | Pressure Drop Assisted | 35° to 150° | 4 1/4" | 5 1/2" | 00000000 | 00000 |

| 1 1/2 | Female | NPT | 160 psi @ 70° F | Pressure Drop Assisted | 35° to 150° | 5 13/16" | 7 1/16" | 00000000 | 000000 |

| 2 | Female | NPT | 160 psi @ 70° F | Pressure Drop Assisted | 35° to 150° | 6 1/2" | 8 1/2" | 00000000 | 000000 |

Normally Open—24V AC | |||||||||

| 1 | Female | NPT | 175 psi @ 70° F | Pressure Drop Assisted | 35° to 150° | 4 1/4" | 5 15/16" | 00000000 | 000000 |

Normally Open—120V AC | |||||||||

| 1 | Female | NPT | 175 psi @ 70° F | Pressure Drop Assisted | 35° to 150° | 4 1/4" | 5 15/16" | 00000000 | 000000 |

Compact Solenoid On/Off Valves for Coolant

- For Use With: Ethylene Glycol

- Seal Material: Fluoroelastomer Rubber

- Specifications Met: See table

Reduce your pipeline footprint with these low-profile valves that are about half the size of standard valves for coolant. They operate on electricity to automatically start and stop flow.

Valves are normally closed unless actuated. They don’t require a minimum pressure drop between the inlet and outlet for operation. The actuator is directly mounted to the valve body to minimize movement and reduce wear.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Gender | Thread Type | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Temp. Range, °F | Valve Lg. | O'all Ht. | No. of Mounting Holes | Mounting Hole Dia. | Fasteners Included | Each | |

Acetal Plastic Body with Wire Leads | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Normally Closed—24V DC | |||||||||||||

| 1/8 | Female | NPT | 0.09 | 100 psi @ 150° F | Zero Pressure Drop | 0° to 150° | 1 5/16" | 2 1/4" | 2 | 1/4" | No | 00000000 | 000000 |

| 1/8 | Female | NPT | 0.2 | 30 psi @ 150° F | Zero Pressure Drop | 0° to 150° | 1 5/16" | 2 1/4" | 2 | 1/4" | No | 00000000 | 00000 |

Normally Closed—120V AC | |||||||||||||

| 1/8 | Female | NPT | 0.09 | 300 psi @ 150° F | Zero Pressure Drop | 0° to 150° | 1 5/16" | 2 1/4" | 2 | 1/4" | No | 00000000 | 00000 |

| 1/8 | Female | NPT | 0.2 | 125 psi @ 150° F | Zero Pressure Drop | 0° to 150° | 1 5/16" | 2 1/4" | 2 | 1/4" | No | 00000000 | 00000 |

Solenoid On/Off Valves for Chemicals

To stand up to aggressive and corrosive solutions in chemical-processing applications, these valves have a plastic body and a fluoroelastomer seal. They operate on electricity to automatically start and stop flow. Valves have union fittings on each end that separate into multiple pieces for easy installation and removal from your pipeline. They come with both threaded NPT fittings and unthreaded socket-connect female fittings.

All are normally closed unless actuated. Valves don’t require a minimum pressure drop between the inlet and outlet for operation. The actuator is directly mounted to the valve body to minimize movement and reduce wear. Valves meet NEMA 4 for resistance to washdowns, splashing water, corrosive liquid, and dust.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- For Use With: Water, Oil, Diesel Fuel, Ethylene Glycol, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Nitric Acid, Salt Water, Sodium Hypochlorite, Sulfuric Acid, Citric Acid, Phosphoric Acid

- Ball Material: PVC Plastic

- Diaphragm Material: Fluoroelastomer Rubber

- Actuator Housing Material: Plastic

- Specifications Met: CSA Certified

| Pipe Size | Gender | Thread Type | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Temp. Range, °F | Valve Lg. | O'all Ht. | No.of Mounting Slots | Mounting Slot Lg. | Fasteners Included | Environmental Rating | Each | |

Normally Closed—120V AC | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | Female | NPT | 2.3 | 120 psi @ 70° F | Zero Pressure Drop | 35° to 140° | 5 1/2" | 6 3/8" | 2 | 1/4" | No | NEMA 4 | 0000000 | 0000000 |

| 3/4 | Female | NPT | 3.2 | 120 psi @ 70° F | Zero Pressure Drop | 35° to 140° | 5 1/2" | 6 5/8" | 2 | 1/4" | No | NEMA 4 | 0000000 | 000000 |

| 1 | Female | NPT | 3.8 | 120 psi @ 70° F | Zero Pressure Drop | 35° to 140° | 5 1/2" | 6 5/8" | 2 | 1/4" | No | NEMA 4 | 0000000 | 000000 |

- For Use With: Water, Diesel Fuel, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Nitric Acid, Salt Water, Sodium Hypochlorite, Sulfuric Acid, Citric Acid, Phosphoric Acid

- Diaphragm Material: Fluoroelastomer Rubber

- Actuator Housing Material: Plastic

- Specifications Met: CSA Certified

| Pipe Size | Gender | Thread Type | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Temp. Range, °F | Valve Lg. | O'all Ht. | No.of Mounting Slots | Mounting Slot Lg. | Fasteners Included | Environmental Rating | Each | |

Normally Closed—120V AC | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | Female | NPT | 2.3 | 120 psi @ 70° F | Zero Pressure Drop | 35° to 190° | 5 5/16" | 6 3/8" | 2 | 1/4" | No | NEMA 4 | 0000000 | 0000000 |

| 3/4 | Female | NPT | 3.2 | 120 psi @ 70° F | Zero Pressure Drop | 35° to 190° | 5 1/2" | 6 5/8" | 2 | 1/4" | No | NEMA 4 | 0000000 | 000000 |

| 1 | Female | NPT | 3.8 | 120 psi @ 70° F | Zero Pressure Drop | 35° to 190° | 5 1/2" | 6 5/8" | 2 | 1/4" | No | NEMA 4 | 0000000 | 000000 |

Food Industry Solenoid On/Off Valves with Push-to-Connect Fittings

- For Use With: Food, Beverage

- Seal Material: EPR Rubber

- Specifications Met: CSA Certified, NSF/ANSI 169

Insert tubing into the fittings on these valves—no heat, solder, or flux required. Valves meet NSF/ANSI 169 for use with food equipment. They operate on electricity to automatically start and stop flow.

All are normally closed unless actuated. Valves don’t require a minimum pressure drop between the inlet and outlet for operation. The actuator is directly mounted to the valve body to minimize movement and reduce wear.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | Gender | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Temp. Range, °F | Valve Lg. | O'all Ht. | Quick-Disconnect Tab Wd. | Each | |

Polycarbonate Plastic Body with Quick-Disconnect Terminals | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Normally Closed—24V DC | ||||||||||

| 1/4" | Female | 0.3 | 80 psi @ 70° F | Zero Pressure Drop | -10° to 100° | 2" | 3" | 1/4" | 00000000 | 0000000 |

| 1/4" | Female | 0.4 | 40 psi @ 70° F | Zero Pressure Drop | -10° to 100° | 2" | 3" | 1/4" | 00000000 | 000000 |

Normally Closed—120V AC | ||||||||||

| 1/4" | Female | 0.3 | 80 psi @ 70° F | Zero Pressure Drop | -10° to 100° | 2" | 3" | 1/4" | 00000000 | 000000 |

| 1/4" | Female | 0.4 | 40 psi @ 70° F | Zero Pressure Drop | -10° to 100° | 2" | 3" | 1/4" | 00000000 | 000000 |

Polysulfone Plastic Body with Quick-Disconnect Terminals | ||||||||||

Normally Closed—24V DC | ||||||||||

| 1/4" | Female | 0.2 | 120 psi @ 70° F | Zero Pressure Drop | -10° to 100° | 2" | 3" | 1/4" | 00000000 | 000000 |

Normally Closed—120V AC | ||||||||||

| 1/4" | Female | 0.2 | 120 psi @ 70° F | Zero Pressure Drop | -10° to 100° | 2" | 3" | 1/4" | 00000000 | 000000 |

Solenoid On/Off Valves for Drinking Water

Safe for automated on/off control in drinking-water systems, these valves meet NSF/ANSI Standard 61. They operate on electricity to automatically start and stop flow.

All valves are normally closed unless actuated. They require a minimum pressure drop between the inlet and the outlet for operation; the upstream pressure must be greater than the downstream pressure. The actuator is directly mounted to the valve body to minimize movement and reduce wear.

NSF/ANSI Standard 169 valves are rated for use with food equipment.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water

- Seal Material: EPDM Rubber

- Specifications Met: CSA Certified, NSF/ANSI 169, NSF/ANSI 61

| Pipe Size | Gender | Thread Type | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Temp. Range, °F | Valve Lg. | O'all Ht. | Each | |

Normally Closed—24V DC | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | Female | NPT | 5 | 150 psi @ 180° F | Pressure Drop Assisted | 35° to 180° | 4 5/8" | 3 5/16" | 0000000 | 0000000 |

| 3/4 | Female | NPT | 7 | 150 psi @ 180° F | Pressure Drop Assisted | 35° to 180° | 4 13/16" | 3 5/8" | 0000000 | 000000 |

| 1 | Female | NPT | 13 | 150 psi @ 125° F | Pressure Drop Assisted | 35° to 180° | 6 1/8" | 3 11/16" | 0000000 | 000000 |

Normally Closed—120V AC | ||||||||||

| 1/2 | Female | NPT | 5 | 150 psi @ 180° F | Pressure Drop Assisted | 35° to 180° | 4 5/8" | 3 5/16" | 0000000 | 000000 |

| 3/4 | Female | NPT | 7 | 150 psi @ 180° F | Pressure Drop Assisted | 35° to 180° | 4 13/16" | 3 5/8" | 0000000 | 000000 |

| 1 | Female | NPT | 13 | 150 psi @ 125° F | Pressure Drop Assisted | 35° to 180° | 6 1/8" | 3 11/16" | 0000000 | 000000 |

Solenoid Diverting Valves for Chemicals

- For Use With: Acetone, Air, Ammonia, Argon, Chlorine, Citric Acid, Deionized Water, Diesel Fuel, Ethylene Glycol, Fuel Oil, Helium, Hydrochloric Acid, Krypton, Methanol, Neon, Nitric Acid, Oil, Oxygen, Phosphoric Acid, Salt Water, Sulfuric Acid, Water, Xenon, Xylene

- Seal Material: PTFE Plastic

Often used for chemical analysis and other laboratory testing, these valves have a PTFE seal and body to withstand aggressive and corrosive solutions. All operate on electricity to automatically divert flow between ports. They do not require a pressure drop for operation. Any port can be used as an inlet or an outlet. Valves can direct flow from the inlet port to either outlet port. They cannot shut off flow. The actuator is mounted directly to the valve body to minimize movement and reduce wear.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

Mounting Holes | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Size | Flow Pattern | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Min. Pressure Drop Required | Temp. Range, °F | Actuation Time | Valve Lg. | O'all Ht. | Mounting Fasteners Included | No. of | Thread Size | Each | |

PTFE Plastic Body with Wire Leads—12V DC | |||||||||||||||

NPSM Female × NPSM Female × NPSM Female | |||||||||||||||

| 1/8 | __ | L-Pattern | 15.85 | 30 psi @ 70° F | Zero Pressure Drop | None | 35° to 155° | 0.04 sec. | 1 3/4" | 2" | No | 7 | 4-40 | 0000000 | 0000000 |

UNF Female × UNF Female × UNF Female | |||||||||||||||

| __ | 1/4"-28 | L-Pattern | 10.57 | 30 psi @ 70° F | Zero Pressure Drop | None | 35° to 155° | 0.02 sec. | 1 1/2" | 1 13/16" | No | 7 | 4-40 | 0000000 | 000000 |

| __ | 10-32 | L-Pattern | 2.64 | 30 psi @ 70° F | Zero Pressure Drop | None | 35° to 155° | 0.02 sec. | 3/4" | 1 3/16" | No | 5 | 2-56 | 0000000 | 000000 |

PTFE Plastic Body with Wire Leads—24V DC | |||||||||||||||

NPSM Female × NPSM Female × NPSM Female | |||||||||||||||

| 1/8 | __ | L-Pattern | 15.85 | 30 psi @ 70° F | Zero Pressure Drop | None | 35° to 155° | 0.04 sec. | 1 3/4" | 2" | No | 7 | 4-40 | 0000000 | 000000 |

UNF Female × UNF Female × UNF Female | |||||||||||||||

| __ | 1/4"-28 | L-Pattern | 10.57 | 30 psi @ 70° F | Zero Pressure Drop | None | 35° to 155° | 0.02 sec. | 1 1/2" | 1 13/16" | No | 7 | 4-40 | 0000000 | 000000 |

| __ | 10-32 | L-Pattern | 2.64 | 30 psi @ 70° F | Zero Pressure Drop | None | 35° to 155° | 0.02 sec. | 3/4" | 1 3/16" | No | 5 | 2-56 | 0000000 | 000000 |

Single-Action Electrically Operated Air Directional Control Valves

These valves create one action, such as extending a cylinder. Apply voltage to the electrical connection to actuate. Also known as 3-way and 3/2 valves, they direct airflow from the inlet to your equipment and exhaust return airflow to create motion. In the off position, they exhaust air from the system, allowing equipment to reset so the action can be repeated.

Normally closed valves block airflow until actuated.

Valves with spring return actuation go back to their original position when voltage is removed.

Manifold-mount valves plug into a manifold (sold separately) to create multiple actions from a single pressure input. Manifolds with multiple exhaust ports have one set of inlet and exhaust ports on each side, so they can be strung together in a series. When using a single manifold, cover the ports on the side you are not using with plugs (sold separately).

Flow coefficient (Cv) is a measurement that indicates how much airflow can pass through a valve. When selecting between valves with the same port size, choose the valve with the higher flow coefficient to ensure it provides enough airflow to operate your system.

For technical drawings and 3-D models, click on a part number.

O'all | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Flow Ports | For Inlet Tube OD | For Outlet Tube OD | Exhaust Connection Type | Max. Flow Rate | Flow Coefficient (Cv) | Pressure Range, psi | Lg. | Wd. | Ht. | Mount Type | Choose a Voltage | Each | ||

Single Solenoid—Spring Return Actuation | ||||||||||||||

| K | 3 | 5/32" | 5/32" | Push to Connect | 0.6 scfm @ 100 psi | 0.01 | 0 to 120 | 1 3/8" | 5/8" | 1 3/4" | Screw In, Manifold | 0000000 | 0000000 | |

| K | 3 | 5/32" | 5/32" | Push to Connect | 1.1 scfm @ 100 psi | 0.02 | 0 to 120 | 1 3/8" | 5/8" | 1 3/4" | Screw In, Manifold | 0000000 | 000000 | |

No. of | Overall | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stations | Flow Ports | Inlet Ports | Exhaust Ports | For Inlet Tube OD | For Exhaust Tube OD | Lg. | Wd. | Ht. | Mount Type | Mounting Hole Dia. | For DIN Rail Size | Mounting Fasteners Included | Each | |

| 2 | 2 | 1 | 1 | 1/4" | 5/32" | 2" | 5/8" | 1 7/8" | DIN Rail | 0.69" | 15 mm | No | 00000000 | 000000 |

| 3 | 2 | 1 | 1 | 1/4" | 5/32" | 2 5/8" | 5/8" | 1 1/4" | DIN Rail | 0.69" | 15 mm | No | 00000000 | 00000 |

| 4 | 2 | 1 | 1 | 1/4" | 5/32" | 3 1/4" | 5/8" | 1 1/4" | DIN Rail | 0.69" | 15 mm | No | 00000000 | 00000 |

| 5 | 2 | 1 | 1 | 1/4" | 5/32" | 3 7/8" | 5/8" | 1 1/4" | DIN Rail | 0.69" | 15 mm | No | 00000000 | 00000 |

Two-Speed Two-Action Electrically Operated Air Directional Control Valves

Often used to extend and then retract a cylinder at different speeds, these valves create two actions and have two exhaust ports, which allows you to control the speed of each action by attaching a flow control valve to each exhaust port. Also known as 4-way and 5/2 valves, they actuate when voltage is applied to the electrical connection. They direct airflow from the inlet to your equipment and exhaust return airflow to create motion.

Valves with spring return actuation go back to their original position when voltage is removed. Valves with electric (solenoid) return actuation go back to their original position when voltage is moved from the first solenoid to the second solenoid.

Flow coefficient (Cv) is a measurement that indicates how much airflow can pass through a valve. When selecting between valves with the same port size, choose the valve with the higher flow coefficient to ensure it provides enough airflow to operate your system.

For technical drawings and 3-D models, click on a part number.

Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Flow Ports | For Inlet Tube OD | For Outlet Tube OD | Max. Flow Rate, scfm @ 100 psi | Flow Coefficient (Cv) | Pressure Range, psi | Vacuum Rating, in. of Hg | Lg. | Wd. | Ht. | Mount Type | Voltage | Each | ||

Single Solenoid—Spring Return Actuation | ||||||||||||||

| K | 5 | 6 mm | 6 mm | 17.5 | 0.31 | 44-101 | 29.52 | 3 1/8" | 7/16" | 2 1/8" | Screw In | 24V DC | 0000000 | 0000000 |

Double Solenoid—Electric (Solenoid) Return Actuation | ||||||||||||||

| K | 5 | 6 mm | 6 mm | 17.5 | 0.31 | 29-101 | 29.52 | 3 1/4" | 7/16" | 2 1/8" | Screw In | 24V DC | 0000000 | 000000 |

Two-Speed Two-Action Electrically Operated Air

Directional Control Valves with Full Shut-Off

These valves close all ports in the off position to stop equipment in a locked position with air pressure holding it in place. Often used to extend and then retract a cylinder at different speeds, they create two actions and have two exhaust ports, which allows you to control the speed of each action by attaching a flow control valve to each exhaust port. Apply voltage to the electrical connection to actuate. They direct airflow from the inlet to your equipment and exhaust return airflow to create motion. Also known as 4-way and 5/3 closed center valves.

Manifold-mount valves plug into a manifold (sold separately) to create multiple actions from a single pressure input. Manifolds with multiple exhaust ports have one set of inlet and exhaust ports on each side, so they can be strung together in a series. When using a single manifold, cover the ports on the side you are not using with plugs (sold separately).

Flow coefficient (Cv) is a measurement that indicates how much airflow can pass through a valve. When selecting between valves with the same port size, choose the valve with the higher flow coefficient to ensure it provides enough airflow to operate your system.

For technical drawings and 3-D models, click on a part number.

O'all | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Flow Ports | For Inlet Tube OD | For Outlet Tube OD | Max. Flow Rate, scfm @ 100 psi | Flow Coefficient (Cv) | Pressure Range, psi | Vacuum Rating, in. of Hg | Lg. | Wd. | Ht. | Mount Type | Voltage | Each | ||

Double Solenoid—Spring Return Actuation | ||||||||||||||

| C | 5 | 6 mm | 6 mm | 17.5 | 0.31 | 44-101 | 29.52 | 3 1/4" | 7/16" | 2 1/8" | Screw In | 24V DC | 0000000 | 0000000 |

Electrically Operated Air Directional Control Valves with Flow Control

Create motion and control the speed of that motion with a single valve. Also known as 4-way valves, these valves create two actions, such as extending and retracting a double-acting cylinder. They direct airflow from the inlet to your equipment and exhaust return airflow to create motion, and adjust the volume of air exiting an air cylinder (meter out) to control speed. Apply voltage to the electrical connection to actuate.

5/3 (closed center valves) close all ports in the off position to stop equipment in a locked position with air pressure holding it in place. 5/3 (pressure center) valves create two actions at the same time, such as extending two single-acting cylinders at once.

Valves with spring return actuation go back to their original position when voltage is removed. Valves with electric (solenoid) return actuation go back to their original position when voltage moves from the first solenoid to the second solenoid.

Flow coefficient (Cv) is a measurement that indicates how much airflow can pass through a valve.

For technical drawings and 3-D models, click on a part number.

Valves | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Inlet Tube | For Outlet Tube | Overall | Replacement Solenoids | |||||||||||||||

| No. of Flow Ports | ID | OD | ID | OD | Exhaust Connection Type | Max. Flow Rate, scfm @ 100 psi | Flow Coefficient (Cv) | Pressure Range, psi | Vacuum Rating | Lg. | Wd. | Ht. | Mounting Fasteners Included | Choose a Voltage | Each | Each | ||

5/2 Flow Pattern | ||||||||||||||||||

Single Solenoid—Spring Return Actuation | ||||||||||||||||||

| 5 | 11/64" | 1/4" | 11/64" | 1/4" | Threaded | 24.7 | 0.7 | 20-150 | Not Rated | 4 3/4" | 1 3/8" | 2 3/4" | No | 24V DC | 0000000 | 0000000 | 0000000 | 0000000 |

| 5 | 11/64" | 1/4" | 11/64" | 1/4" | Threaded | 24.7 | 0.7 | 20-150 | Not Rated | 4 3/4" | 1 3/8" | 2 3/4" | No | 120V AC | 0000000 | 000000 | 0000000 | 000000 |

| 5 | 1/4" | 3/8" | 1/4" | 3/8" | Threaded | 24.7 | 0.7 | 20-150 | Not Rated | 4 3/4" | 1 3/8" | 2 3/4" | No | 24V DC | 0000000 | 000000 | 0000000 | 000000 |

| 5 | 1/4" | 3/8" | 1/4" | 3/8" | Threaded | 24.7 | 0.7 | 20-150 | Not Rated | 4 3/4" | 1 3/8" | 2 3/4" | No | 120V AC | 0000000 | 000000 | 0000000 | 000000 |

Double Solenoid—Electric (Solenoid) Return Actuation | ||||||||||||||||||

| 5 | 11/64" | 1/4" | 11/64" | 1/4" | Threaded | 24.7 | 0.7 | 20-150 | Not Rated | 7 3/8" | 1 3/8" | 2 3/4" | No | 000000 | 000000 | 000000 | 00 | |

| 5 | 1/4" | 3/8" | 1/4" | 3/8" | Threaded | 24.7 | 0.7 | 20-150 | Not Rated | 7 3/8" | 1 3/8" | 2 3/4" | No | 000000 | 000000 | 000000 | 00 | |

5/3 (Closed Center) Flow Pattern | ||||||||||||||||||

Double Solenoid—Electric (Solenoid) Return Actuation | ||||||||||||||||||

| 5 | 11/64" | 1/4" | 11/64" | 1/4" | Threaded | 24.7 | 0.7 | 20-150 | Not Rated | 7 3/8" | 1 3/8" | 2 3/4" | No | 000000 | 000000 | 000000 | 00 | |

| 5 | 1/4" | 3/8" | 1/4" | 3/8" | Threaded | 24.7 | 0.7 | 20-150 | Not Rated | 7 3/8" | 1 3/8" | 2 3/4" | No | 000000 | 000000 | 000000 | 00 | |

5/3 (Pressure Center) Flow Pattern | ||||||||||||||||||

Double Solenoid—Electric (Solenoid) Return Actuation | ||||||||||||||||||

| 5 | 11/64" | 1/4" | 11/64" | 1/4" | Threaded | 24.7 | 0.7 | 20-150 | Not Rated | 7 3/8" | 1 3/8" | 2 3/4" | No | 000000 | 000000 | 000000 | 00 | |

| 5 | 1/4" | 3/8" | 1/4" | 3/8" | Threaded | 24.7 | 0.7 | 20-150 | Not Rated | 7 3/8" | 1 3/8" | 2 3/4" | No | 000000 | 000000 | 000000 | 00 | |

Washdown-Resistant Electrically Operated Air Directional Control Valves

3-way valves create one action, such as extending a cylinder. 4-way valves create two actions, such as extending and then retracting a double-acting cylinder. 5/3 (closed center) valves close all ports in the off position to stop equipment in a locked position with air pressure holding it in place. Valves with spring return actuation go back to their original position when voltage is removed. Valves with electric (solenoid) return actuation go back to their original position when voltage moves from the first solenoid to the second solenoid. Valves with two exhaust ports allow you to independently control the speed of two different actions. Connect a flow control valve to each exhaust port. Flow coefficient (Cv) is a measurement that indicates how much airflow can pass through a valve.

O'all | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Air Directional Control Valve Type | Flow Pattern | No. of Flow Ports | No. of Exhaust Ports | Max. Flow Rate, scfm @ 100 psi | Flow Coefficient (Cv) | Pressure Range, psi | Vacuum Rating, in. of Hg | Voltage | Lg. | Wd. | Ht. | Each | |

Single Solenoid—Spring Return Actuation | |||||||||||||

| 3-Way | 3/2 | 3 | 1 | 25.11 | 0.711 | -13 to 145 | 26.5 | 24V DC | 190.5 mm | 34.9 mm | 68.58 mm | 0000000 | 0000000 |

| 4-Way | 5/2 | 5 | 2 | 25.11 | 0.711 | -13 to 145 | 26.5 | 24V DC | 190.5 mm | 34.9 mm | 68.58 mm | 0000000 | 000000 |

| 4-Way | 5/3 (Closed Center) | 5 | 2 | 25.11 | 0.711 | -13 to 145 | 26.5 | 24V DC | 190.5 mm | 34.9 mm | 68.58 mm | 0000000 | 000000 |

Double Solenoid—Electric (Solenoid) Return Actuation | |||||||||||||

| 4-Way | 5/2 | 5 | 2 | 25.11 | 0.711 | -13 to 145 | 26.5 | 24V DC | 190.5 mm | 34.9 mm | 68.58 mm | 0000000 | 000000 |

O'all | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Air Directional Control Valve Type | Flow Pattern | No. of Flow Ports | No. of Exhaust Ports | For Inlet Tube OD | For Outlet Tube OD | Max. Flow Rate, scfm @ 100 psi | Flow Coefficient (Cv) | Pressure Range, psi | Vacuum Rating, in. of Hg | Voltage | Lg. | Wd. | Ht. | Each | |

SingleSolenoid—Spring Return Actuation | |||||||||||||||

| 3-Way | 3/2 | 3 | 1 | 8 mm | 8 mm | 25.11 | 0.711 | -13 to 145 | 26.5 | 24V DC | 190.5 mm | 34.9 mm | 76.2 mm | 0000000 | 0000000 |

| 4-Way | 5/2 | 5 | 2 | 8 mm | 8 mm | 25.11 | 0.711 | -13 to 145 | 26.5 | 24V DC | 190.5 mm | 34.9 mm | 76.2 mm | 0000000 | 000000 |

| 4-Way | 5/3 (Closed Center) | 5 | 2 | 8 mm | 8 mm | 25.11 | 0.711 | -13 to 145 | 26.5 | 24V DC | 190.5 mm | 34.9 mm | 76.2 mm | 0000000 | 000000 |

DoubleSolenoid—Electric (Solenoid) Return Actuation | |||||||||||||||

| 4-Way | 5/2 | 5 | 2 | 8 mm | 8 mm | 25.11 | 0.711 | -13 to 145 | 26.5 | 24V DC | 190.5 mm | 34.9 mm | 76.2 mm | 0000000 | 000000 |

Robot-Arm-Mounted Electrically Operated Air Directional Control Valves

With two 3-way integrated solenoid valves, these electrically controlled valves direct airflow to end-of-arm tools that don’t require vacuum suction, such as pick-and-place grippers. Also known as 3/2 valves, each of the two solenoid valves directs air to a different port. Use one of the valves for tools that have a single-acting cylinder, or both of the valves for those with a double-acting cylinder. The exhausted air creates the motion to move your tool. These valves are curved and have a foam mounting pad that fits collaborative robot arms. Secure them close to your tools, but out of the way, with the hook-and-loop straps.

These valves have a normally closed starting position, which means airflow is blocked until the valves are actuated. With spring return actuation, they will go back to their original position when the voltage is removed. All of the electrical connections you need are included.

Valves with 90° elbow M8 plug will work with FANUC CRX and Universal Robots models. They include a USB flash drive with software for Universal Robots, called URCap, that plugs into your teach pendant to program the valve.

For technical drawings and 3-D models, click on a part number.

For Tube OD, mm | O'all | With Wire Leads | With 90° Elbow M8 Plug | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Flow Ports | Inlet | Outlet | Max. Flow Rate | Flow Coefficient (Cv) | Pressure Range, psi | Voltage | Lg. | Ht. | Each | For Robot Arm Manufacturer (Series/Model No.) | Each | ||

3/2 Flow Pattern | |||||||||||||

Double Solenoid—Spring Return Actuation | |||||||||||||

| 3 | 6 | 6 | 2 scfm @ 80 psi | 0.09 | 0-100 | 24V DC | 2" | 2 1/2" | 0000000 | 0000000 | FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) | 0000000 | 0000000 |

Robot-Arm-Mounted Electrically Operated Air On/Off Valves

With two 2-way integrated solenoid valves, these electrically controlled valves direct airflow to venturi pumps, which generate the suction you need to run end-of-arm tools, such as vacuum cups. You can use the two solenoid valves with two different pumps to operate two vacuum cups, or use one valve with a pump and the other to create a burst of air for removing parts that may not drop when the airflow stops, such as those with adhesive on them. All of these valves are curved and have a foam mounting pad that fits collaborative robot arms. Use the hook-and-loop straps to secure them in place—close to your tools, but out of the way.

These valves have a vacuum switch that uses analog and PNP digital feedback to send information about your pump’s vacuum level to your controller. The switch has an LED display that shows the vacuum setting and status. Set and change the vacuum setting with push buttons. These valves have a normally closed starting position, which means airflow is blocked until the valves are actuated. All of the electrical connections you need are included.

Valves with 90° elbow M8 plug will work with FANUC CRX and Universal Robots models. They include a USB flash drive with software for Universal Robots, called URCap, that plugs into your teach pendant to program the valve.

For technical drawings and 3-D models, click on a part number.

For Tube OD, mm | O'all | With Wire Leads | With 90° Elbow M8 Plug | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inlet | Outlet | Exhaust | Flow Coefficient (Cv) | Maximum Flow Rate @ 80 psi | Max. Pressure, psi | Temp. Range, °F | Voltage | Lg. | Ht. | Each | For Robot Arm Manufacturer (Series/Model No.) | Each | ||

Push-to-Connect Female Inlet, Outlet, and Exhaust | ||||||||||||||

Plastic Body | ||||||||||||||

| 6 | 6 | 6 | 0.24 | 6 scfm | 100 | 35° to 120° | 24V DC | 3 1/2" | 4 1/8" | 0000000 | 0000000 | FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) | 0000000 | 0000000 |