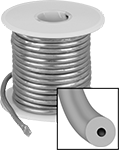

Rosin Flux-Core Solder for Electronics and Electrical Applications

Rosin flux is quick acting with strong cleaning action, but it leaves residue that requires flux remover. This solder is electrically conductive, so it’s good for electronics and electronic applications.

Lead-free solder is safer to use than leaded solder and helps meet industry regulations.

For technical drawings and 3-D models, click on a part number.

Material Composition | |||||||

|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Lead | Melting Temperature, °F | Dia. | Wt. | Each | |

For Joining Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | |||||||

| Sn40Pb60 | 40% | 60% | 460° | 0.015" | 1 lbs. | 00000000 | 000000 |

| Sn40Pb60 | 40% | 60% | 460° | 0.020" | 1 lbs. | 00000000 | 00000 |

| Sn40Pb60 | 40% | 60% | 460° | 0.031" | 1 lbs. | 00000000 | 00000 |

| Sn40Pb60 | 40% | 60% | 460° | 0.050" | 1 lbs. | 00000000 | 00000 |

| Sn50Pb50 | 50% | 50% | 420° | 0.015" | 1 lbs. | 00000000 | 00000 |

| Sn50Pb50 | 50% | 50% | 420° | 0.020" | 1 lbs. | 00000000 | 00000 |

| Sn50Pb50 | 50% | 50% | 420° | 0.040" | 1 lbs. | 00000000 | 00000 |

| Sn50Pb50 | 50% | 50% | 420° | 0.050" | 1 lbs. | 00000000 | 00000 |

| Sn50Pb50 | 50% | 50% | 420° | 0.093" | 1 lbs. | 00000000 | 00000 |

| Sn50Pb50 | 50% | 50% | 420° | 0.125" | 1 lbs. | 00000000 | 00000 |

| Sn63Pb37 | 63% | 37% | 370° | 0.093" | 1 lbs. | 00000000 | 00000 |

| Sn63Pb37 | 63% | 37% | 370° | 0.125" | 1 lbs. | 00000000 | 00000 |

Material Composition | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Silver | Antimony | Copper | Lead | Melting Temperature, °F | Dia. | Wt. | Each | |

For Joining Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | ||||||||||

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | __ | 0.5% | 0% | 460° | 0.015" | 1 lbs. | 00000000 | 0000000 |

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | __ | 0.5% | 0% | 460° | 0.025" | 1 lbs. | 00000000 | 000000 |

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | __ | 0.5% | 0% | 460° | 0.125" | 1 lbs. | 00000000 | 000000 |

| Sn97Cu2Sb0.8Ag0.2 | 97% | 0.2% | 0.8% | 2% | 0% | 460° | 0.015" | 1 lbs. | 00000000 | 00000 |

| Sn97Cu2Sb0.8Ag0.2 | 97% | 0.2% | 0.8% | 2% | 0% | 460° | 0.025" | 1 lbs. | 00000000 | 00000 |

| Sn97Cu2Sb0.8Ag0.2 | 97% | 0.2% | 0.8% | 2% | 0% | 460° | 0.050" | 1 lbs. | 00000000 | 00000 |

| Sn97Cu2Sb0.8Ag0.2 | 97% | 0.2% | 0.8% | 2% | 0% | 460° | 0.125" | 1 lbs. | 00000000 | 00000 |

| Sn97Cu3 | 97% | __ | __ | 3% | 0% | 480° | 0.015" | 1 lbs. | 00000000 | 00000 |

| Sn97Cu3 | 97% | __ | __ | 3% | 0% | 480° | 0.025" | 1 lbs. | 00000000 | 00000 |

| Sn97Cu3 | 97% | __ | __ | 3% | 0% | 480° | 0.050" | 1 lbs. | 00000000 | 00000 |

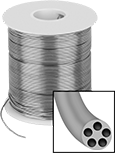

Fast-Flowing No-Clean Flux-Core Solder

for Electronics and Electrical Applications

The five flux cores in this solder allow fast soldering that uses solder efficiently and reduces the heat to your joint. The flux it’s filled with leaves minimal residue so there’s no cleanup. This solder is electrically conductive, making it good for electronics and electrical applications.

Lead-free solder is safer to use than leaded solder and helps meet industry regulations.

For technical drawings and 3-D models, click on a part number.

Material Composition | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Silver | Antimony | Copper | Lead | Melting Temperature, °F | Dia. | Wt., lbs. | Each | |

Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | ||||||||||

| Sn60Pb40 | 60% | 0% | 0% | 0% | 40% | 365° | 0.015" | 1 | 0000000 | 000000 |

| Sn60Pb40 | 60% | 0% | 0% | 0% | 40% | 365° | 0.020" | 1 | 0000000 | 00000 |

| Sn60Pb40 | 60% | 0% | 0% | 0% | 40% | 365° | 0.025" | 1 | 0000000 | 00000 |

| Sn60Pb40 | 60% | 0% | 0% | 0% | 40% | 365° | 0.032" | 1 | 0000000 | 00000 |

| Sn60Pb40 | 60% | 0% | 0% | 0% | 40% | 365° | 0.050" | 1 | 0000000 | 00000 |

| Sn60Pb40 | 60% | 0% | 0% | 0% | 40% | 365° | 0.062" | 1 | 0000000 | 00000 |

| Sn60Pb40 | 60% | 0% | 0% | 0% | 40% | 365° | 0.093" | 1 | 0000000 | 00000 |

| Sn60Pb40 | 60% | 0% | 0% | 0% | 40% | 365° | 0.125" | 1 | 0000000 | 00000 |

| Sn62Pb36Ag2 | 62% | 2% | 0% | 0% | 36% | 365° | 0.050" | 1 | 0000000 | 000000 |

| Sn62Pb36Ag2 | 62% | 2% | 0% | 0% | 36% | 365° | 0.062" | 1 | 0000000 | 000000 |

| Sn63Pb37 | 63% | 0% | 0% | 0% | 37% | 365° | 0.015" | 1 | 0000000 | 00000 |

| Sn63Pb37 | 63% | 0% | 0% | 0% | 37% | 365° | 0.025" | 1 | 0000000 | 00000 |

| Sn63Pb37 | 63% | 0% | 0% | 0% | 37% | 365° | 0.032" | 1 | 0000000 | 00000 |

| Sn63Pb37 | 63% | 0% | 0% | 0% | 37% | 365° | 0.050" | 1 | 0000000 | 00000 |

| Sn63Pb37 | 63% | 0% | 0% | 0% | 37% | 365° | 0.062" | 1 | 0000000 | 00000 |

| Sn63Pb37 | 63% | 0% | 0% | 0% | 37% | 365° | 0.093" | 1 | 0000000 | 00000 |

| Sn63Pb37 | 63% | 0% | 0% | 0% | 37% | 365° | 0.125" | 1 | 0000000 | 00000 |

Material Composition | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Silver | Antimony | Copper | Lead | Melting Temperature, °F | Dia. | Wt., lbs. | Each | |

Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | ||||||||||

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | 0% | 0.5% | 0% | 425° | 0.015" | 1 | 0000000 | 0000000 |

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | 0% | 0.5% | 0% | 425° | 0.020" | 1 | 0000000 | 000000 |

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | 0% | 0.5% | 0% | 425° | 0.025" | 1 | 0000000 | 000000 |

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | 0% | 0.5% | 0% | 425° | 0.032" | 1 | 0000000 | 000000 |

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | 0% | 0.5% | 0% | 425° | 0.040" | 1 | 0000000 | 000000 |

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | 0% | 0.5% | 0% | 425° | 0.062" | 1 | 0000000 | 000000 |

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | 0% | 0.5% | 0% | 425° | 0.125" | 1 | 0000000 | 000000 |

| Sn96Ag4 | 96% | 4% | 0% | 0% | 0% | 430° | 0.032" | 1 | 0000000 | 000000 |

| Sn96Ag4 | 96% | 4% | 0% | 0% | 0% | 430° | 0.040" | 1 | 0000000 | 000000 |

| Sn96Ag4 | 96% | 4% | 0% | 0% | 0% | 430° | 0.062" | 1 | 0000000 | 000000 |

| Sn97Ag3 | 97% | 3% | 0% | 0% | 0% | 430° | 0.032" | 1 | 0000000 | 000000 |

| Sn97Ag3 | 97% | 3% | 0% | 0% | 0% | 430° | 0.040" | 1 | 0000000 | 000000 |

| Sn97Ag3 | 97% | 3% | 0% | 0% | 0% | 430° | 0.062" | 1 | 0000000 | 000000 |

| Sn97Ag3 | 97% | 3% | 0% | 0% | 0% | 430° | 0.093" | 1 | 0000000 | 000000 |

| Sn97Ag3 | 97% | 3% | 0% | 0% | 0% | 430° | 0.125" | 1 | 0000000 | 000000 |

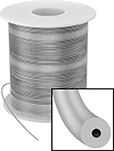

Easy-Clean Flux-Core Solder for Electronics and Electrical Applications

Wash away flux residue from this solder with water. It is electrically conductive, so it is good for electronics and electrical applications.

Lead-free solder is safer to use than leaded solder and helps meet industry regulations.

For technical drawings and 3-D models, click on a part number.

Material Composition | ||||||||

|---|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Lead | Dia. | Melting Temperature,°F | Wt., lbs. | Specifications Met | Each | |

For Joining Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | ||||||||

| Sn60Pb40 | 60% | 40% | 0.015" | 365° | 1 | J-STD-006 | 0000000 | 000000 |

| Sn60Pb40 | 60% | 40% | 0.020" | 365° | 1 | J-STD-006 | 0000000 | 00000 |

| Sn60Pb40 | 60% | 40% | 0.031" | 365° | 1 | J-STD-006 | 0000000 | 00000 |

| Sn60Pb40 | 60% | 40% | 0.040" | 365° | 1 | J-STD-006 | 0000000 | 00000 |

| Sn60Pb40 | 60% | 40% | 0.050" | 365° | 1 | J-STD-006 | 0000000 | 00000 |

| Sn60Pb40 | 60% | 40% | 0.062" | 365° | 1 | J-STD-006 | 0000000 | 00000 |

| Sn60Pb40 | 60% | 40% | 0.125" | 365° | 1 | J-STD-006 | 0000000 | 00000 |

| Sn63Pb37 | 63% | 37% | 0.040" | 365° | 1 | J-STD-006 | 0000000 | 00000 |

Material Composition | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Silver | Copper | Lead | Dia. | Melting Temperature, °F | Wt., lbs. | Each | |

For Joining Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | |||||||||

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | 0.5% | 0% | 0.025" | 365° | 1 | 0000000 | 0000000 |

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | 0.5% | 0% | 0.040" | 365° | 1 | 0000000 | 000000 |

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | 0.5% | 0% | 0.125" | 365° | 1 | 0000000 | 000000 |

| Sn97Cu3 | 97% | __ | 3% | 0% | 0.025" | 445° | 1 | 0000000 | 00000 |

| Sn97Cu3 | 97% | __ | 3% | 0% | 0.031" | 445° | 1 | 0000000 | 00000 |

| Sn97Cu3 | 97% | __ | 3% | 0% | 0.050" | 445° | 1 | 0000000 | 00000 |

| Sn97Cu3 | 97% | __ | 3% | 0% | 0.125" | 445° | 1 | 0000000 | 00000 |

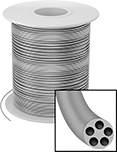

Fast-Flowing Easy-Clean Flux-Core Solder

for Electronics and Electrical Applications

Electrically conductive and with five flux cores, this solder speeds up the process of soldering electronics, so you use less solder and transmit less heat to the joint. Easily wash away the flux residue with just water.

For technical drawings and 3-D models, click on a part number.

Material Composition | |||||||

|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Lead | Melting Temperature, °F | Dia. | Wt., lbs. | Each | |

For Joining Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | |||||||

| Sn60Pb40 | 60% | 40% | 365° | 0.025" | 1 | 0000000 | 000000 |

| Sn60Pb40 | 60% | 40% | 365° | 0.032" | 1 | 0000000 | 00000 |

| Sn60Pb40 | 60% | 40% | 365° | 0.050" | 1 | 0000000 | 00000 |

| Sn60Pb40 | 60% | 40% | 365° | 0.062" | 1 | 0000000 | 00000 |

| Sn60Pb40 | 60% | 40% | 365° | 0.125" | 1 | 0000000 | 00000 |

| Sn63Pb37 | 63% | 37% | 365° | 0.025" | 1 | 0000000 | 00000 |

| Sn63Pb37 | 63% | 37% | 365° | 0.032" | 1 | 0000000 | 00000 |

| Sn63Pb37 | 63% | 37% | 365° | 0.062" | 1 | 0000000 | 00000 |

| Sn63Pb37 | 63% | 37% | 365° | 0.125" | 1 | 0000000 | 00000 |

Solder for Electronics and Electrical Applications

Electrically conductive, this solder is best for electronics and electronics applications. It does not have a flux core, so you can choose the flux that works best for your application.

For technical drawings and 3-D models, click on a part number.

Material Composition | 1 lbs. | 5 lbs. | ||||||

|---|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Lead | Melting Temperature, °F | Dia. | Each | Each | ||

For Joining Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | ||||||||

| Sn60Pb40 | 60% | 40% | 375° | 0.062" | 0000000 | 000000 | 0000000 | 0000000 |

| Sn60Pb40 | 60% | 40% | 375° | 0.125" | 0000000 | 00000 | 0000000 | 000000 |

| Sn63Pb37 | 63% | 37% | 360° | 0.031" | 000000 | 00000 | 000000 | 00 |

| Sn63Pb37 | 63% | 37% | 360° | 0.062" | 000000 | 00000 | 000000 | 00 |

| Sn63Pb37 | 63% | 37% | 360° | 0.125" | 000000 | 00000 | 000000 | 000000 |

Rosin Flux-Core High-Melting-Point Solder

for Electronics and Electrical Applications

Rosin flux is quick acting with strong cleaning action, but leaves residue that requires flux remover. The high melting point of this solder prevents remelting when soldering successive joints with another solder. It is electrically conductive.

For technical drawings and 3-D models, click on a part number.

Solder for Torch Soldering

This solder does not have a flux core, so you can choose the flux that works best for your application.

For technical drawings and 3-D models, click on a part number.

Material Composition | 1 lbs. | 5 lbs. | ||||||

|---|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Lead | Dia. | Melting Temperature, °F | Each | Each | ||

For Joining Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | ||||||||

| Sn40Pb60 | 40% | 60% | 0.025" | 365° | 0000000 | 000000 | 000000 | 00 |

| Sn40Pb60 | 40% | 60% | 0.040" | 365° | 0000000 | 00000 | 000000 | 00 |

| Sn40Pb60 | 40% | 60% | 0.050" | 365° | 0000000 | 00000 | 000000 | 00 |

| Sn40Pb60 | 40% | 60% | 0.093" | 365° | 0000000 | 00000 | 000000 | 00 |

| Sn40Pb60 | 40% | 60% | 0.125" | 460° | 0000000 | 00000 | 0000000 | 0000000 |

| Sn40Pb60 | 40% | 60% | 0.148" | 365° | 0000000 | 00000 | 000000 | 00 |

| Sn40Pb60 | 40% | 60% | 0.250" | 365° | 000000 | 00 | 0000000 | 000000 |

Solder

Use this solder for general purpose applications. It does not have a flux core, so you can choose the flux that works best for your application.

For technical drawings and 3-D models, click on a part number.

Material Composition | 1 lbs. | 5 lbs. | ||||||

|---|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Lead | Melting Temperature, °F | Dia. | Each | Each | ||

For Joining Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | ||||||||

| Sn50Pb50 | 50% | 50% | 420° | 0.025" | 0000000 | 000000 | 000000 | 00 |

| Sn50Pb50 | 50% | 50% | 420° | 0.032" | 0000000 | 00000 | 0000000 | 0000000 |

| Sn50Pb50 | 50% | 50% | 420° | 0.040" | 0000000 | 00000 | 000000 | 00 |

| Sn50Pb50 | 50% | 50% | 420° | 0.050" | 0000000 | 00000 | 000000 | 00 |

| Sn50Pb50 | 50% | 50% | 420° | 0.062" | 0000000 | 00000 | 0000000 | 000000 |

| Sn50Pb50 | 50% | 50% | 420° | 0.093" | 0000000 | 00000 | 0000000 | 000000 |

| Sn50Pb50 | 50% | 50% | 420° | 0.125" | 0000000 | 00000 | 0000000 | 000000 |

| Sn50Pb50 | 50% | 50% | 420° | 0.250" | 000000 | 00 | 0000000 | 000000 |

Solder Pellets

Also known as solder slugs, these pellets create strong, electrically conductive connections between battery terminal lugs and cable. They are measured for the precise amount of solder you need. These pellets make stronger connections than those created by crimping or compression. Place a pellet in your lug and heat it until melted. Put your cable in the liquid solder and hold until the solder solidifies for a secure connection. These pellets do not have a flux core, so you can choose the flux that works best for your application.

Material Composition | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Wire Gauge | Solder Composition | Tin | Lead | Melting Temperature, °F | Dia. | Lg. | Color | Pkg. Qty. | Pkg. | |

For Joining Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel, Tin | ||||||||||

| 6 | Sn63Pb37 | 63% | 37% | 210° | 0.195" | 0.400" | Gray | 25 | 0000000 | 000000 |

| 4 | Sn63Pb37 | 63% | 37% | 210° | 0.240" | 0.400" | Gray | 25 | 0000000 | 00000 |

| 2 | Sn63Pb37 | 63% | 37% | 210° | 0.330" | 0.500" | Green | 25 | 0000000 | 00000 |

| 1 | Sn63Pb37 | 63% | 37% | 210° | 0.330" | 0.546" | Red | 25 | 0000000 | 00000 |

| 1/0 | Sn63Pb37 | 63% | 37% | 210° | 0.410" | 0.600" | Black | 10 | 0000000 | 00000 |

| 2/0 | Sn63Pb37 | 63% | 37% | 210° | 0.445" | 0.600" | Orange | 10 | 0000000 | 00000 |

| 3/0 | Sn63Pb37 | 63% | 37% | 210° | 0.510" | 0.600" | Purple | 10 | 0000000 | 00000 |

| 4/0 | Sn63Pb37 | 63% | 37% | 210° | 0.585" | 0.600" | Yellow | 10 | 0000000 | 00000 |