Rosin Flux-Core Solder for Electronics and Electrical Applications

Rosin flux is quick acting with strong cleaning action, but it leaves residue that requires flux remover. This solder is electrically conductive, so it’s good for electronics and electronic applications.

Lead-free solder is safer to use than leaded solder and helps meet industry regulations.

For technical drawings and 3-D models, click on a part number.

Material Composition | |||||||

|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Lead | Melting Temperature, °F | Dia. | Wt. | Each | |

For Joining Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | |||||||

| Sn40Pb60 | 40% | 60% | 460° | 0.093" | 1 lbs. | 000000 | 000000 |

| Sn40Pb60 | 40% | 60% | 460° | 0.093" | 5 lbs. | 000000 | 000000 |

| Sn50Pb50 | 50% | 50% | 420° | 0.093" | 1 lbs. | 00000000 | 00000 |

| Sn60Pb40 | 60% | 40% | 370° | 0.093" | 1 lbs. | 0000000 | 00000 |

| Sn63Pb37 | 63% | 37% | 370° | 0.093" | 1 lbs. | 00000000 | 00000 |

Material Composition | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Silver | Copper | Lead | Melting Temperature, °F | Dia. | Wt. | Each | |

For Joining Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | |||||||||

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | 0.5% | 0% | 460° | 0.093" | 1 lbs. | 0000000 | 0000000 |

| Sn97Cu3 | 97% | __ | 3% | 0% | 480° | 0.093" | 1 lbs. | 00000000 | 00000 |

| Sn99.3Cu0.7 | 99.3% | __ | 0.7% | 0% | 440° | 0.093" | 1 lbs. | 00000000 | 000000 |

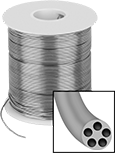

Fast-Flowing Rosin Flux-Core Solder for

Electronics and Electrical Applications

The five flux cores allow fast soldering that uses less solder and transmits less heat to the joint. Rosin flux is quick acting with strong cleaning action but leaves residue that requires flux remover. Since this solder is electrically conductive, it’s good for electronics and electrical applications.

For technical drawings and 3-D models, click on a part number.

No-Clean Flux-Core Solder for Electronics and Electrical Applications

The flux leaves minimal residue so there's no need for cleanup. All of this solder is electrically conductive.

Lead-free solder is safer to use than leaded solder and helps meet industry regulations.

For technical drawings and 3-D models, click on a part number.

Material Composition | |||||||

|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Lead | Melting Temperature, °F | Dia. | Wt., lbs. | Each | |

For Joining Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | |||||||

| Sn60Pb40 | 60% | 40% | 365° | 0.093" | 1 | 0000000 | 000000 |

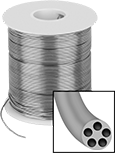

Fast-Flowing No-Clean Flux-Core Solder

for Electronics and Electrical Applications

The five flux cores in this solder allow fast soldering that uses solder efficiently and reduces the heat to your joint. The flux it’s filled with leaves minimal residue so there’s no cleanup. This solder is electrically conductive, making it good for electronics and electrical applications.

Lead-free solder is safer to use than leaded solder and helps meet industry regulations.

For technical drawings and 3-D models, click on a part number.

Material Composition | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Silver | Antimony | Copper | Lead | Melting Temperature, °F | Dia. | Wt., lbs. | Each | |

Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | ||||||||||

| Sn97Ag3 | 97% | 3% | 0% | 0% | 0% | 430° | 0.093" | 1 | 0000000 | 0000000 |

Acid Flux-Core Solder for Electronics and Electrical Applications

Acid flux has strong cleaning action, but leaves corrosive residue that washes away with water. This solder is electrically conductive.

For technical drawings and 3-D models, click on a part number.

Solder for Electronics and Electrical Applications

Electrically conductive, this solder is best for electronics and electronics applications. It does not have a flux core, so you can choose the flux that works best for your application.

Lead-free solder is safer to use than leaded solder and helps meet industry regulations.

For technical drawings and 3-D models, click on a part number.

Material Composition | 1 lbs. | |||||||

|---|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Silver | Copper | Lead | Melting Temperature, °F | Dia. | Each | |

For Joining Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | ||||||||

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | 0.5% | 0% | 420° | 0.093" | 0000000 | 0000000 |

Solder for Torch Soldering

This solder does not have a flux core, so you can choose the flux that works best for your application.

For technical drawings and 3-D models, click on a part number.

Material Composition | 1 lbs. | |||||

|---|---|---|---|---|---|---|

| Solder Composition | Tin | Lead | Dia. | Melting Temperature, °F | Each | |

For Joining Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | ||||||

| Sn40Pb60 | 40% | 60% | 0.093" | 365° | 0000000 | 000000 |

Solder

Use this solder for general purpose applications. It does not have a flux core, so you can choose the flux that works best for your application.

For technical drawings and 3-D models, click on a part number.

Solder for Machine Soldering

This solder does not have a flux core, so you can choose the flux that works best for your application.

For technical drawings and 3-D models, click on a part number.

Material Composition | 1 lbs. | |||||

|---|---|---|---|---|---|---|

| Solder Composition | Tin | Lead | Melting Temperature, °F | Dia. | Each | |

For Joining Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | ||||||

| Sn30Pb70 | 30% | 70% | 490° | 0.093" | 0000000 | 000000 |

Solder for High-Temperature Applications

This solder keeps its strength in applications where vibration and frequent and extreme temperature changes occur, such as in water lines and refrigeration equipment. It does not have a flux core, so you can choose the flux that works best for your application. This solder is lead-free, so it is safer to use than leaded solder and helps met industry regulations.

For technical drawings and 3-D models, click on a part number.

Material Composition | ||||||||

|---|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Antimony | Lead | Melting Temperature, °F | Dia. | Wt., lbs. | Each | |

For Joining Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | ||||||||

| Sn95Sb5 | 95% | 5% | 0% | 460° | 0.093" | 1 | 0000000 | 000000 |

No-Clean Flux-Core Solder for High-Temperature Applications

The flux leaves minimal residue so there's no cleanup. The solder keeps its strength in applications where vibration and frequent and extreme temperature changes occur, such as in water lines and refrigeration equipment. This solder is lead-free, so it is safer to use than leaded solder and helps meet industry requirements.

For technical drawings and 3-D models, click on a part number.

Material Composition | ||||||||

|---|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Antimony | Lead | Melting Temperature, °F | Dia. | Wt., lbs. | Each | |

Lead Free | ||||||||

For Joining Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | ||||||||

| Sn95Sb5 | 95% | 5% | 0% | 460° | 0.093" | 1 | 00000000 | 000000 |

Solder for Food Service Equipment

Composed of pure tin, this solder is safe for use with food service equipment. It does not have a flux core, so you can choose the flux that works best for your application. This solder is lead-free, which means it is safer to use than leaded solder and helps meet industry regulations.

For technical drawings and 3-D models, click on a part number.

Material Composition | ||||||||

|---|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Lead | Melting Temperature, °F | Solder Type | Dia. | Wt., lbs. | Each | |

For Joining Brass, Bronze, Copper, Stainless Steel, Steel | ||||||||

| Sn100 | 100% | 0% | 450° | Flux Required | 0.093" | 1 | 00000000 | 000000 |

Solder for Stainless Steel

Without a flux core, this solder allows you to choose the flux that works best for your application.

For technical drawings and 3-D models, click on a part number.

Material Composition | ||||||||

|---|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Lead | Silver | Melting Temperature, °F | Dia. | Wt., lbs. | Each | |

Leaded | ||||||||

| Sn45Pb54Ag1 | 45% | 54% | 1% | 410° | 0.093" | 1 | 0000000 | 000000 |