Machinable Milling-Machine Vise Jaws

Made from unhardened metal, machine these jaws to fit the contours and curves of your workpiece. They have an industry standard hole pattern that fits most manufacturers' vises, including Kurt, Chick, TE-CO, Toolex, and Palmgren.

Steel jaws are more durable than aluminum.

For technical drawings and 3-D models, click on a part number.

Jaw | Mounting | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Wd. | Ht. | Thick. | Thick. Tolerance | Fasteners Included | Hole Dia. | Hole Ctr.-to-Ctr. | For Mounting Screw Size | Pair | |

6061 Aluminum | |||||||||

| 4" | 1 1/2" | 1" | -0.002" to 0.002" | No | 0.409" | 2 1/2" | 3/8"-16 | 0000000 | 000000 |

| 4" | 1 1/2" | 1.5" | -0.002" to 0.002" | No | 0.409" | 2 1/2" | 3/8"-16 | 0000000 | 00000 |

| 6" | 2" | 1" | -0.002" to 0.002" | No | 0.532" | 3 7/8" | 1/2"-13 | 0000000 | 00000 |

| 6" | 2" | 1.25" | -0.002" to 0.002" | No | 0.532" | 3 7/8" | 1/2"-13 | 0000000 | 00000 |

| 6" | 2" | 1.5" | -0.002" to 0.002" | No | 0.532" | 3 7/8" | 1/2"-13 | 0000000 | 00000 |

| 6" | 2" | 2" | -0.002" to 0.002" | No | 0.532" | 3 7/8" | 1/2"-13 | 0000000 | 00000 |

| 6" | 3" | 2" | -0.002" to 0.002" | No | 0.532" | 3 7/8" | 1/2"-13 | 0000000 | 000000 |

| 8" | 2" | 1.5" | -0.002" to 0.002" | No | 0.532" | 3 7/8" | 1/2"-13 | 0000000 | 00000 |

| 8" | 2 1/2" | 1" | -0.002" to 0.002" | No | 0.654" | 4 3/4" | 5/8"-11 | 0000000 | 00000 |

| 8" | 2 1/2" | 2" | -0.002" to 0.002" | No | 0.654" | 4 3/4" | 5/8"-11 | 0000000 | 000000 |

| 10" | 2" | 1.5" | -0.002" to 0.002" | No | 0.532" | 3 7/8" | 1/2"-13 | 0000000 | 00000 |

1018 Carbon Steel | |||||||||

| 4" | 1 1/2" | 1" | -0.002" to 0.002" | No | 0.409" | 2 1/2" | 3/8"-16 | 0000000 | 00000 |

| 4" | 1 1/2" | 1.5" | -0.002" to 0.002" | No | 0.409" | 2 1/2" | 3/8"-16 | 0000000 | 00000 |

| 6" | 2" | 1" | -0.002" to 0.002" | No | 0.532" | 3 7/8" | 1/2"-13 | 0000000 | 00000 |

| 6" | 2" | 1.25" | -0.002" to 0.002" | No | 0.532" | 3 7/8" | 1/2"-13 | 0000000 | 00000 |

| 6" | 2" | 1.5" | -0.002" to 0.002" | No | 0.532" | 3 7/8" | 1/2"-13 | 0000000 | 000000 |

| 6" | 2" | 2" | -0.002" to 0.002" | No | 0.532" | 3 7/8" | 1/2"-13 | 0000000 | 000000 |

| 6" | 3" | 2" | -0.002" to 0.002" | No | 0.532" | 3 7/8" | 1/2"-13 | 0000000 | 000000 |

| 8" | 2" | 1.5" | -0.002" to 0.002" | No | 0.532" | 3 7/8" | 1/2"-13 | 0000000 | 000000 |

| 8" | 2 1/2" | 1" | -0.002" to 0.002" | No | 0.654" | 4 3/4" | 5/8"-11 | 0000000 | 000000 |

| 8" | 2 1/2" | 2" | -0.002" to 0.002" | No | 0.654" | 4 3/4" | 5/8"-11 | 0000000 | 000000 |

| 10" | 2" | 1.5" | -0.002" to 0.002" | No | 0.532" | 3 7/8" | 1/2"-13 | 0000000 | 000000 |

Magnetic-Mount Bench Vise Jaw Liners

Quickly install these magnetic-backed liners to protect workpieces from marring.

Grooved liners are used for clamping uneven and round workpieces. Style E have tabs to keep the liner in place.

Fiber-coated liners are nonabsorbent and firmer than rubber.

Rubber-coated liners are slip resistant and will conform slightly to a part.

Overall | ||||||

|---|---|---|---|---|---|---|

| For Jaw Wd. | Wd. | Ht. | Thick. | Pair | ||

Fiber-Coated Aluminum | ||||||

| A | 4" | 4" | 1 1/8" | 7/8" | 0000000 | 000000 |

| A | 4 1/2" | 4 1/2" | 1 1/8" | 7/8" | 0000000 | 00000 |

| A | 5" | 5" | 1 1/8" | 7/8" | 0000000 | 00000 |

| A | 6" | 6" | 1 1/8" | 7/8" | 0000000 | 00000 |

Rubber-Coated Aluminum | ||||||

| A | 4" | 4" | 1 1/8" | 7/8" | 0000000 | 00000 |

| A | 4 1/2" | 4 1/2" | 1 1/8" | 7/8" | 0000000 | 00000 |

| A | 5" | 5" | 1 1/8" | 7/8" | 0000000 | 00000 |

| A | 5 1/2" | 5 1/2" | 1 1/4" | 7/16" | 0000000 | 00000 |

| A | 6" | 6" | 1 1/8" | 7/8" | 0000000 | 00000 |

| A | 6 1/2" | 6" | 1 1/4" | 7/16" | 0000000 | 00000 |

| A | 8" | 8" | 1" | 1/2" | 0000000 | 00000 |

Aluminum | ||||||

| B | 3" | 3" | 1" | 1" | 0000000 | 00000 |

Overall | ||||||||

|---|---|---|---|---|---|---|---|---|

| Groove Orientation | For Jaw Wd. | Wd. | Ht. | Thick. | For Workpiece Dia. | Pair | ||

Aluminum | ||||||||

| C | Horizontal | 4" | 4" | 1 1/8" | 3/4" | __ | 0000000 | 000000 |

| C | Horizontal | 4 1/2" | 4 1/2" | 1 1/8" | 3/4" | __ | 0000000 | 00000 |

| C | Horizontal | 5" | 5" | 1 1/8" | 3/4" | __ | 0000000 | 00000 |

| C | Horizontal | 5 1/2" | 5 1/2" | 1 1/4" | 7/16" | __ | 0000000 | 00000 |

| C | Horizontal | 6" | 6" | 1 1/8" | 3/4" | __ | 0000000 | 00000 |

| C | Horizontal | 6 1/2" | 6" | 1 1/4" | 7/16" | __ | 0000000 | 00000 |

| D | Horizontal | 4" | 4" | 1" | 1/2" | __ | 0000000 | 00000 |

| D | Horizontal | 4 1/2" | 4 1/2" | 1" | 1/2" | __ | 0000000 | 00000 |

| D | Horizontal | 5" | 5" | 1" | 1/2" | __ | 0000000 | 00000 |

| D | Horizontal | 6" | 6" | 1" | 1/2" | __ | 0000000 | 00000 |

| D | Horizontal | 8" | 8" | 1" | 1/2" | __ | 0000000 | 00000 |

| E | Horizontal, Vertical | 4" | 4" | 1 1/8" | 3/4" | __ | 0000000 | 00000 |

| E | Horizontal, Vertical | 4 1/2" | 4 1/2" | 1 1/8" | 3/4" | __ | 0000000 | 00000 |

| E | Horizontal, Vertical | 5" | 5" | 1 1/8" | 3/4" | __ | 0000000 | 00000 |

| E | Horizontal, Vertical | 5 1/2" | 5 1/2" | 1 1/4" | 7/16" | __ | 0000000 | 00000 |

| E | Horizontal, Vertical | 6" | 6" | 1 1/8" | 3/4" | __ | 0000000 | 00000 |

| E | Horizontal, Vertical | 6 1/2" | 6" | 1 1/4" | 7/16" | __ | 0000000 | 00000 |

| F | Vertical | 5" | 5" | 1 1/8" | 2 1/8" | 5mm, 9mm, 10mm, 12mm, 14mm, 20mm, 25mm, 30mm, 36mm | 0000000 | 00000 |

Nylon Plastic | ||||||||

| G | Horizontal, Vertical, Diagonal | 5" | 4 7/8" | 1" | 1/2" | __ | 000000 | 00000 |

Polyurethane Plastic | ||||||||

| H | Horizontal, Vertical | 6" | 6" | 1" | 1/2" | 1/2" | 0000000 | 00000 |

V-Block Magnetic-Mount Bench Vise Jaw Liners

Attach these V-shaped liners to vise jaws and hold large round material. Liners are made of plastic that won't mar workpieces.

Wraparound Bench Vise Jaw Liners

Fold the pliable tabs over vise jaws to protect workpieces from marring.

Copper liners resist weld spatter.

Overall | |||||

|---|---|---|---|---|---|

| For Jaw Wd. | Wd. | Ht. | Thick. | Pair | |

Smooth | |||||

Aluminum | |||||

| 3" | 3" | 3/4" | 1 1/8" | 0000000 | 000000 |

| 3 1/2" | 3 1/2" | 3/4" | 1 1/8" | 0000000 | 00000 |

| 4" | 4" | 3/4" | 1 1/8" | 0000000 | 00000 |

| 4 1/2" | 4 1/2" | 3/4" | 1 1/8" | 0000000 | 00000 |

| 5" | 5" | 3/4" | 1 1/8" | 0000000 | 00000 |

| 6" | 6" | 3/4" | 1 1/8" | 0000000 | 00000 |

| 8" | 8" | 3/4" | 1 1/8" | 0000000 | 00000 |

Copper | |||||

| 3" | 3 1/4" | 1 1/16" | 2 1/4" | 0000000 | 00000 |

| 3 1/2" | 3 3/4" | 1 3/8" | 3 1/2" | 0000000 | 00000 |

| 4" | 4 1/4" | 1 1/2" | 3 1/2" | 0000000 | 00000 |

| 4 1/2" | 4 3/4" | 1 3/8" | 3 1/2" | 0000000 | 00000 |

| 5" | 5 1/4" | 1 3/8" | 3 1/2" | 0000000 | 000000 |

| 6" | 6 1/4" | 1 3/4" | 4 5/8" | 0000000 | 000000 |

| 6 1/2" | 6 3/4" | 1 3/4" | 4 5/8" | 0000000 | 000000 |

Brass | |||||

| 8" | 8" | 1 3/4" | 5" | 0000000 | 000000 |

Drop-In Bench Vise Jaw Liners

Insert these one-piece grooved liners between vise jaws and tighten to squeeze closed and hold small-diameter material vertically.

Overall | |||||||

|---|---|---|---|---|---|---|---|

| Groove Orientation | For Jaw Wd. | Wd. | Ht. | Thick. | For Workpiece Dia. | Each | |

Grooved | |||||||

Aluminum | |||||||

| Vertical | 1 1/4" | 1 1/4" | 1 3/8" | 1" | 5/16"-13/32" | 0000000 | 000000 |

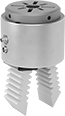

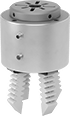

Machinable Lathe Chuck Jaws

Machine these jaws to fit the curves and edges of your unique workpiece for a tighter hold and more stability than standard hardened jaws. They have industry standard 1.5 mm x 60° serrations, which mount to most CNC lathe chucks from Kitagawa, LMC, Samchully, Seoam, and Auto Strong. Attach to your chuck with jaw nuts (not included). For the tightest fit to your workpiece, use boring rings to hold your jaws in place while machining.

Pointed jaws provide three points of contact on the workpiece. They are the best choice for most custom workholding.

Full-grip jaws surround the workpiece for maximum grip from every angle, ensuring an exact fit on thin or intricate parts.

Aluminum jaws are lighter in weight than steel and can be turned at higher speeds with less wear on your machine.

Steel jaws are more durable than aluminum. For repeated use, harden them after machining.

For technical drawings and 3-D models, click on a part number.

| For Lathe Chuck Dia. | Ht. | Lg. | Wd. | Slot Wd. | No. of Pieces | Serration Size | For Screw Size | Mounting Hole Ctr.-to-Ctr. | Weight, lbs. | Each | |

6061 Aluminum | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 6" | 1 1/2" | 3" | 1 1/4" | 0.472" | 3 | 1.5 mm × 60° | M10 | 0.787" | 1.2 | 0000000 | 000000 |

| 6" | 2" | 3" | 1 1/4" | 0.472" | 3 | 1.5 mm × 60° | M10 | 0.787" | 1.8 | 00000000 | 00000 |

| 6" | 3" | 3" | 1 1/4" | 0.472" | 3 | 1.5 mm × 60° | M10 | 0.787" | 2.4 | 00000000 | 00000 |

| 8" | 2" | 4" | 1 1/2" | 0.551" | 3 | 1.5 mm × 60° | M12 | 0.984" | 3 | 00000000 | 00000 |

| 8" | 3" | 4" | 1 1/2" | 0.551" | 3 | 1.5 mm × 60° | M12 | 0.984" | 4.2 | 00000000 | 00000 |

| 8" | 4" | 4" | 1 1/2" | 0.551" | 3 | 1.5 mm × 60° | M12 | 0.984" | 5.7 | 00000000 | 00000 |

| 10" | 2" | 4 1/2" | 1 1/2" | 0.63" | 3 | 1.5 mm × 60° | M12 | 1.181" | 3.3 | 00000000 | 00000 |

| 10" | 3" | 4 1/2" | 1 1/2" | 0.63" | 3 | 1.5 mm × 60° | M12 | 1.181" | 4.8 | 00000000 | 00000 |

| 10" | 4" | 4 1/2" | 1 1/2" | 0.63" | 3 | 1.5 mm × 60° | M12 | 1.181" | 6.6 | 00000000 | 000000 |

| 12" | 2" | 5 1/2" | 2" | 0.827" | 3 | 1.5 mm × 60° | M16 | 1.181" | 5.4 | 00000000 | 00000 |

| 12" | 3" | 5 1/2" | 2" | 0.827" | 3 | 1.5 mm × 60° | M16 | 1.181" | 7.8 | 0000000 | 000000 |

| 12" | 4" | 5 1/2" | 2" | 0.827" | 3 | 1.5 mm × 60° | M16 | 1.181" | 10.5 | 00000000 | 000000 |

| 15" | 3" | 6 1/2" | 2 1/2" | 0.866" | 3 | 1.5 mm × 60° | M20 | 1.693" | 11.4 | 00000000 | 000000 |

| 15" | 4" | 6 1/2" | 2 1/2" | 0.866" | 3 | 1.5 mm × 60° | M20 | 1.693" | 15.3 | 00000000 | 000000 |

1018 Carbon Steel | |||||||||||

| 6" | 1 1/2" | 3" | 1 1/4" | 0.472" | 3 | 1.5 mm × 60° | M10 | 0.787" | 3.5 | 00000000 | 00000 |

| 6" | 2" | 3" | 1 1/4" | 0.472" | 3 | 1.5 mm × 60° | M10 | 0.787" | 4.7 | 00000000 | 00000 |

| 6" | 3" | 3" | 1 1/4" | 0.472" | 3 | 1.5 mm × 60° | M10 | 0.787" | 7.1 | 00000000 | 00000 |

| 8" | 2" | 4" | 1 1/2" | 0.551" | 3 | 1.5 mm × 60° | M12 | 0.984" | 8.1 | 00000000 | 00000 |

| 8" | 3" | 4" | 1 1/2" | 0.551" | 3 | 1.5 mm × 60° | M12 | 0.984" | 12.3 | 00000000 | 00000 |

| 8" | 4" | 4" | 1 1/2" | 0.551" | 3 | 1.5 mm × 60° | M12 | 0.984" | 16.2 | 00000000 | 000000 |

| 10" | 2" | 4 1/2" | 1 1/2" | 0.63" | 3 | 1.5 mm × 60° | M12 | 1.181" | 9.1 | 0000000 | 00000 |

| 10" | 3" | 4 1/2" | 1 1/2" | 0.63" | 3 | 1.5 mm × 60° | M12 | 1.181" | 13.8 | 00000000 | 000000 |

| 10" | 4" | 4 1/2" | 1 1/2" | 0.63" | 3 | 1.5 mm × 60° | M12 | 1.181" | 18.5 | 00000000 | 000000 |

| 12" | 2" | 5 1/2" | 2" | 0.827" | 3 | 1.5 mm × 60° | M16 | 1.181" | 15 | 00000000 | 000000 |

| 12" | 3" | 5 1/2" | 2" | 0.827" | 3 | 1.5 mm × 60° | M16 | 1.181" | 22.5 | 00000000 | 000000 |

| 12" | 4" | 5 1/2" | 2" | 0.827" | 3 | 1.5 mm × 60° | M16 | 1.181" | 30.3 | 00000000 | 000000 |

| 15" | 3" | 6 1/2" | 2 1/2" | 0.866" | 3 | 1.5 mm × 60° | M20 | 1.693" | 33.1 | 00000000 | 000000 |

| 15" | 4" | 6 1/2" | 2 1/2" | 0.866" | 3 | 1.5 mm × 60° | M20 | 1.693" | 45 | 00000000 | 000000 |

6061 Aluminum | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Lathe Chuck Dia. | Ht. | Dia. | Slot Wd. | No. of Pieces | Serration Size | For Screw Size | Mounting Hole Ctr.-to-Ctr. | Weight, lbs. | Each | |

| 6" | 2" | 6" | 0.472" | 3 | 1.5 mm × 60° | M10 | 0.787" | 5.7 | 00000000 | 000000 |

| 6" | 3" | 6" | 0.472" | 3 | 1.5 mm × 60° | M10 | 0.787" | 8.1 | 00000000 | 000000 |

| 6" | 4" | 6" | 0.472" | 3 | 1.5 mm × 60° | M10 | 0.787" | 10.8 | 0000000 | 000000 |

| 8" | 2" | 8" | 0.551" | 3 | 1.5 mm × 60° | M12 | 0.984" | 10.2 | 00000000 | 000000 |

| 8" | 3" | 8" | 0.551" | 3 | 1.5 mm × 60° | M12 | 0.984" | 14.7 | 00000000 | 000000 |

| 8" | 4" | 8" | 0.551" | 3 | 1.5 mm × 60° | M12 | 0.984" | 19.8 | 00000000 | 000000 |

| 10" | 2" | 10" | 0.63" | 3 | 1.5 mm × 60° | M12 | 1.181" | 16.2 | 00000000 | 000000 |

| 10" | 3" | 10" | 0.63" | 3 | 1.5 mm × 60° | M12 | 1.181" | 24 | 00000000 | 000000 |

| 10" | 4" | 10" | 0.63" | 3 | 1.5 mm × 60° | M12 | 1.181" | 31.5 | 00000000 | 000000 |

| 12" | 2" | 12" | 0.827" | 3 | 1.5 mm × 60° | M16 | 1.181" | 23.4 | 00000000 | 000000 |

| 12" | 3" | 12" | 0.827" | 3 | 1.5 mm × 60° | M16 | 1.181" | 34.2 | 00000000 | 000000 |

| 12" | 4" | 12" | 0.827" | 3 | 1.5 mm × 60° | M16 | 1.181" | 45.3 | 00000000 | 000000 |

| 15" | 3" | 15" | 0.866" | 3 | 1.5 mm × 60° | M20 | 1.693" | 53.7 | 0000000 | 000000 |

| 15" | 4" | 15" | 0.866" | 3 | 1.5 mm × 60° | M20 | 1.693" | 70.8 | 00000000 | 000000 |

Boring Rings for Machinable Lathe Chuck Jaws

Hold machinable lathe chuck jaws in place during machining to make accurate cuts, ensuring the jaws will securely grip your workpiece. These boring rings pin the jaws down, creating the same clamping pressure you’ll use on your workpiece, which keeps the jaws from warping or deforming while they hold your workpiece.

Designed with an open center, these rings leave room for you to machine the center of your jaws. Fit the pins on the rings to the screw holes on your jaws, then clamp the jaws down to hold the ring in place. Once the ring is attached, rotate it to adjust the jaws to the center of their stroke before machining.

Match standard rings to your lathe chuck’s diameter for machining the center of your jaws. Line them up with your jaws by sliding the pins along their curved tracks.

Adjustable rings fit a range of lathe chuck diameters. The pins are mounted to straight tracks—slide them in and out of the ring to adjust the diameter. They are also reversible, which allows you to machine both the inside and outside of your jaws. When the pin screws are outside the ring, you can machine the center of your jaws. Flip them around to the center of the ring to machine the outside of your jaws.

Pin | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Lathe Chuck Dia. | For Jaw Grip Style | OD | ID | Ht. | Dia. | Ht. | Max. Speed, rpm | Material | Each | |

Standard | ||||||||||

| 6" | Outside | 6.6" | 3.2" | 0.47" | 0.65" | 0.354" | 900 | Alloy Steel | 00000000 | 0000000 |

| 8" | Outside | 8.6" | 4 1/2" | 0.47" | 0.728" | 0.354" | 900 | Alloy Steel | 00000000 | 000000 |

| 10" | Outside | 10.2" | 5.9" | 0.47" | 0.728" | 0.354" | 900 | Alloy Steel | 00000000 | 000000 |

| 12" | Outside | 12.4" | 7.4" | 0.59" | 0.886" | 0.354" | 900 | Alloy Steel | 00000000 | 000000 |

| 15" | Outside | 15" | 9.1" | 0.79" | 1.22" | 0.63" | 900 | Alloy Steel | 00000000 | 000000 |

Adjustable | ||||||||||

| 5"-8" | Inside, Outside | 6.7" | 3.9" | 1.02" | 0.512" | 0.276" | 800 | Alloy Steel | 00000000 | 000000 |

| 6"-10" | Inside, Outside | 7.9" | 4.9" | 1.02" | 0.642" | 0.315" | 700 | Alloy Steel | 00000000 | 000000 |

| 8"-12" | Inside, Outside | 9.8" | 6.3" | 1.22" | 0.72" | 0.315" | 600 | Alloy Steel | 00000000 | 000000 |

Lathe Chuck Jaw Nuts

Secure jaws to a CNC lathe chuck with industry standard 1.5 mm × 60° serrations or wider 3 mm × 60° serrations.

Jaw nuts with M6, M8, M10, M12, M16, and M20 threads fit most chucks made by Kitagawa, LMC, Samchully, Seoam, Auto Strong, and other brands.

Jaw nuts with inch and M14 threads fit most chucks made by Matsumoto.

For technical drawings and 3-D models, click on a part number.

Thread | Base | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Lathe Chuck Dia. | For Slot Wd. | Size | Pitch, mm | Ht. | Lg. | Wd. | Overall Ht. | For Serration Size | Mounting Hole Ctr.-to-Ctr. | Material | Each | |

| 4" | 0.315" | M6 | 1 | 11/64" | 61/64" | 29/64" | 17/32" | 1.5 mm × 60° | 0.591" | Steel | 0000000 | 000000 |

| 5" | 0.392" | M8 | 1.25 | 7/32" | 1 11/64" | 35/64" | 39/64" | 1.5 mm × 60° | 0.713" | Steel | 0000000 | 00000 |

| 6" | 0.472" | M10 | 1.5 | 19/64" | 1 13/32" | 11/16" | 23/32" | 1.5 mm × 60° | 0.787" | Steel | 0000000 | 00000 |

| 8" | 0.551" | M12 | 1.75 | 11/32" | 1 27/32" | 13/16" | 13/16" | 1.5 mm × 60° | 0.984" | Steel | 0000000 | 00000 |

| 10" | 0.63" | M12 | 1.75 | 11/32" | 1 63/64" | 7/8" | 27/32" | 1.5 mm × 60° | 1.181" | Steel | 0000000 | 00000 |

| 12" | 0.705" | M14 | 2 | 17/32" | 2 3/16" | 1 1/8" | 1 11/64" | 1.5 mm × 60° | 1.26" | Steel | 0000000 | 00000 |

| 12" | 0.827" | M16 | 2 | 29/64" | 2 9/16" | 1 5/32" | 1 3/32" | 1.5 mm × 60° | 1.181" | Steel | 0000000 | 00000 |

| 15" | 0.866" | M20 | 2.5 | 21/32" | 3 5/32" | 1 5/16" | 1 51/64" | 1.5 mm × 60° | 1.693" | Steel | 0000000 | 00000 |

| 21", 24" | 0.982" | M20 | 2.5 | 11/16" | 3 59/64" | 1 7/16" | 2 1/16" | 3 mm × 60° | 2.36" | Steel | 0000000 | 00000 |

Base | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Lathe Chuck Dia. | For Slot Wd. | Thread Size | Ht. | Lg. | Wd. | Overall Ht. | For Serration Size | Mounting Hole Ctr.-to-Ctr. | Material | Each | |

| 6" | 0.432" | 5/16"-18 | 9/32" | 1 9/16" | 11/16" | 25/32" | 1.5 mm × 60° | 0.984" | Steel | 0000000 | 000000 |

| 8" | 0.551" | 7/16"-14 | 21/64" | 1 3/4" | 51/64" | 7/8" | 1.5 mm × 60° | 0.984" | Steel | 0000000 | 00000 |

| 10" | 0.629" | 1/2"-13 | 5/16" | 2 3/64" | 57/64" | 57/64" | 1.5 mm × 60° | 1.26" | Steel | 0000000 | 00000 |

| 15" | 0.865" | 3/4"-10 | 49/64" | 3 9/64" | 1 21/64" | 1 35/64" | 3 mm × 60° | 1.96" | Steel | 0000000 | 00000 |

Robot-Ready Electric Soft Grippers

Mimicking a human hand, these grippers have soft, flexible silicone fingers that curl around items to pick them up. Unlike standard grippers with rigid fingers, these grippers can grasp fruit, bagged items, and other delicate objects without crushing them. They are powered and actuated entirely by your robot, so there's no need for an air supply or control valves. Connect them to terminals on your robot controller with the included 9 1/2 ft. electrical cord. A simple toggle on your controller’s digital outputs opens and closes the fingers. Mount them to most robot arms, like FANUC CRX and Universal Robots arms, thanks to their mounting slots that match a variety of ISO mounting patterns.

To program their range of motion and position, you’ll have access to a simple web-based interface from any smartphone or laptop. You don’t have to worry about hooking these up to your network. They generate their own wireless network like a hotspot, so you can connect your device to the setup interface to program them. If you are using these grippers with a Universal Robots arm, you can download a URCap plugin from the manufacturer's website for user-friendly control through your teach pendant software.

The fingers are made of FDA-compliant silicone for direct contact with food.

Grippers with fixed grip force apply the same amount of force every time. This helps them pick up most items successfully.

Grippers with adjustable grip force are the best choice to grip extremely sensitive items, such as baked goods or fragile glassware, because you can fine-tune the gripping force. These grippers also have part confirmation, which means they can send a signal to one of your robot controller's digital inputs to tell it whether a part has been successfully picked up. If the pickup fails, you can program your robot to try the pickup again.

2-finger grippers are good at picking up objects with uniform shapes, such as bottles and boxes.

4-finger grippers are a good choice if you plan to pick up irregularly shaped objects and need additional points of contact for a secure hold. They work well with fruits and vegetables, fabrics and flexible packaging.

Finger covers (sold separately) protect the gripper fingers from residue left from the material you're picking. These silicone covers slide over the fingers for picking and slide off for cleaning. They are FDA compliant for direct contact with food.

Stroke width describes the maximum total change in distance between fingers when the gripper actuates.

For technical drawings and 3-D models, click on a part number.

O'all | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Finger Configuration | External Gripping Force, lbs. | Max. Gripping Cap. | Cycles per Sec. | Stroke Wd., mm | Max. Finger Spacing, mm | Mounting Hole Pattern Compatibility | Dia., mm | Lg., mm | Each | |

Aluminum Housing and Silicone Rubber Fingers | ||||||||||

| 2-Finger | 1.1 | 3.3 lbs. / 1.5 kg | 1 | 0-175 | 175 | ISO 31.5 ISO 40 ISO 50 ISO 63 | 105 | 172 | 00000000 | 000000000 |

| 4-Finger | 1.1 | 3.3 lbs. / 1.5 kg | 1 | 0-190 | 190 | ISO 31.5 ISO 40 ISO 50 ISO 63 | 119 | 187 | 00000000 | 00000000 |

O'all | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Finger Configuration | External Gripping Force Range, lbs. | Max. Gripping Cap. | Cycles per Sec. | Stroke Wd., mm | Max. Finger Spacing, mm | Mounting Hole Pattern Compatibility | Dia., mm | Lg., mm | Each | |

Aluminum Housing and Silicone Rubber Fingers | ||||||||||

| 2-Finger | 0.23-1.1 | 3.3 lbs. / 1.5 kg | 1 | 0-175 | 175 | ISO 31.5 ISO 40 ISO 50 ISO 63 | 105 | 172 | 00000000 | 000000000 |

| 4-Finger | 0.23-1.1 | 3.3 lbs. / 1.5 kg | 1 | 0-190 | 190 | ISO 31.5 ISO 40 ISO 50 ISO 63 | 119 | 187 | 00000000 | 00000000 |