Fracture- and Thermally Shock-Resistant Silicon-Nitride Ceramic Balls

- Color: Black

- Max. Temperature: 1470° F

- Porosity: 13%

- Compressive Strength: 550,000 psi

Often used to create bearings, silicon-nitride ceramic is harder than many types of bearing steel but is lightweight and can be easily polished. It also withstands high temperatures.

For technical drawings and 3-D models, click on a part number.

| Dia. | Dia. Tolerance | Sphericity | Pkg. Qty. | Pkg. | |

| 1/32" | -0.00004" to 0.00005" | 99.99995% | 5 | 0000000 | 000000 |

| 1/16" | -0.00004" to 0.00005" | 99.99995% | 5 | 0000000 | 0000 |

| 3/32" | -0.00004" to 0.00005" | 99.99995% | 5 | 0000000 | 0000 |

| 1/8" | -0.00004" to 0.00005" | 99.99995% | 5 | 0000000 | 0000 |

| 5/32" | -0.00004" to 0.00005" | 99.99995% | 5 | 0000000 | 00000 |

| 3/16" | -0.00004" to 0.00005" | 99.99995% | 2 | 0000000 | 0000 |

| 7/32" | -0.00004" to 0.00005" | 99.99995% | 2 | 0000000 | 00000 |

| 1/4" | -0.00004" to 0.00005" | 99.99995% | 2 | 0000000 | 0000 |

| 9/32" | -0.00004" to 0.00005" | 99.99995% | 2 | 0000000 | 0000 |

| 5/16" | -0.00004" to 0.00005" | 99.99995% | 2 | 0000000 | 00000 |

| 3/8" | -0.00004" to 0.00005" | 99.99995% | 1 | 0000000 | 0000 |

| 1/2" | -0.00004" to 0.00005" | 99.99995% | 1 | 0000000 | 00000 |

| 9/16" | -0.00004" to 0.00005" | 99.99995% | 1 | 0000000 | 00000 |

Extra-Strength Fracture- and Thermally

Shock-Resistant Silicon-Nitride Ceramic Sheets

- Color: Gray

- Maximum Temperature: 1,830° F

- Fabrication: Fired

- Dielectric Strength: 254V/mil

- Porosity: 0%

- Compressive Strength: 580,000 psi

Pressed into ultra-dense sheets, these silicon-nitride ceramic sheets resist deforming, expanding, or cracking when compressed, bent, or exposed to quick temperature changes. They’re just as strong and fracture resistant as zirconia ceramic, and hold their strength and shape at higher temperatures. All are stronger, harder, and more fracture resistant than most other ceramics.

Use these sheets for high-stress parts, such as engine parts. You can even use them as a substrate or insulator for electronic parts, such as computer chips. Since they stand up to temperature swings better than silicon carbide and mullite, they’re also good for use in furnaces and immersion heaters. Able to withstand wear, these sheets can be used to make cutting and roughing tools.

These sheets hold up to harsh chemicals, such as acids, but may corrode from nitric acid. They are not as corrosion resistant as silicon carbide.

For technical drawings and 3-D models, click on a part number.

Extra-Strength Fracture- and Thermally

Shock-Resistant Silicon-Nitride Ceramic Discs

- Color: Gray

- Maximum Temperature: 1,830° F

- Fabrication: Fired

- Porosity: 0%

- Compressive Strength: 580,000 psi

To resist deforming, expanding, or cracking when compressed, bent, or exposed to quick temperature changes, these silicon-nitride ceramic discs have been pressed into ultra-dense discs. They’re just as strong and fracture resistant as zirconia ceramic, and hold their strength and shape at higher temperatures. All are stronger, harder, and more fracture resistant than most other ceramics.

These discs are good for use as high-stress parts, such as engine parts. You can even use them as a substrate or insulator for electronic parts, such as computer chips. Since they stand up to temperature swings better than silicon carbide and mullite, they’re also good for use in furnaces and immersion heaters. Able to withstand wear, these discs can be used to make bearings, rollers, bushings, and seals.

All of these discs hold up to harsh chemicals, such as acids, but may corrode from nitric acid. They are not as corrosion resistant as silicon carbide.

For technical drawings and 3-D models, click on a part number.

| Diameter | Diameter Tolerance | Length | Each | |

| 1 3/32" | 0" to 0.020" | 17/32" | 0000000 | 0000000 |

| 1 3/32" | 0" to 0.020" | 21/32" | 0000000 | 000000 |

| 1 3/32" | 0" to 0.020" | 7/8" | 0000000 | 000000 |

| 1 3/32" | 0" to 0.020" | 1 1/4" | 0000000 | 000000 |

| 1 29/32" | 0" to 0.020" | 13/16" | 0000000 | 000000 |

| 1 29/32" | 0" to 0.020" | 31/32" | 0000000 | 000000 |

| 1 29/32" | 0" to 0.020" | 1 1/8" | 0000000 | 000000 |

| 1 29/32" | 0" to 0.020" | 1 3/8" | 0000000 | 000000 |

Extra Thermally Shock-Resistant Single-Closed-End SiAlON Ceramic Tubes

- Color: Gray

- Maximum Temperature: 1,830° F

- Fabrication: Fired

- Porosity: 0%

- Compressive Strength: 510,000 psi

Often used as a protective shield in thermocouples and other conditions with drastic climate changes, these SiAlON ceramic tubes won't deform, expand, or crack when repeatedly exposed to large temperature changes. Submerge the closed end of the tube into harsh settings, such as tanks and furnaces, to protect contents from coming into contact with harmful liquids and gases.

These tubes are stronger and resist thermal shock better than mullite and alumina, though they don’t remain as stable in ultra-high temperatures. They're not as hard as silicon carbide, so they shouldn't be used when wear resistance is necessary. Because they hold up to chemicals, they’re good for use with molten metal, such as aluminum and zinc. Similar to nonporous alumina, these tubes help seal out gas and liquids.

For technical drawings and 3-D models, click on a part number.

6" Lg. | 12" Lg. | 24" Lg. | ||||||

|---|---|---|---|---|---|---|---|---|

| OD | ID | Wall Thickness | Each | Each | Each | |||

One Open and One Closed End | ||||||||

| 0.492" | 0.256" | 0.118" | 00000000 | 0000000 | 00000000 | 0000000 | 00000000 | 0000000 |

| 0.629" | 0.354" | 0.137" | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 000000 |

| 0.866" | 0.472" | 0.197" | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 000000 |

| 1.102" | 0.630" | 0.236" | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 000000 |

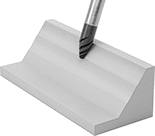

Fast-Cutting Carbide Barrel End Mills

Variable spacing between the flutes reduces vibration, allowing these end mills to provide fast cuts, smooth finishes, and long tool life on hard materials. Also known as barrel cutters, these end mills create the smooth finish of a ball end mill, but with a tapered cutting surface that removes more material with each pass. They're ideal for 5-axis machining where you need to cut from many angles. Plus, compared to ball end mills, they move farther between overlapping passes (stepover), which decreases machining time and tool wear, so they’ll last longer. All are center cutting, allowing plunge cuts into a surface.

Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking. A titanium-aluminum-silicon-nitride (TiAlSiN) coating makes them extremely resistant to wear and diffusion because they have especially high hardness, even at high temperatures.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

For technical drawings and 3-D models, click on a part number.

| Mill Dia., mm | Max. Taper Dia., mm | Shank Dia., mm | Lg. of Cut, mm | Overall Lg., mm | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Aluminum Silicon Nitride (TiAISiN) Coated | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

4 Flute | ||||||||||

| 1 | 3 | 6 | 9.5 | 58 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 0000000 |

| 1.5 | 3 | 6 | 8 | 58 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 1.5 | 4 | 8 | 10.5 | 80 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 2 | 4 | 8 | 9.5 | 80 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

6 Flute | ||||||||||

| 2 | 3 | 16 | 15 | 109 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 2 | 5 | 10 | 12.5 | 89 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 2 | 5 | 16 | 31 | 109 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 2 | 6 | 12 | 20 | 100 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 2.5 | 5 | 10 | 11.5 | 89 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

8 Flute | ||||||||||

| 2.5 | 6 | 12 | 14.4 | 100 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 3 | 5 | 16 | 18.5 | 109 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 3 | 5 | 16 | 27.5 | 109 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 3 | 6 | 12 | 13.5 | 100 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 4 | 5 | 16 | 21 | 109 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 4 | 5 | 16 | 24 | 109 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 4 | 5 | 16 | 28.5 | 109 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 4 | 8 | 16 | 18.5 | 109 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

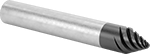

Carbide Rounded-Edge Square End Mills for Copy Milling

Replicate the shape of complex parts with these end mills. Also known as torus end mills, they have a rounded edge for precision contouring. These end mills are also used for slotting and pocketing cuts in mold and die making. Their 90° profile and rounded corners reduce flute breakage and chipping. All are center cutting, allowing plunge cuts into a surface.

Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking. A titanium-aluminum-silicon-nitride (TiAlSiN) coating makes them extremely resistant to wear and diffusion because they have especially high hardness, even at high temperatures.

For technical drawings and 3-D models, click on a part number.

For Max. Hardness Rockwell C65 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mill Dia., mm | Shank Dia., mm | Lg. of Cut, mm | Corner Cut Radius, mm | Overall Lg., mm | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Aluminum Silicon Nitride (TiAISiN) Coated | ||||||||||

4 Flute | ||||||||||

| 1 | 4 | 1 | 0.1 | 45 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 000000 |

| 1 | 4 | 1 | 0.2 | 45 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 1.5 | 4 | 1.5 | 0.2 | 45 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 2 | 6 | 2 | 0.1 | 45 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 2 | 6 | 2 | 0.2 | 54 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 2 | 6 | 2 | 0.5 | 54 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 3 | 6 | 3 | 0.1 | 54 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 3 | 6 | 3 | 0.3 | 54 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 3 | 6 | 3 | 0.5 | 54 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 4 | 6 | 4 | 0.2 | 57 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 4 | 6 | 4 | 0.3 | 57 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 4 | 6 | 4 | 0.5 | 57 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 5 | 6 | 5 | 0.2 | 57 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 5 | 6 | 5 | 0.5 | 57 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 5 | 6 | 5 | 1 | 57 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 6 | 6 | 6 | 0.2 | 57 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 6 | 6 | 6 | 0.3 | 57 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 6 | 6 | 6 | 0.5 | 57 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 6 | 6 | 6 | 1 | 57 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 6 | 6 | 6 | 1.5 | 57 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 6 | 6 | 6 | 2 | 57 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 8 | 8 | 8 | 0.3 | 63 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 000000 |

| 8 | 8 | 8 | 0.5 | 63 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 000000 |

| 8 | 8 | 8 | 1 | 63 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 000000 |

| 8 | 8 | 8 | 1.5 | 63 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 000000 |

| 8 | 8 | 8 | 2 | 63 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 000000 |

| 10 | 10 | 10 | 0.3 | 72 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 000000 |

| 10 | 10 | 10 | 0.5 | 72 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 000000 |

| 10 | 10 | 10 | 1 | 72 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 000000 |

| 10 | 10 | 10 | 1.5 | 72 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 000000 |

| 10 | 10 | 10 | 2 | 72 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 000000 |

| 10 | 10 | 10 | 3 | 72 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 000000 |

| 12 | 12 | 12 | 0.5 | 83 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 000000 |

| 12 | 12 | 12 | 1 | 83 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 000000 |

| 12 | 12 | 12 | 2 | 83 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 000000 |

| 12 | 12 | 12 | 3 | 83 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 000000 |

| 12 | 12 | 12 | 4 | 83 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 000000 |

Fast-Cutting Carbide Rounded-Edge Square

End Mills for Stainless Steel and Titanium

Variable spacing between the flutes reduces vibration, allowing these end mills to provide fast cuts, smooth finishes, and long tool life. They have a high helix angle and a wear-resistant coating for excellent shearing and chip removal in stainless steel and titanium. Often used for slotting and pocketing cuts in mold and die making, these end mills have a 90° profile and rounded corners, which reduce flute breakage and chipping. Also known as corner radius end mills.

Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking. A titanium-aluminum-silicon-nitride (TiAlSiN) coating makes them extremely resistant to wear and diffusion because they have especially high hardness, even at high temperatures. All are center cutting, allowing plunge cuts into a surface.

For technical drawings and 3-D models, click on a part number.

| Mill Dia. | Shank Dia. | Lg. of Cut | Corner Cut Radius | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Aluminum Silicon Nitride (TiAISiN) Coated | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

4 Flute | ||||||||||

| 1/8" | 1/8" | 1/4" | 0.015" | 1 1/2" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 000000 |

| 1/8" | 1/8" | 1/4" | 0.031" | 1 1/2" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 00000 |

| 3/16" | 3/16" | 3/8" | 0.015" | 2" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 00000 |

| 3/16" | 3/16" | 3/8" | 0.031" | 2" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 00000 |

| 1/4" | 1/4" | 1/2" | 0.015" | 2 1/2" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 00000 |

| 1/4" | 1/4" | 1/2" | 0.031" | 2 1/2" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 00000 |

| 1/4" | 1/4" | 1/2" | 0.062" | 2 1/2" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 00000 |

| 5/16" | 5/16" | 3/4" | 0.015" | 2 1/2" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 00000 |

| 5/16" | 5/16" | 3/4" | 0.031" | 2 1/2" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 00000 |

| 5/16" | 5/16" | 3/4" | 0.062" | 2 1/2" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 00000 |

| 3/8" | 3/8" | 7/8" | 0.015" | 2 1/2" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 00000 |

| 3/8" | 3/8" | 7/8" | 0.031" | 2 1/2" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 00000 |

| 3/8" | 3/8" | 7/8" | 0.062" | 2 1/2" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 00000 |

| 3/8" | 3/8" | 7/8" | 0.09" | 2 1/2" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 00000 |

| 1/2" | 1/2" | 1" | 0.015" | 3 1/2" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 000000 |

| 1/2" | 1/2" | 1" | 0.031" | 3 1/2" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 000000 |

| 1/2" | 1/2" | 1" | 0.062" | 3 1/2" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 000000 |

| 1/2" | 1/2" | 1" | 0.09" | 3 1/2" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 000000 |

| 1/2" | 1/2" | 1" | 0.125" | 3 1/2" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 000000 |

| 5/8" | 5/8" | 1 1/4" | 0.031" | 3 1/2" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 000000 |

| 5/8" | 5/8" | 1 1/4" | 0.062" | 3 1/2" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 000000 |

| 5/8" | 5/8" | 1 1/4" | 0.09" | 3 1/2" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 000000 |

| 5/8" | 5/8" | 1 1/4" | 0.125" | 3 1/2" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 000000 |

| 3/4" | 3/4" | 1 1/2" | 0.031" | 4" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 000000 |

| 3/4" | 3/4" | 1 1/2" | 0.062" | 4" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 000000 |

| 3/4" | 3/4" | 1 1/2" | 0.09" | 4" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 000000 |

| 3/4" | 3/4" | 1 1/2" | 0.125" | 4" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 000000 |

| 3/4" | 3/4" | 1 1/2" | 0.19" | 4" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 000000 |

| 3/4" | 3/4" | 1 1/2" | 0.25" | 4" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 000000 |

| 1" | 1" | 1 1/2" | 0.031" | 5" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 000000 |

| 1" | 1" | 1 1/2" | 0.062" | 5" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 000000 |

| 1" | 1" | 1 1/2" | 0.09" | 5" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 000000 |

| 1" | 1" | 1 1/2" | 0.125" | 5" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 000000 |

| 1" | 1" | 1 1/2" | 0.19" | 5" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 000000 |

| 1" | 1" | 1 1/2" | 0.25" | 5" | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 0000000 | 000000 |

Fast-Cutting Carbide Square End Mills with Chamfer Corner

A 45° corner chamfer improves cutting edge strength, so these end mills last longer than standard square end mills when milling hard material; however they do not create as sharp of a corner. Variable spacing between the flutes reduces vibration, allowing these end mills to provide fast cuts, smooth finishes, and long tool life on hard materials. They have a square end for milling square-bottomed slots, pockets, and edges. All are center cutting, allowing plunge cuts into a surface.

Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking.

Titanium-aluminum-silicon-nitride (TiAlSiN) coated end mills are extremely resistant to wear and diffusion because they have especially high hardness, even at high temperatures.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

End mills with coolant holes allow coolant to run through the tool and directly to the cutting edge to help flush out chips. Use them in CNC machines with coolant-through technology.

For technical drawings and 3-D models, click on a part number.

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Chamfer Wd. | Corner Cutting Angle | Flute Spacing | Helix Angle | No. of Coolant Holes | For Use On | End Mill Type | Each | |

End Mills | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Titanium Aluminum Silicon Nitride (TiAISiN) Coated—3 Flute | ||||||||||||

| 1/8" | 1/8" | 1/4" | 2" | 0.002" | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 3/16" | 3/16" | 3/8" | 2" | 0.003" | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 1/4" | 1/4" | 1/2" | 2 1/2" | 0.004" | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 5/16" | 5/16" | 1/2" | 2 1/2" | 0.005" | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 3/8" | 3/8" | 5/8" | 2 1/2" | 0.006" | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 1/2" | 1/2" | 5/8" | 3" | 0.007" | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 5/8" | 5/8" | 3/4" | 3 1/2" | 0.007" | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 3/4" | 3/4" | 1" | 4" | 0.009" | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 1" | 1" | 1" | 4" | 0.011" | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 3mm | 6mm | 8mm | 57mm | 0.05mm | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 3.5mm | 6mm | 10mm | 57mm | 0.05mm | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 3.7mm | 6mm | 11mm | 57mm | 0.06mm | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 4mm | 6mm | 11mm | 57mm | 0.06mm | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 4.5mm | 6mm | 11mm | 57mm | 0.07mm | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 4.7mm | 6mm | 13mm | 57mm | 0.07mm | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 5mm | 6mm | 13mm | 57mm | 0.08mm | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 5.5mm | 6mm | 13mm | 57mm | 0.08mm | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 5.7mm | 6mm | 13mm | 57mm | 0.09mm | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 6mm | 6mm | 13mm | 57mm | 0.09mm | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 6.5mm | 8mm | 16mm | 63mm | 0.1mm | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 7mm | 8mm | 16mm | 63mm | 0.11mm | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 7.5mm | 8mm | 19mm | 63mm | 0.11mm | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 8mm | 8mm | 19mm | 63mm | 0.12mm | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 8.5mm | 10mm | 19mm | 72mm | 0.13mm | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 9mm | 10mm | 19mm | 72mm | 0.14mm | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 9.5mm | 10mm | 22mm | 72mm | 0.14mm | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 10mm | 10mm | 22mm | 72mm | 0.15mm | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 12mm | 12mm | 26mm | 83mm | 0.18mm | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 16mm | 16mm | 32mm | 92mm | 0.19mm | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 20mm | 20mm | 38mm | 104mm | 0.24mm | 45° | Variable | 41°-45° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

Titanium Aluminum Silicon Nitride (TiAISiN) Coated—4 Flute | ||||||||||||

| 1/8" | 1/8" | 1/4" | 1 1/2" | 0.016" | 45° | Variable | 36°-38° | __ | Stainless Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 3/16" | 3/16" | 3/8" | 2" | 0.016" | 45° | Variable | 36°-38° | __ | Stainless Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 1/4" | 1/4" | 1/2" | 2 1/2" | 0.016" | 45° | Variable | 36°-38° | __ | Stainless Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 5/16" | 5/16" | 3/4" | 2 1/2" | 0.003" | 45° | Variable | 36°-38° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 3/8" | 3/8" | 7/8" | 2 1/2" | 0.016" | 45° | Variable | 36°-38° | __ | Stainless Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 7/16" | 7/16" | 7/8" | 2 1/2" | 0.016" | 45° | Variable | 36°-38° | __ | Stainless Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 1/2" | 1/2" | 1" | 3 1/2" | 0.016" | 45° | Variable | 36°-38° | __ | Stainless Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 5/8" | 5/8" | 1 1/4" | 3 1/2" | 0.006" | 45° | Variable | 36°-38° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 3/4" | 3/4" | 1 1/2" | 4" | 0.007" | 45° | Variable | 36°-38° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 1" | 1" | 1 1/2" | 5" | 0.01" | 45° | Variable | 36°-38° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 4mm | 6mm | 11mm | 57mm | 0.04mm | 45° | Variable | 36°-38° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 5mm | 6mm | 13mm | 57mm | 0.05mm | 45° | Variable | 36°-38° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 5.7mm | 6mm | 13mm | 57mm | 0.06mm | 45° | Variable | 36°-38° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 6mm | 6mm | 13mm | 57mm | 0.06mm | 45° | Variable | 36°-38° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 7.7mm | 8mm | 19mm | 63mm | 0.08mm | 45° | Variable | 36°-38° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 8mm | 8mm | 19mm | 63mm | 0.08mm | 45° | Variable | 36°-38° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 9.7mm | 10mm | 22mm | 72mm | 0.1mm | 45° | Variable | 36°-38° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 10mm | 10mm | 22mm | 72mm | 0.1mm | 45° | Variable | 36°-38° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 11.7mm | 12mm | 26mm | 83mm | 0.12mm | 45° | Variable | 36°-38° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 12mm | 12mm | 26mm | 83mm | 0.12mm | 45° | Variable | 36°-38° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 13.7mm | 14mm | 26mm | 83mm | 0.14mm | 45° | Variable | 36°-38° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 14mm | 14mm | 26mm | 83mm | 0.14mm | 45° | Variable | 36°-38° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 15.6mm | 16mm | 32mm | 92mm | 0.16mm | 45° | Variable | 36°-38° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 16mm | 16mm | 32mm | 92mm | 0.16mm | 45° | Variable | 36°-38° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 19.5mm | 20mm | 38mm | 104mm | 0.2mm | 45° | Variable | 36°-38° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 20mm | 20mm | 38mm | 104mm | 0.2mm | 45° | Variable | 36°-38° | __ | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

End Mills with Coolant Holes | ||||||||||||

Titanium Aluminum Silicon Nitride (TiAISiN) Coated—3 Flute | ||||||||||||

| 1/4" | 1/4" | 1/2" | 2 1/2" | 0.004" | 45° | Variable | 41°-45° | 3 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 5/16" | 5/16" | 1/2" | 2 1/2" | 0.005" | 45° | Variable | 41°-45° | 3 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 3/8" | 3/8" | 5/8" | 2 1/2" | 0.006" | 45° | Variable | 41°-45° | 3 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 1/2" | 1/2" | 5/8" | 3" | 0.007" | 45° | Variable | 41°-45° | 3 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 5/8" | 5/8" | 3/4" | 3 1/2" | 0.007" | 45° | Variable | 41°-45° | 3 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 3/4" | 3/4" | 1" | 4" | 0.009" | 45° | Variable | 41°-45° | 3 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 6mm | 6mm | 13mm | 57mm | 0.09mm | 45° | Variable | 41°-45° | 3 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 8mm | 8mm | 19mm | 63mm | 0.12mm | 45° | Variable | 41°-45° | 3 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 10mm | 10mm | 22mm | 72mm | 0.15mm | 45° | Variable | 41°-45° | 3 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 12mm | 12mm | 26mm | 83mm | 0.18mm | 45° | Variable | 41°-45° | 3 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 16mm | 16mm | 32mm | 92mm | 0.19mm | 45° | Variable | 41°-45° | 3 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

Titanium Aluminum Silicon Nitride (TiAISiN) Coated—4 Flute | ||||||||||||

| 1/4" | 1/4" | 1/2" | 2 1/2" | 0.002" | 45° | Variable | 36°-38° | 4 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 5/16" | 5/16" | 3/4" | 2 1/2" | 0.003" | 45° | Variable | 36°-38° | 4 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 3/8" | 3/8" | 7/8" | 2 1/2" | 0.004" | 45° | Variable | 36°-38° | 4 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 1/2" | 1/2" | 1" | 3 1/2" | 0.005" | 45° | Variable | 36°-38° | 4 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 5/8" | 5/8" | 1 1/4" | 3 1/2" | 0.006" | 45° | Variable | 36°-38° | 4 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 3/4" | 3/4" | 1 1/2" | 4" | 0.007" | 45° | Variable | 36°-38° | 4 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 6mm | 6mm | 13mm | 57mm | 0.06mm | 45° | Variable | 36°-38° | 4 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 8mm | 8mm | 19mm | 63mm | 0.08mm | 45° | Variable | 36°-38° | 4 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

| 10mm | 10mm | 22mm | 72mm | 0.1mm | 45° | Variable | 36°-38° | 4 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 12mm | 12mm | 26mm | 83mm | 0.12mm | 45° | Variable | 36°-38° | 4 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 16mm | 16mm | 32mm | 92mm | 0.16mm | 45° | Variable | 36°-38° | 4 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 20mm | 20mm | 38mm | 104mm | 0.2mm | 45° | Variable | 36°-38° | 4 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

| 25mm | 25mm | 45mm | 121mm | 0.25mm | 45° | Variable | 36°-38° | 4 | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |