About Shoulder Screws

More

Metric Alloy Steel Shoulder Screws

Comparable to Class 12.9 steel, these alloy steel shoulder screws are the strongest we offer. They have a standard shoulder with an undersized tolerance to fit most machinery and equipment. Also known as stripper bolts, they're commonly used in punch and die assemblies, and as an axle or pivot point.

For technical drawings and 3-D models, click on a part number.

Each | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Shoulder Lg., mm | Thread Size | Thread Pitch, mm | Thread Lg., mm | Head Dia., mm | Head Ht., mm | Finish | Tensile Strength, psi | Drive Size, mm | Specifications Met | 1-4 | 5-Up | |

20 mm Shoulder Dia.—Standard Fit (-0.072 to -0.01 mm Dia. Tolerance) | ||||||||||||

| 20 | M16 | 2 | 22 | 30 | 14 | Black Oxide | 140,000 | 10 | ISO 7379 | 000000000 | 000000 | 000000 |

| 25 | M16 | 2 | 22 | 30 | 14 | Black Oxide | 140,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 30 | M16 | 2 | 22 | 30 | 14 | Black Oxide | 140,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 35 | M16 | 2 | 22 | 30 | 14 | Black Oxide | 140,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 40 | M16 | 2 | 22 | 30 | 14 | Black Oxide | 140,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 45 | M16 | 2 | 22 | 30 | 14 | Black Oxide | 140,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 50 | M16 | 2 | 22 | 30 | 14 | Black Oxide | 140,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 55 | M16 | 2 | 22 | 30 | 14 | Black Oxide | 140,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 60 | M16 | 2 | 22 | 30 | 14 | Black Oxide | 140,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 70 | M16 | 2 | 22 | 30 | 14 | Black Oxide | 140,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 80 | M16 | 2 | 22 | 30 | 14 | Black Oxide | 140,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 90 | M16 | 2 | 22 | 30 | 14 | Black Oxide | 140,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 100 | M16 | 2 | 22 | 30 | 14 | Black Oxide | 140,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 120 | M16 | 2 | 22 | 30 | 14 | Black Oxide | 140,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

Metric 18-8 Stainless Steel Shoulder Screws

Made from 18-8 stainless steel, these shoulder screws have good chemical resistance and may be mildly magnetic. A standard shoulder with an undersized tolerance allows them to fit most machinery and equipment. They’re often used to guide or align components, and as an axle or pivot point.

For technical drawings and 3-D models, click on a part number.

Each | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Shoulder Lg., mm | Thread Size | Thread Pitch, mm | Thread Lg., mm | Head Dia., mm | Head Ht., mm | Tensile Strength, psi | Drive Size, mm | Specifications Met | 1-4 | 5-Up | |

20 mm Shoulder Dia.—Standard Fit (-0.072 to -0.01 mm Dia. Tolerance) | |||||||||||

| 14 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 000000 | 000000 |

| 20 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 25 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 30 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 35 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 45 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 50 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 55 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 60 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

For made-to-order shoulder screws, please specify the shoulder length in 0.25 mm increments.

Each | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Thread Pitch, mm | Thread Lg., mm | Head Dia., mm | Head Ht., mm | Tensile Strength, psi | Drive Size, mm | Choose a Shoulder Lg., mm | 1-4 | 5-9 | 10-Up | |

16 mm Shoulder Dia.—Standard Fit (-0.072 to -0.01 mm Dia. Tolerance) | |||||||||||

| M16 | 2 | 18 | 24 | 11 | 70,000 | 8 | 6-49.75 | 000000000 | 000000 | 000000 | 000000 |

| M16 | 2 | 18 | 24 | 11 | 70,000 | 8 | 50-99.75 | 000000000 | 00000 | 00000 | 00000 |

20 mm Shoulder Dia.—Standard Fit (-0.072 to -0.01 mm Dia. Tolerance) | |||||||||||

| M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | 13-49.75 | 000000000 | 00000 | 00000 | 00000 |

| M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | 50-99.75 | 000000000 | 00000 | 00000 | 00000 |

24 mm Shoulder Dia.—Standard Fit (-0.072 to -0.01 mm Dia. Tolerance) | |||||||||||

| M16 | 2 | 27 | 36 | 16 | 70,000 | 12 | 13-49.75 | 000000000 | 00000 | 00000 | 00000 |

| M16 | 2 | 27 | 36 | 16 | 70,000 | 12 | 50-99.75 | 000000000 | 00000 | 00000 | 00000 |

Same-Size Thread 18-8 Stainless Steel Shoulder Screws

With threads the same diameter as the shoulder, these screws can handle heavy loads. Made from 18-8 stainless steel, they have good chemical resistance and may be mildly magnetic. A standard shoulder with an undersized tolerance allows them to fit most machinery and equipment. They’re often used to guide or align components, and as an axle or pivot point.

For technical drawings and 3-D models, click on a part number.

Uncoated | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Each | ||||||||||

| Shoulder Lg., mm | Thread Size | Thread Pitch, mm | Thread Lg., mm | Head Dia., mm | Head Ht., mm | Tensile Strength, psi | Drive Size, mm | 1-4 | 5-Up | |

16 mm Shoulder Dia.—Standard Fit (-0.04 to -0.01 mm Dia. Tolerance) | ||||||||||

| 20 | M16 | 2 | 22 | 24 | 11 | 70,000 | 8 | 000000000 | 000000 | 000000 |

| 25 | M16 | 2 | 22 | 24 | 11 | 70,000 | 8 | 000000000 | 00000 | 00000 |

| 30 | M16 | 2 | 22 | 24 | 11 | 70,000 | 8 | 000000000 | 00000 | 00000 |

| 35 | M16 | 2 | 22 | 24 | 11 | 70,000 | 8 | 000000000 | 00000 | 00000 |

| 40 | M16 | 2 | 22 | 24 | 11 | 70,000 | 8 | 000000000 | 00000 | 00000 |

| 45 | M16 | 2 | 22 | 24 | 11 | 70,000 | 8 | 000000000 | 00000 | 00000 |

| 50 | M16 | 2 | 22 | 24 | 11 | 70,000 | 8 | 000000000 | 00000 | 00000 |

| 60 | M16 | 2 | 22 | 24 | 11 | 70,000 | 8 | 000000000 | 00000 | 00000 |

| 120 | M16 | 2 | 22 | 24 | 11 | 70,000 | 8 | 000000000 | 000000 | 00000 |

Metric 316 Stainless Steel Shoulder Screws

More corrosion resistant than 18-8 stainless steel shoulder screws, these have excellent resistance to chemicals and salt water. They may be mildly magnetic. A standard shoulder with an undersized tolerance allows them to fit most machinery and equipment. They’re often used to guide or align components, and as an axle or pivot point.

Black-oxide stainless steel screws have a matte black finish.

Each | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Shoulder Lg., mm | Thread Size | Thread Pitch, mm | Thread Lg., mm | Head Dia., mm | Head Ht., mm | Tensile Strength, psi | Drive Size, mm | Specifications Met | 1-4 | 5-Up | |

20 mm Shoulder Dia.—Standard Fit (-0.072 to -0.01 mm Dia. Tolerance) | |||||||||||

| 12 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 000000 | 000000 |

| 14 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 16 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 20 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 35 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 40 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 50 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 55 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 60 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 70 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 100 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 110 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 120 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

Each | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Shoulder Lg., mm | Thread Size | Thread Pitch, mm | Thread Lg., mm | Head Dia., mm | Head Ht., mm | Tensile Strength, psi | Drive Size, mm | Specifications Met | 1-4 | 5-Up | |

20 mm Shoulder Dia.—Standard Fit (-0.072 to -0.01 mm Dia. Tolerance) | |||||||||||

| 12 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 000000 | 000000 |

| 14 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 16 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 20 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 25 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 30 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 35 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 40 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 45 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 50 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 55 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 60 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 70 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 80 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 90 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 100 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 110 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 120 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 130 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 140 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 150 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 160 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 170 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 180 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 00000 | 00000 |

| 190 | M16 | 2 | 22 | 30 | 14 | 70,000 | 10 | ISO 7379 | 000000000 | 000000 | 00000 |

Metric Steel Hex Head Shoulder Screws

Also known as wheel and axle bolts, these metric screws have an unthreaded shoulder that acts as a shaft, so material attached to the threaded end can rotate. Made of steel, they are strong enough to withstand pulling and stretching without breaking. They are often used with bearings, pulleys, valves, and pumps. The hex head lets you tighten these screws with a wrench, and keeps them in place once they are installed. All of these screws meet DIN 609, which is an international standard for shoulder screw dimensions.

For technical drawings and 3-D models, click on a part number.

Each | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Shoulder Lg., mm | Thread Size | Thread Pitch, mm | Thread Lg., mm | Head Wd., mm | Head Ht., mm | Tensile Strength, psi | Specifications Met | 1-4 | 5-Up | |

17 mm Shoulder Dia.—Standard Fit (0.001 mm to 0.012 mm Dia. Tolerance) | ||||||||||

| 21.5 | M16 | 2 | 27 | 24 | 10 | 120,000 | DIN 609 | 000000000 | 000000 | 00000 |

| 29.5 | M16 | 2 | 27 | 24 | 10 | 120,000 | DIN 609 | 000000000 | 00000 | 0000 |

| 39.5 | M16 | 2 | 27 | 24 | 10 | 120,000 | DIN 609 | 000000000 | 00000 | 00000 |

| 49.5 | M16 | 2 | 27 | 24 | 10 | 120,000 | DIN 609 | 000000000 | 00000 | 00000 |

| 59.5 | M16 | 2 | 27 | 24 | 10 | 120,000 | DIN 609 | 000000000 | 00000 | 00000 |

| 69.5 | M16 | 2 | 27 | 24 | 10 | 120,000 | DIN 609 | 000000000 | 00000 | 00000 |

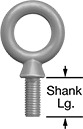

Eyebolts—For Lifting

Also known as machinery eyebolts.

Zinc-plated steel eyebolts offer good corrosion resistance.

Galvanized steel eyebolts have a hot-dipped finish for more corrosion resistance than zinc-plated steel.

304 stainless steel eyebolts are more corrosion resistant than galvanized steel.

316 stainless steel are the most corrosion resistant eyebolts.

Note: Capacities listed are for vertical lifting only. Eyebolts with shoulder can be used for angular lifting up to 45°, but the capacities will be significantly reduced. For angular lifting, we recommend Hoist Rings.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Thread | With Shoulder | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Size | Pitch, mm | Lg., mm | Shank Lg., mm | Overall Lg., mm | Eye Dia., mm | Vertical Capacity, lbs. | Specifications Met | Each | |

Steel | |||||||||

| M16 | 2 | 32 | 32 | 108 | 35 | 3,500 | __ | 0000000 | 000000 |

| M16 | 2 | 76 | 76 | 151 | 35 | 3,500 | __ | 0000000 | 00000 |

Zinc-Plated Steel | |||||||||

| M16 | 2 | 27 | 27 | 89 | 35 | 1,525 | DIN 580 | 0000000 | 00000 |

Galvanized Steel | |||||||||

| M16 | 2 | 45 | 45 | 121 | 35 | 3,500 | __ | 0000000 | 00000 |

304 Stainless Steel | |||||||||

| M16 | 2 | 27 | 27 | 89 | 35 | 1,525 | DIN 580 | 0000000 | 00000 |

316 Stainless Steel | |||||||||

| M16 | 2 | 27 | 27 | 89 | 35 | 1,525 | DIN 580 | 0000000 | 00000 |

Eyebolts with Nuts—For Lifting

Also known as nut eyebolts, these are designed for through-hole applications.

316 stainless steel are the most corrosion resistant eyebolts.

Note: Capacities listed are for vertical lifting only. Eyebolts with shoulder can be used for angular lifting up to 45°, but the capacities will be significantly reduced. For angular lifting, we recommend Hoist Rings.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Thread | Nuts | With Shoulder | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Pitch, mm | Lg., mm | Shank Lg., mm | Eye Dia., mm | Vertical Capacity, lbs. | Threading | No. Included | Style | No. of Washers Included | Overall Lg., mm | Each | |

316 Stainless Steel | ||||||||||||

| M16 | 2 | 45 | 51 | 31 | 3,425 | Partially Threaded | 1 | Hex | 1 | 113 | 0000000 | 000000 |

Rotating Eyebolts—For Lifting

Unlike conventional eyebolts, you can rotate the eye 360° to match the angle of your load.

Powder-coated steel eyebolts are impact resistant, but less corrosion resistant than stainless steel eyebolts. They include a removable key for tightening the bolt.

Stainless steel eyebolts are more corrosion resistant than powder-coated steel eyebolts.

Note: Capacities listed are for vertical lifting only. Eyebolts with shoulder can be used for angular lifting up to 45°, but the capacities will be significantly reduced. For angular lifting, we recommend Hoist Rings.

Warning: Never use to lift people or items over people.

Nylon-Coated Eyebolts—For Lifting

Route wire and cable through the smooth eye without snagging.

Note: Capacities listed are for vertical lifting only. Eyebolts with shoulder can be used for angular lifting up to 45°, but the capacities will be significantly reduced. For angular lifting, we recommend Hoist Rings.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Thread | With Shoulder | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Size | Pitch, mm | Lg., mm | Shank Lg., mm | Eye Dia., mm | Vertical Capacity, lbs. | Temperature Range, °F | Overall Lg., mm | Each | |

Nylon-Coated Steel | |||||||||

| M16 | 2 | 32 | 32 | 35 | 3,500 | 30° to 275° | 106 | 0000000 | 000000 |